Patents

Literature

114results about How to "Ensure flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

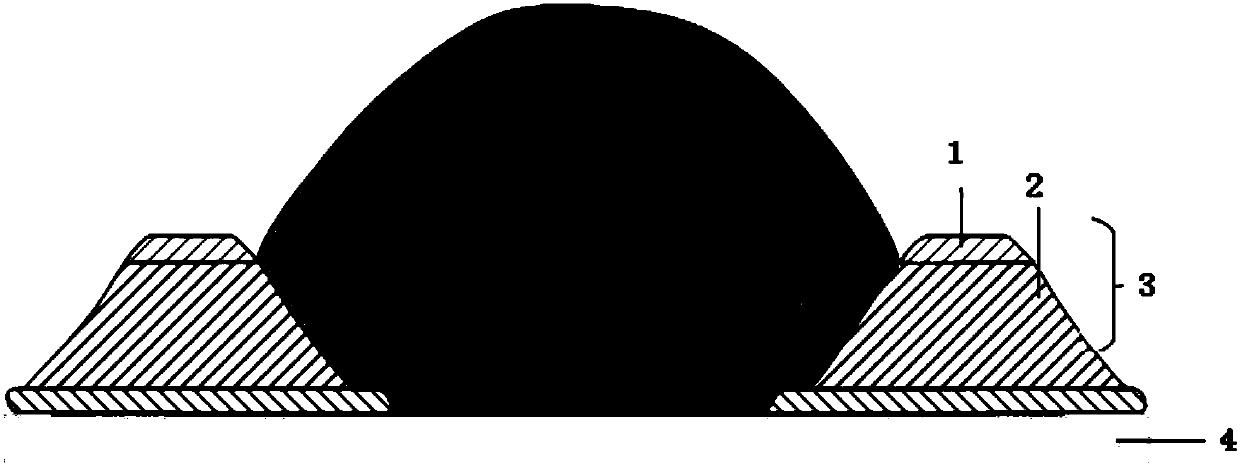

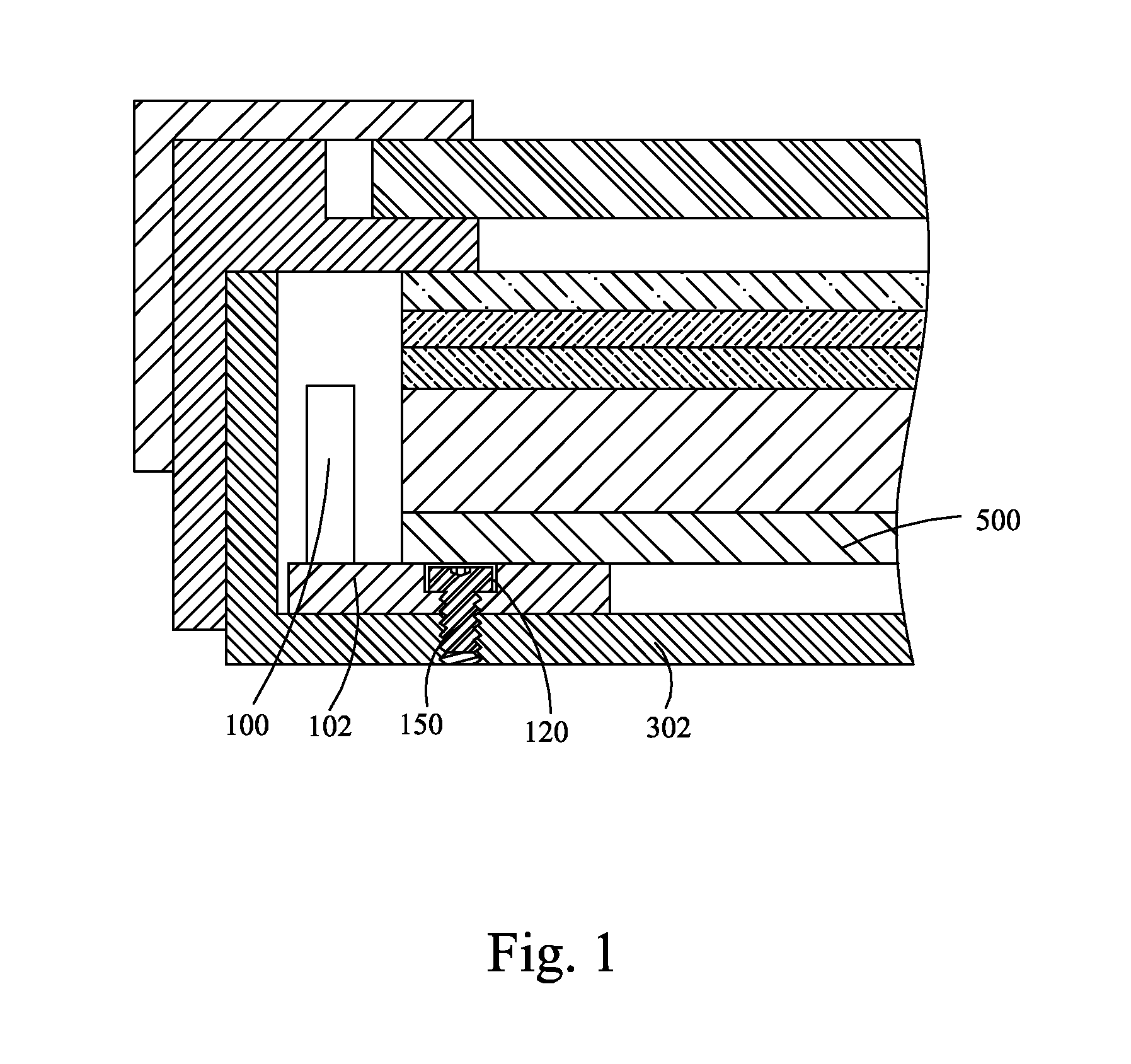

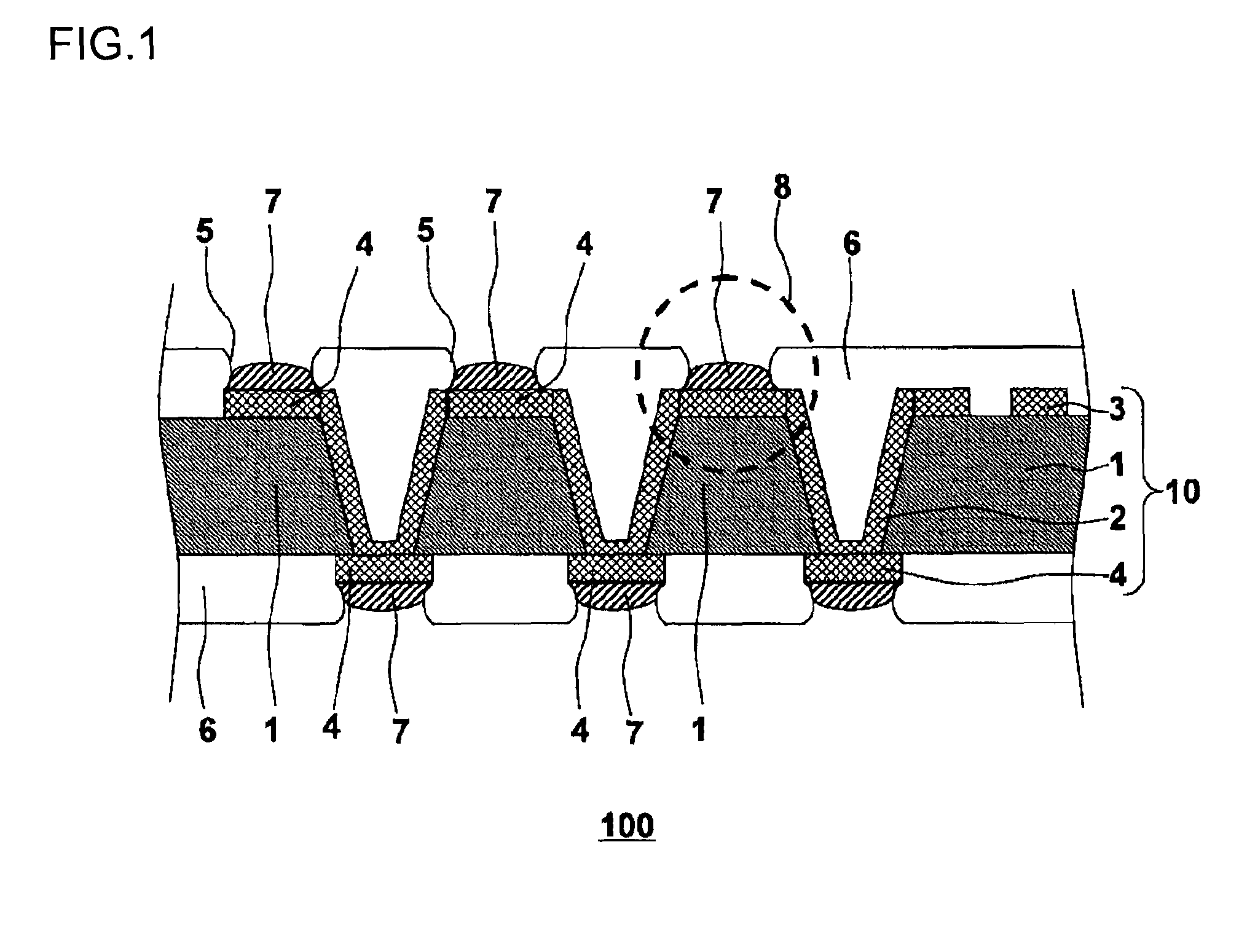

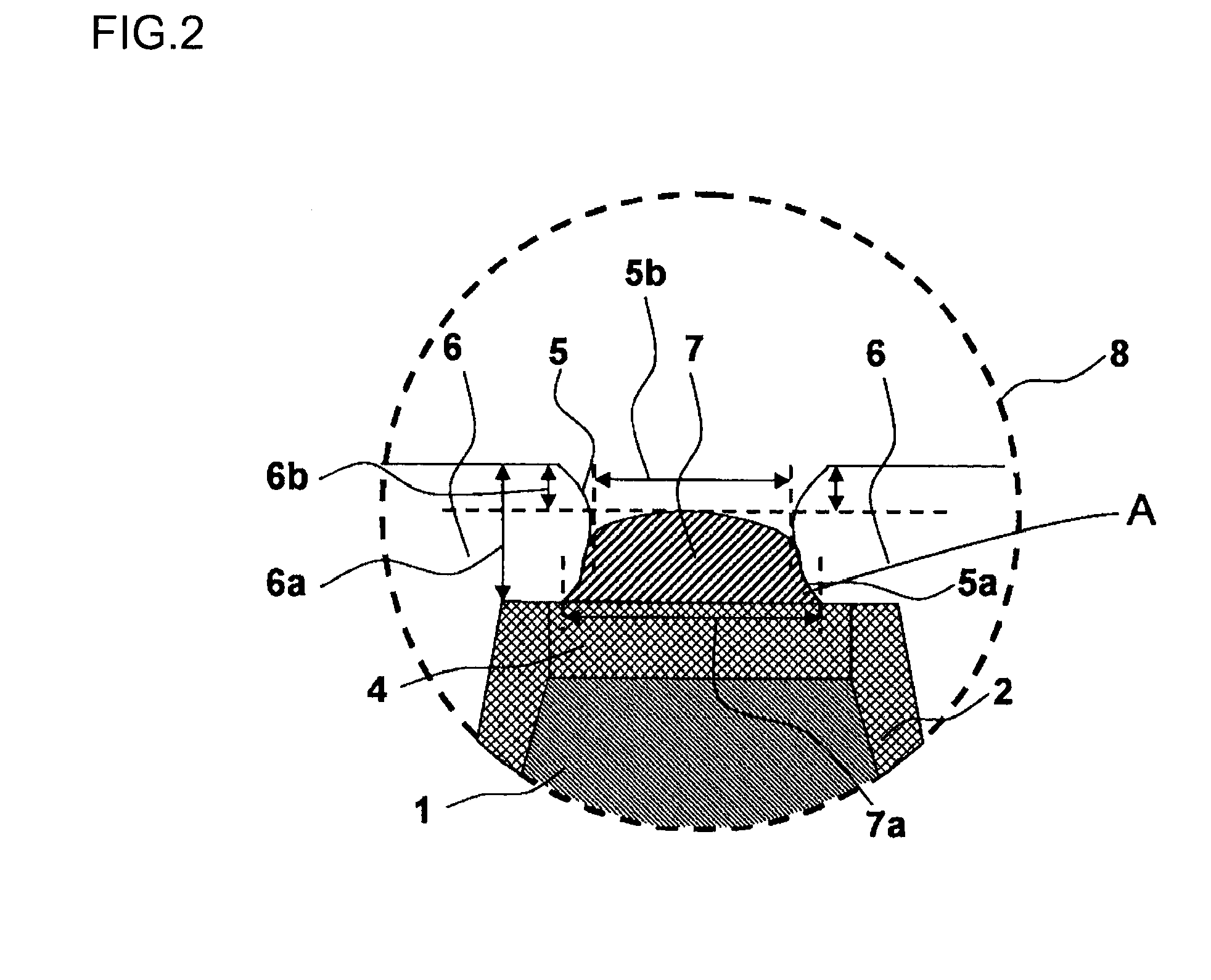

Packaging board, semiconductor module, and portable apparatus

InactiveUS20080061437A1Improving handleabilitySecuring connection reliabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A technology is provided for a packaging board adapted to mount a device capable of improving handleability and securing connection reliability. The packaging board includes: a pad electrode formed on a substrate; an insulating layer covering the substrate, having an opening at least in part in an area over the pad electrode; and a joint layer formed on the pad electrode inside the opening. The surface of the joint layer is lower than the top lip of the opening.

Owner:SANYO ELECTRIC CO LTD

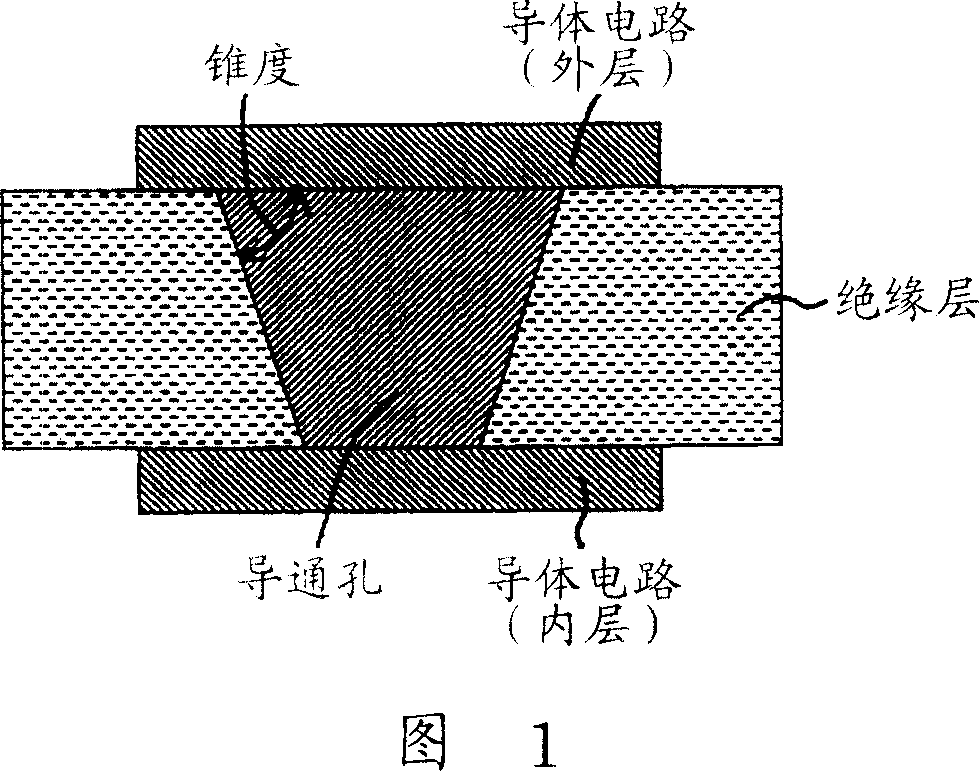

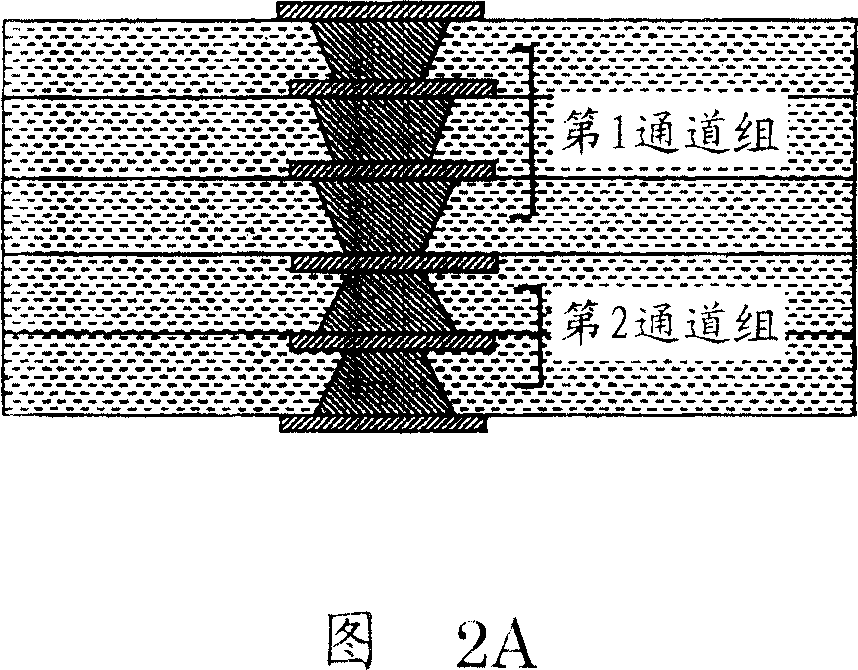

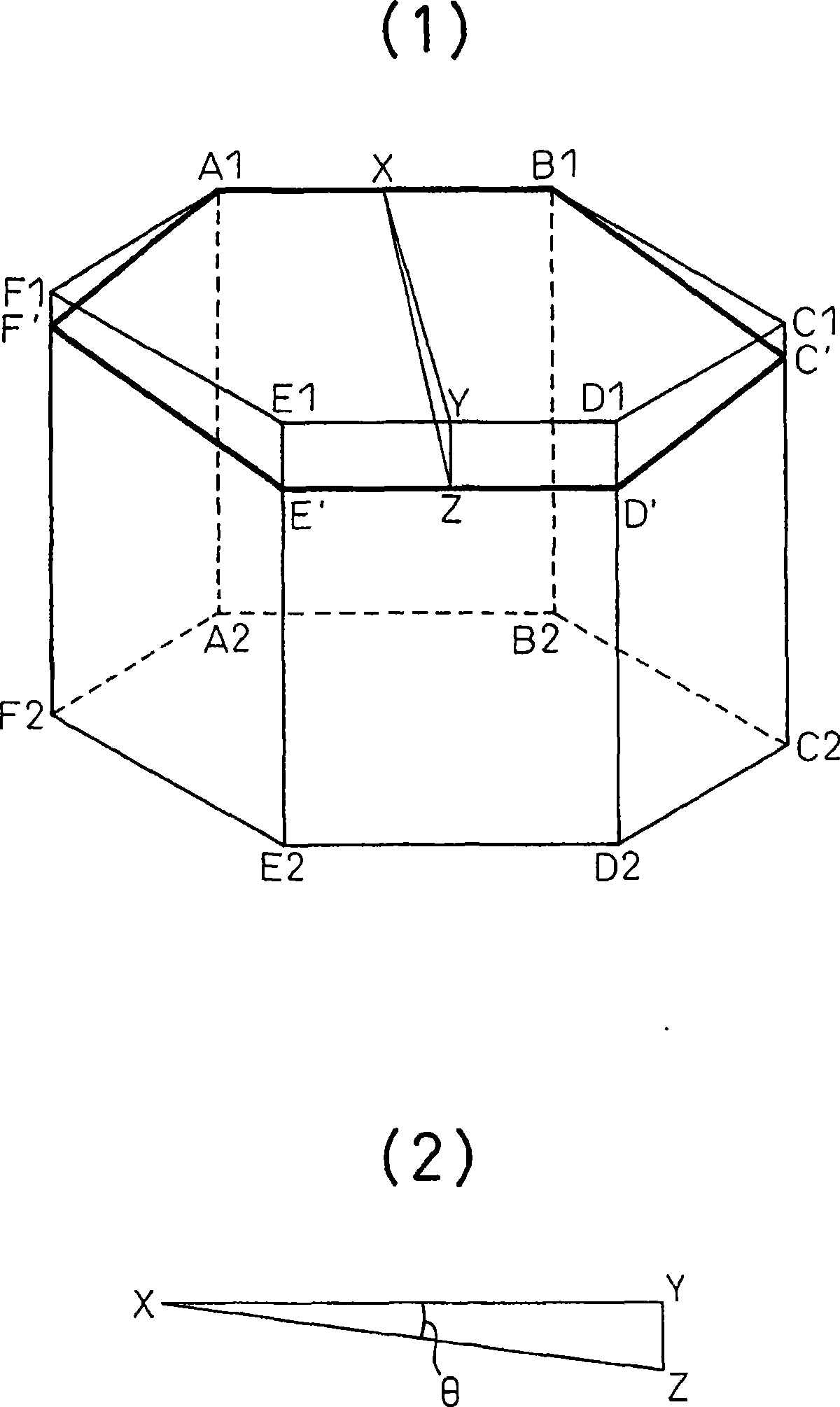

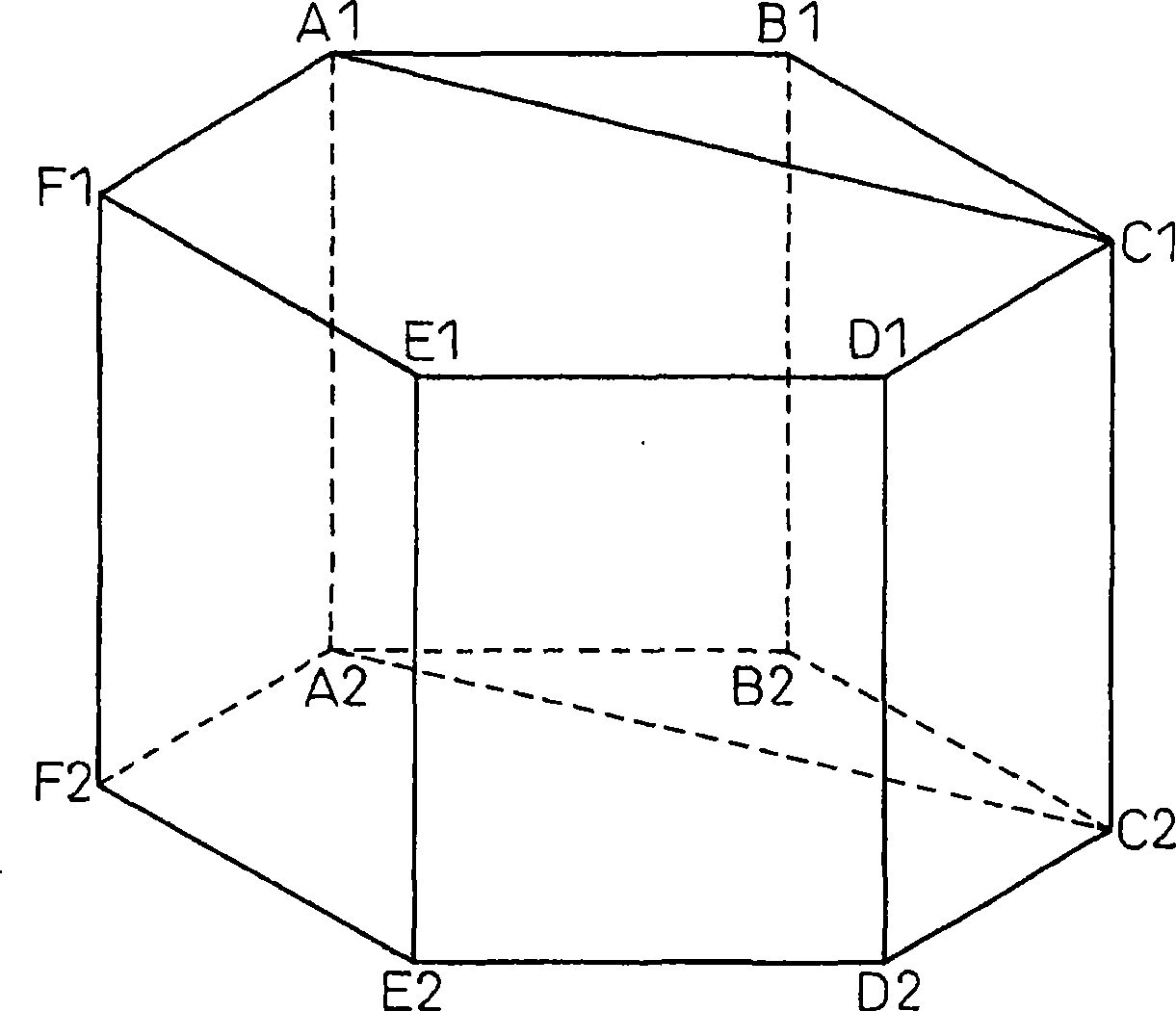

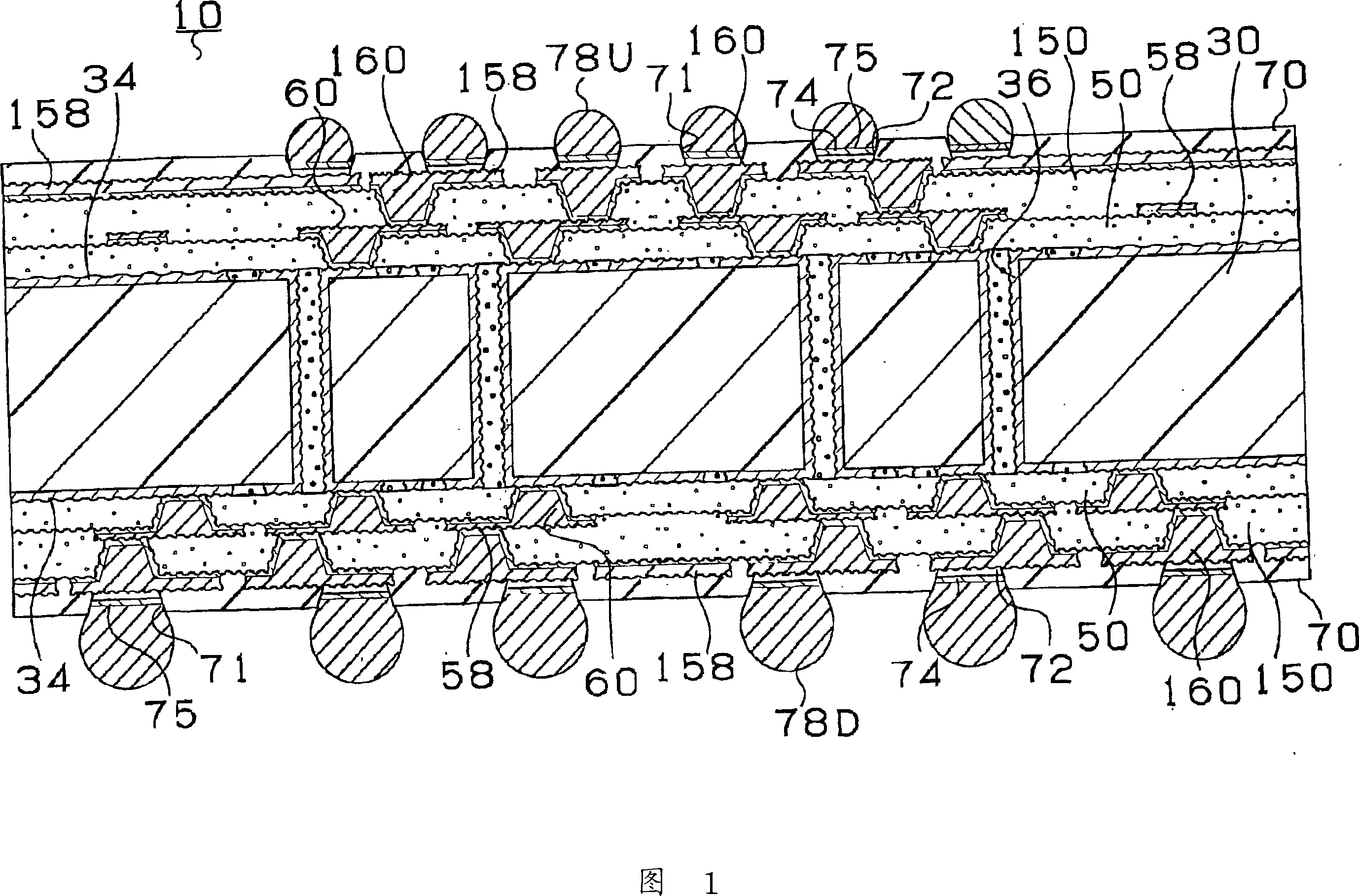

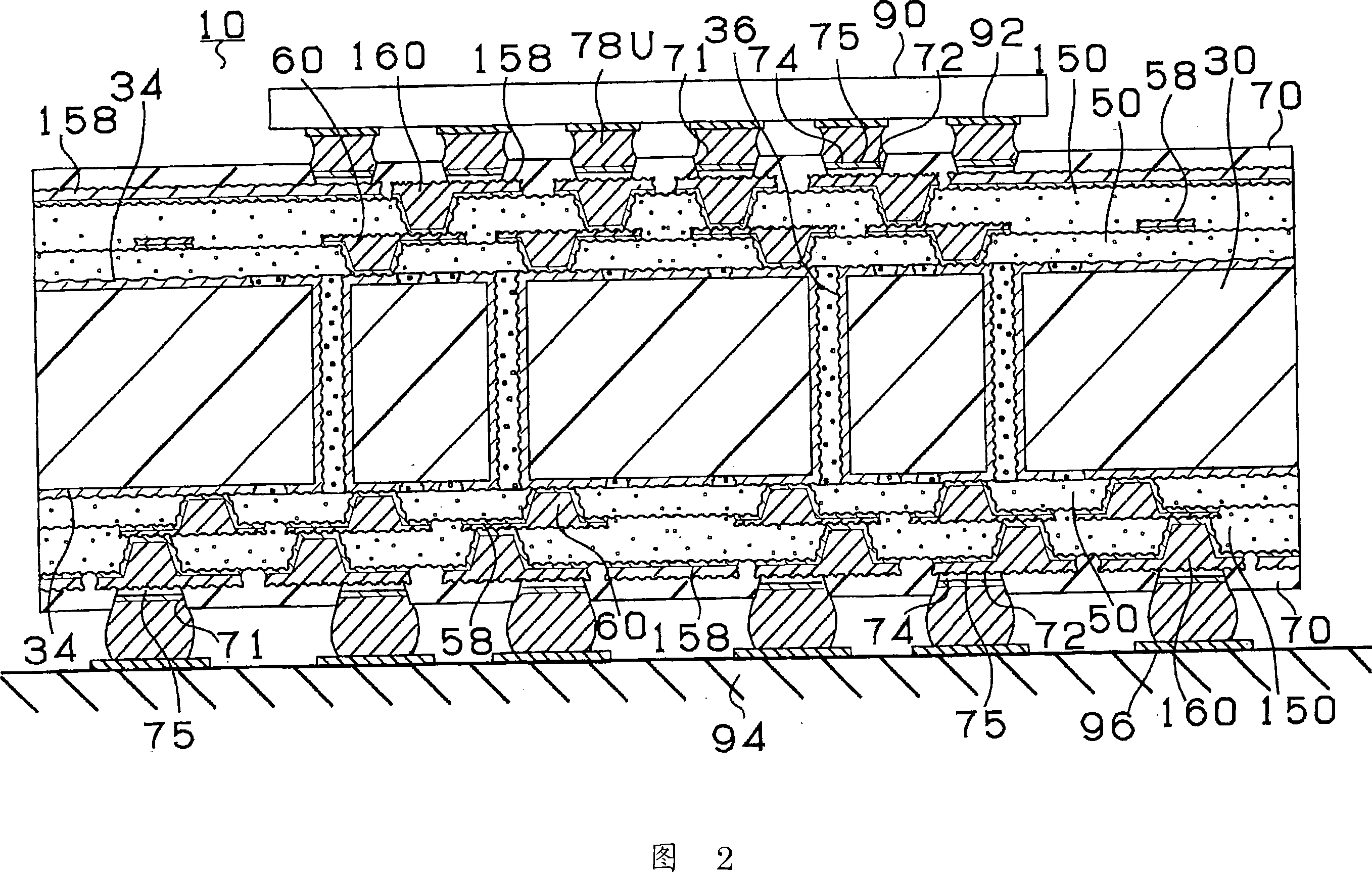

Multilayer printed wiring board

ActiveCN101069458AImprove rigidityReduce liftSemiconductor/solid-state device detailsPrinted circuit aspectsElectrical conductorEngineering

A multilayer printed wiring board comprises a plurality of insulating layers which is about 100 mum or less in thickness and a plurality of conductor circuits formed on the insulating layers. Each of a plurality of viaholes electrically connecting conductor circuits on the insulating layers to each other is formed tapered inwardly from the surface of the insulating layer and the viaholes are disposed opposite to each other to form a multistage stacked vias.

Owner:IBIDEN CO LTD

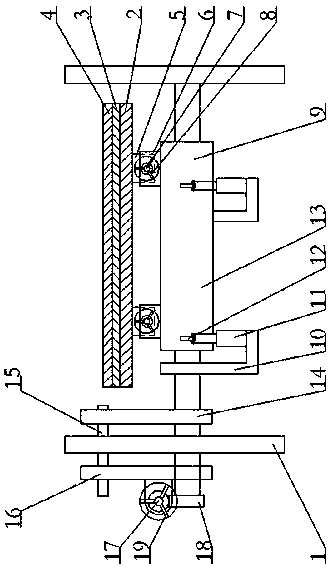

Coater scraper apparatus

ActiveCN103350055AMake sure the thicknessEnsure flatnessLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to a coater scraper apparatus. The apparatus comprises a scraper rack connected to a coater frame, a scarper having a cutting edge corresponding the coating roller of a coater is press-fitted on the scraper rack through a scraper press plate, a scraper rack adjusting shaft paralleling to the scraper rack is movably arranged on the coater frame in a penetrating mode, the scraper rack is connected with the scraper rack adjusting shaft and rotate around the scraper rack adjusting shaft, an adjusting worm gear is fixedly connected with the scraper rack adjusting shaft in a penetrating mode, the coater frame supports an adjusting worm having a driving cooperation with the adjusting worm gear, and the adjusting worm is connected with a hand wheel. The coater scraper apparatus accurately controls the adjustment between the scraper and the coating roller by adopting the scraper rack rotatablely far from or close to the coating roller and combining the scraper adjusting seat and a trimming cylinder, so the apparatus has the advantages of simple and compact structure, convenient and accurate adjustment, and effective ensure of the thickness of a glue solution on the coating roller for the uniform adjustment, and is suitable for the use of various different specification coating rollers and coating thicknesses.

Owner:泰兴联创绝缘材料有限公司

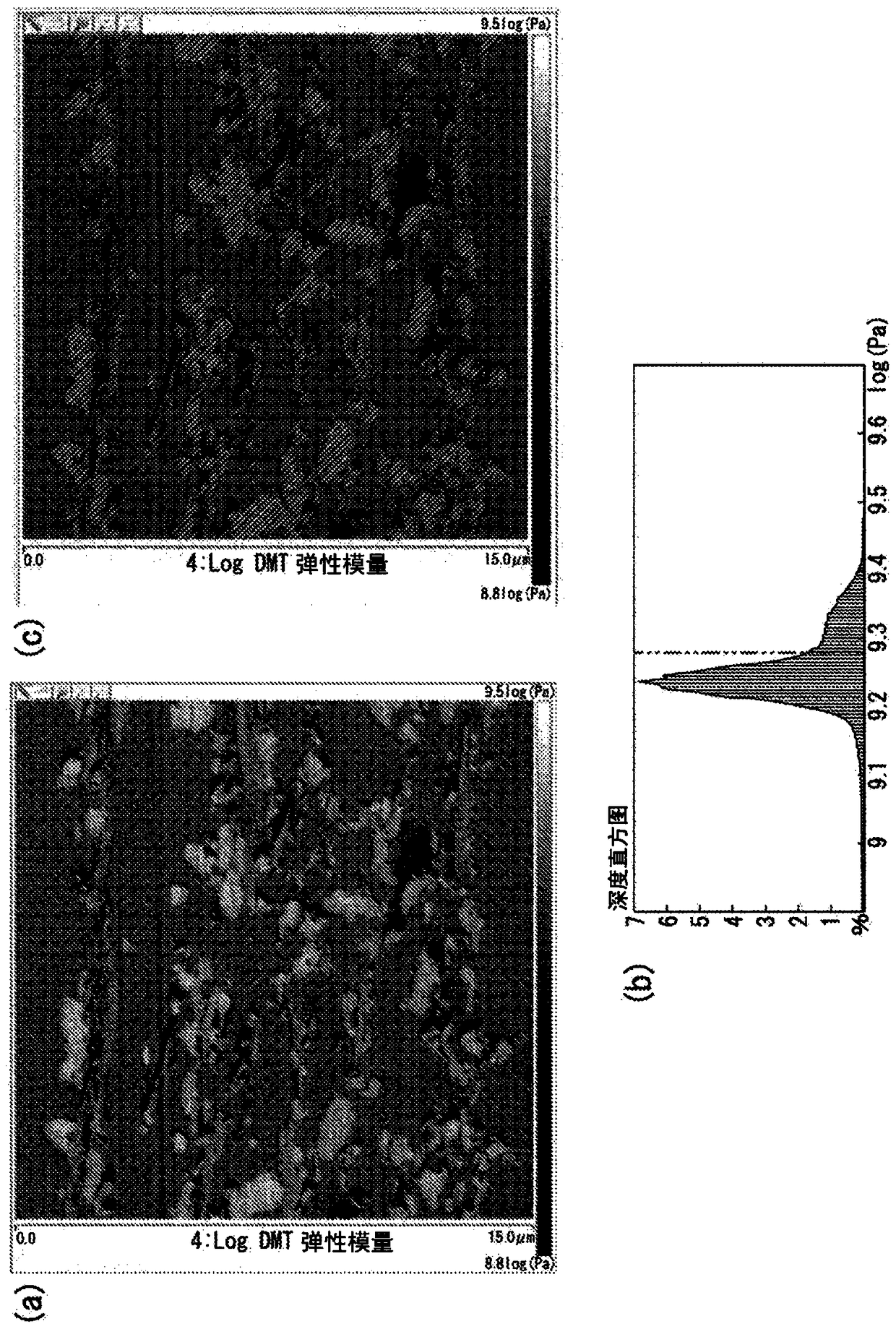

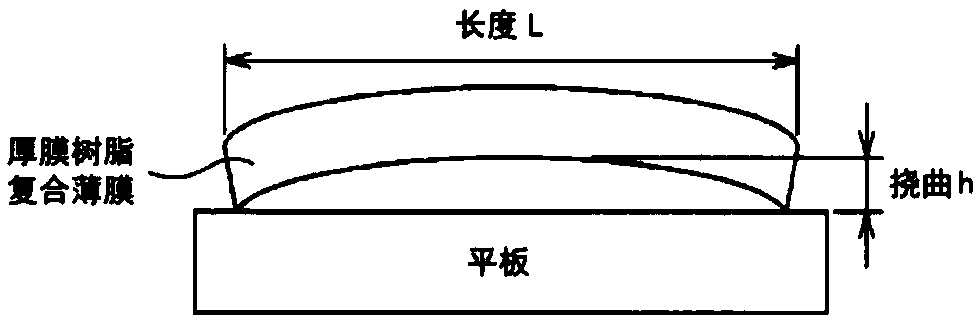

Resin composite film including cellulose microfiber layer

ActiveCN108884251AImprove thermal shock resistanceEnsure flatnessPolymeric diaphragmsSemiconductor/solid-state device detailsCelluloseImaging analysis

A resin composite film comprising a cellulose microfiber sheet and a resin, the resin composite film satisfying the following: (1) in a modulus mapping obtained by an examination of a cross-section with an AFM along the thickness direction, the fibers constituting the cellulose microfiber sheet have an average fiber diameter and a maximum fiber diameter, both calculated through image analysis, of0.01-2.0 [mu]m and 15 [mu]m or smaller, respectively; and (2) at least one surface of the resin composite film has an overcoat resin layer having an average thickness, determined from the modulus mapping, of 0.3-100 [mu]m.

Owner:ASAHI KASEI KK

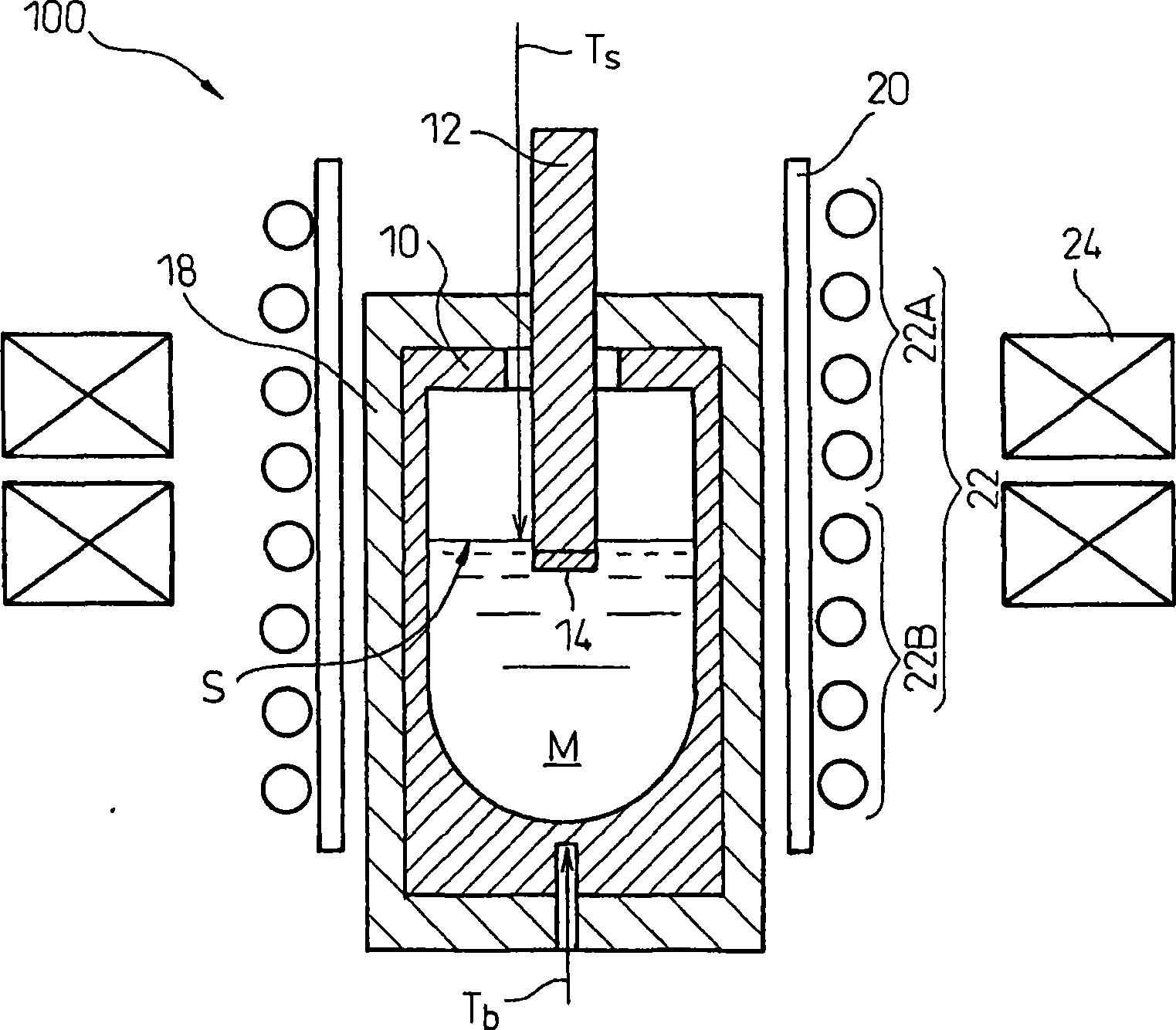

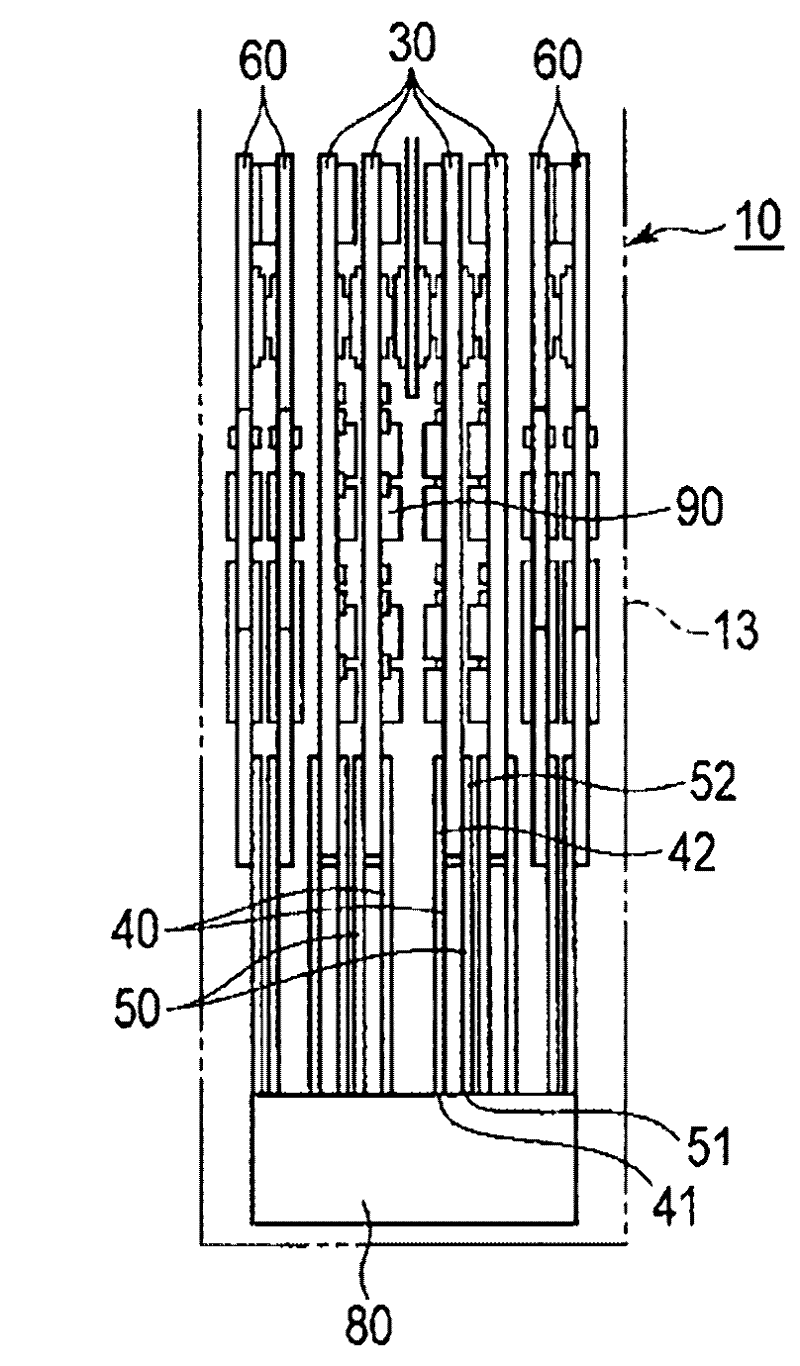

Process for producing SiC single crystal

InactiveCN101421442AEnsure flatnessPrevent polycrystallizationPolycrystalline material growthLiquid-phase epitaxial-layer growthSeed crystalTemperature gradient

Owner:TOYOTA JIDOSHA KK

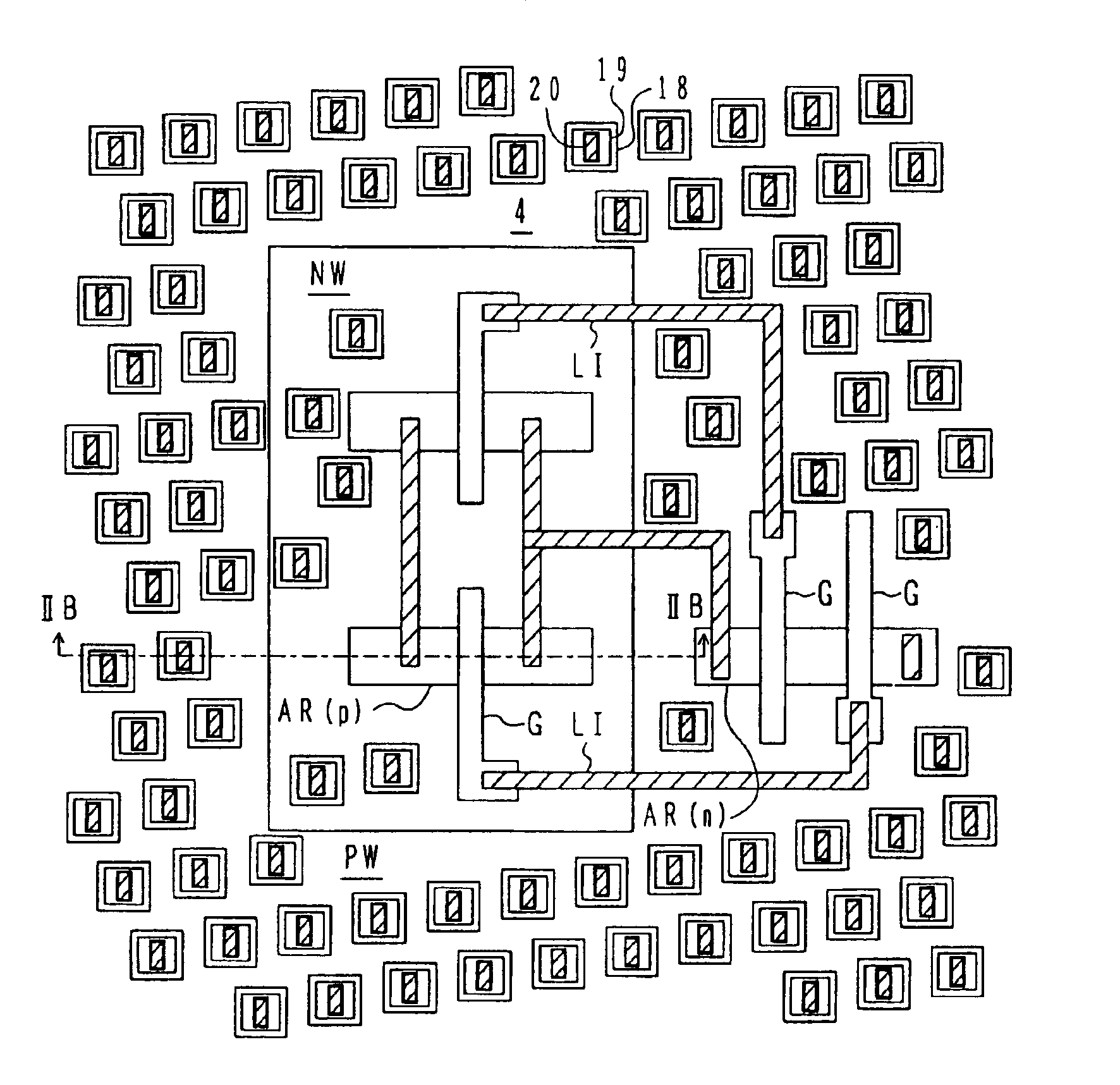

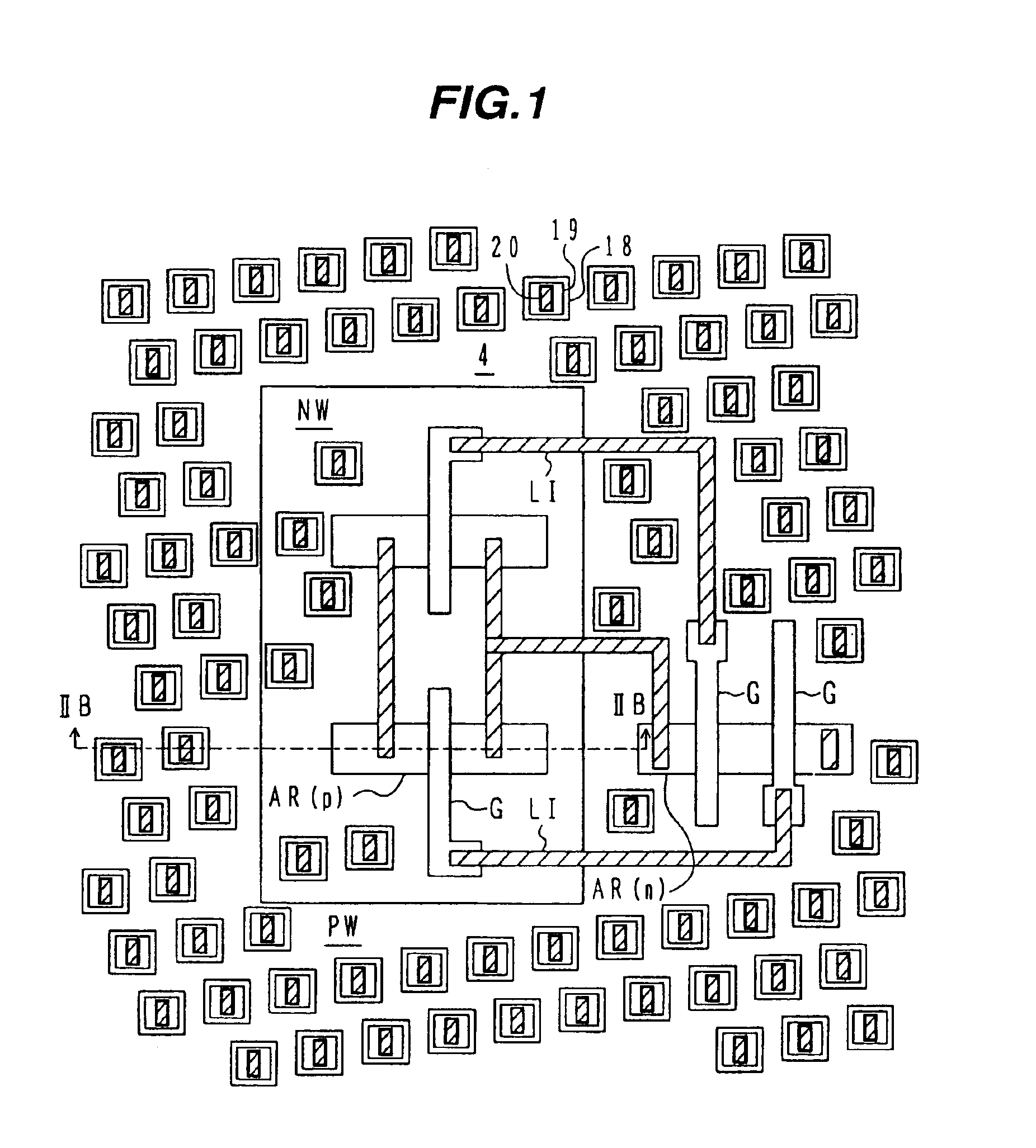

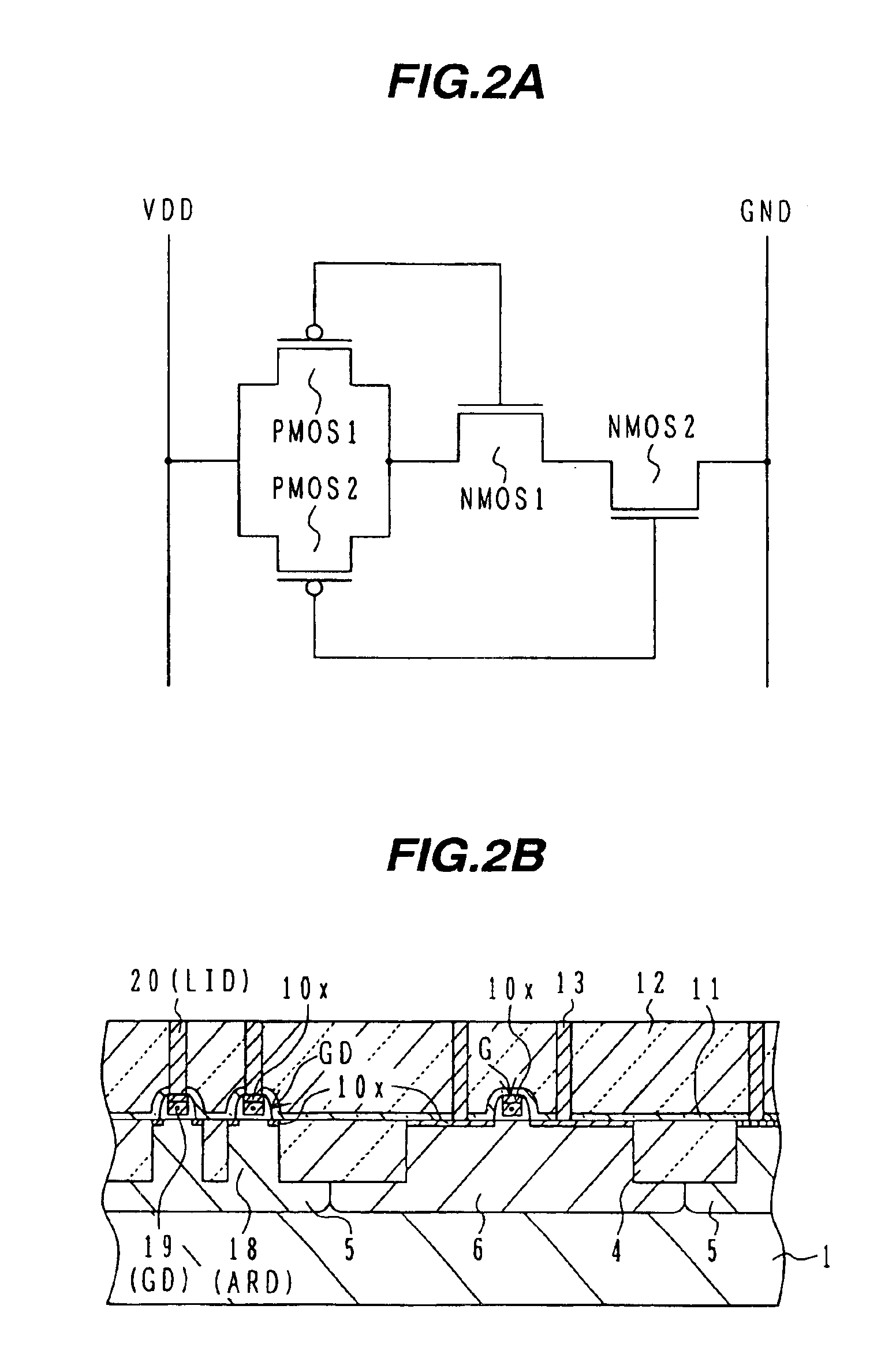

Semiconductor device with dummy structure

ActiveUS6909189B2Electrical shortageAvoid failureTransistorSemiconductor/solid-state device detailsDevice materialSemiconductor device

A semiconductor device having: a semiconductor substrate with an isolation region defining a plurality of active regions; a gate electrode formed above each active region, constituting a semiconductor element; an interlevel insulator covering the gate electrode; local interconnects formed through the interlevel insulator and electrically connected to the semiconductor element; local interconnect dummies formed through the interlevel insulator and electrically separated from the local interconnects; and lower level dummies, each comprising either one of an active region dummy, a laminated dummy of an active region dummy and a gate electrode dummy formed thereon, and a gate electrode dummy formed on the isolation region, wherein each of the local interconnect dummies is not connected to two or more lower level dummies.

Owner:FUJITSU SEMICON LTD

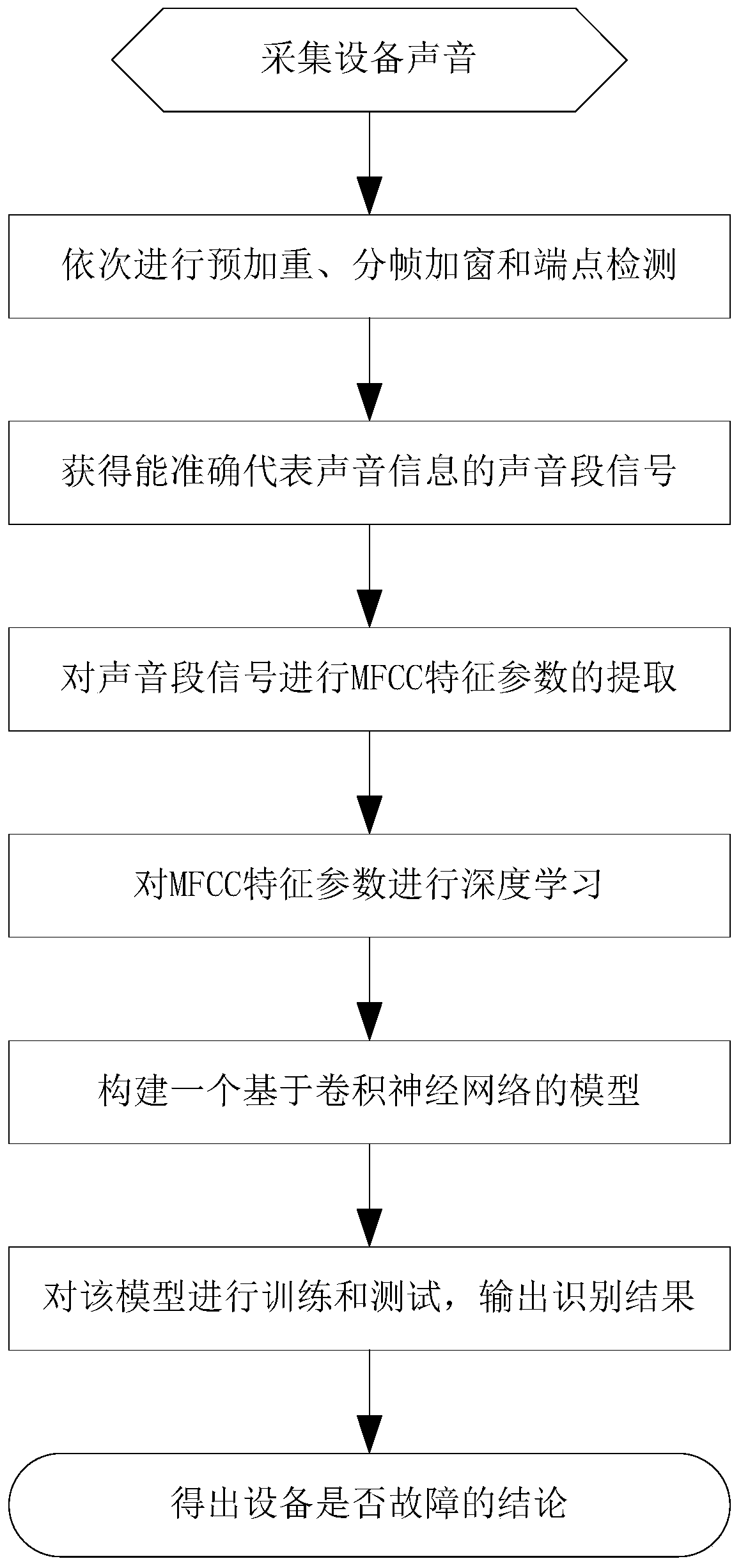

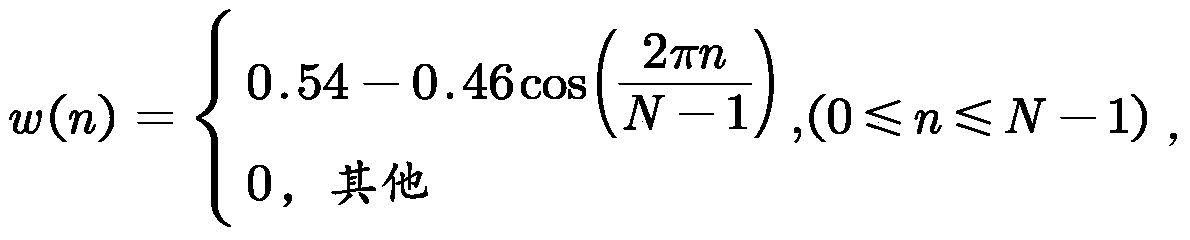

Noise analysis method in transformer substation

InactiveCN110335617AImprove accuracyPrevent omission or misjudgmentSpeech recognitionEngineeringDevice failure

The invention discloses a noise analysis method in a transformer substation and belongs to the technical field of transformer substation equipment. The method comprises the following steps of: firstly, acquiring equipment sound, and preprocessing to obtain a sound segment signal capable of accurately representing sound information; carrying out MFCC characteristic parameter extraction on the soundsegment signal; then, carrying out deep learning is carried out on MFCC characteristic parameters, and constructing a model based on a convolutional neural network; after the model is trained and tested, outputting an identification result; finally, judging whether abnormal noise is sent out by the equipment or not according to the identification result. In this way, whether the equipment has a fault or not is illustrated. According to the invention, the problem of inaccurate inspection result caused by missed judgment and misjudgment when the inspection robot in the existing transformer substation judges the equipment fault is solved.

Owner:STATE GRID XINJIANG ELECTRIC POWER CO URUMQI ELECTRIC POWER SUPPLY CO +1

Display substrate and manufacturing method thereof, and display device

InactiveCN108258154ADry evenlyGuaranteed material utilizationSolid-state devicesSemiconductor/solid-state device manufacturingCoffee ring effectDisplay device

The invention provides a display substrate and a manufacturing method thereof, and a display device, which belong to the technical field of display. The manufacturing method of the display substrate comprises a step of printing organic solution in a sub-pixel region defined by a pixel definition layer to prepare a functional film layer. The step comprises the following sub steps: printing organicsolution in the sub-pixel region; and heating and drying the organic solution, and making the evaporation rate of the solvent in the edge portion of the sub-pixel region lower than the evaporation rate of the solvent in the middle portion of the sub-pixel region during heating and drying. Through the technical scheme of the invention, a functional film layer with uniform thickness can be formed inthe sub-pixel region, and the coffee ring effect is avoided.

Owner:BOE TECH GRP CO LTD +1

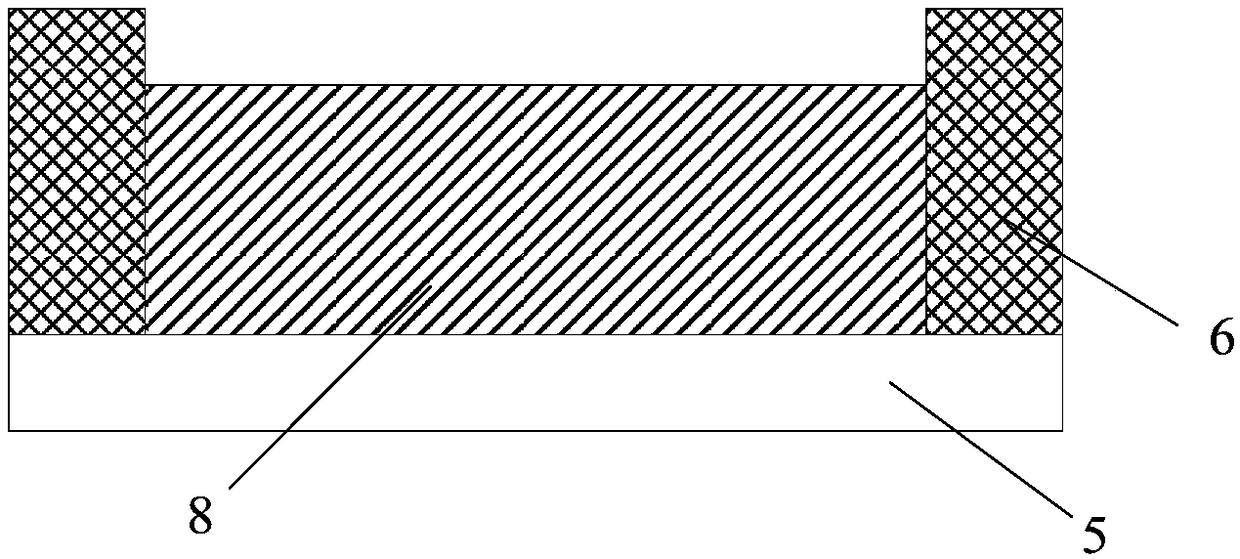

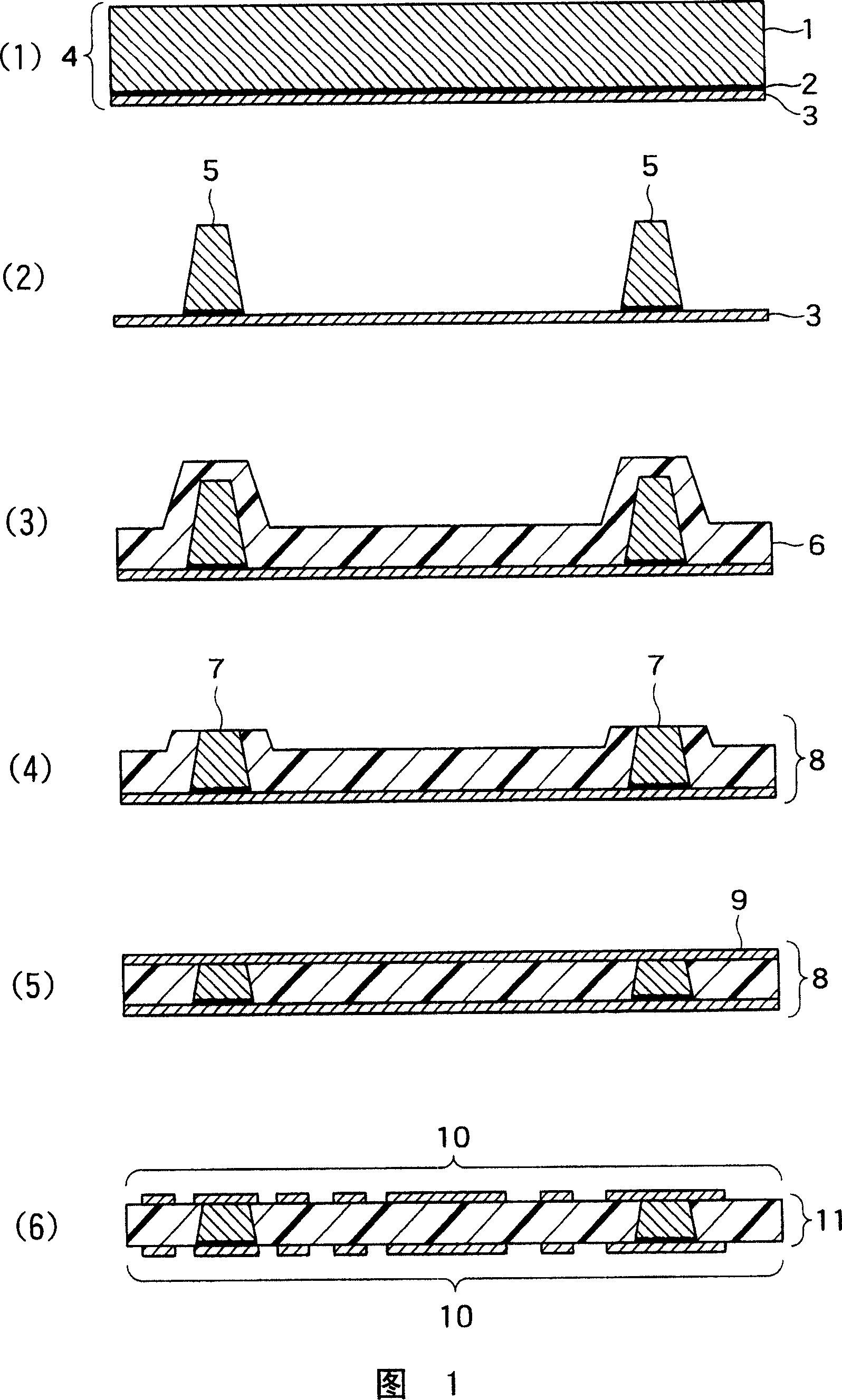

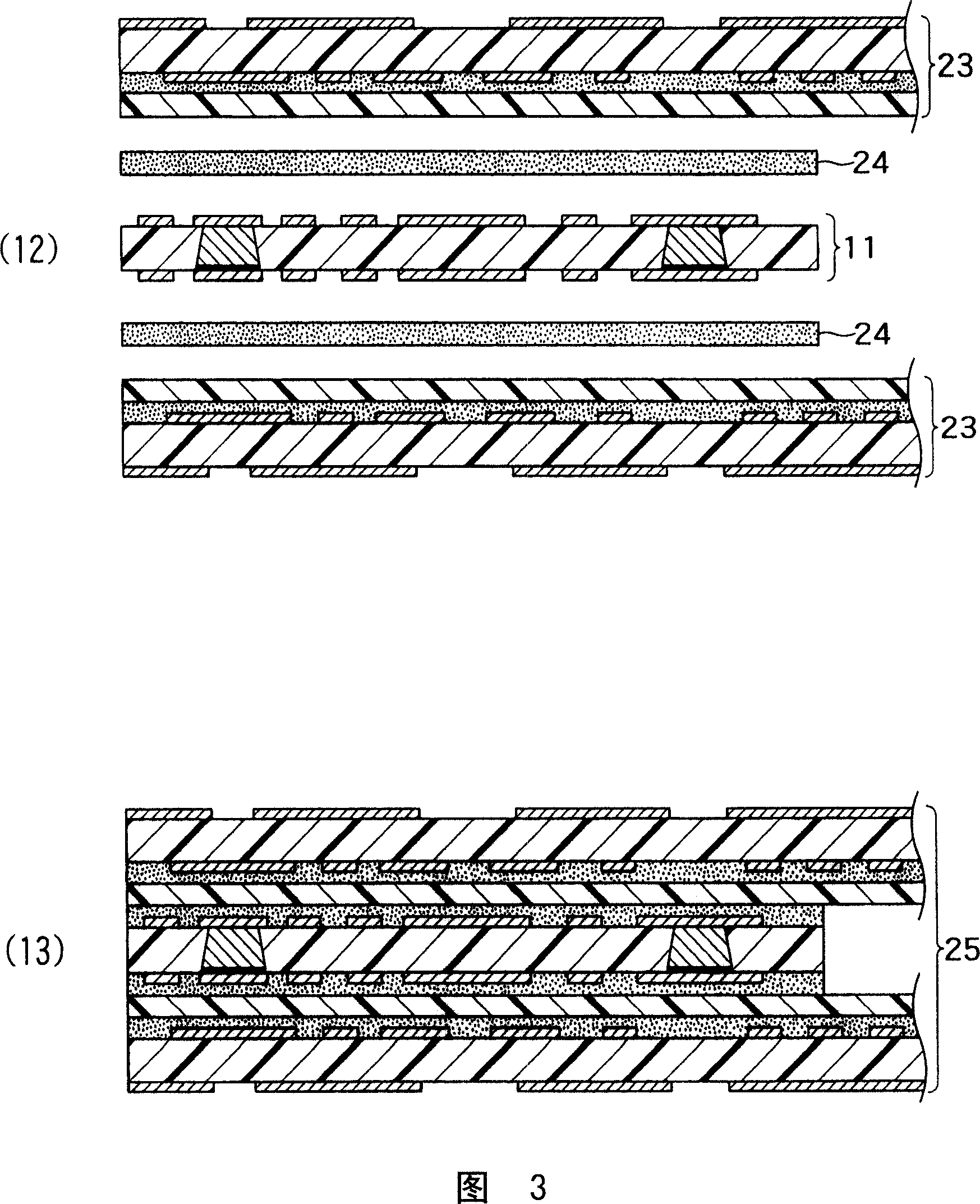

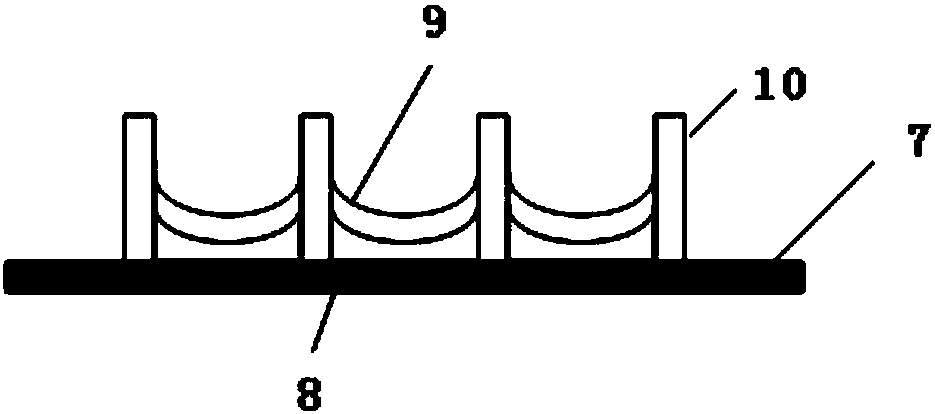

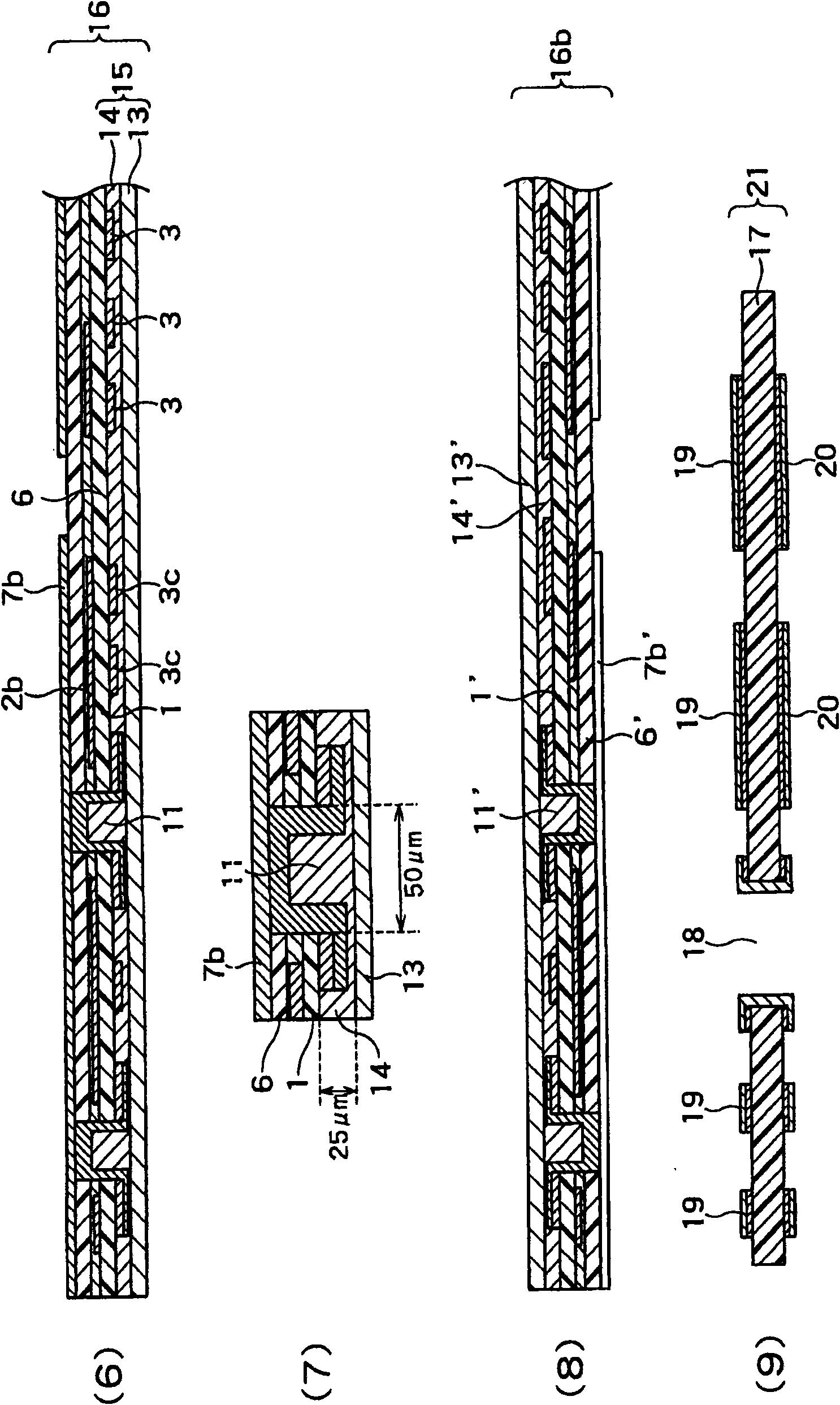

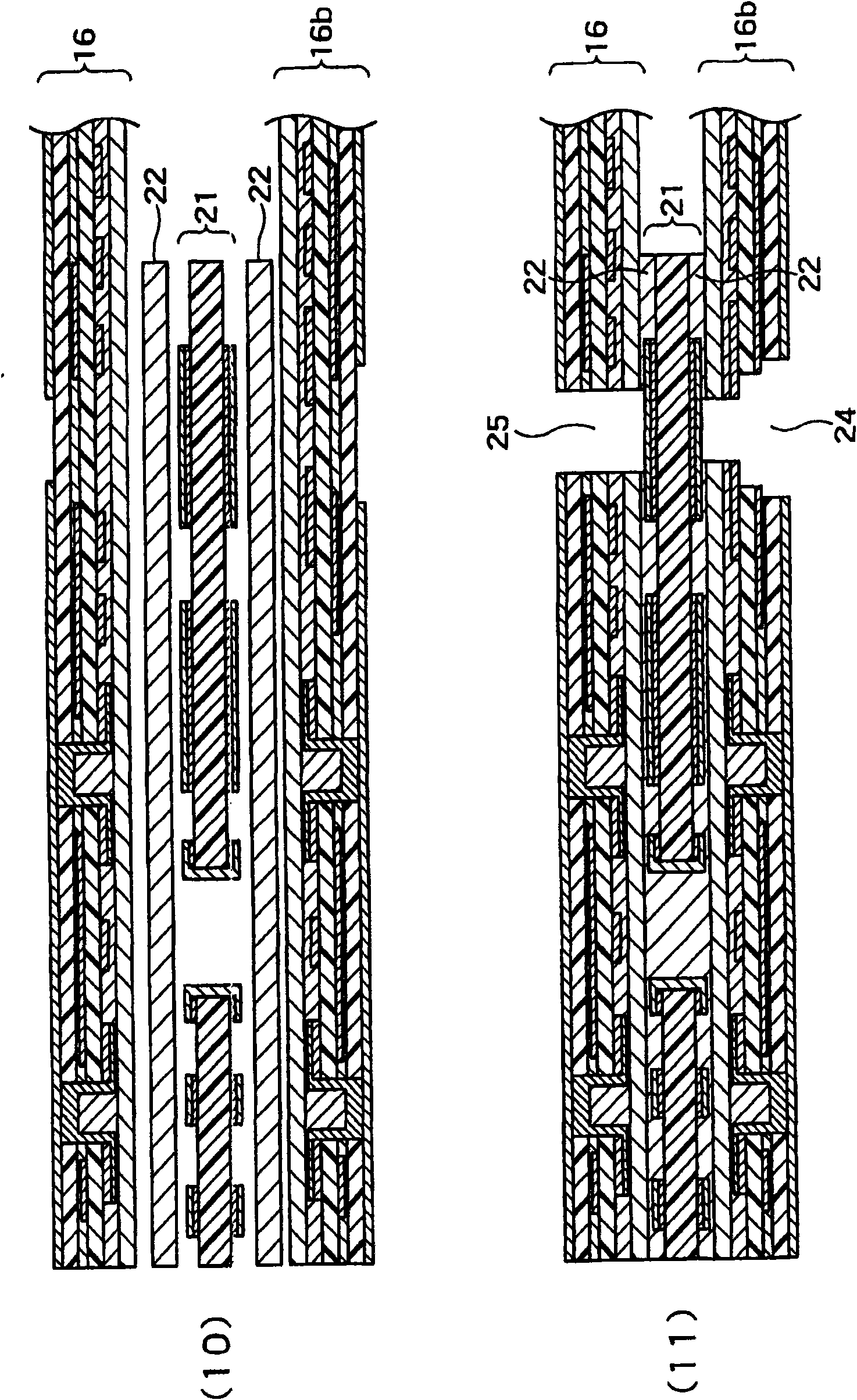

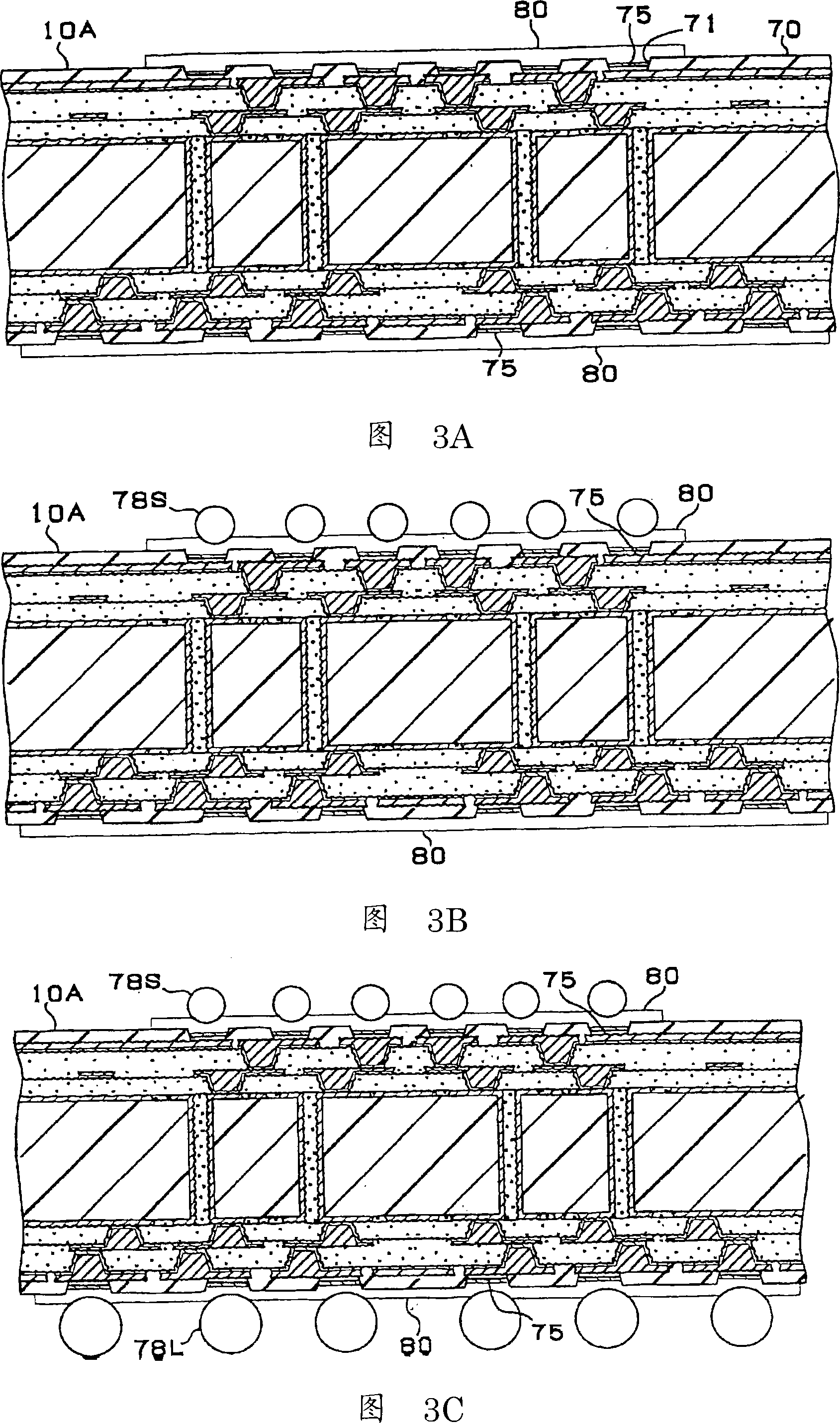

Method for manufacturing multilayer wiring substrate with cable

InactiveCN1972571AWiring miniaturizationEnsure flatnessMultilayer circuit manufacturePrinted element electric connection formationLaser processingEngineering

The invention provides a method for inexpensively and stably manufacturing a multilayer wiring board having a cable section with a high integration degree capable of loading narrow pitch CSP. The manufacturing method of the multilayer flexible wiring board having the cable section in at least an outer layer, includes a) a process for manufacturing an inner layer core substrate (8, 58); b) a process for forming an opening of copper foil in a conduction hole forming part on an outer layer side in a double sided copper clad laminate having flexibility, and forming a circuit pattern (10, 60) comprising an opening of a conduction hole forming part on an inner layer side of the double sided copper clad laminate; c) a process for forming a cover ray (22, 70) on the circuit pattern to make it to be an outer layer built-up layer (23, 67); d) a process for laminating the outer layer built-up layer by turning a side where the cover ray is formed to a side of the inner layer core substrate, and forming the lamination circuit substrate (25, 73); e) a process for performing laser processing on the conduction hole forming part of the outer layer side through the opening of copper foil, and forming a conduction hole (26, 27, 28, 74, 75, 76) in the lamination circuit substrate; f) a process for performing laser processing on the conduction hole forming part of the outer layer side by acting the opening of the copper foil and the opening of the conduction hole forming part as a mask for shielding laser, and forming the conduction hole in the lamination circuit substrate; and g) a process for performing a conduction processing on the conduction hole, and forming a via hole (29, 30, 31, 77, 78, 79) with electrolytic plating. The double sided copper clad laminate can be replaced by a single sided copper clad laminate.

Owner:NIPPON MEKTRON LTD

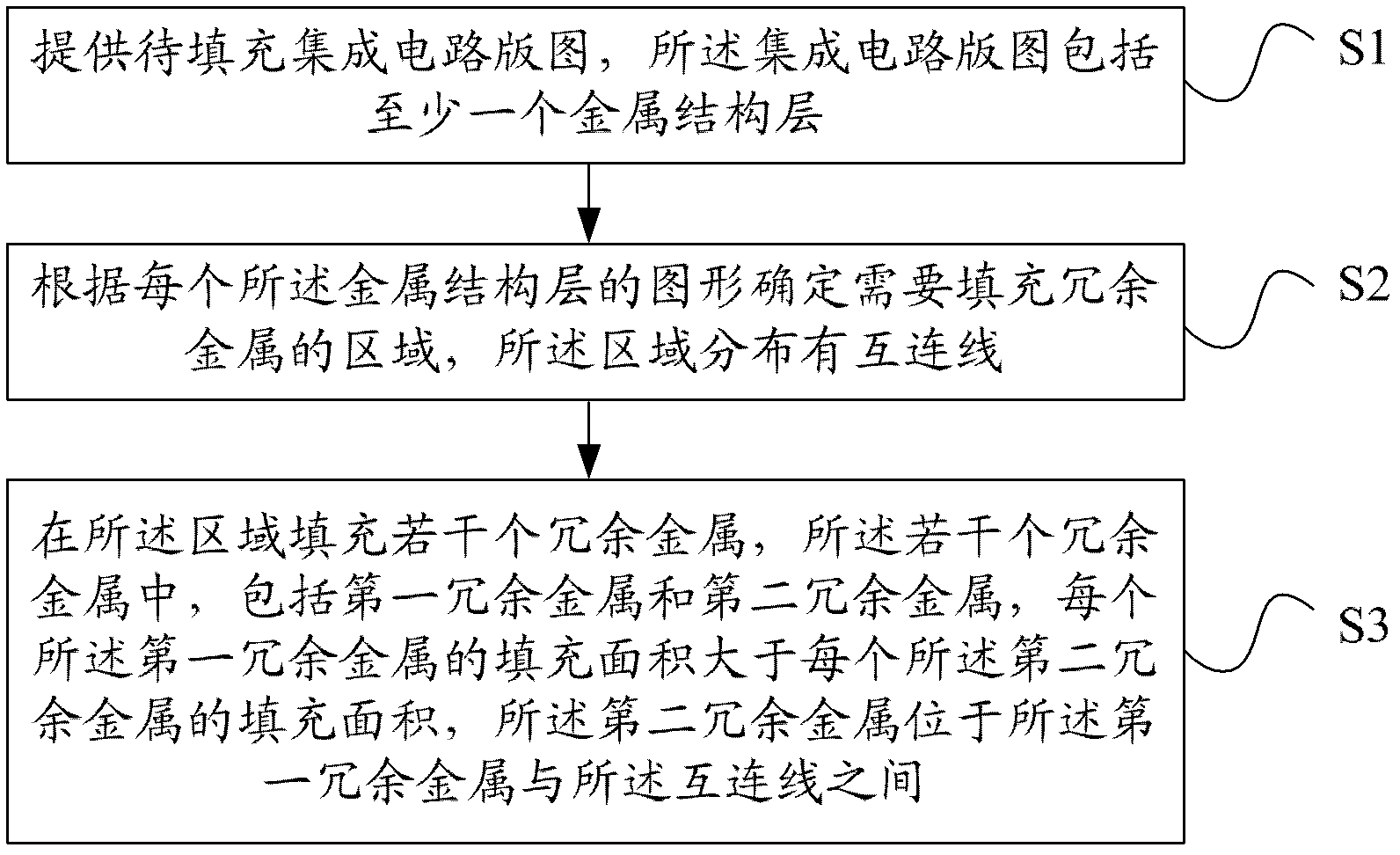

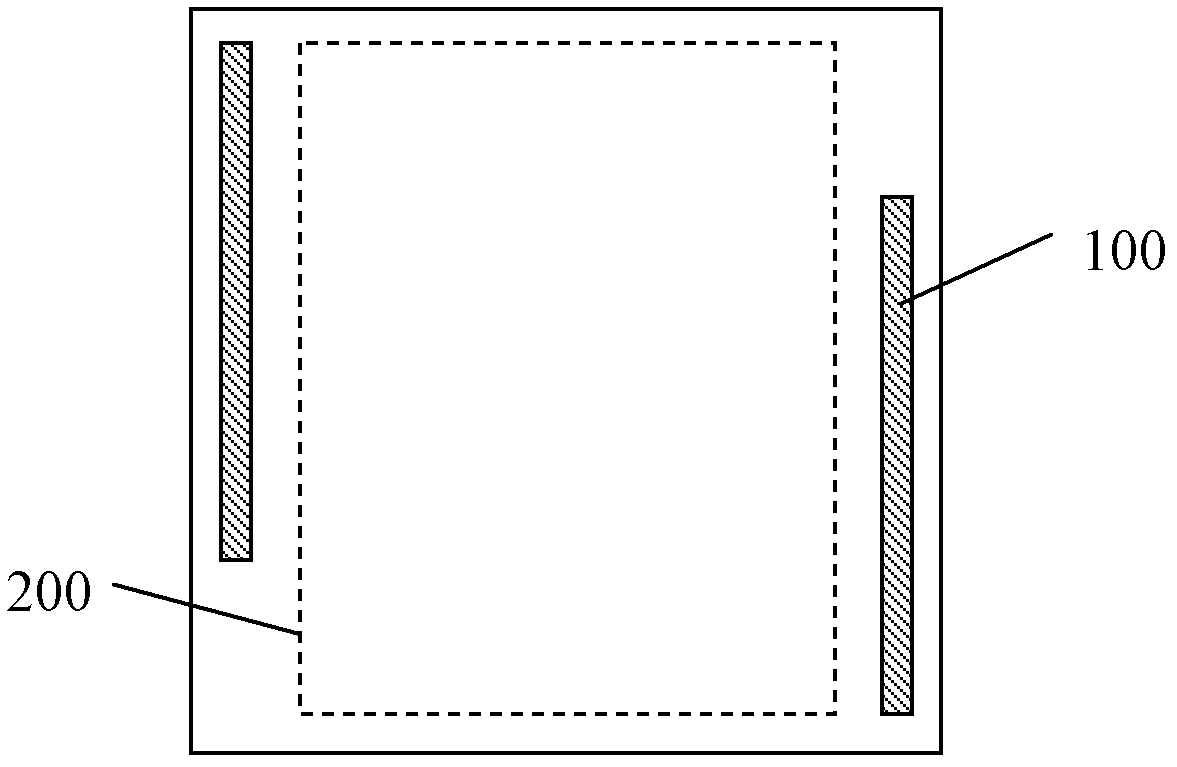

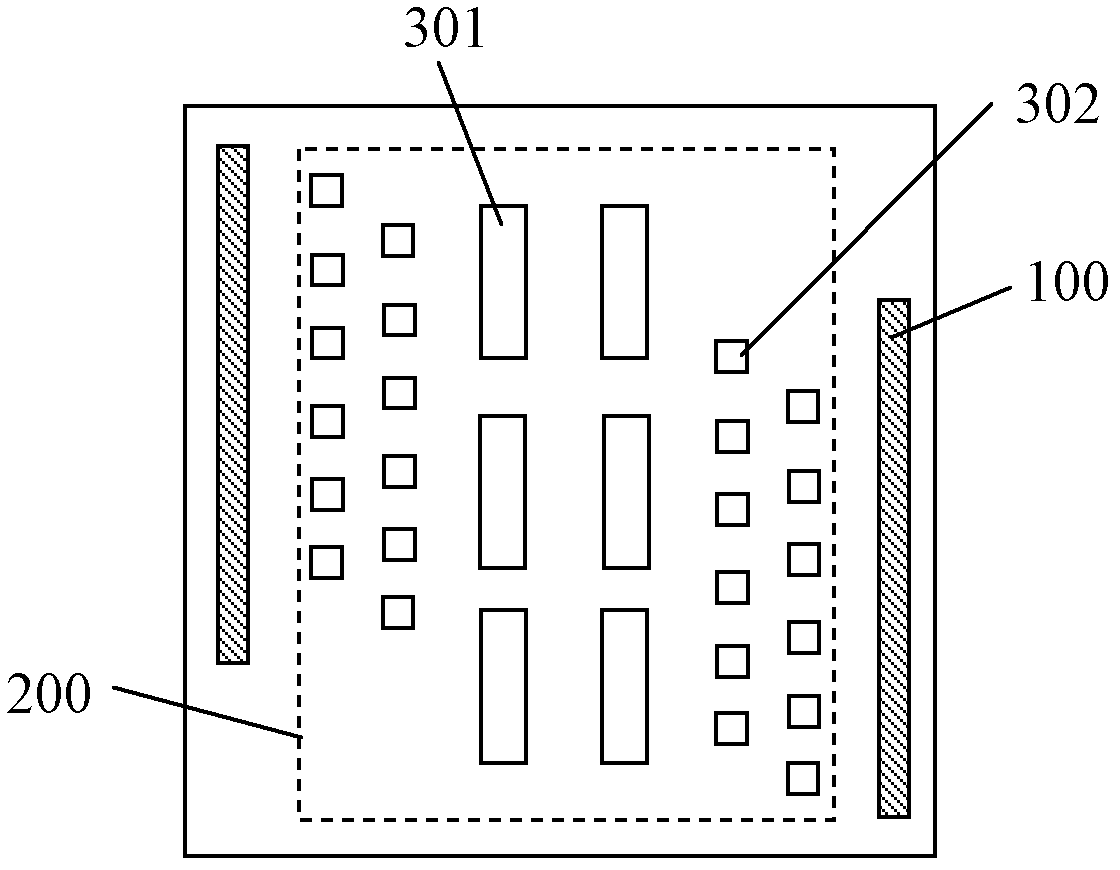

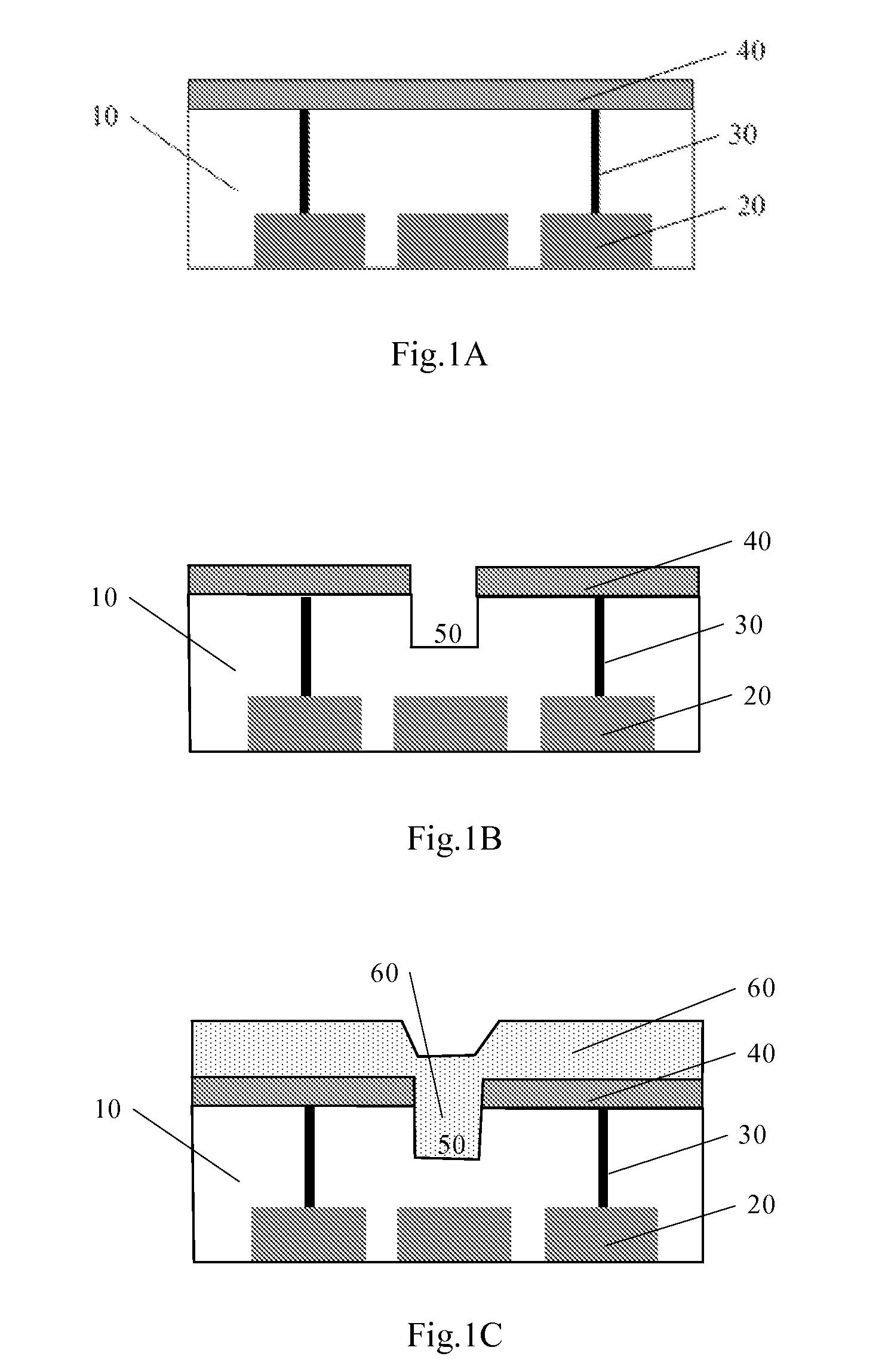

Dummy metal filling method and integrated circuit layout structure

ActiveCN102543853AAchieve Thickness ConsistencyIncrease capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceIntegrated circuit interconnect

The invention provides a dummy metal filling method. According to the invention, a plurality of dummy metals are filled in an area required to be filled by the dummy metals including first dummy metals and second dummy metals; the filling area of each first dummy metal is larger than that of each second dummy metal; and the second dummy metals are positioned between interconnection lines of the first dummy metals and the area where the dummy metals are positioned. Accordingly, the invention further provides an integrated circuit layout structure. Through the dummy metal filling method provided by the invention, the thickness consistency of an integrated circuit layout is realized, and the capacitance increment between the interconnection lines of an integrated circuit is reduced at the same time, the function of the chip is prevented from being damaged due to the introduction of the dummy metals, the dummy metals in different areas can be filled in the area required to be filled by the dummy metals, the filling number of the dummy metals is reduced, and other calculation data quality is reduced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Array substrate, preparation method, display panel and display device

InactiveCN107731879AImprove utilization efficiencyUniform brightnessSolid-state devicesSemiconductor/solid-state device manufacturingCoffee ring effectDisplay device

The invention provides an array substrate, a preparation method, a display panel and a display device. The array substrate comprises a substrate and positive electrode layers arranged on the substratein an array, wherein the thickness of each positive electrode layer is gradually increased in the direction from the center of each positive electrode layer to the edge of each positive electrode layer in a preset distance range to the edge of each positive electrode layer. The positive electrode layers arranged on the substrate in the array are such manufactured that the thickness of each positive electrode layer is gradually increased in the direction from the center of each positive electrode layer to the edge of each positive electrode layer in the preset distance range to the edge of each positive electrode layer, and then a coffee-ring effect can be effectively avoided when a luminescent material is continuously printed on an electrode, so that a film with uniform thickness is formed, the uniformity of the printed film is improved, the flatness of the pixel film is guaranteed, the brightness for electroluminescence device illumination can be uniform, and the utilization efficiency of the material is further improved.

Owner:BOE TECH GRP CO LTD

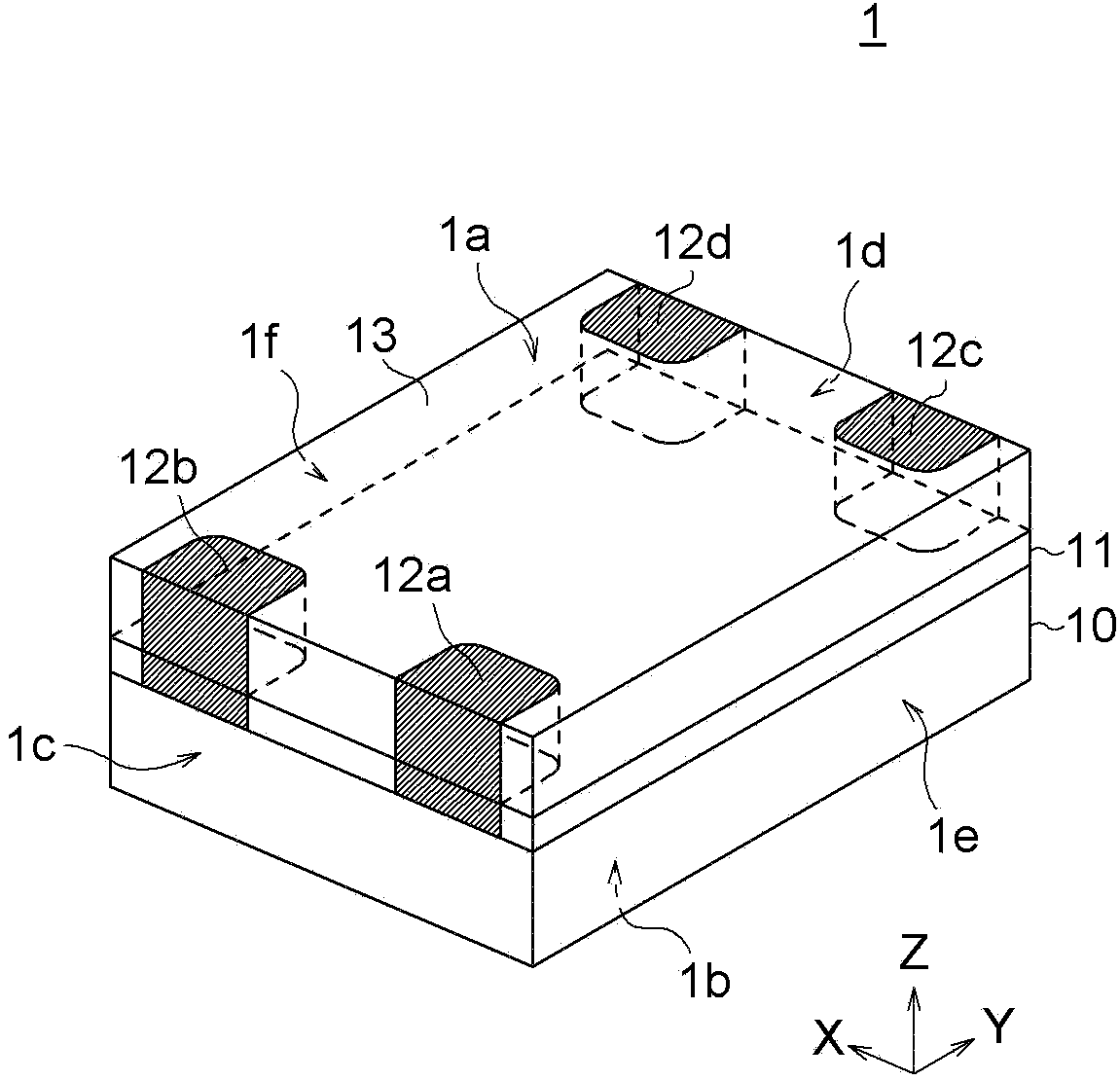

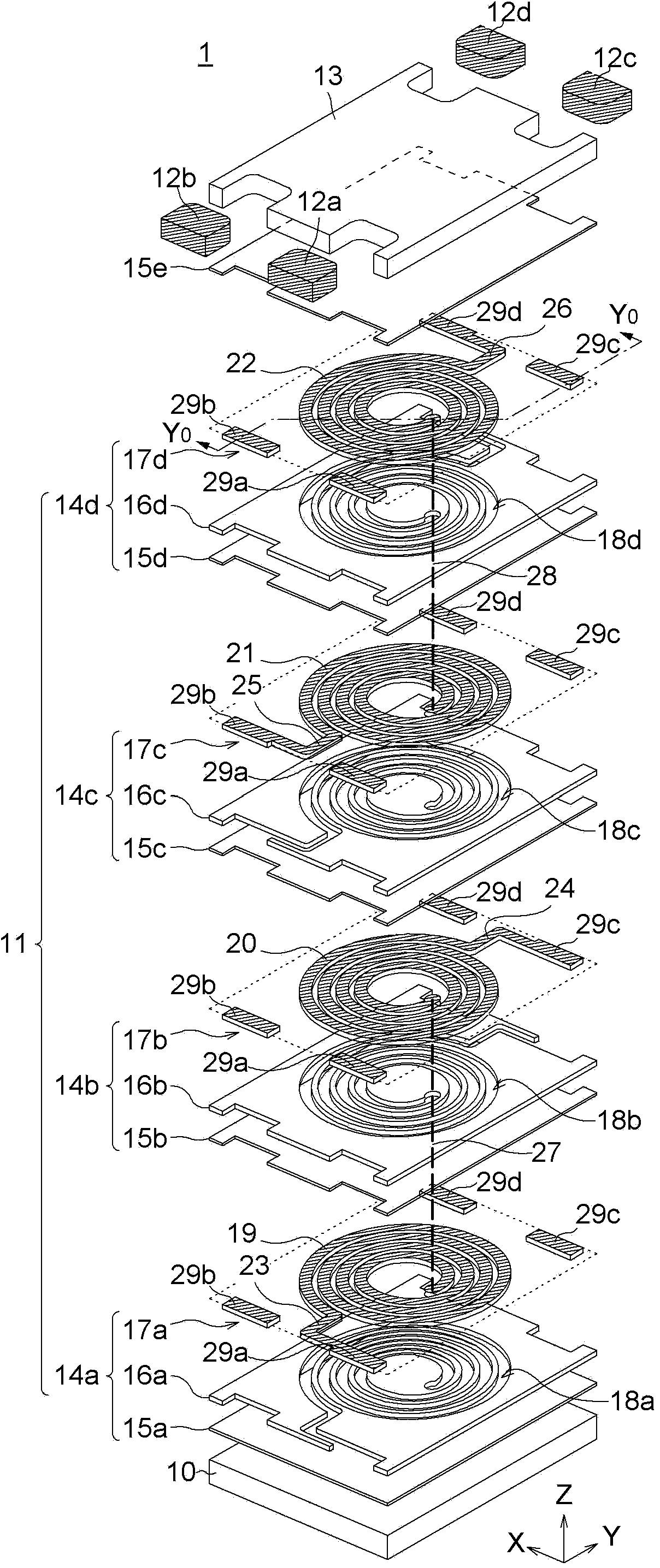

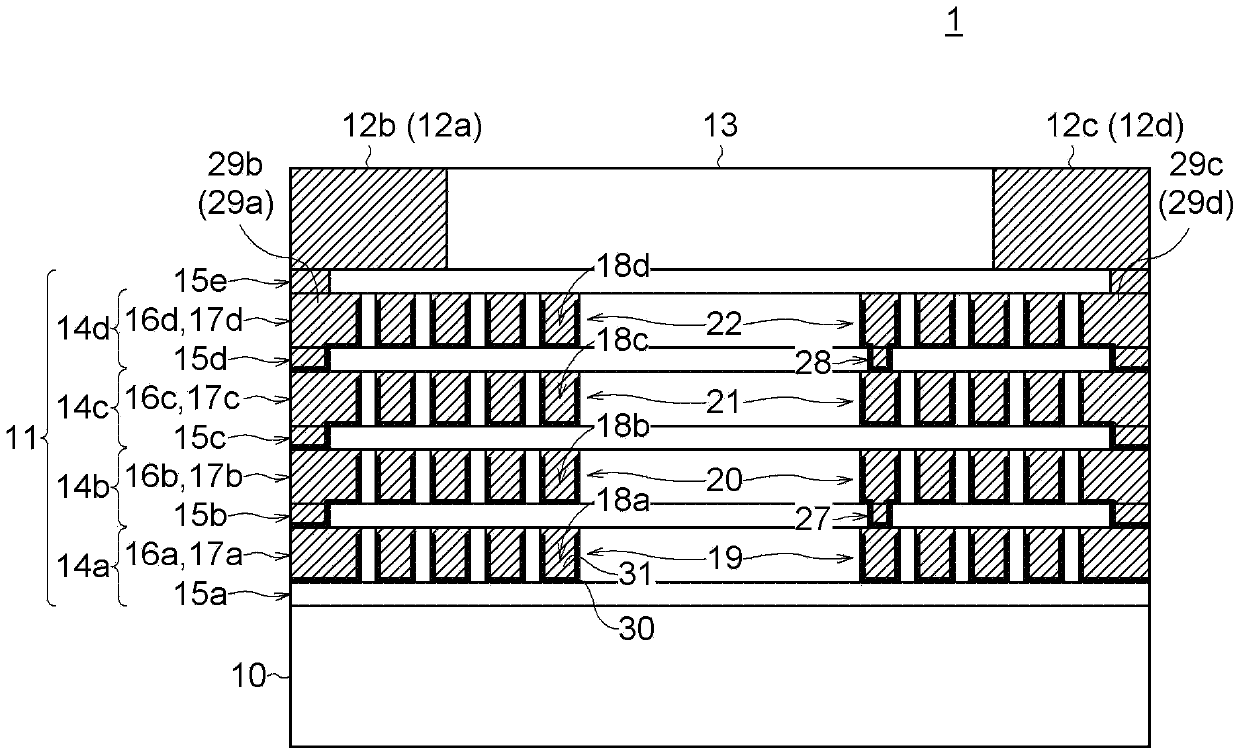

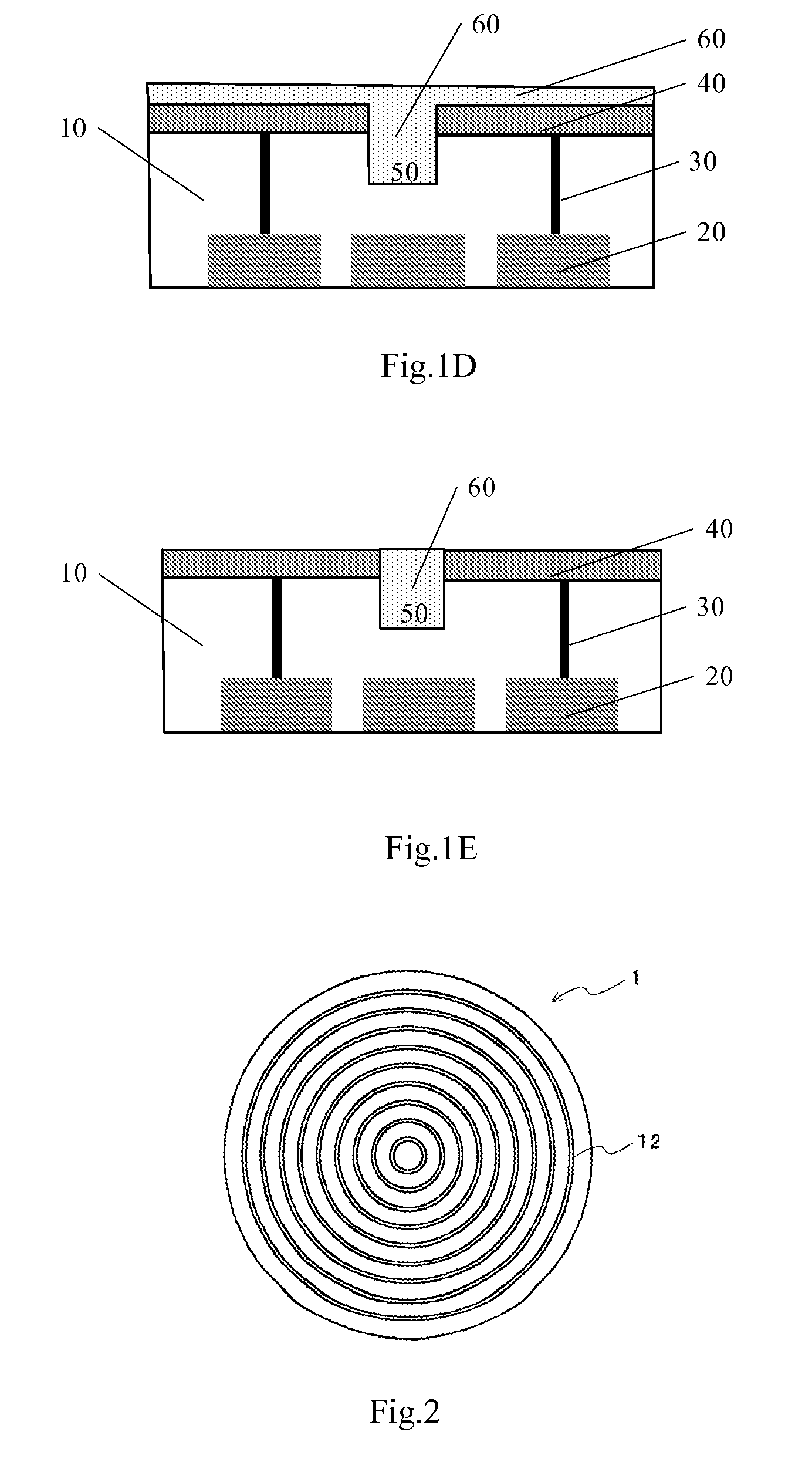

Coil part and manufacturing method thereof

InactiveCN104183354AImprove performanceImprove reliabilityTransformers/inductances coils/windings/connectionsCoils manufactureElectrical conductorNegative pattern

The invention provides a coil part which is characterized in that even if a coil pattern is made in a high aspect ratio, there is no shifting or thermal peeling problems, and the performance and the reliability are high. The coil part (1) is provided with coil layers (14a-14d), and each coil layer (14a-14d) is provided with an insulating layer (15a-15d), a framework layer (16a-16d) formed on the insulating layer (15a-15d), and a conductor layer (17a-17d) which is formed on the same plane as the framework layer (16a-16d) and includes a spiral conductor (19-22). Each framework layer (16a-16d) comprises an opening image (18a-18d) including a negative pattern of a coil pattern, and the spiral conductors (19-22) are formed in the opening image (18a-18d). The spiral conductors (19-22) are provided with seed layers (30) for covering the bottom surfaces and the inner side surfaces of the opening images (18a-18d), and clad layers (31) arranged on the surfaces of the seed layers (30).

Owner:TDK CORPARATION

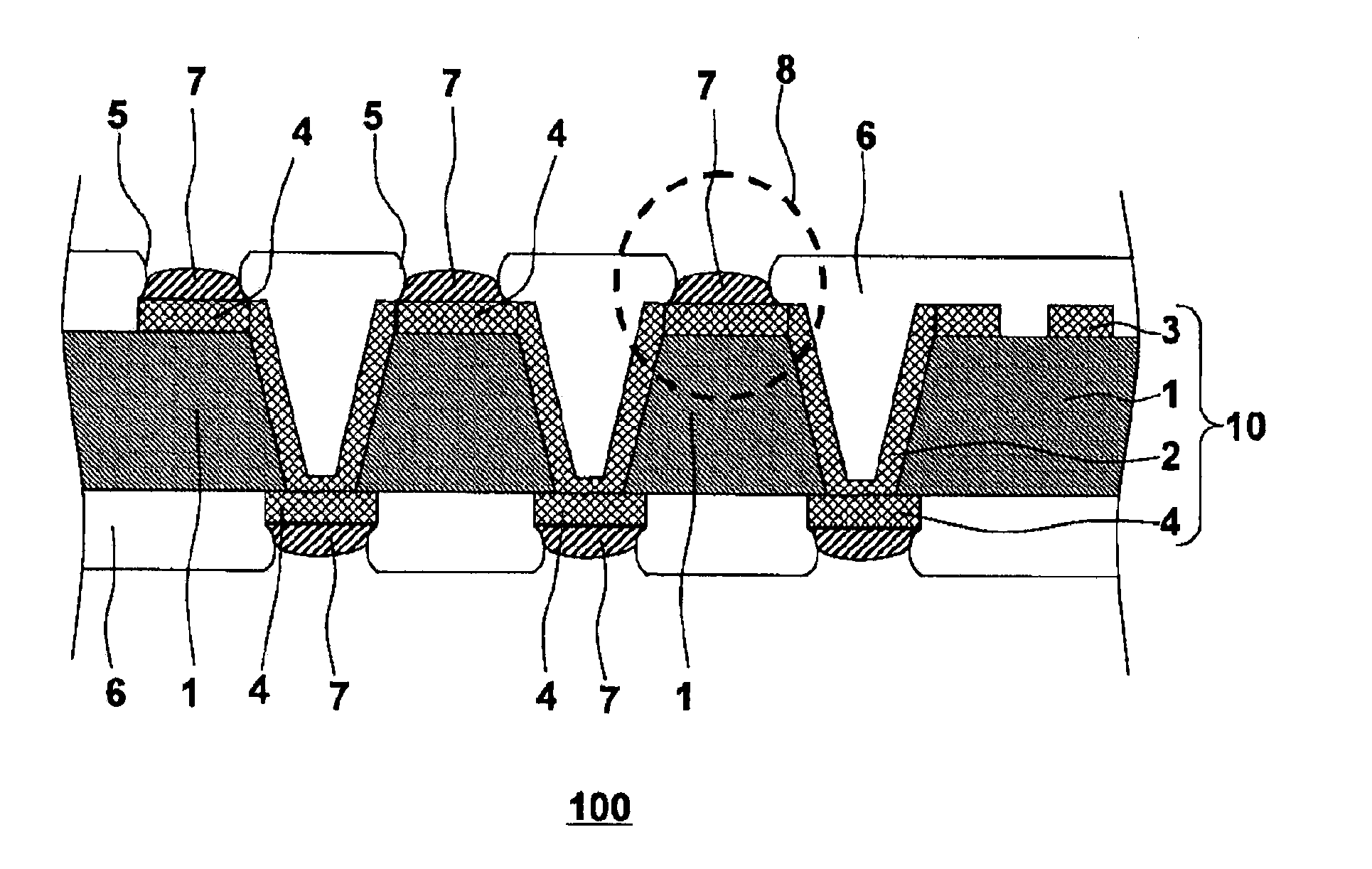

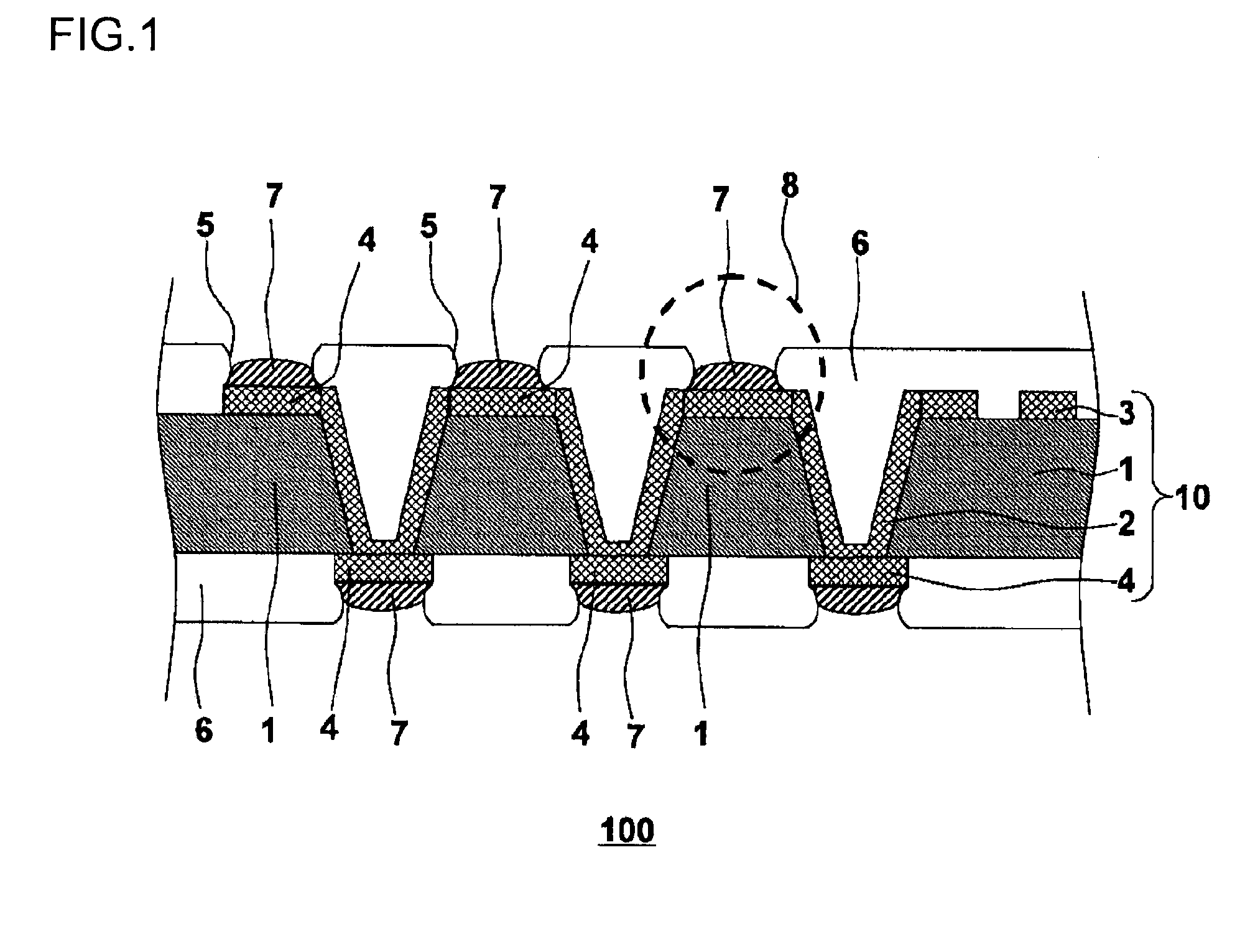

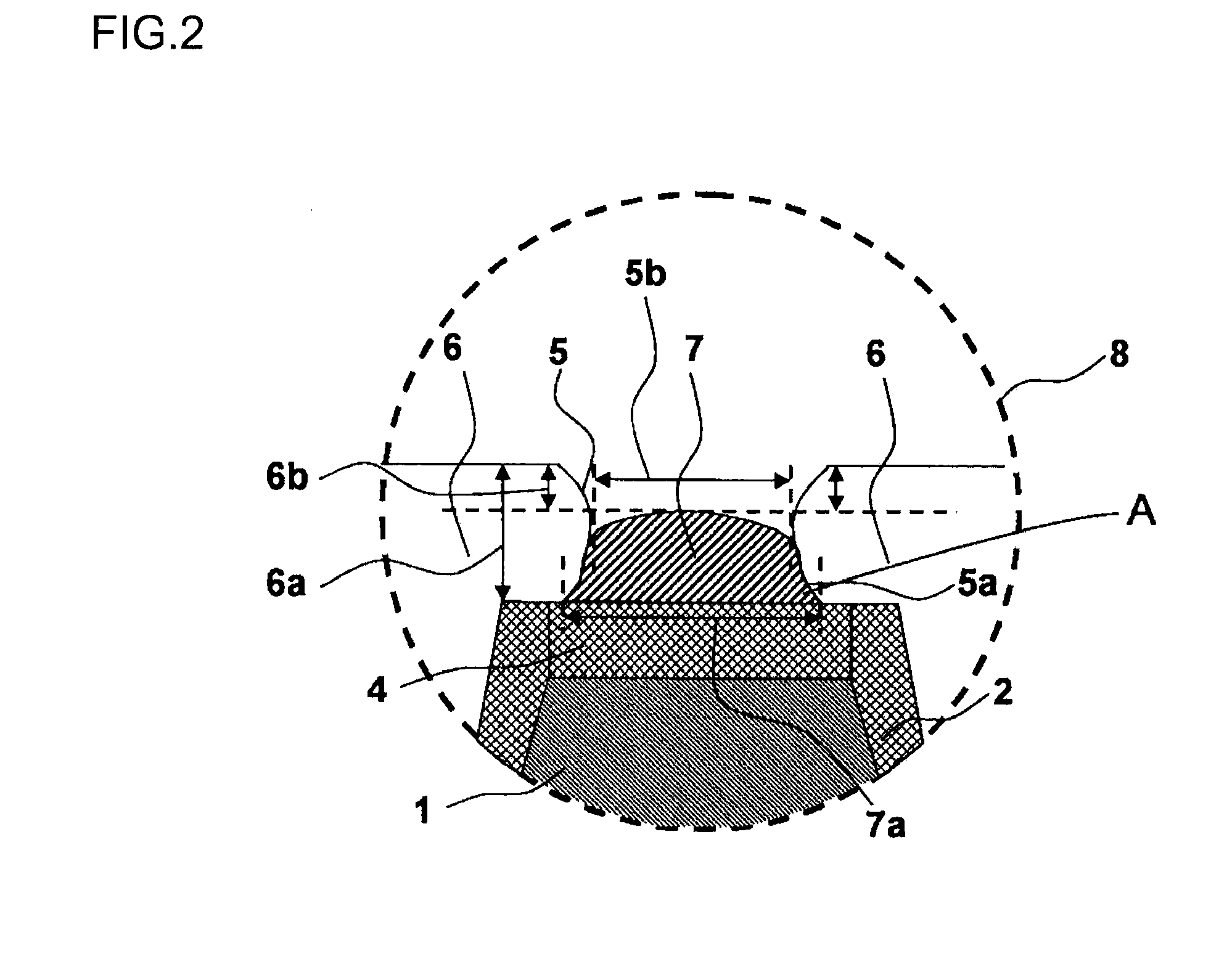

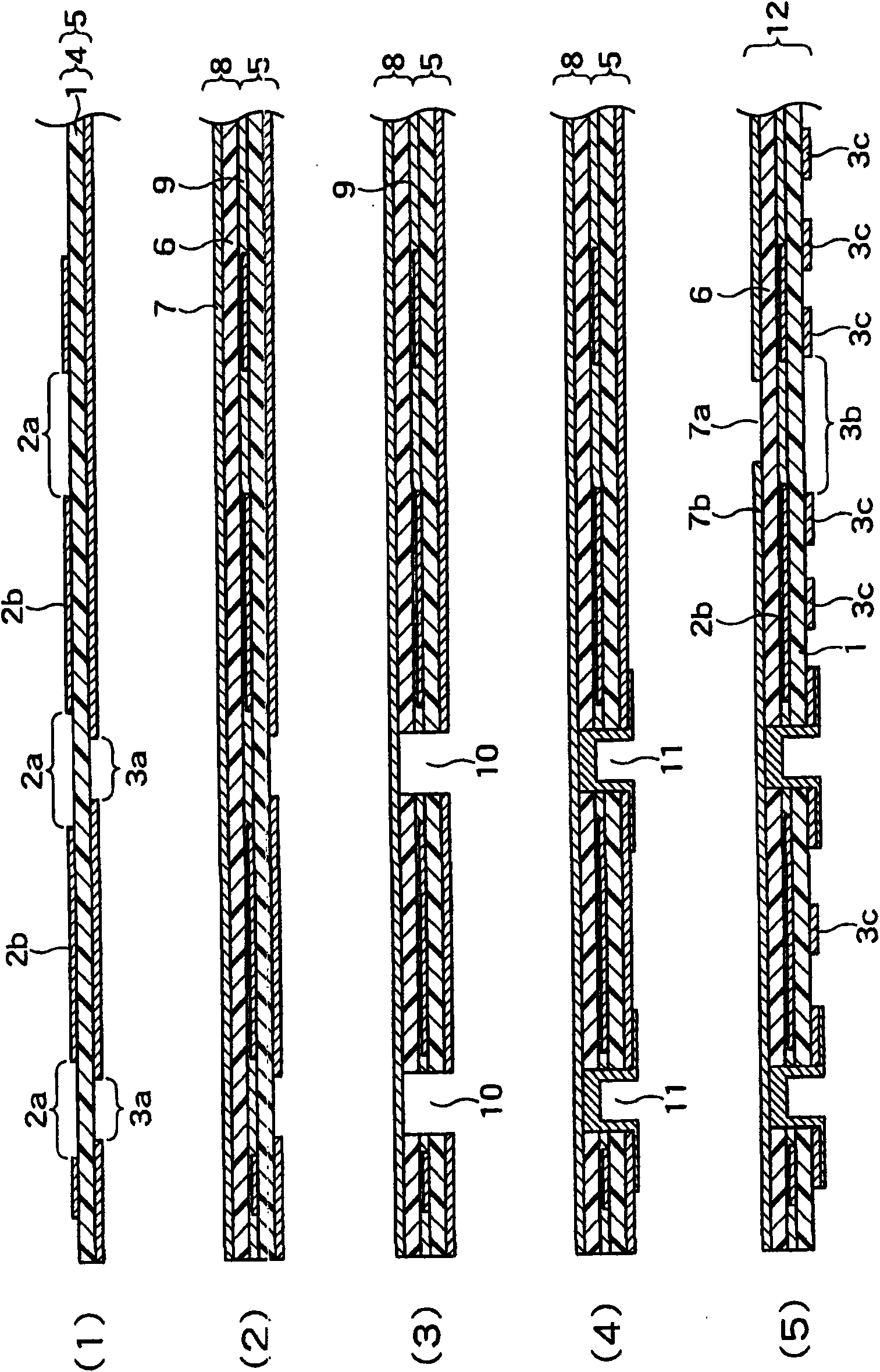

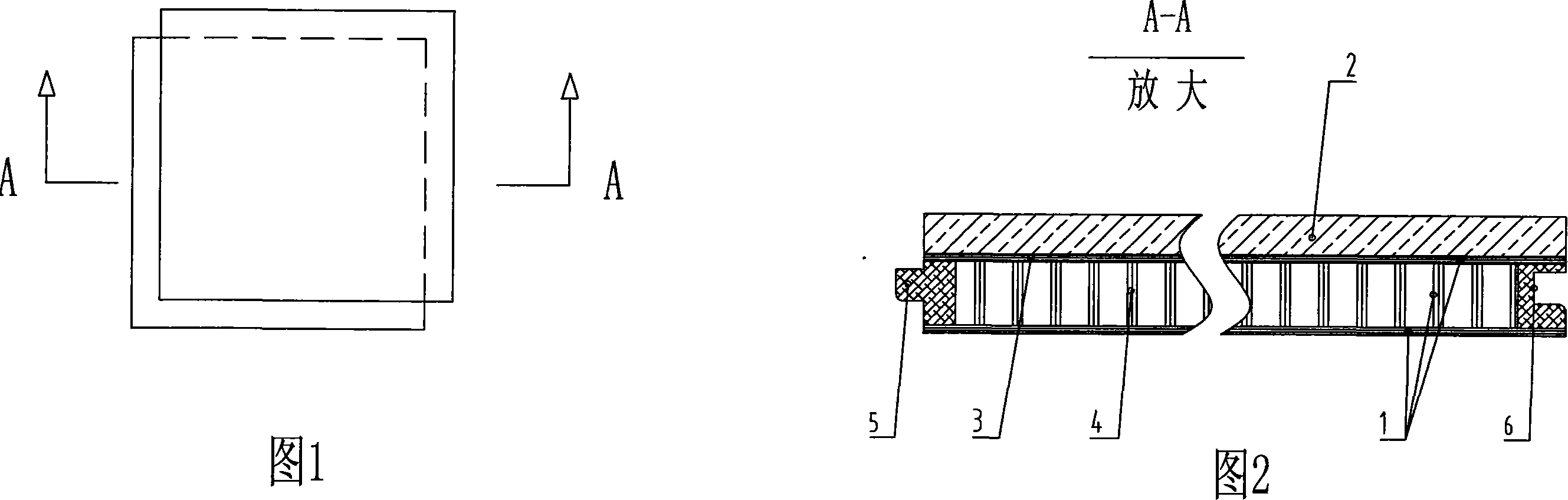

Multi-layer flexible printed circuit board and method of manufacturing the same

InactiveCN101568226ASuitable for installationImprove electrical characteristicsPrinted circuit detailsSemiconductor/solid-state device detailsHigh densityPrinted circuit board

The present invention provides a multi-layer flexible printed circuit board which is capable of carrying narrow space length high-density CSP and a method for manufacturing the same. The multi-layer flexible printed circuit board comprises a three-layered structure lamination layer on at least one single surface of a core substrate of which two surfaces are provided with wiring pattern, and is characterized in that the a first conductive layer (7) of the first layer from the outer side of the lamination layer is provided with an installation solder pad (34) for installing a chip level packaging, a second conductive layer (2) of the second layer from the outer side of the lamination layer is provided with a grounding layer which at least is below the zone carrying the chip level packaging, a third conductive layer of the third layer from the outer side of the lamination layer is provided with wiring pattern for leading and winding a signal circuit, the wiring pattern is conducted by jumping a jumping conducting hole (28) of the grounding layer of the second conductive layer from the installation solder pad, the jumping conducting hole is a blind hole with a bottom and the bottom is connected with the back surface of the installation solder pad of the first conductive layer, and the multi-layer flexible printed circuit board is also provided with a conducting holes (40) of the conducting lamination layer and the core substrate (21) besides the jumping conducting hole, and a flexible cable part which is integrated with the lamination layer.

Owner:NIPPON MEKTRON LTD

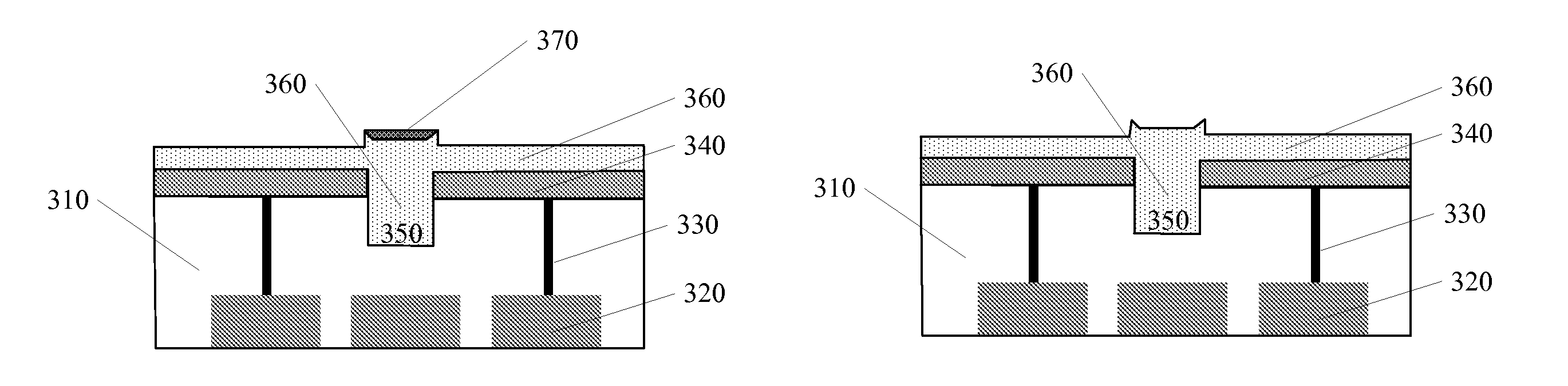

Method for planarization of wafer and method for formation of isolation structure in top metal layer

ActiveUS8058175B2Ensure flatnessImprove display qualityAfter-treatment detailsDecorative surface effectsResistSurface layer

The invention discloses a planarization method for a wafer having a surface layer with a recess, comprises: forming an etching-resist layer on the surface layer to fill the entire recess; etching the etching-resist layer and the surface layer, till the surface layer outside the recess is flush to or lower than the bottom of the recess, the etching speed of the surface layer being higher than that of the etching-resist layer; removing the etching-resist layer; and etching the surface layer to a predetermined depth. The method can avoid concentric ring recesses on the surface of the wafer resulted from a chemical mechanical polishing (CMP) process in the prior art, and can be used to obtain a wafer surface suitable for optical applications.

Owner:SEMICON MFG INT (SHANGHAI) CORP

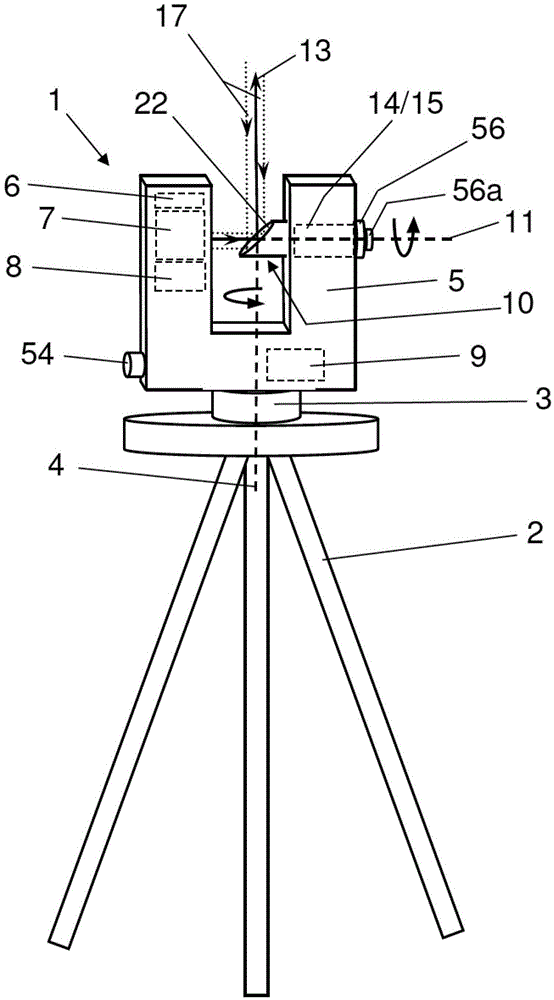

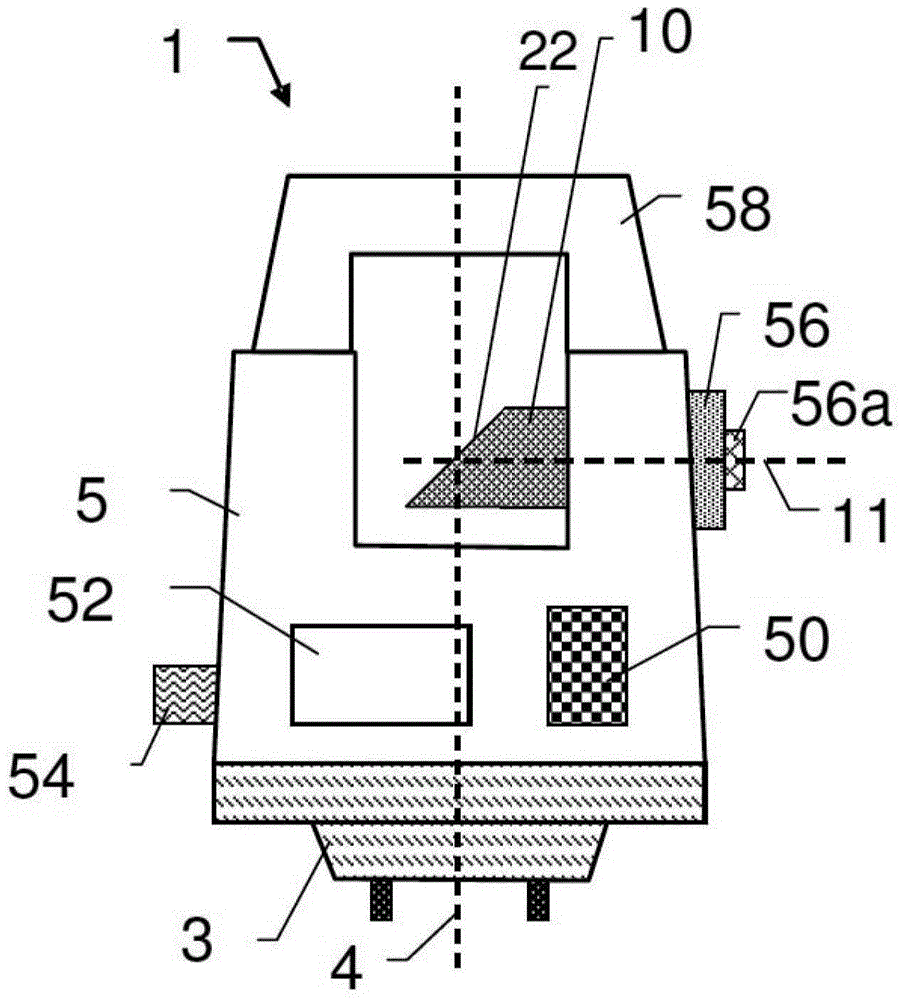

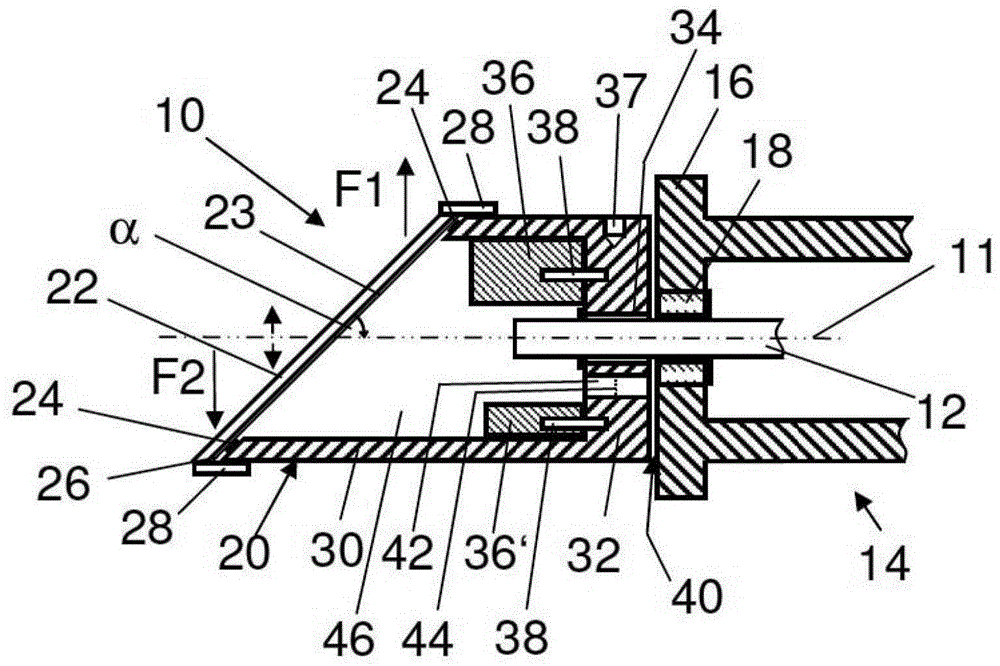

Surveying device having a rotation mirror for optically scanning an environment

ActiveCN104567814AReduce flyingReduce riskWave based measurement systemsPhotogrammetry/videogrammetryMotor driveLight beam

Some embodiments of the invention relate to a rotation unit for a surveying device, in particular a laser scanner for optically scanning an environment and such a surveying device. The surveying device has a rotation unit having a rotation mirror, for deflecting an emission light beam and a reception light beam, and a rotation body implemented as a cylinder having a on a beveled, free end. The rotation body is implemented as a hollow cylinder having a cylinder bottom and a beveled cylinder wall on its free end. The hollow cylinder is connected coaxially with respect to its cylinder axis in a rotationally-fixed manner to a motor-driven shaft via the cylinder bottom. The rotation mirror is fastened in the region of its free end to the cylinder wall of the hollow cylinder so it is supported thereby.

Owner:HEXAGON TECH CENT GMBH

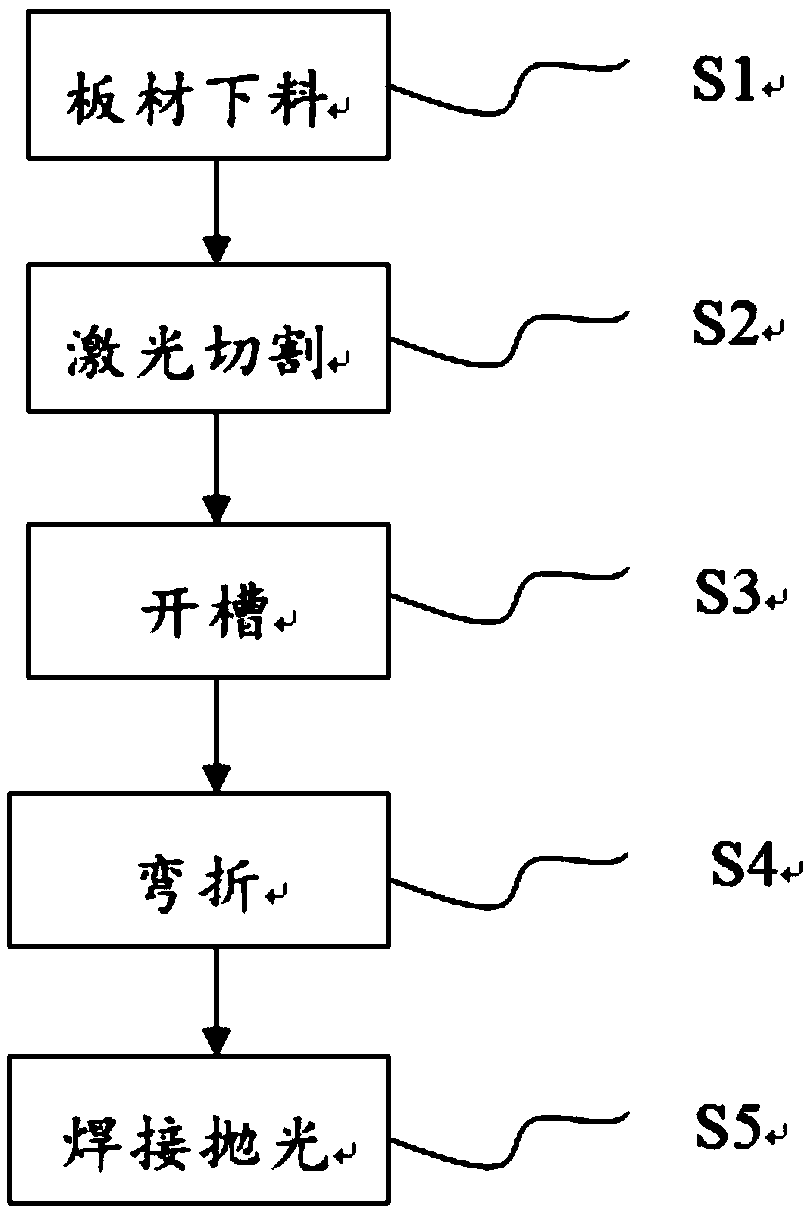

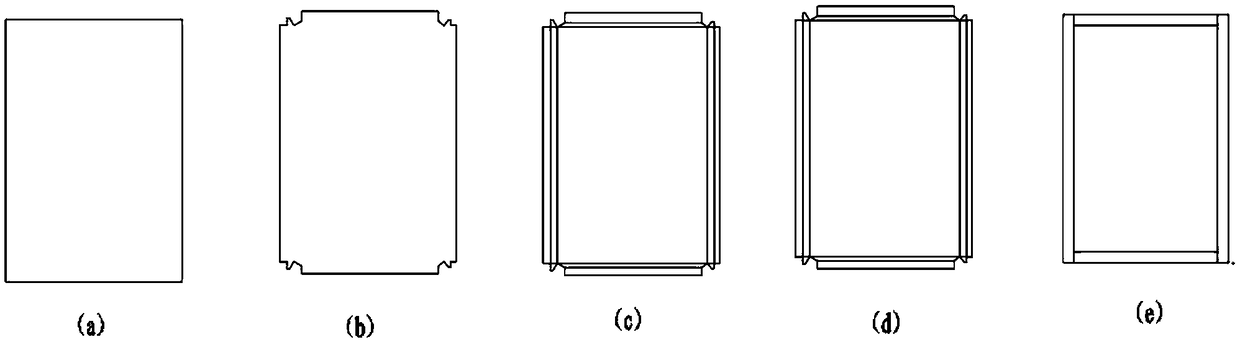

Panel for assembly and machining technology thereof and dryer

InactiveCN108747228APrevent disappearingAvoid chromatic aberrationDrying solid materialsBoundary contourButt joint

The invention relates to a panel for assembly and a machining technology thereof and a dryer. The machining technology comprises the steps that S1, plate blanking is carried out; S2, laser cutting iscarried out, specifically, laser cutting is carried out on a plate according to the boundary contour of a developing drawing of a finished panel; S3, slotting is carried out, specifically, a pluralityof bent lines are drawn on the plate, and slotting is carried out along the bent lines; S4, bending is carried out, specifically, bending treatment is carried out along slotted lines, one opposite sides are bent first, and then the other opposite sides are bend; and S5, welding and polishing are carried out, specifically, butt joints of the edges are subjected to welding and polishing treatment.According to the machining technology, five visible surfaces of the panel have no side seams which need to be welded, all positions which need to be welded are arranged on the inside side surfaces, namely, the invisible surfaces, line disappearance and chromatic aberration of the visible surfaces after welding and polishing are avoided, and an integral attractive effect is achieved. Meanwhile, themachining technology of the panel can effectively simplify the operation steps of bending and effectively ensure the overall flatness and attractive degree of bent parts.

Owner:TRUKING TECH LTD

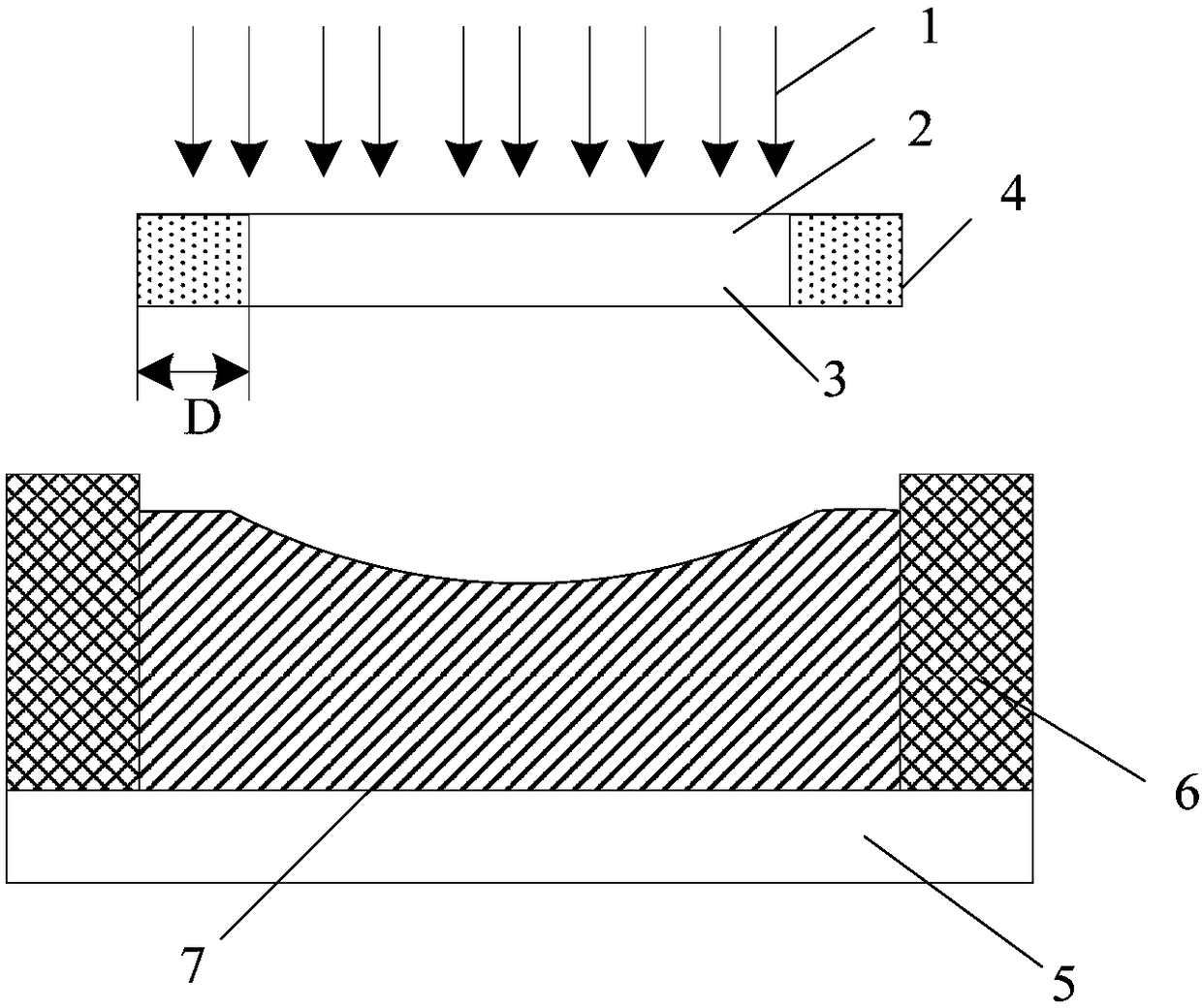

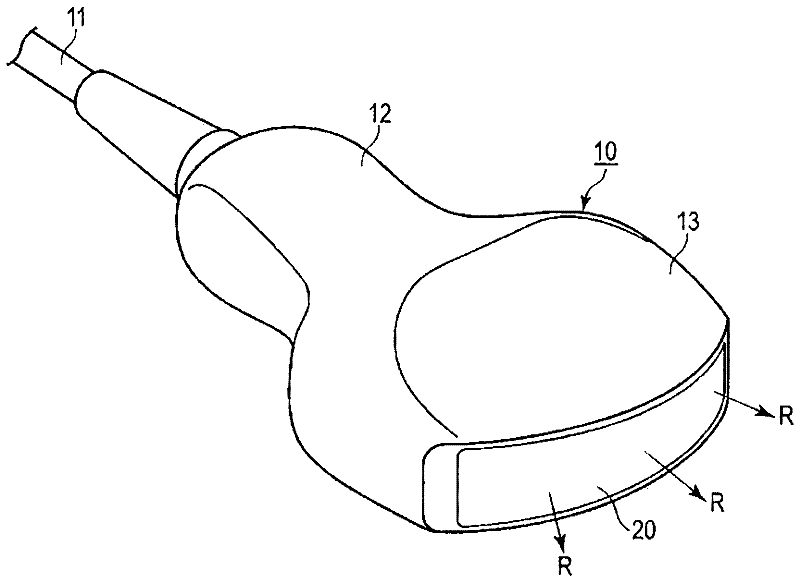

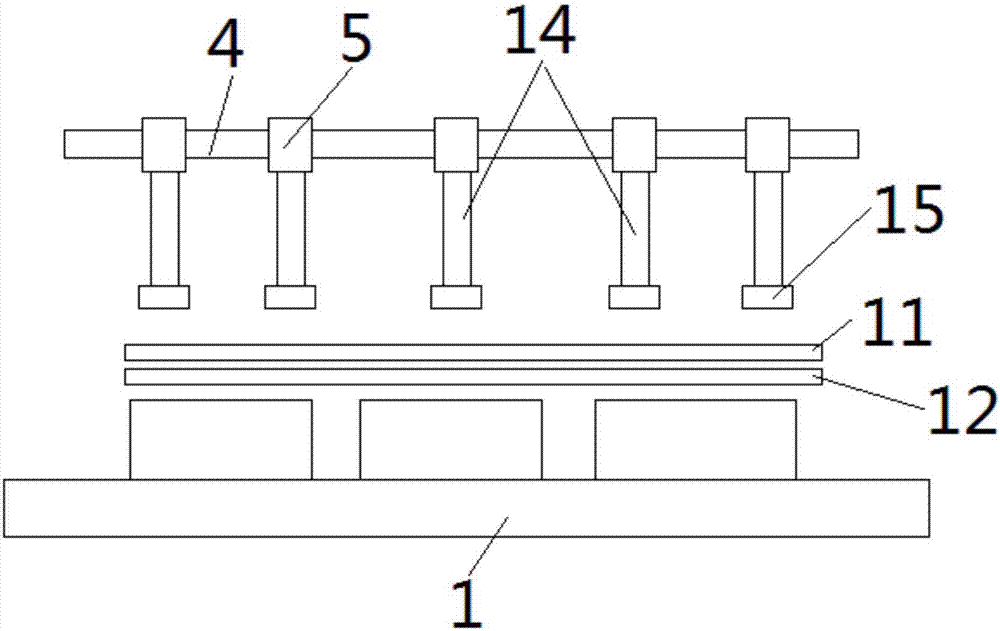

Ultrasonic probe and method for manufacturing ultrasonic probe

InactiveCN102688067AEnsure flatnessSolve the lack of pressurizationUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsTransducerEngineering

An ultrasonic probe includes, a transducer, a substrate includes electrodes formed on a front surface and a back surface and electronic components, first flexible wire substrates connected in such a manner that a first end is connected to the transducer and a second end is connected to a electrode at a side of the front surface of the substrate, second flexible wire substrates connected in such a manner that a first end is connected to the transducer and a second end is connected to a electrode at a side of the back surface of the substrate, and a dummy materials including the same rigidity and thickness as those of the first flexible wire substrate is arranged at a space, adjacent to a electrode at the side of the front surface of the substrate, corresponding to the second end of the second flexible wire substrate.

Owner:KK TOSHIBA

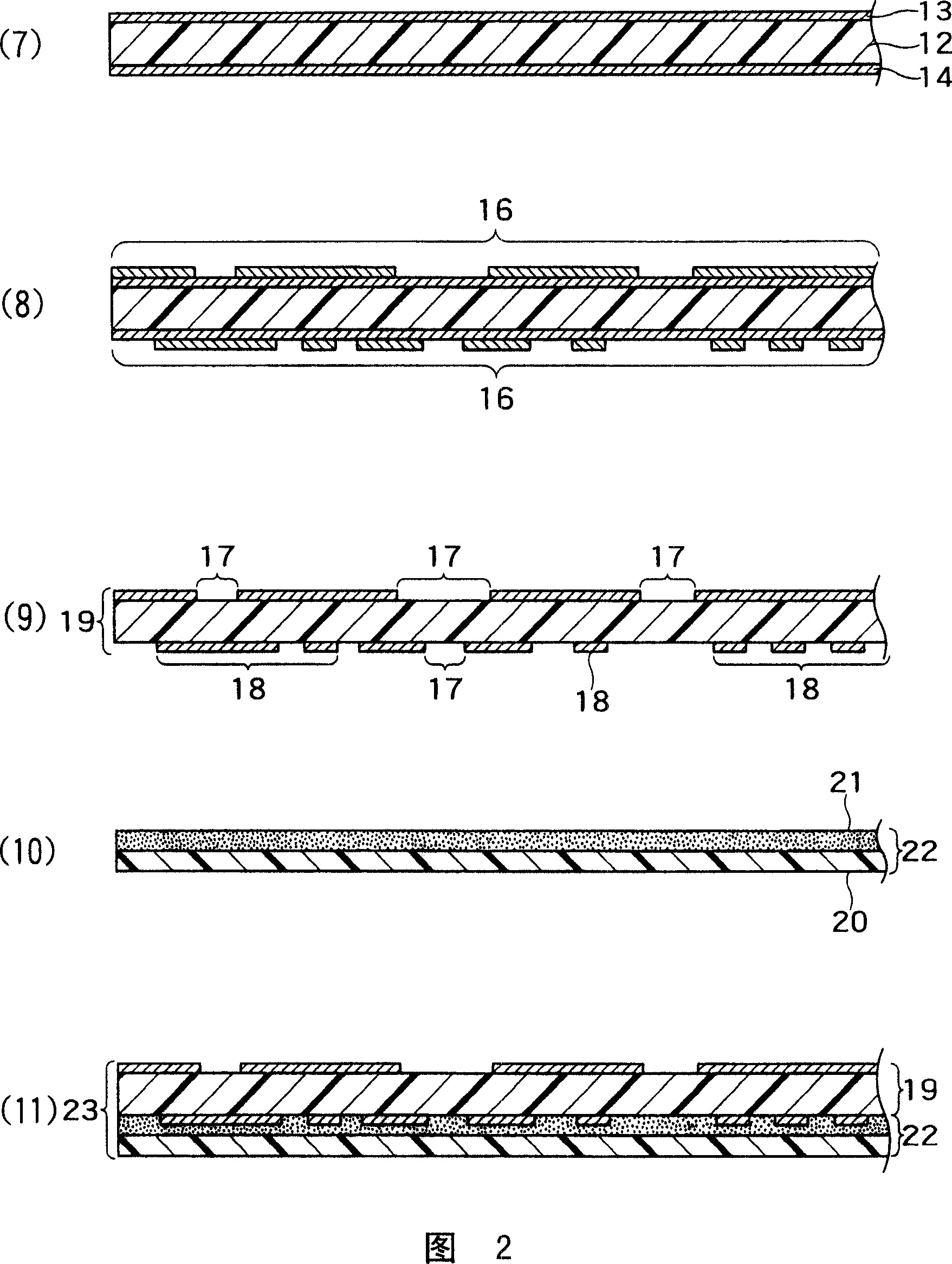

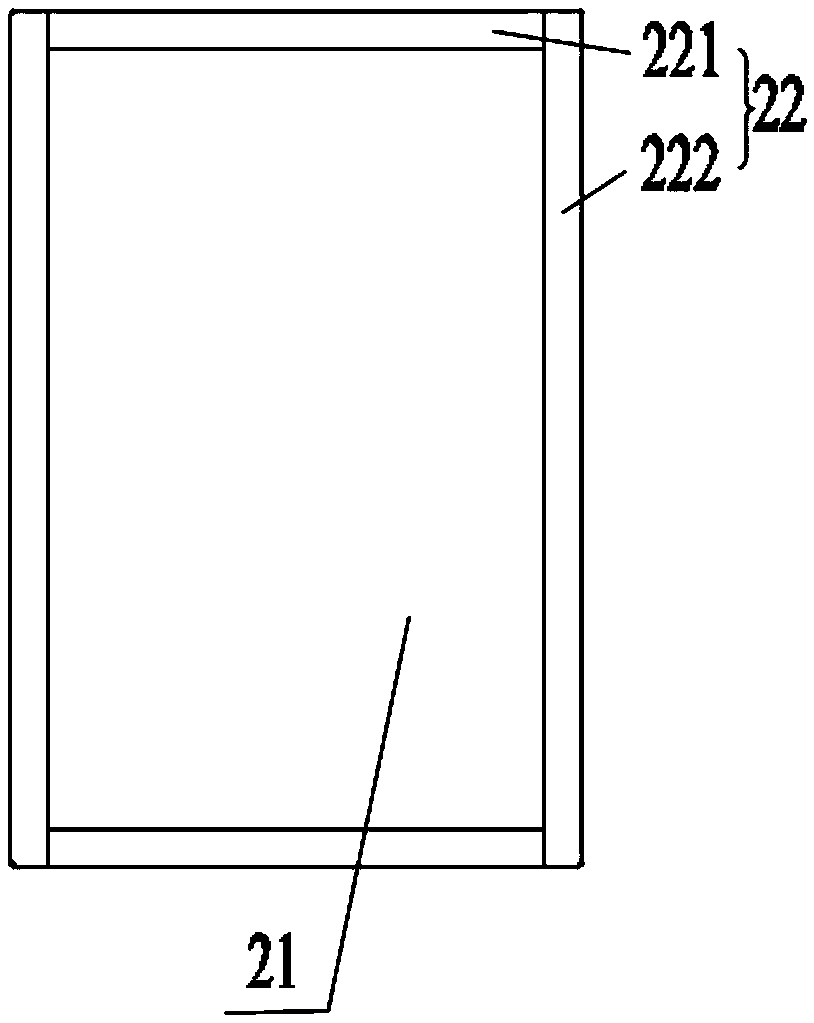

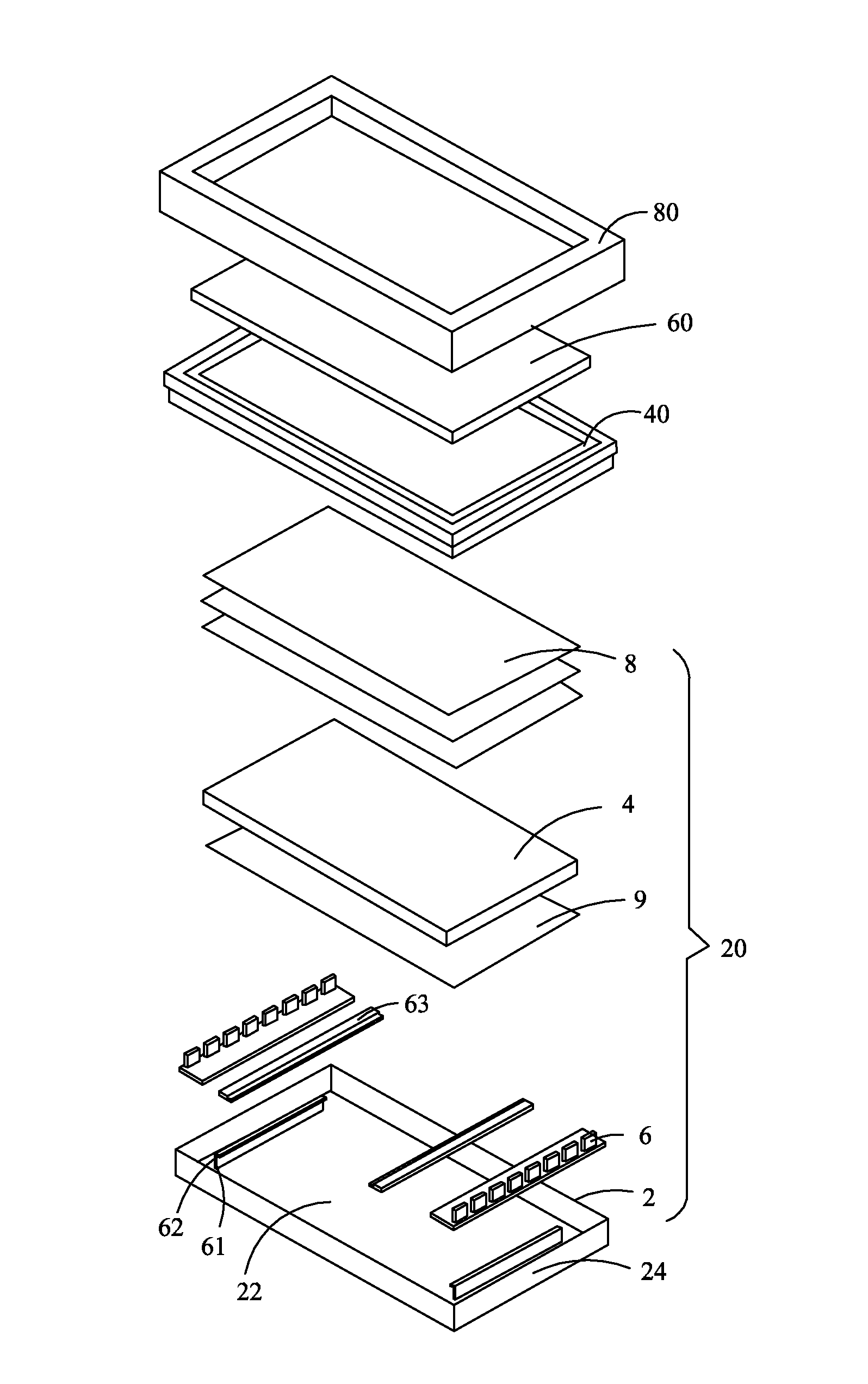

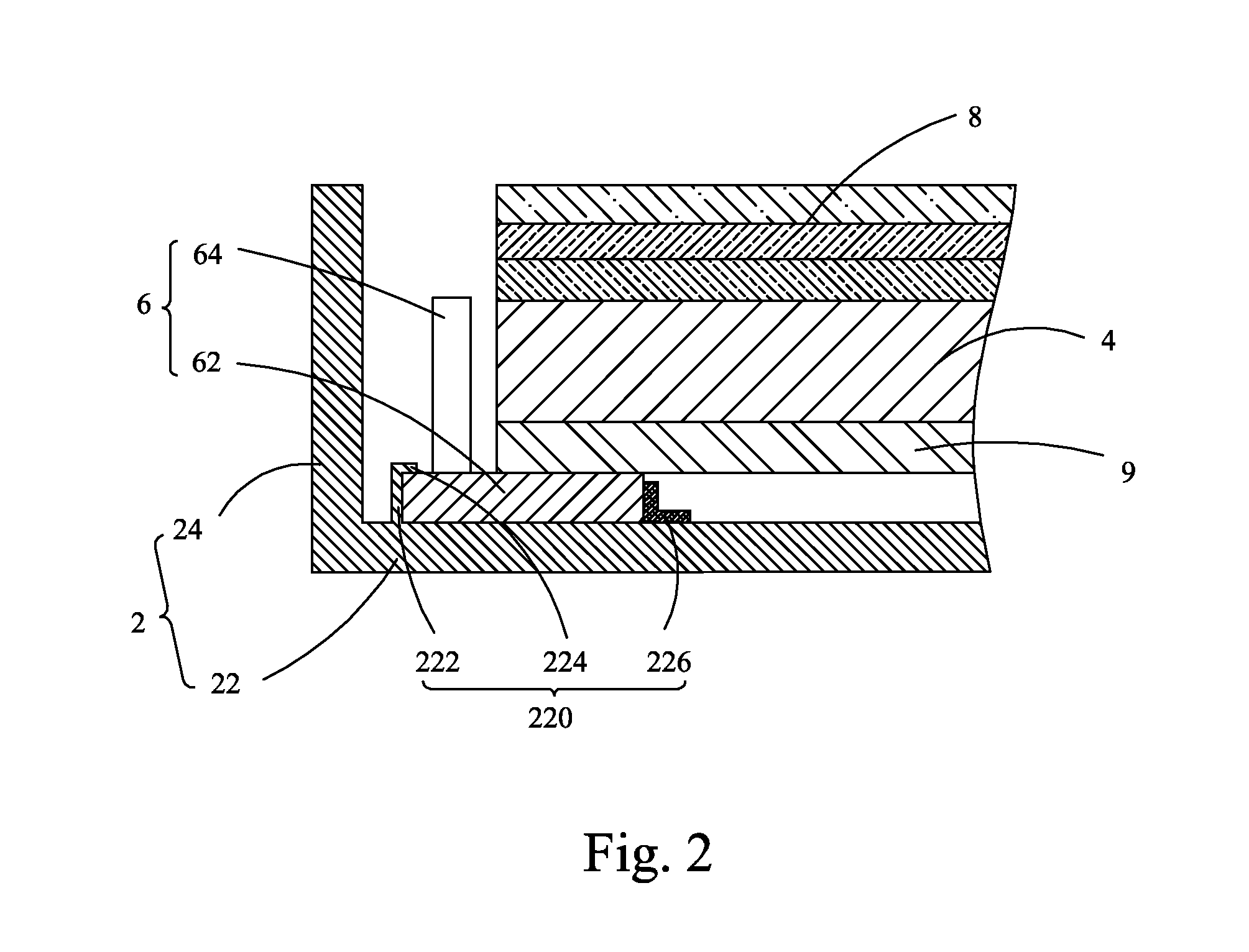

Backlight module and liquid crystal display device using same

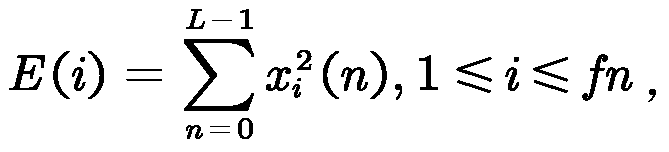

ActiveUS20150116626A1Simple structureMounting strength can be ensuredMechanical apparatusLight guides for lighting systemsLiquid-crystal displayLight guide

The present invention provides a backlight module and a liquid crystal display device using the backlight module. The backlight module includes: a backplane (2), a light guide plate (4) arranged in the backplane (2), a backlight source (6) arranged in the backplane (2), an optic film assembly (8) arranged above the light guide plate (4), and a reflection plate (9) arranged between the backplane (2) and the light guide plate (4). The backlight source (6) includes a PCB (62) and a plurality of LED lights (64) mounted on and electrically connected to the PCB (62). The backplane (2) includes a bottom plate (22) and a plurality of side plates (24) perpendicularly connected to the bottom plate (22). The bottom plate (22) of the backplane (2) includes a snap-engagement structure (220) formed thereon. The PCB (62) is snap-fit into and retained by the snap-engagement structure (220). The reflection plate (9) is directly positioned on and supported by the PCB (62).

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

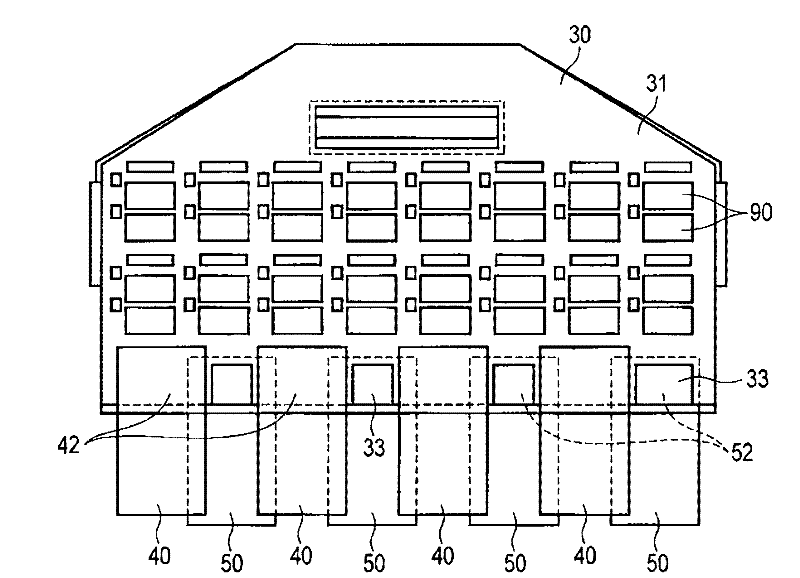

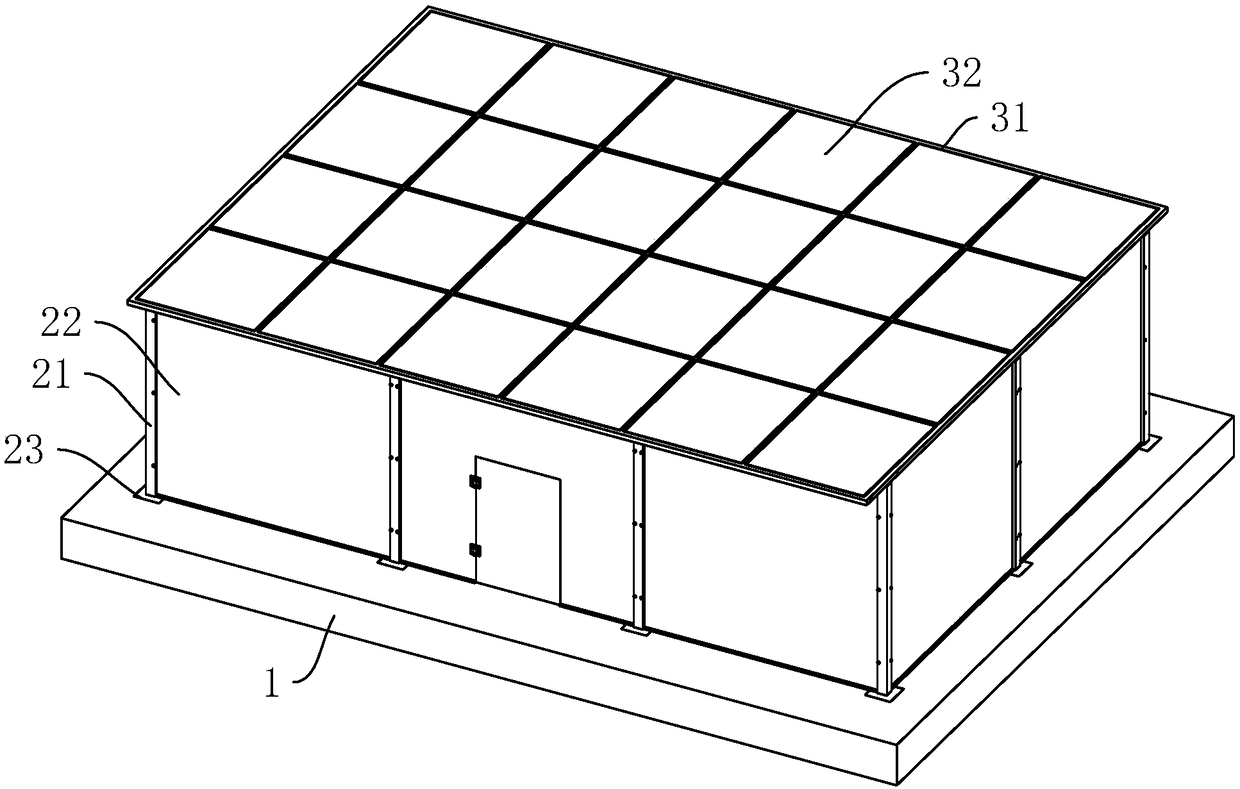

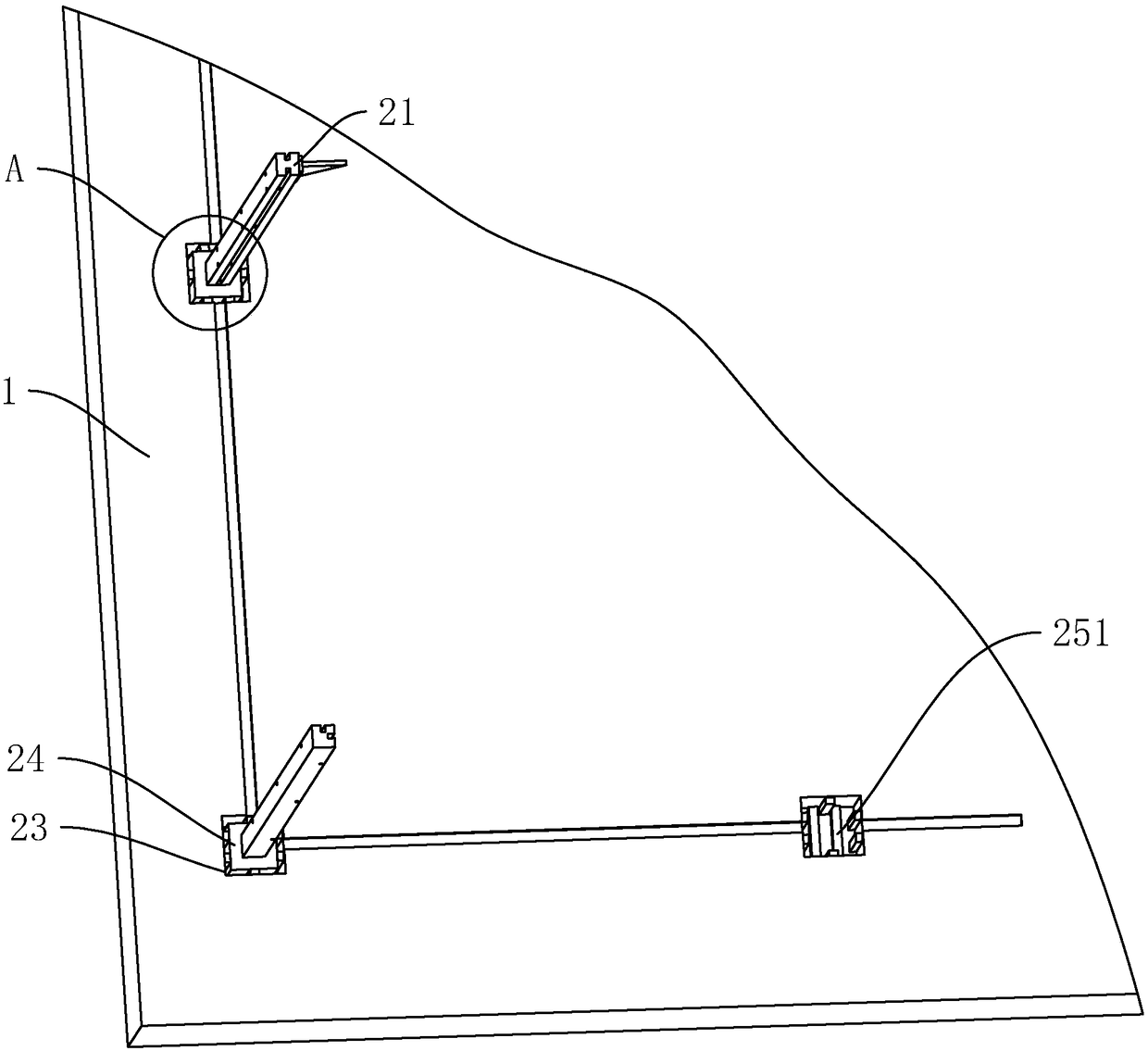

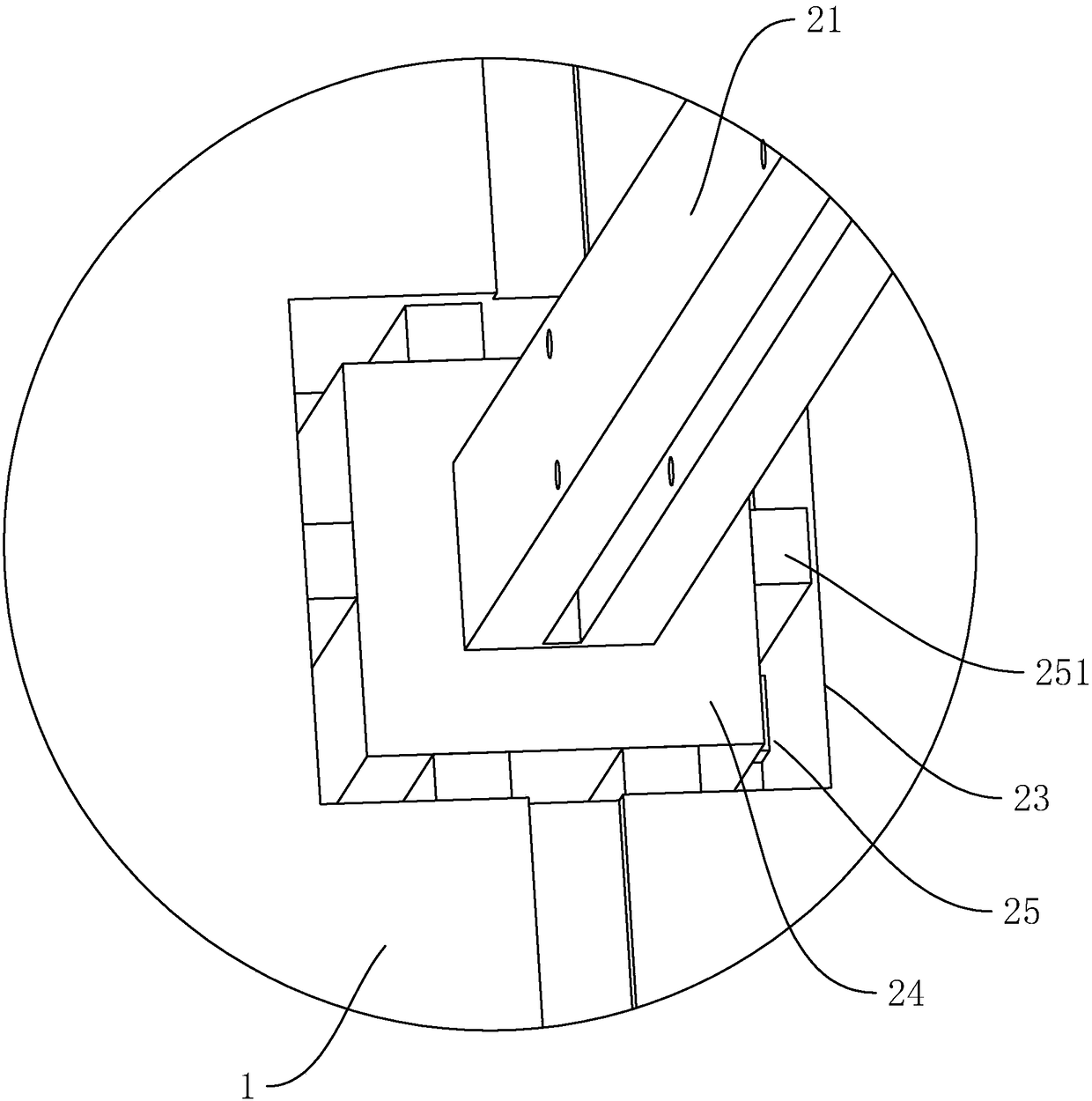

Assembly type building structure

InactiveCN108301505AImprove installation strengthPrevent overflowPhotovoltaic supportsRoof covering using slabs/sheetsStructural engineeringUltimate tensile strength

The invention discloses an assembly type building structure, and aims at solving the problem of stability. The key point of the technical scheme is that the assembly type building structure comprisesa concrete foundation, a wall surface structure fixed to the concrete foundation and a roof structure arranged at the top portion of the wall surface structure. The wall surface structure comprises aplurality of support columns and assembly plates which are inserted and fixed between the adjacent support columns, and the concrete foundation is provided with buried pits based on an installation position of each support column. Buried-in blocks embedded with the buried pits are arranged on the bottom ends of the support columns, and a post-pouring area is formed between each buried-in block andeach buried pit. According to the assembly type building structure, the connection strength between ground and the assembly plates is strengthened by adding the support columns, thus the stability ofa building is improved.

Owner:华洲建设温州有限公司

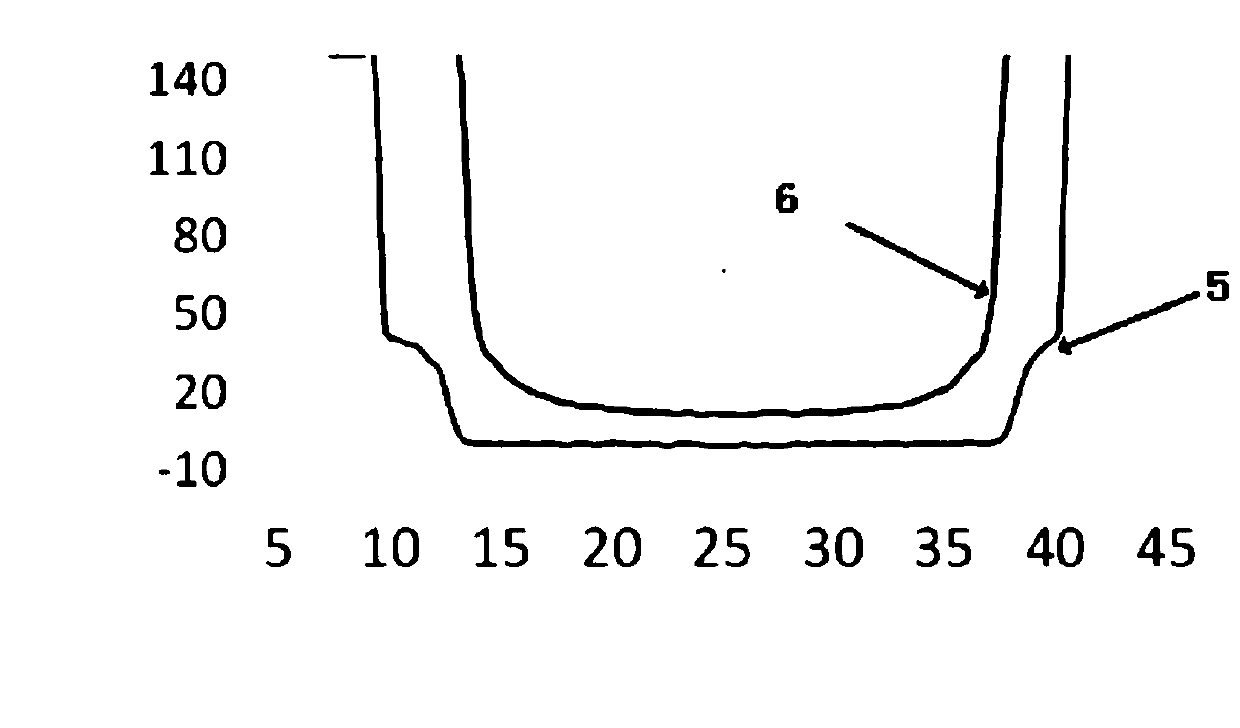

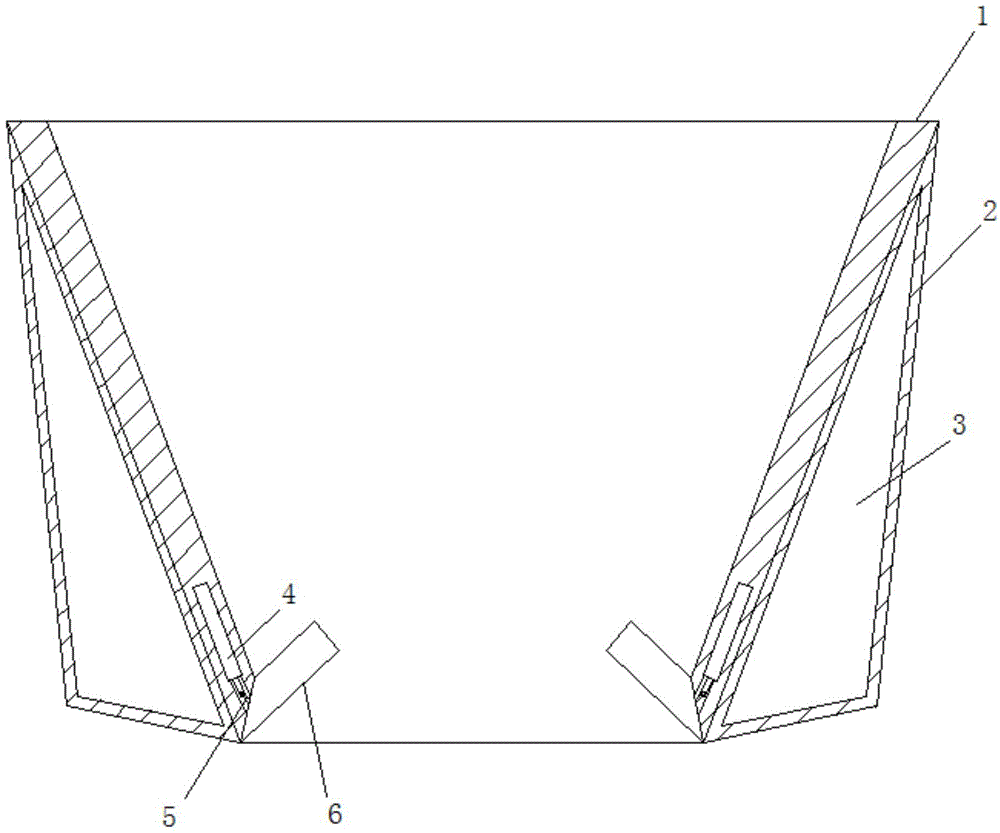

Printed wiring board

ActiveCN101171895APrevent peelingSmall insulation resistancePrinted circuit assemblingSemiconductor/solid-state device detailsResistElectrical conductor

A printed wiring board comprises a wiring substrate provided with at least one conductor circuit, a solder resist layer provided on the surface of the wiring substrate, at least one conductor pad formed from a part of the conductor circuit exposed from an opening provided in the solder resist layer, and at least one solder bump for mounting electronic parts on the conductor pad. In the printed wiring board, since the at least one conductor pad is aligned at a pitch of 200 µm or less, and a ratio (W / D) of a diameter W of the solder bump to an opening diameter D of the opening formed in the solder resist layer is within a range of 1.05 to 1.7, connection reliability and insulation reliability can be easily improved.

Owner:IBIDEN CO LTD

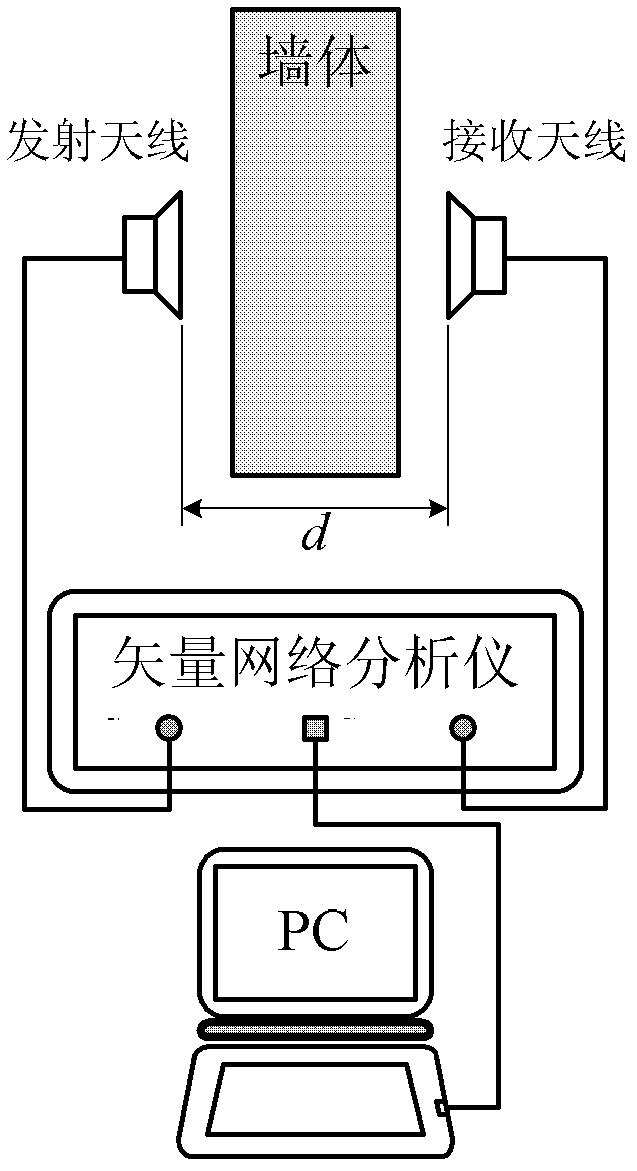

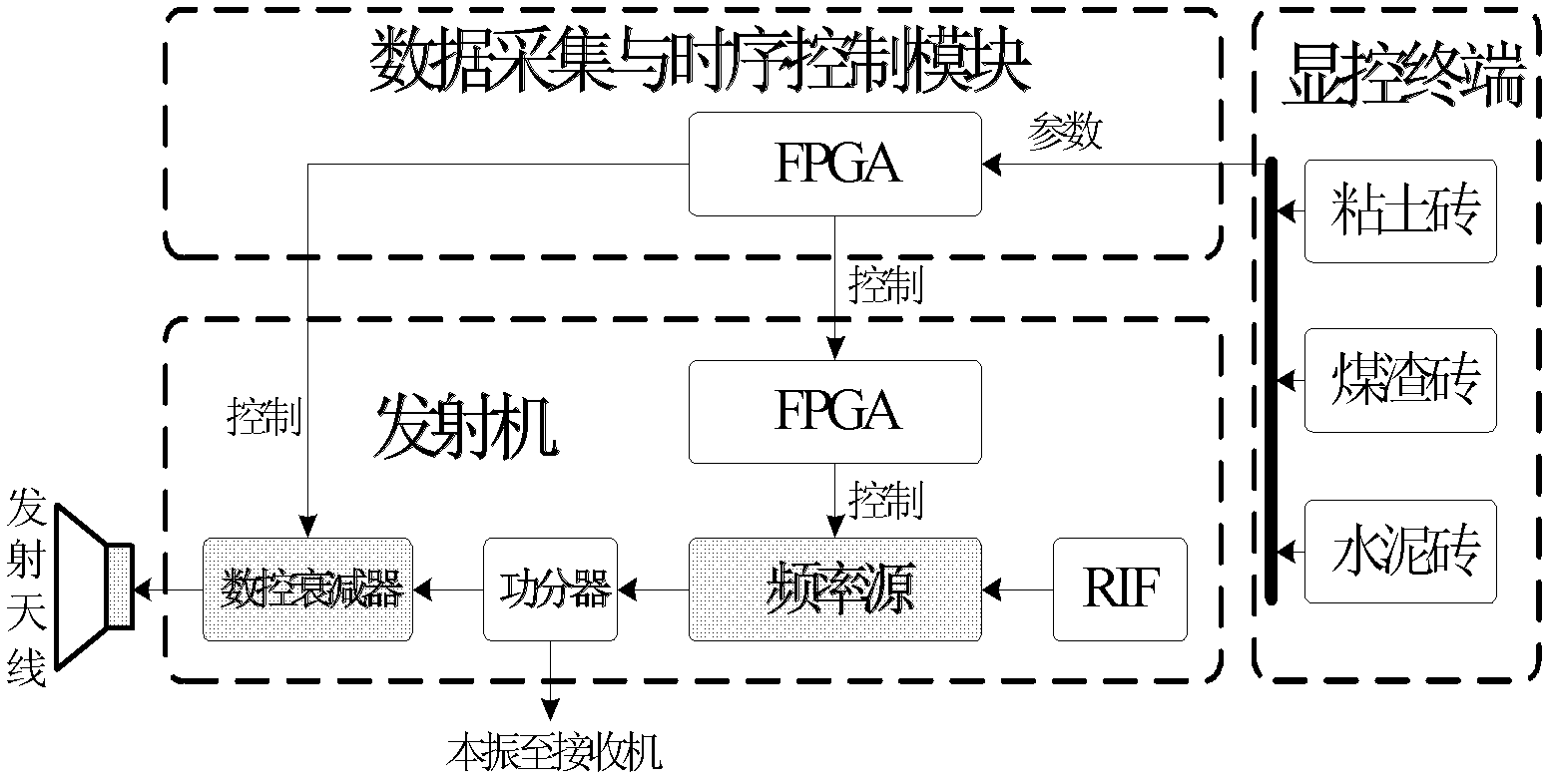

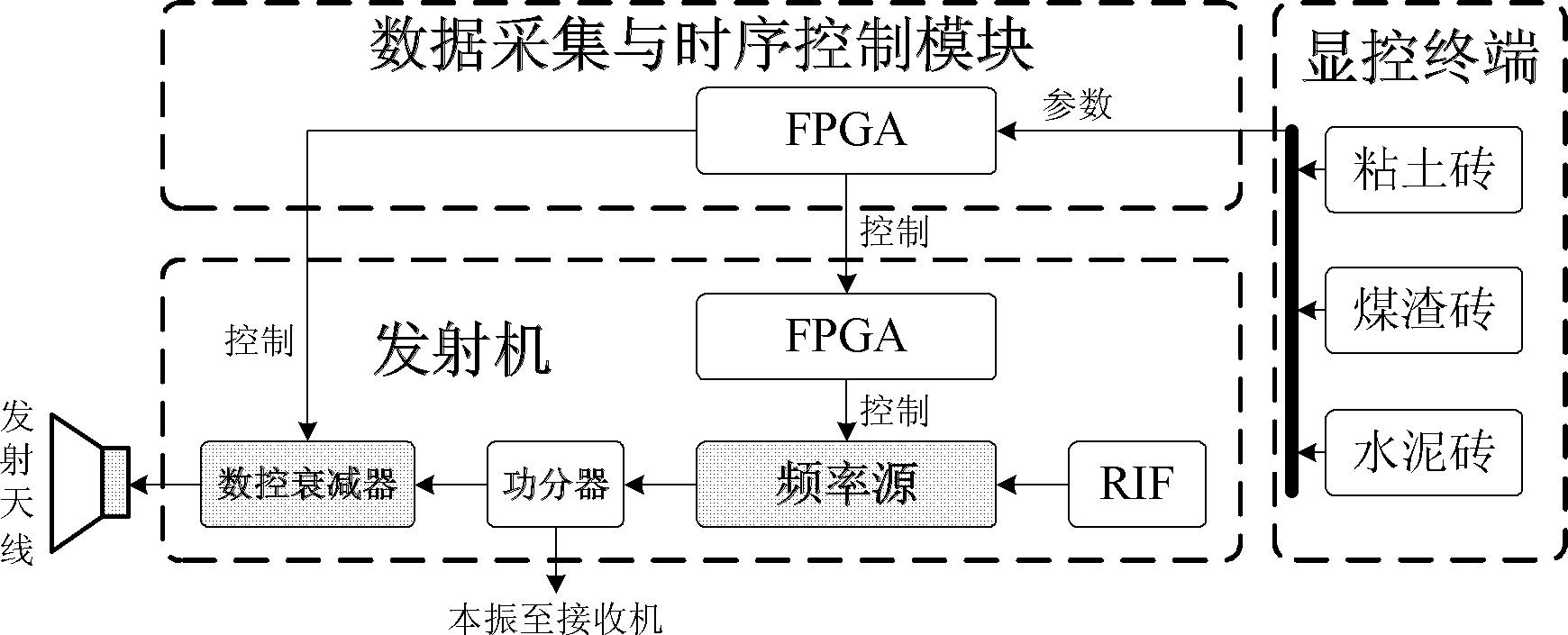

Frequency point power self-adaptive control method for stepped frequency through-wall radar

InactiveCN102680950AEnsure flatnessPower Attenuation Difference CompensationWave based measurement systemsUltra-widebandTransmitted power

The invention provides a frequency point power self-adaptive control method for a stepped frequency through-wall radar. The method comprises the following steps of: determination of the attenuation characteristic of a wall: determining the power attenuation characteristic of each discrete frequency point of an ultra-wideband stepped frequency signal in the process of penetrating through the wall forwards and backwards for two times; and control over the transmitting power of the frequency points: determining the power attenuation characteristic corresponding to the wall type of a building which is currently detected, and pre-compensating the transmitting power of each discrete frequency point on an ultra-wideband stepped frequency transmitter according to the power attenuation characteristic in the process of penetrating through the wall forwards and backwards for two times. By adoption of the frequency point power self-adaptive control method for the stepped frequency through-wall radar, the flatness of the power of each frequency point of a target echo of a human body can be ensured, widening and distortion of pulse waveform caused by power fluctuation of the frequency points of the stepped frequency target echo are eliminated, and the positioning accuracy of a hidden human body target in the building is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

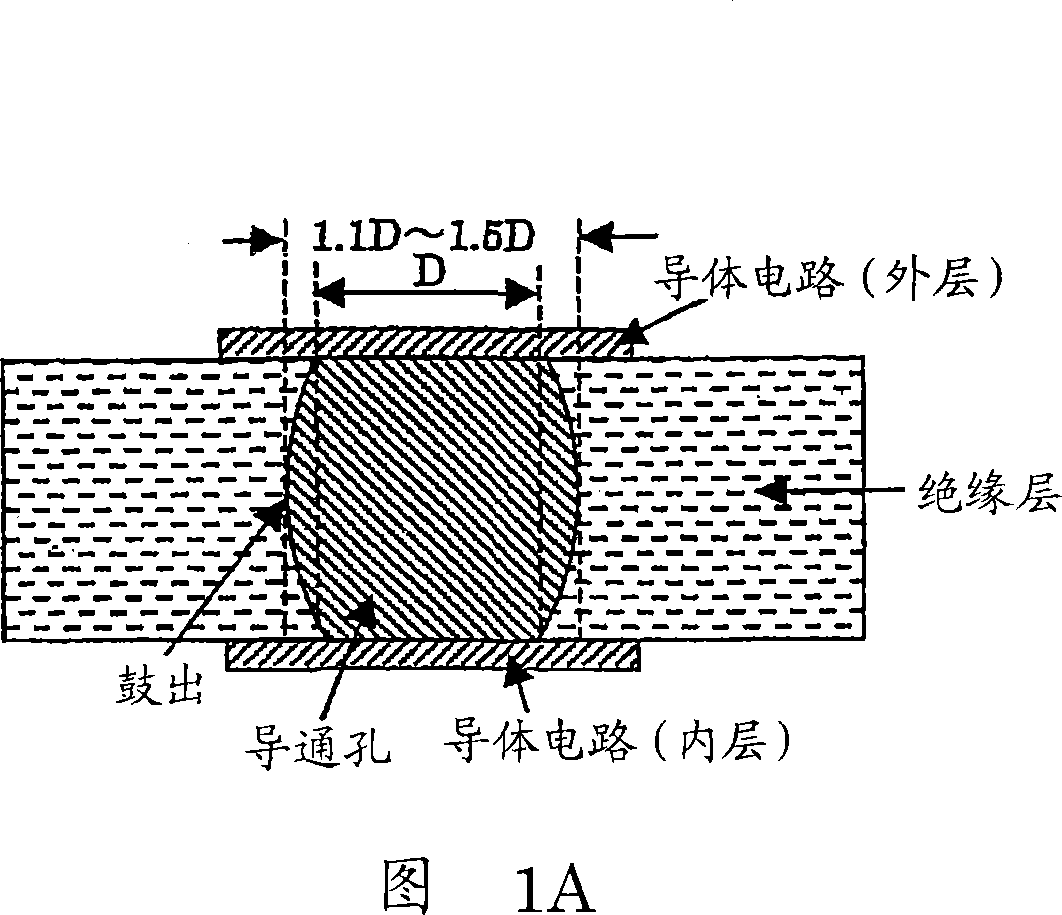

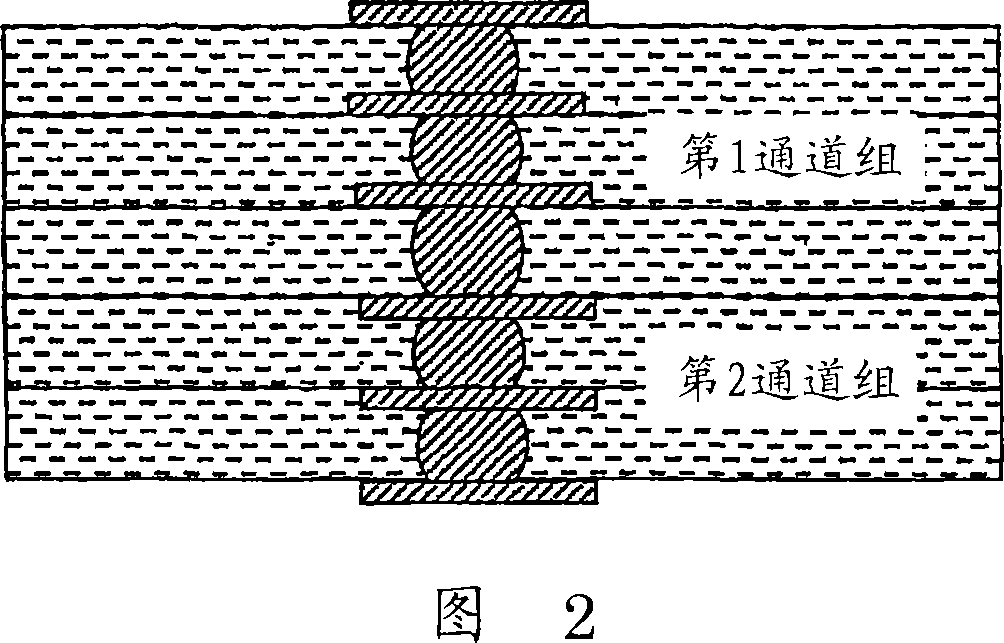

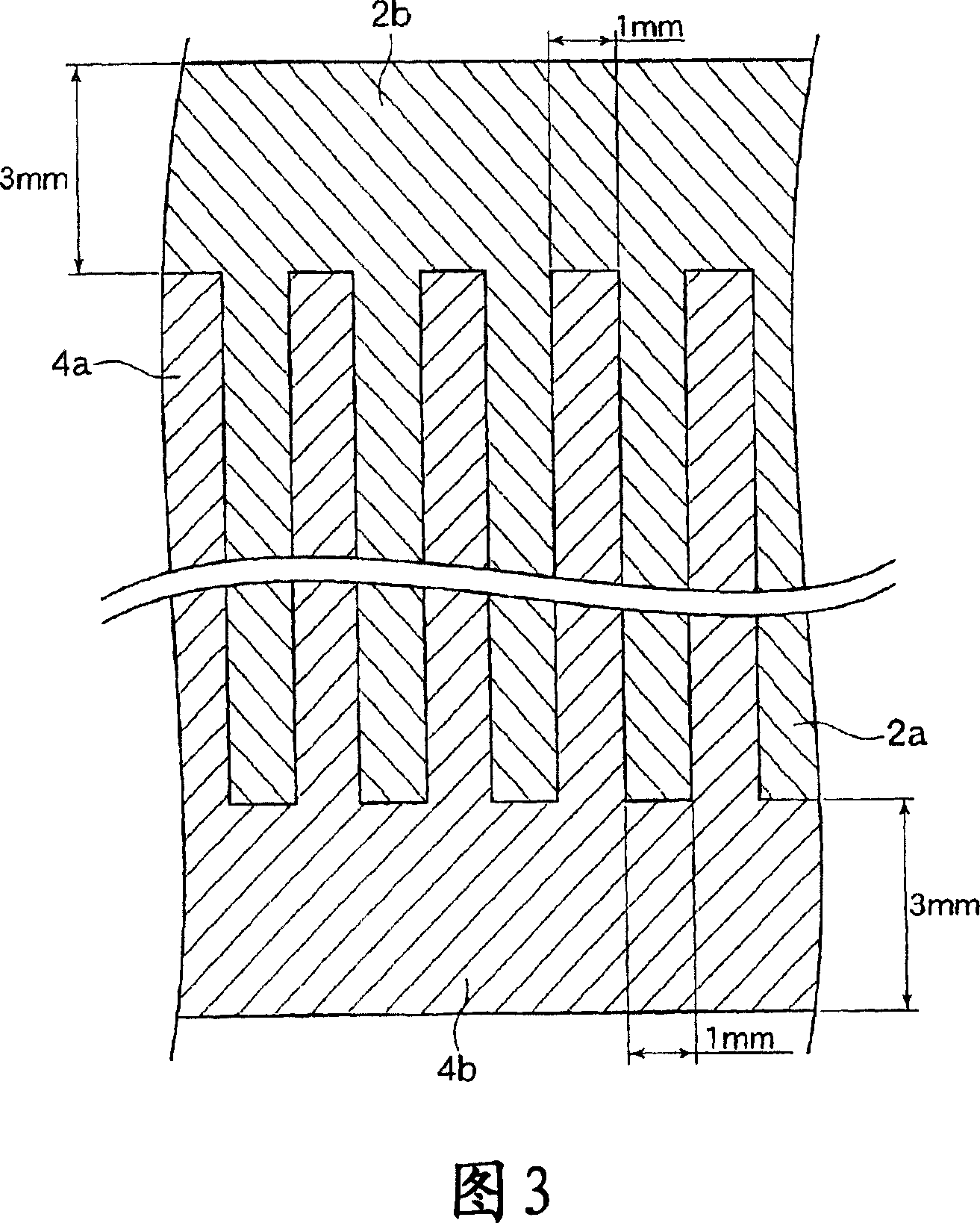

Multilayer printed wiring board

InactiveCN101069457ASuppression of warpingInhibition of fracturePrinted circuit aspectsThin material handlingDrop impactElectrical conductor

In a multilayer printed wiring board, insulating layers and conductor layers are alternately stacked, and the conductor layers are electrically connected through via holes arranged on the insulating layers. The via hole is formed to have a swell at least on a part of it, in a substantially vertical direction to a thickness direction of the insulating layer. External stresses, such as a force of impact when dropped, are suppressed to have an insulating substrate not to easily warp, and cracks, disconnection, and the like of the conductor circuit are prevented. Thus, deterioration of reliability and drop impact resistance of a mounting substrate can be reduced.

Owner:IBIDEN CO LTD

Glass substrate defect inspection device and glass substrate defect inspection method

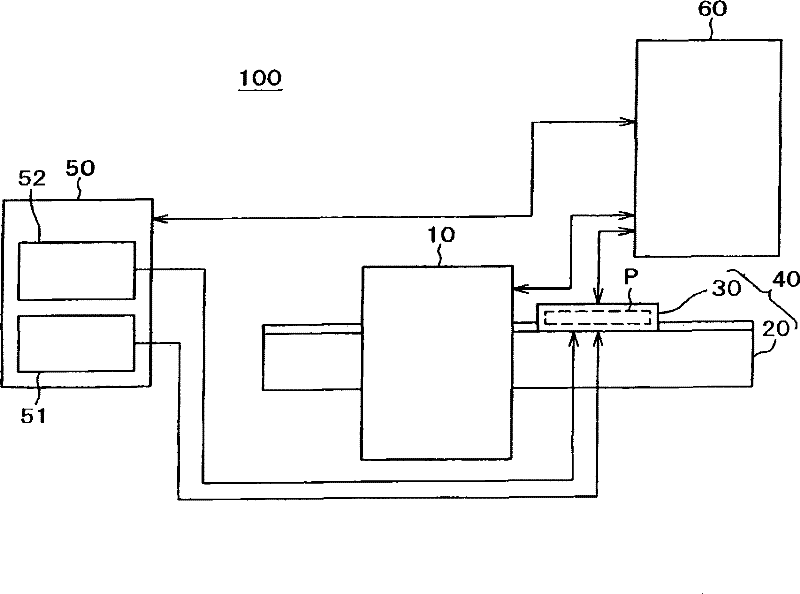

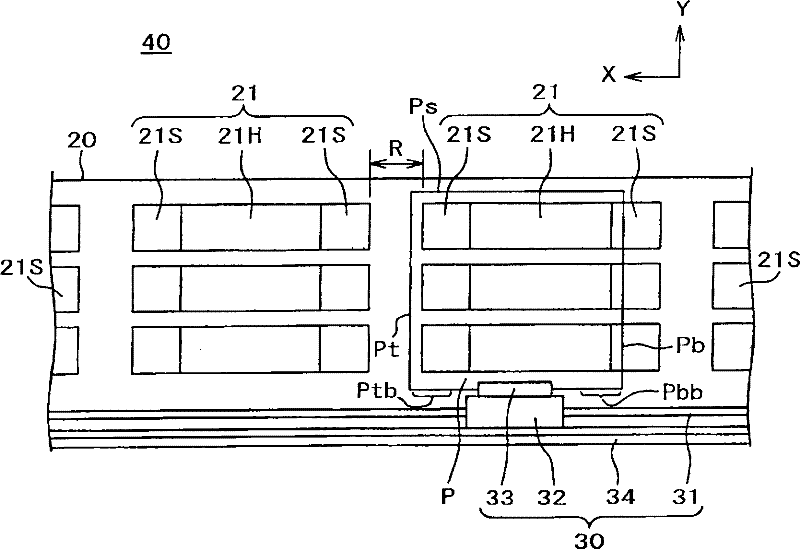

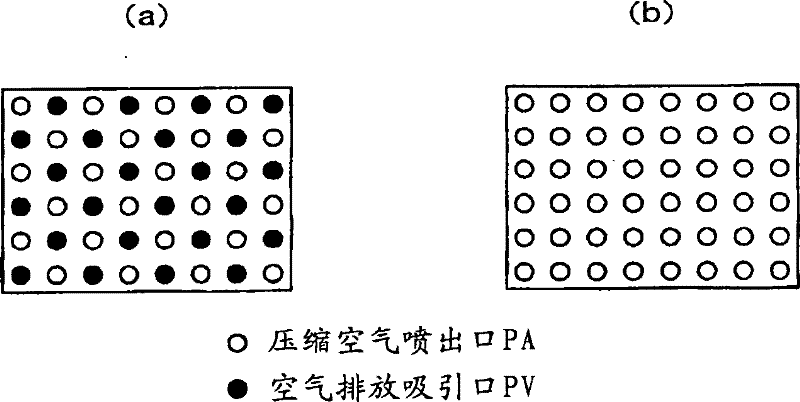

InactiveCN102565092AEnsure flatnessHigh precision inspectionMaterial analysis by optical meansUsing optical meansEngineeringInspection method

A glass substrate defect inspecting device and an inspection method thereof are provided to reduce or remove bouncing phenomenon and steadily perform an inspection by reducing the corrected amount during the inspection. A glass substrate (100) comprises a lifting device, a transfer device, and an optical inspection device. The lifting device lifts up a glass substrate(P) using air. The transfer device transfers the glass substrate to an inspection area where the lifting device is absent. The optical inspection device takes a picture of the glass substrate, thereby performing an inspection. A glass substrate defect inspecting device comprises a reduction device. The reduction device reduces the displacement caused by the bouncing of an end part of the glass substrate toward a transferring direction.

Owner:HITACHI HIGH-TECH CORP

Temperature compensation method and device for linear power amplifier

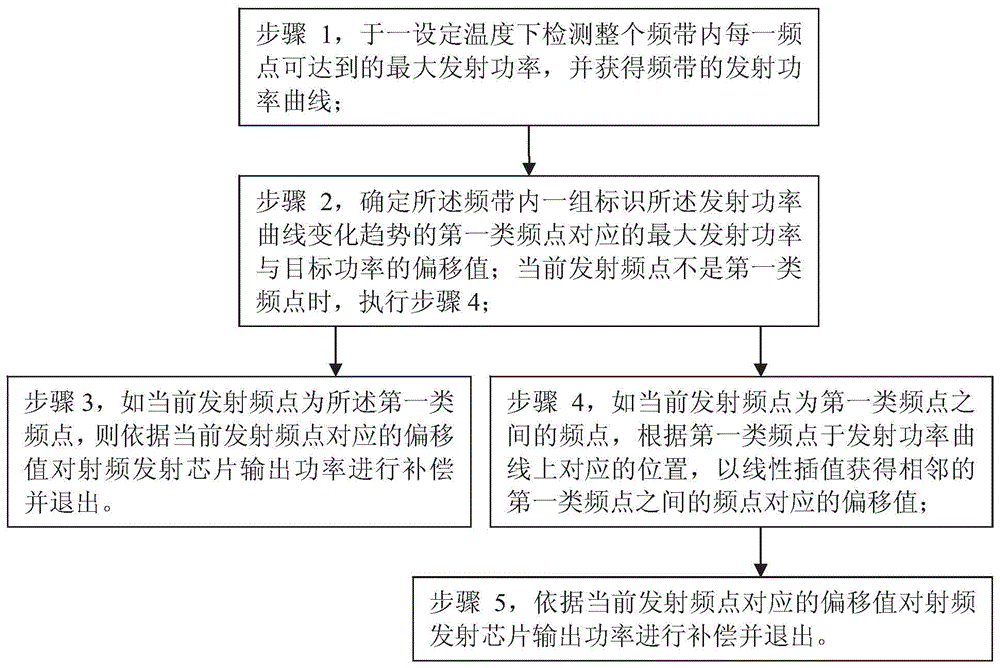

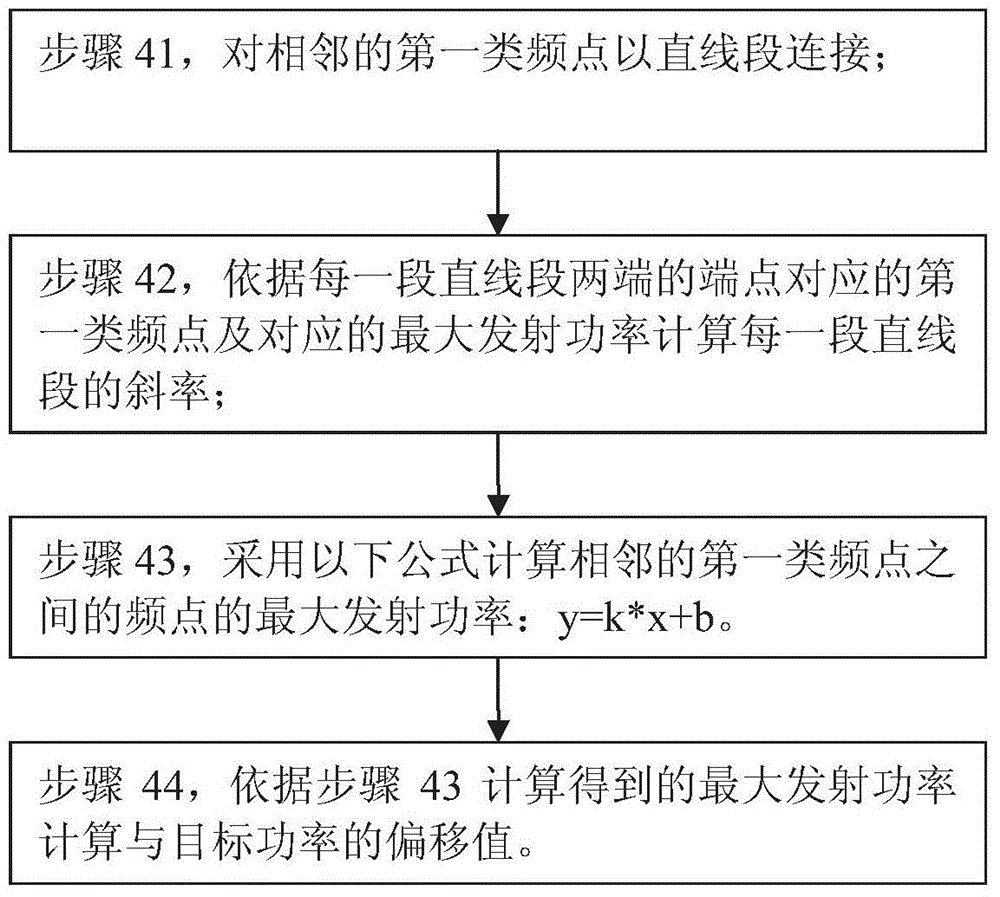

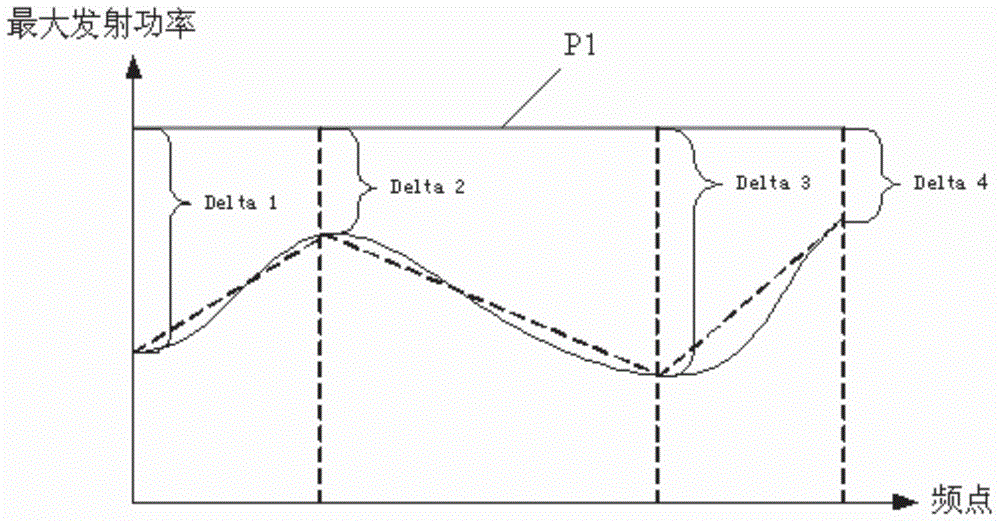

InactiveCN105450183AConsistent transmit powerEnsure flatnessAmplifier modifications to reduce temperature/voltage variationPower compensationLinear power amplifier

The invention relates to the technical field of electronic communication and especially relates to a temperature compensation method for a linear power amplifier. The method comprises: detecting the maximum transmitting power of each frequency point in a whole frequency band under a setting temperature and obtaining a transmitting power curve of the frequency band; determining offset values of maximum transmitting powers and target powers, wherein the maximum transmitting powers are corresponding to frequency points of a first type which indicate a change trend of the transmitting power curve in the frequency band; if a current transmitting frequency point is a frequency point of the first type, performing output power compensation to an RF transmitter chip on the basis of an offset value corresponding to the current transmitting frequency point and quitting; if a current transmitting frequency point is a frequency point between the frequency points of the first type, obtaining offset values corresponding to frequency points using linear interpolation, wherein the frequency points are between the adjacent frequency points of the first type; performing output power compensation to the RF transmitter chip on the basis of an offset value corresponding to the current transmitting frequency point and quitting. By use of the method, the number of channels needed in temperature compensation is reduced, and the transmitting power evenness of a cell phone in a whole frequency band is maintained.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

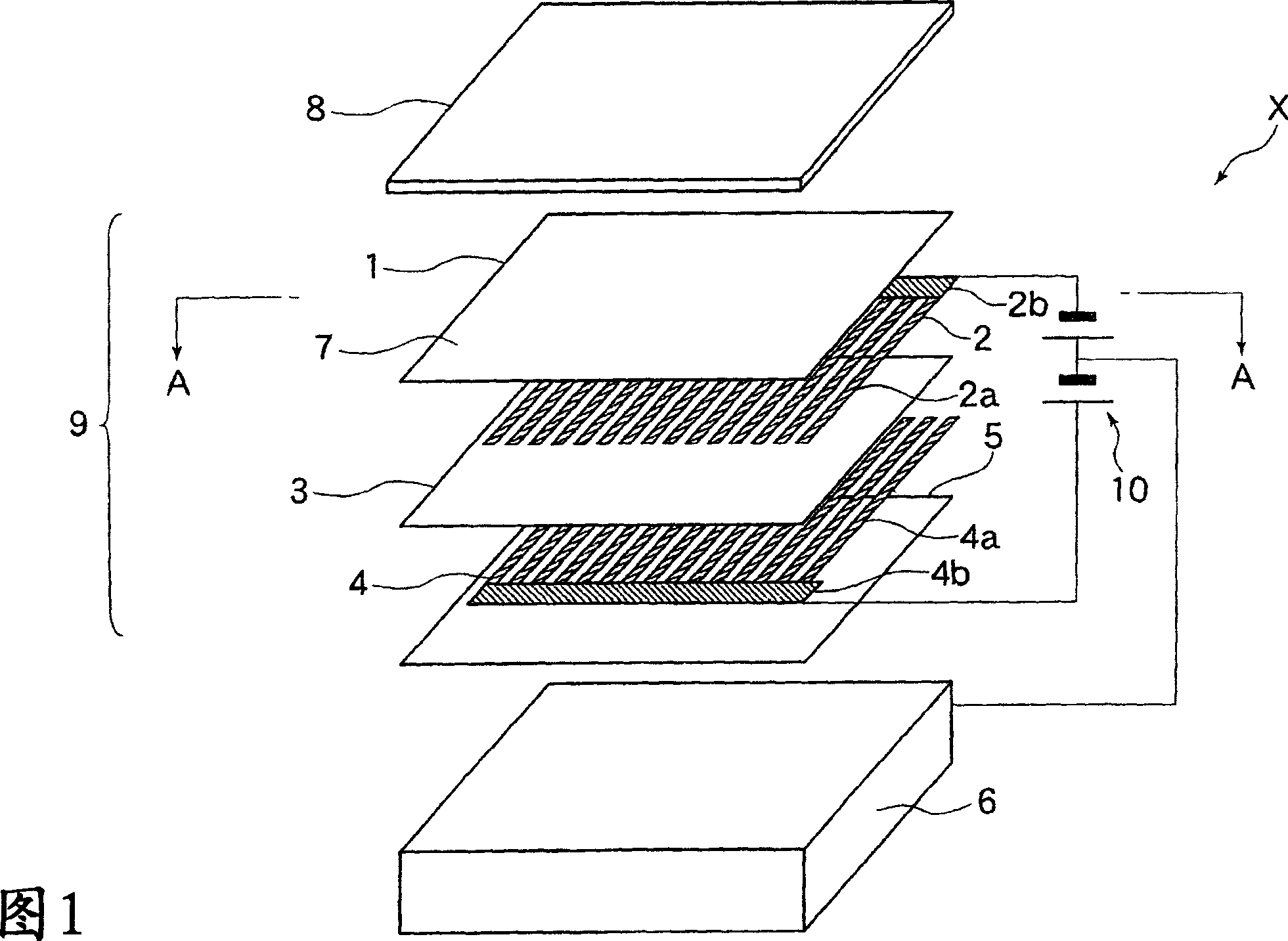

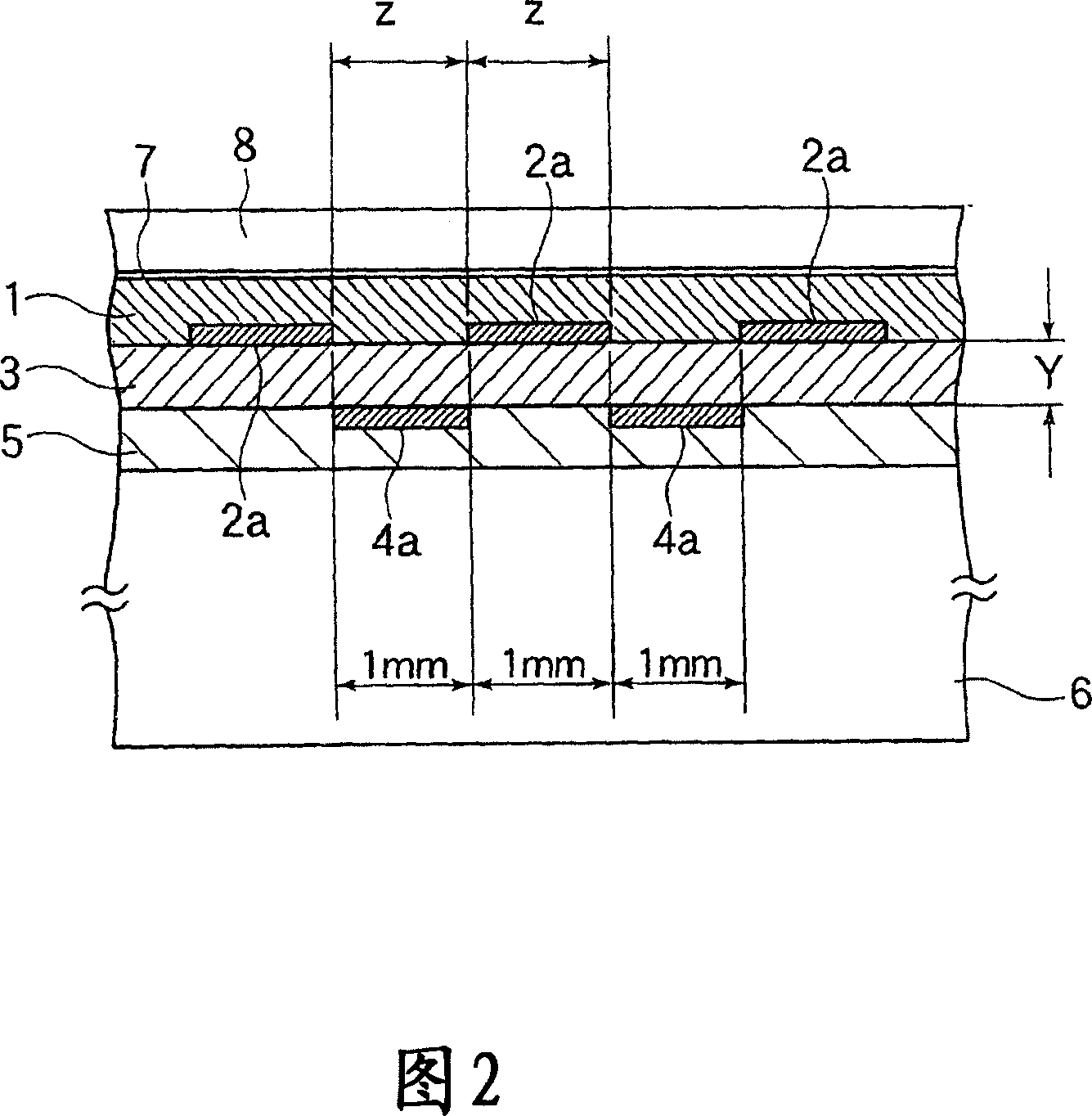

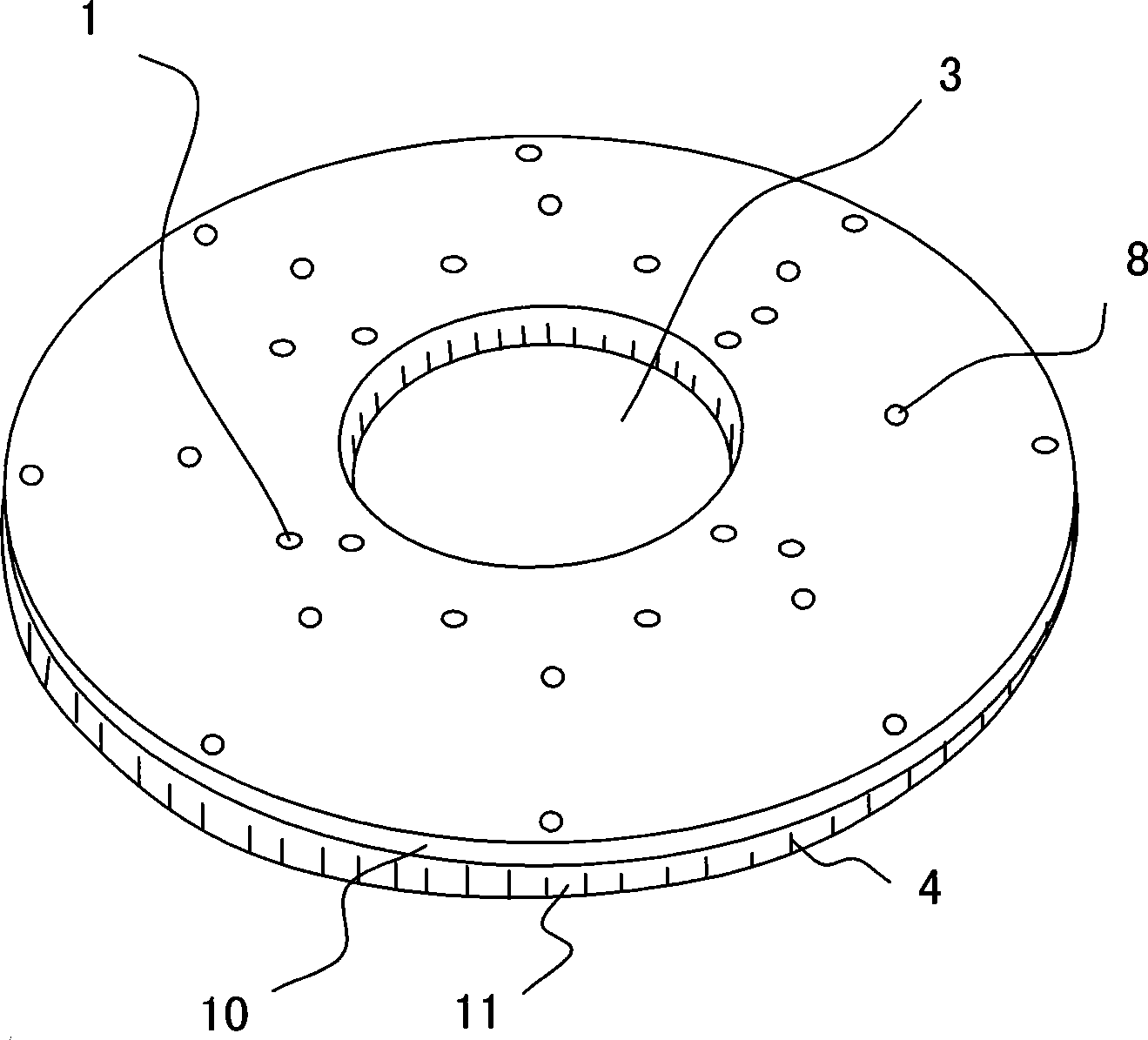

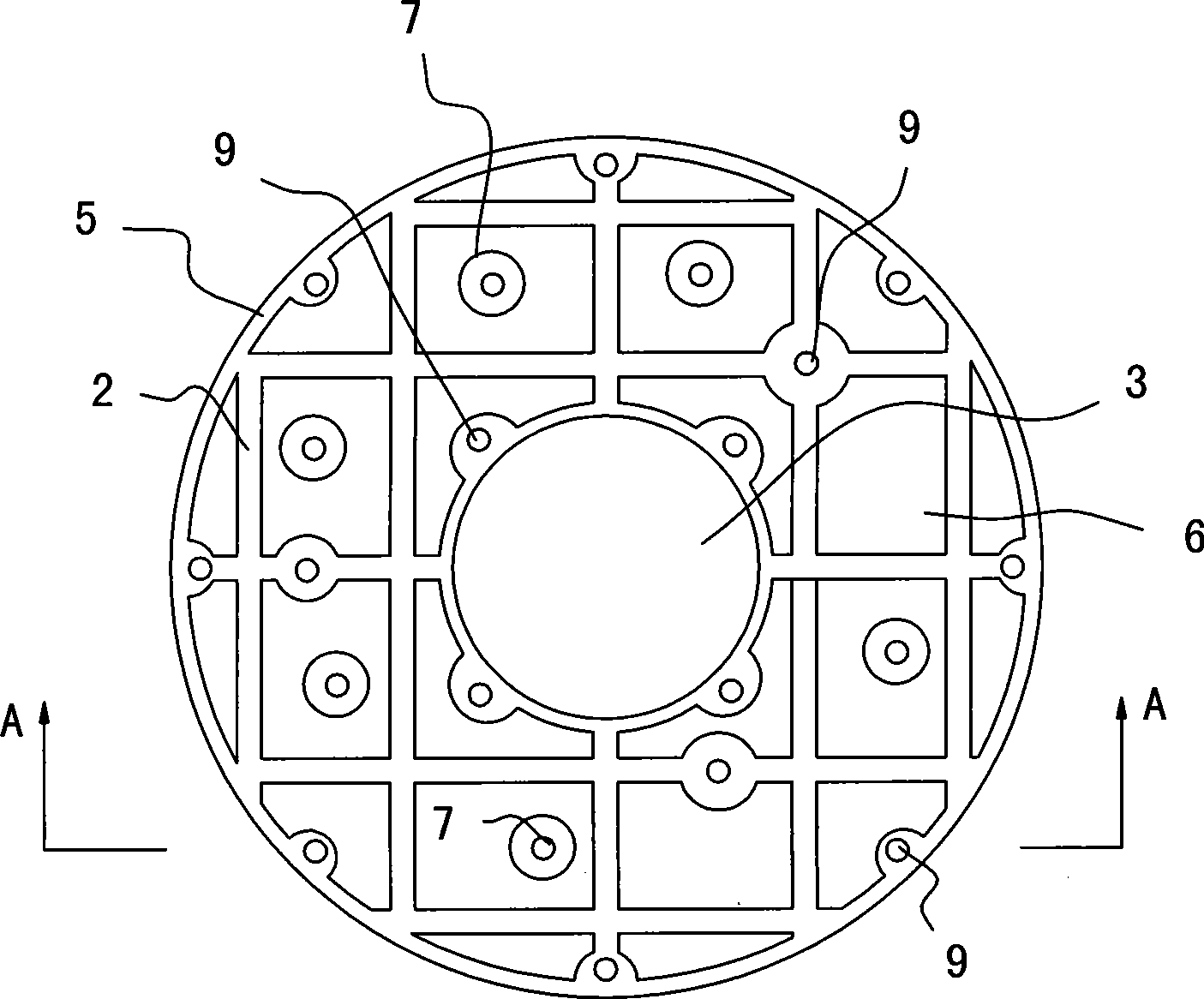

Bipolar electrostatic chuck

InactiveCN1934693AImprove insulation stabilityImprove reliabilitySemiconductor/solid-state device manufacturingElectrostatic holding devicesPhysicsVoltage

A bipolar electrostatic chuck which has excellent dielectric breakdown strength and provides excellent attracting performance. The bipolar electrostatic chuck eliminates difficulty in peeling off a sample from a sample attracting plane as much as possible after application of a voltage to electrodes is finished. The bipolar electrostatic chuck is provided with a first electrode and a second electrode in an insulator and permits a surface of the insulator to be the sample attracting plane. The insulator has the first electrode, an interelectrode insulating layer and the second electrode in this order from the sample attracting plane in the depth direction. The second electrode has a region not overlapping with the first electrode in a normal line direction of the sample attracting plane.

Owner:CREATIVE TECH CORP

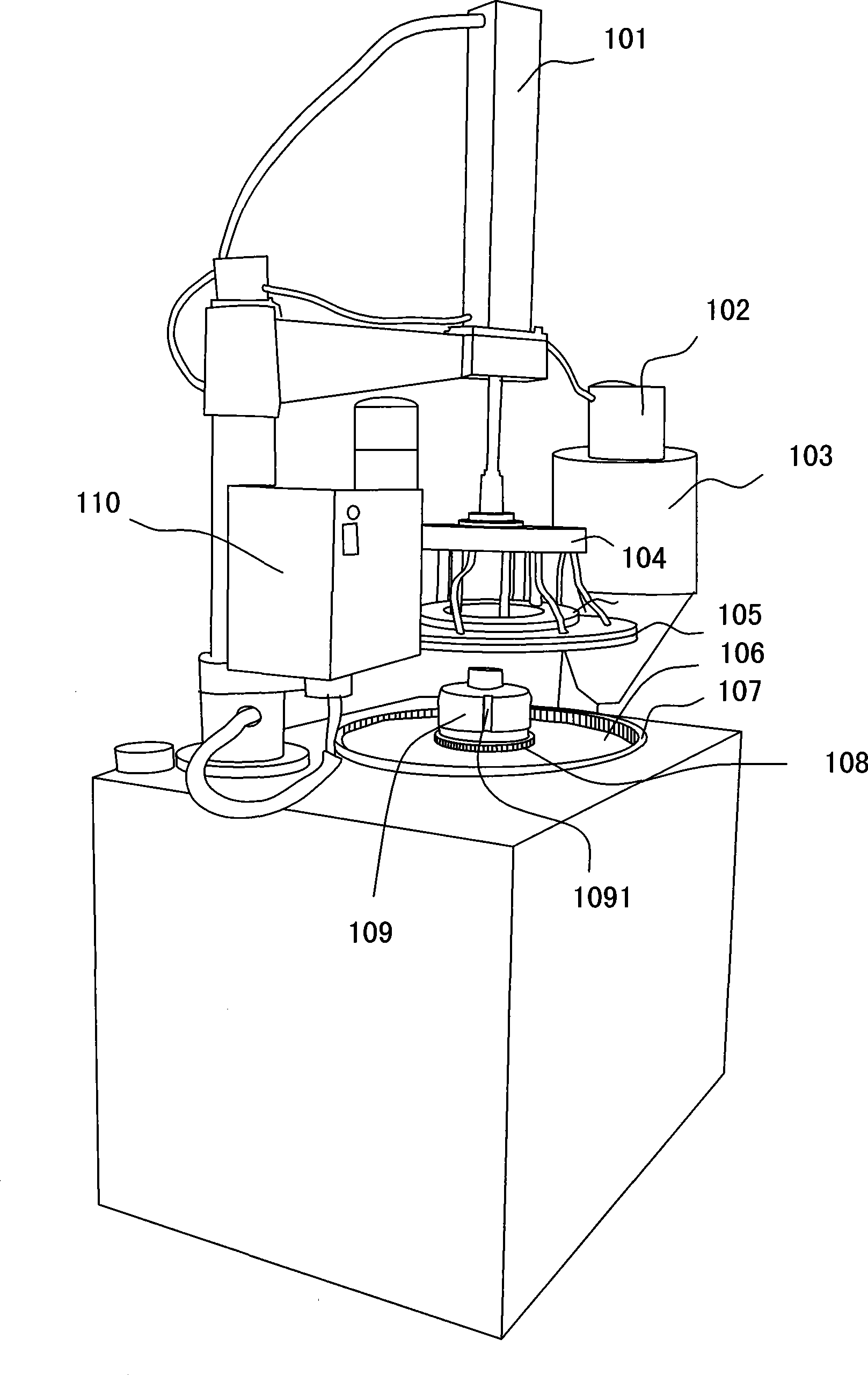

Planet grinding device

InactiveCN101508093AWill not deformEnsure flatnessPolishing machinesSemiconductor/solid-state device manufacturingEngineeringCarbon steel

The planet grinding machine, which comprises a grinding disc, wherein the grinding disc consists of a tool player provided with a plurality of tool counter bores and a plurality of liquid holes and a grinding layer provided with radially and uniformly distributed grinding fluid embedded grooves with axial depth. The tool layer and the grinding layer are split and connected into a whole through a fastening piece, the grinding layer consists of a grinding liquid embedded groove layer, a solid layer and a convex rib grid layer, the solid layer is provided with through holes corresponding to the liquid holes, the liquid holes are communicated with the grinding fluid embedded grooves through the through holes, and convex ribs on the convex rib grid layer are provided with a plurality of connecting counter bores which are uniformly distributed. In the planet grinding machine, an integral grinding disc made of cast iron or carbon steel is horizontally divided into two independent parts connected by a fastening piece without changing the overall shape and size of the prior grinding disc, the grinding layer can be changed independently after being worn, and the material is saved; and the grinding layer is insusceptible to thermal deformation, the factors influencing the internal stress are reduced, and the flatness, parallelism and service life of the grinding layer are ensured.

Owner:胡林宝

Mobile assembly type natural stone composite floor board and production technique thereof

The invention relates to building decoration material and the manufacture technology, in particular to a movable splicing composite floor tiles made of natural stone material, comprising an aluminum honeycomb reinforcing sheet and a stone surface slab, wherein, the aluminum honeycomb reinforcing sheet comprises two pieces of glass fiber cloth and an aluminum honeycomb core; the glass fiber cloth is bound with the aluminum honeycomb core; the aluminum honeycomb reinforcing sheet is bound with the stone slab. The invention is characterized in that one side of the stone slab is bound with the aluminum honeycomb reinforcing sheet, then high strength epoxy adhesive with proper concentration is applied on the four sides of the integrated floor tiles to fabricate a plurality of chase mortises; the tenons on the two adjacent lateral faces are made using a plurality of fixing strips with grooves as tenon mold; a plurality of grooves are arranged on the other two adjacent lateral faces; the finished product is produced through precise processing after the adhesive of the tenon slot is fully solidified. The invention has the advantages of light weight and high strength due to the adoption of the stone honeycomb slab, good water and moisture-proof performance due to the adoption of tenon slots made of special epoxy adhesive through forming on the periphery of the floor tiles, convenient, simple and rapid construction, saved cost for installation material and repeated removal for reutilization.

Owner:仇洪祥

Guide cylinder used in single crystal furnace

InactiveCN104419978AEnsure flatnessImprove insulation effectPolycrystalline material growthBy pulling from meltFiberCarbon fibers

The invention belongs to the field of solar photovoltaics and particularly relates to a guide cylinder used in a single crystal furnace for Czochralski silicon which is applied in the single crystal furnace. The guide cylinder comprises a cylinder body of which the diameter is gradually reduced from top to bottom and which is made of a multi-layered composite carbon fiber material, wherein the edge of the lower end opening of the cylinder body is provided with a plurality of rotatable gas adjusting devices by virtue of a plurality of adjusting parts, an outer cylinder is arranged at the outer peripheral surface of the cylinder body and a thermal-insulation space is formed between the outer cylinder and the cylinder body and is internally provided with a thermal-insulation material layer. The guide cylinder has the advantages that the gas adjusting devices are controlled by virtue of the adjusting parts to carry out guide adjustment on gas inside the cylinder body, the volatilization of latent heat of crystallization at solid-liquid interfaces of the crystals can be effectively controlled and thus the flatness of the solid-liquid interfaces is effectively maintained and meanwhile, the thermal-insulation effect of the guide cylinder is improved.

Owner:常州华腾合金材料有限公司

Packaging board, semiconductor module, and portable apparatus

InactiveUS8115316B2Easy to operateFirmly connectedSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A technology is provided for a packaging board adapted to mount a device capable of improving handleability and securing connection reliability. The packaging board includes: a pad electrode formed on a substrate; an insulating layer covering the substrate, having an opening at least in part in an area over the pad electrode; and a joint layer formed on the pad electrode inside the opening. The surface of the joint layer is lower than the top lip of the opening.

Owner:SANYO ELECTRIC CO LTD

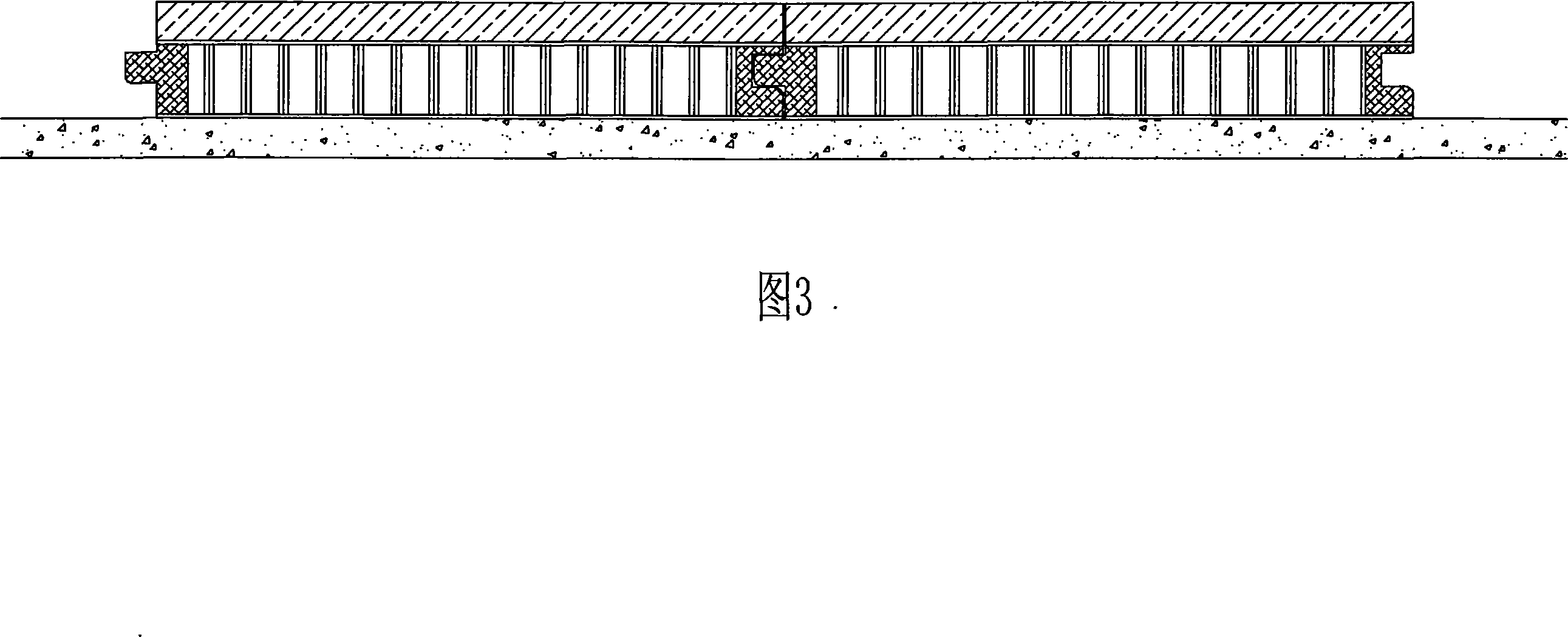

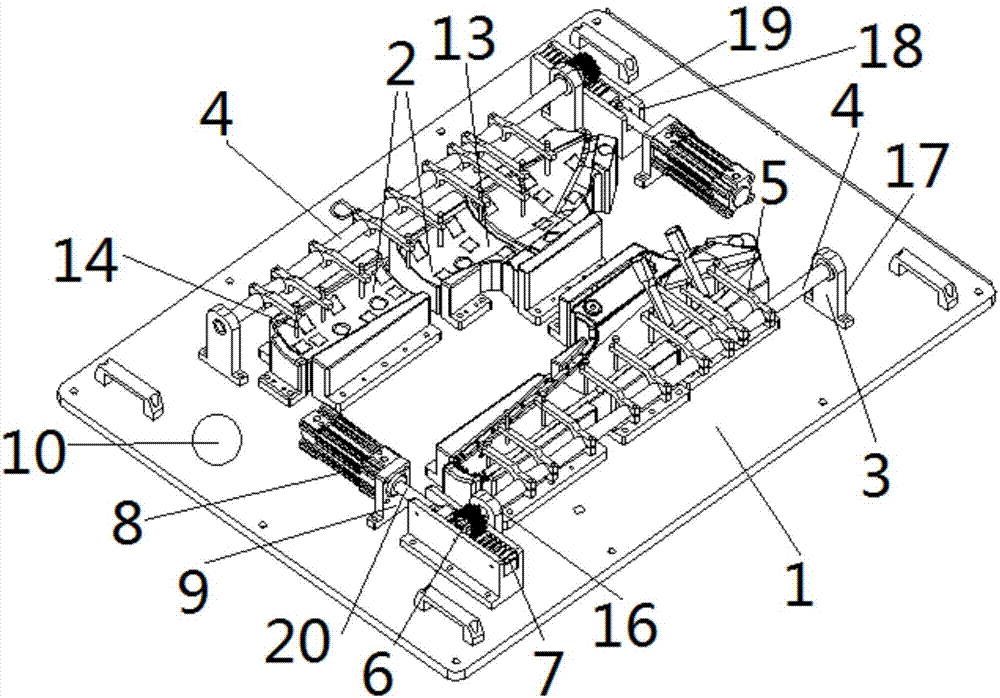

Auxiliary tool for processing of decorative plate for edge beam of car door

PendingCN107364217AReliable implementation of sticky connectionsEnsure connection reliabilityLamination ancillary operationsLaminationGear wheelRack and pinion

The invention provides an auxiliary tool for processing of a decorative plate for the edge beam of a car door, belonging to the technical field of production equipment for decorative plates used for the edge beams of car doors. A tool base (1) of the auxiliary tool is provided with a plurality of locating blocks (2) and an installation block (3); a rotating shaft (4) on the installation block (3) is provided with a pressing block (5); one end of the rotating shaft (4) is provided with a gear (6); the gear (6) is engaged with a rack (7); the rack (7) is connected with a telescoping rod (9); and the telescoping rod (9) is connected with a control part (10). The auxiliary tool provided by the invention is simple in structure, can conveniently complete press fitting and bonding of an edge beam decorative plate member I and an edge beam decorative plate member II, ensures connection reliability and smoothness after press fitting and bonding of the edge beam decorative plate member I and the edge beam decorative plate member II, and improves the processing quality and processing efficiency of the decorative plate for the edge beam of the car door.

Owner:WUHU GUOFENG PLASTIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com