Assembly type building structure

A building structure and prefabricated technology, applied in the direction of building components, building structures, buildings, etc., can solve the problems of lack of stability, lack of connection structure between assembled panels and the ground, etc., to improve stability, ensure hardness and flatness, The effect of improving the mounting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

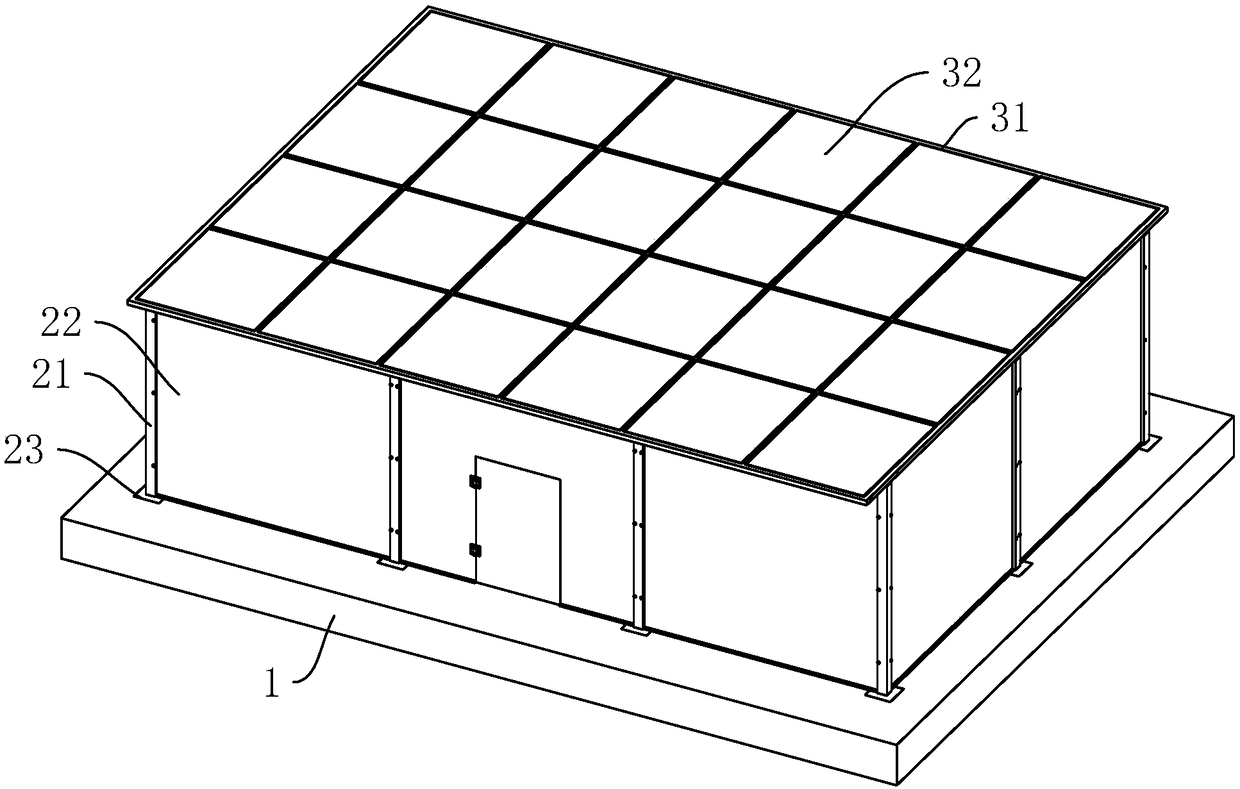

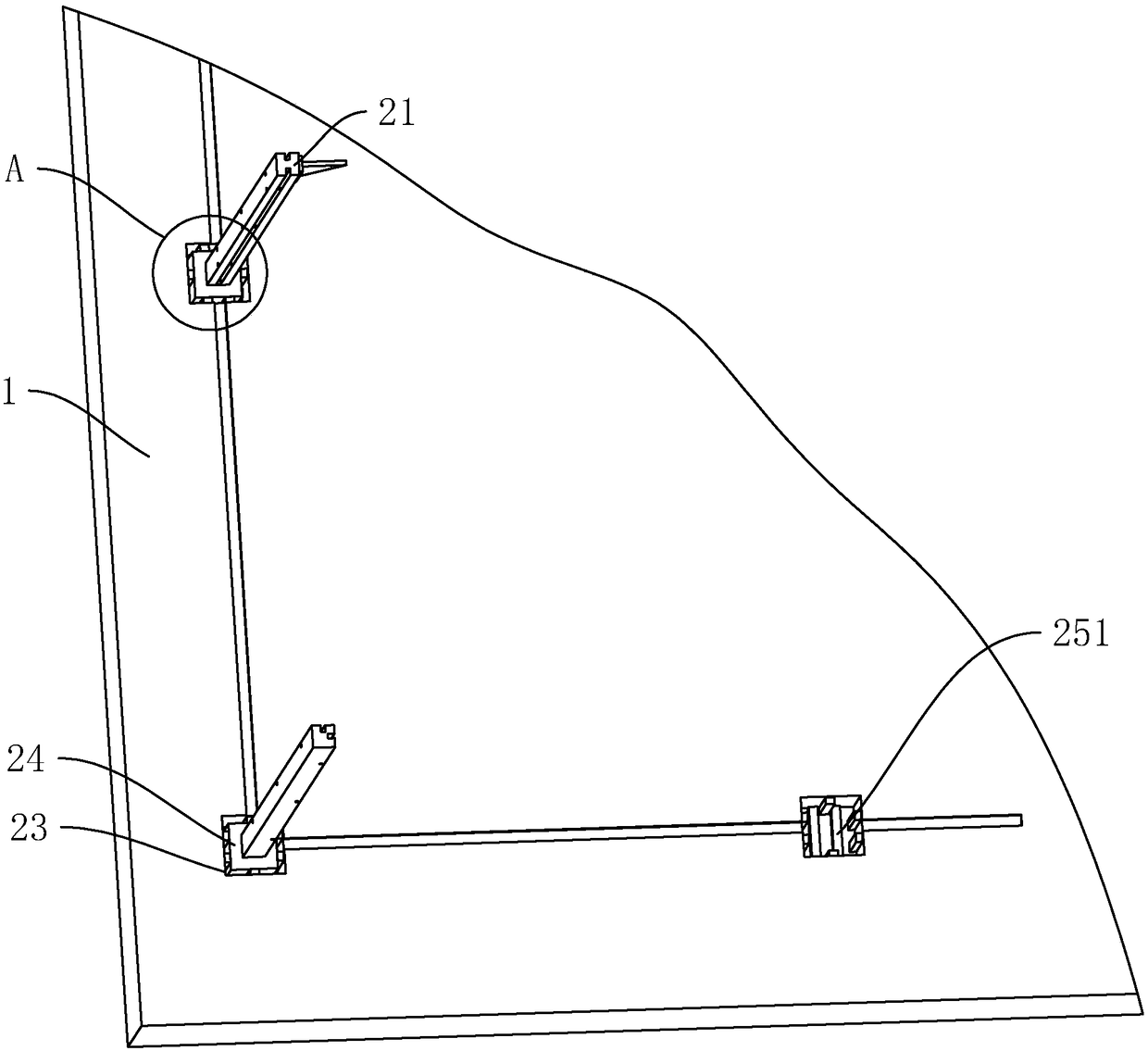

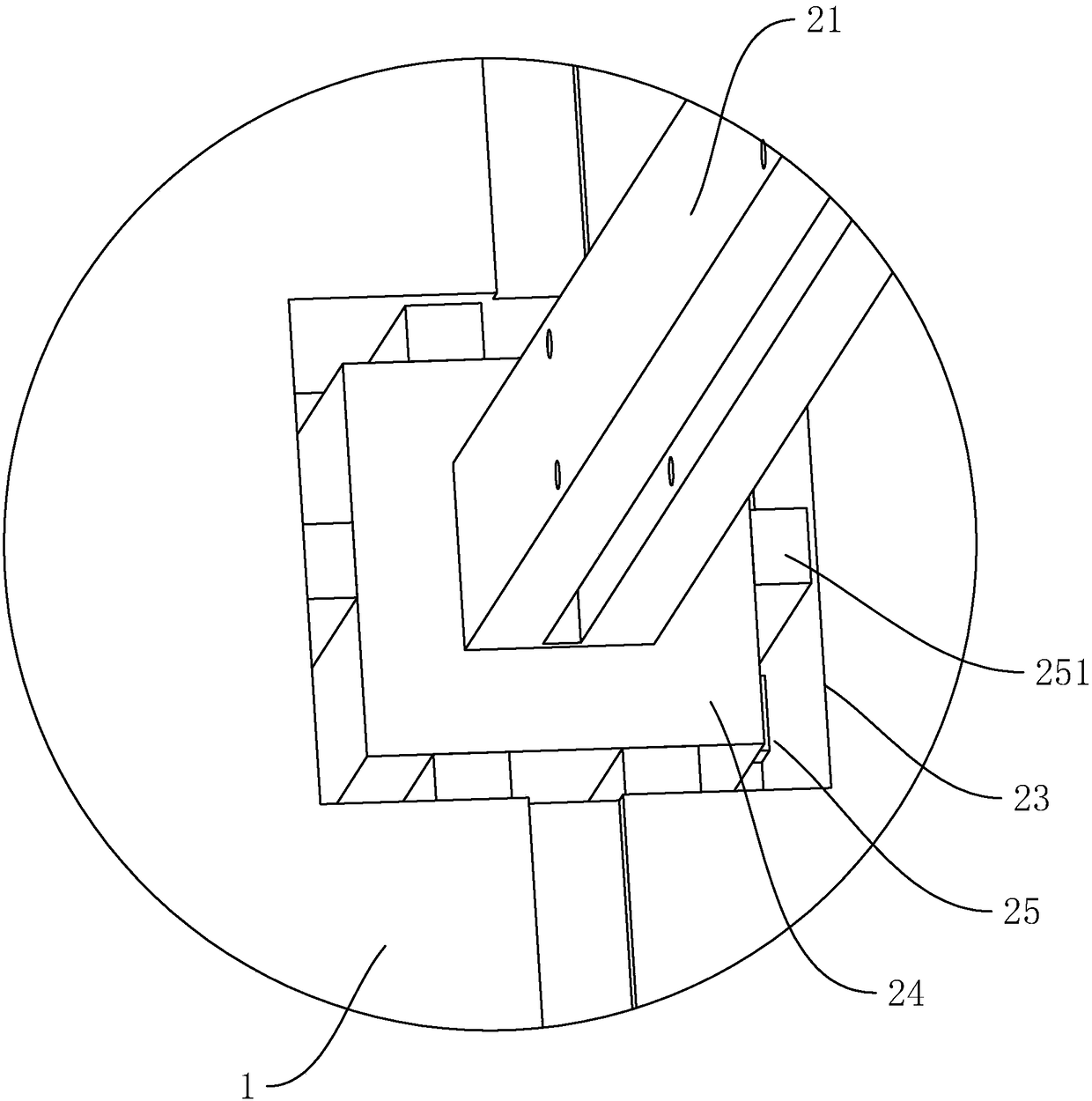

[0042] A prefabricated building structure, such as figure 1 , figure 2 , image 3 As shown, it includes a concrete foundation 1, a wall structure fixed to the concrete foundation 1, and a roof structure arranged on the top of the wall structure. The wall structure includes a plurality of support columns 21 and is plugged and fixed between adjacent support columns 21. Assembled slabs 22, the concrete foundation 1 is formed with buried pits 23 at the installation positions of each support column 21, and the bottom of the support column 21 is poured with an embedded block 24 that is fitted with the buried pit 23. Between the embedded block 24 and the buried pit 23 A post-pouring area 25 is formed between them.

[0043] In the actual assembly of this embodiment, a foundation pit is dug on the ground in a predetermined area, and after the foundation pit is fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com