Method for manufacturing multilayer wiring substrate with cable

A manufacturing method and a technology of a flexible wiring substrate, applied in multilayer circuit manufacturing, printed circuit manufacturing, electrical components, etc., can solve the problems of reducing wiring density, difficulty in forming micro-circuits, increasing wiring layers, etc., to ensure reliability and productivity Good, high pass rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

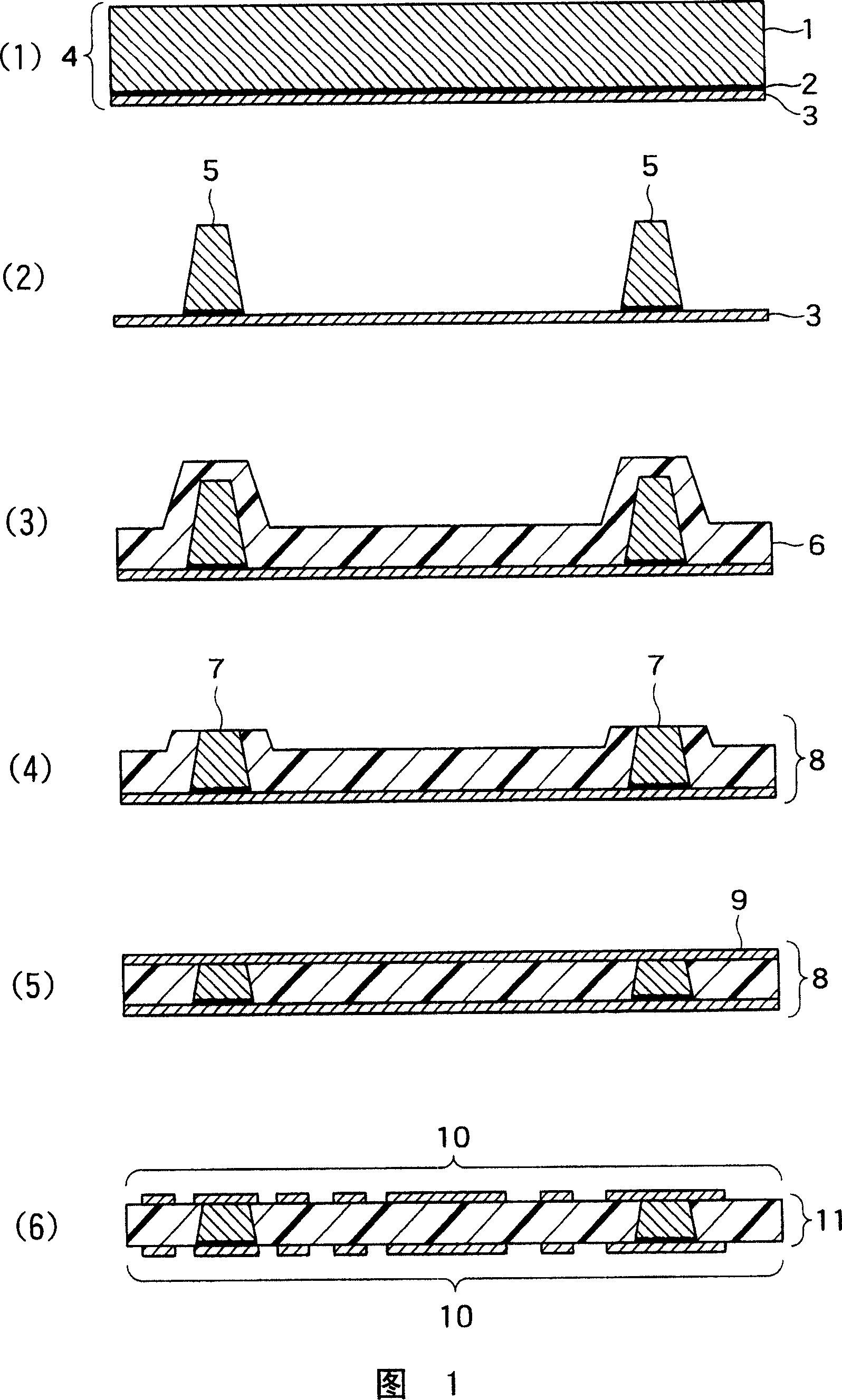

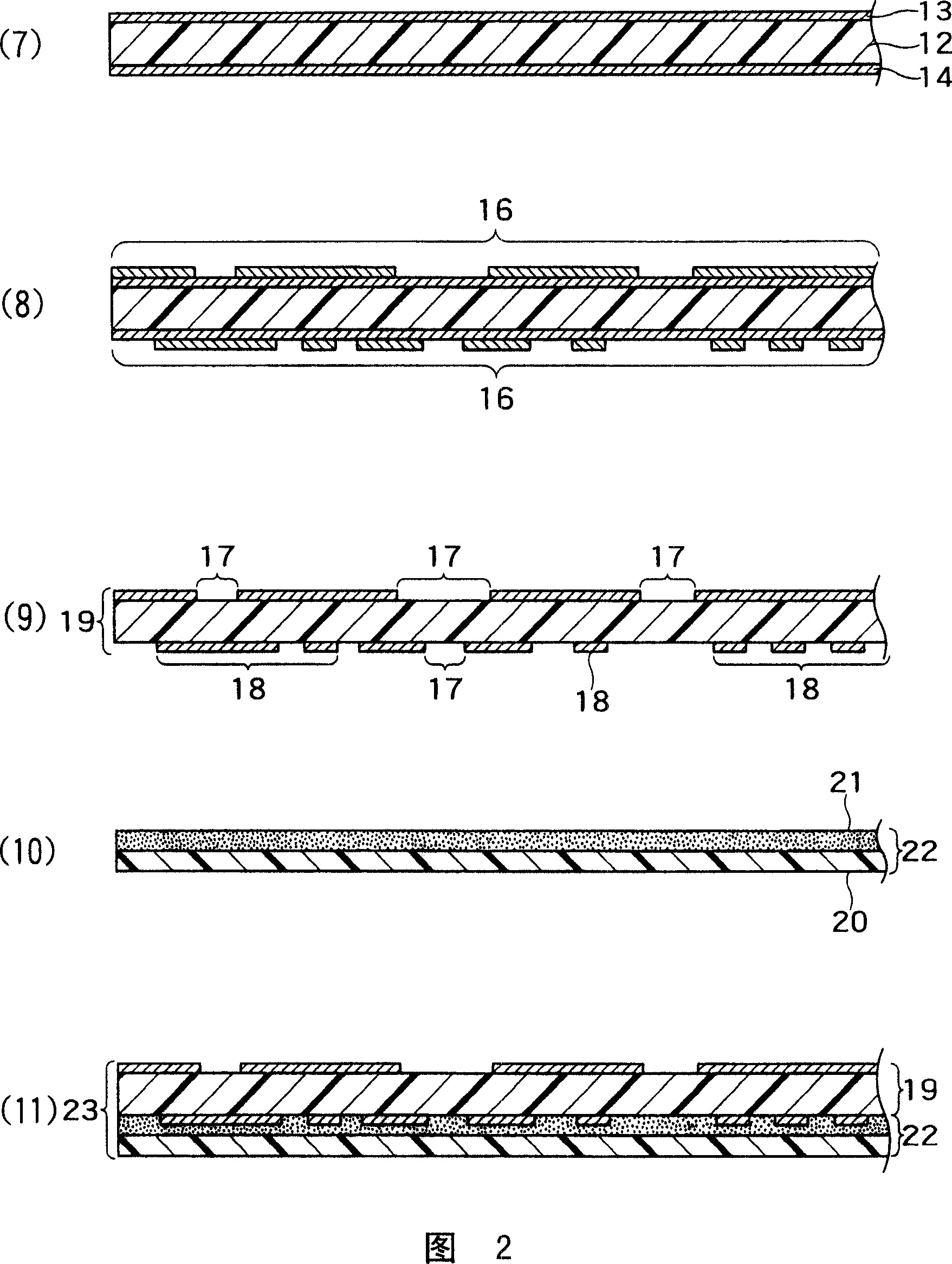

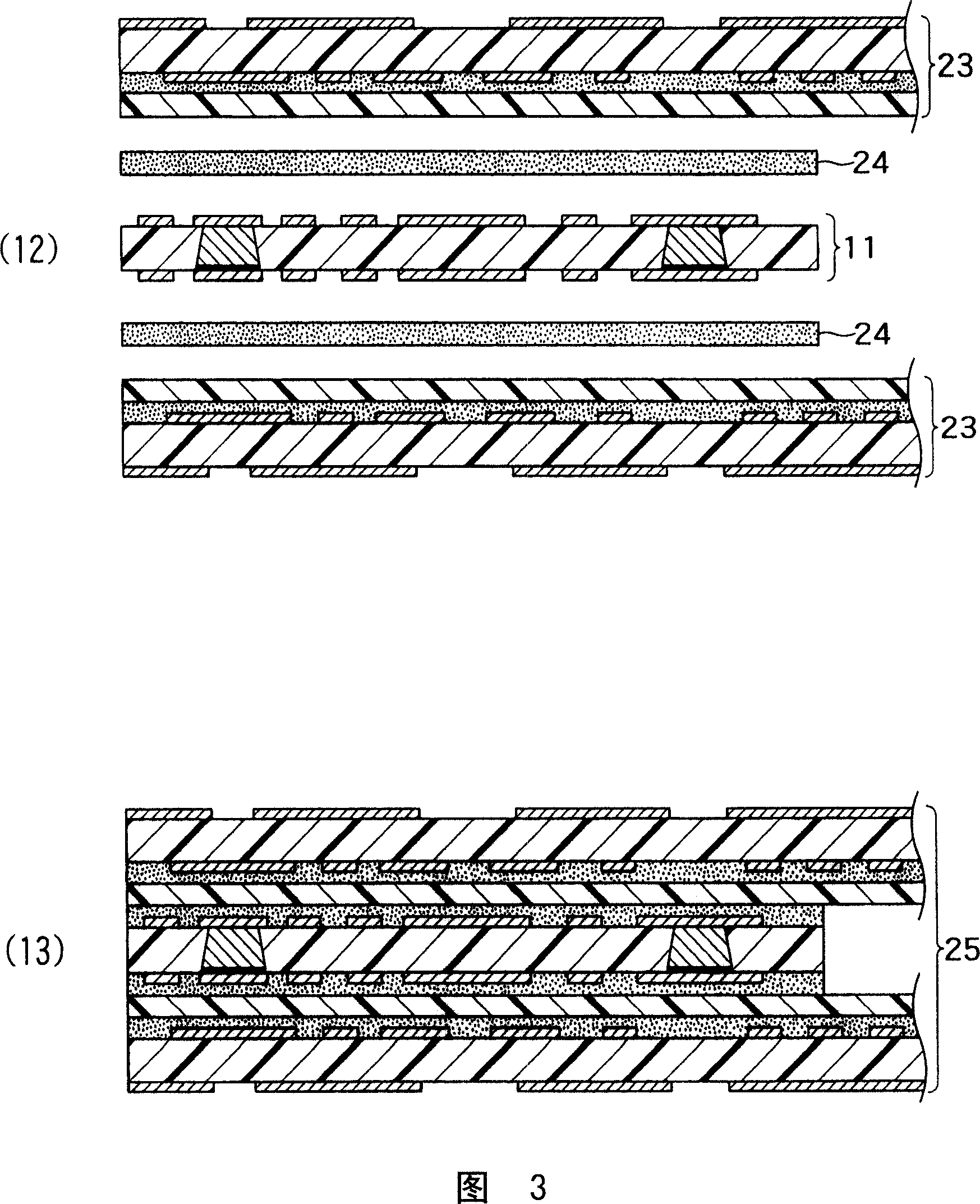

[0091] 1 to 5 are cross-sectional process diagrams showing Embodiment 1 of the present invention. First, as shown in FIG. 2 (for example, thickness 2 μm) / copper foil 3 (for example, thickness 12 μm) three-layer metal substrate 4 .

[0092] Next, as shown in FIG. 1(2), conductive protrusions 5 are formed on the copper foil 3 by selective etching. The etching solution at this time uses an etching solution used in a conventional copper etching process, such as an etching solution containing copper chloride, to etch about 80 to 90% of the overall thickness of the copper foil 1; An etchant for selectively etching copper, such as an alkaline etchant containing ammonia, etch and remove the remaining portion of the copper foil 1 to expose the nickel foil; Hydrogen oxide or nitric acid etchant is used to etch and remove the exposed nickel foil 2 . Thus, the structure shown in Fig. 1(2) is obtained.

[0093] Next, as shown in FIG. 1 (3), the preform 6 in the state of section B is pas...

Embodiment approach 2

[0119] 6 to 9 are cross-sectional process diagrams showing Embodiment 2 of the present invention. First, as shown in FIG. 6(1), when manufacturing a double-sided flexible wiring board, prepare a Metal substrate 54 having a three-layer structure of nickel foil 2 (for example, thickness 2 μm) / copper foil 53 (for example, thickness 12 μm).

[0120] Next, as shown in FIG. 6(2), conductive protrusions 55 are formed on the copper foil 53 by selective etching. The etching solution at this moment, at first, uses the etching solution that adopts in conventional copper etching process, for example the etching solution containing cupric chloride etches about 80~90% of the overall thickness of copper foil 1; , an etchant that selectively etches copper, for example an alkaline etchant containing ammonia to etch away the remaining portion of the copper foil 1 to expose the nickel foil; then, use an etchant that is less corrosive to copper and selectively etches nickel, for example containin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com