Mobile assembly type natural stone composite floor board and production technique thereof

A composite and stone technology, applied in floors, buildings, building structures, etc., can solve problems such as troublesome construction and installation, high cost of installation materials, and heavy decorative floors, so as to reduce the cost of installation materials, reduce construction waste and noise , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

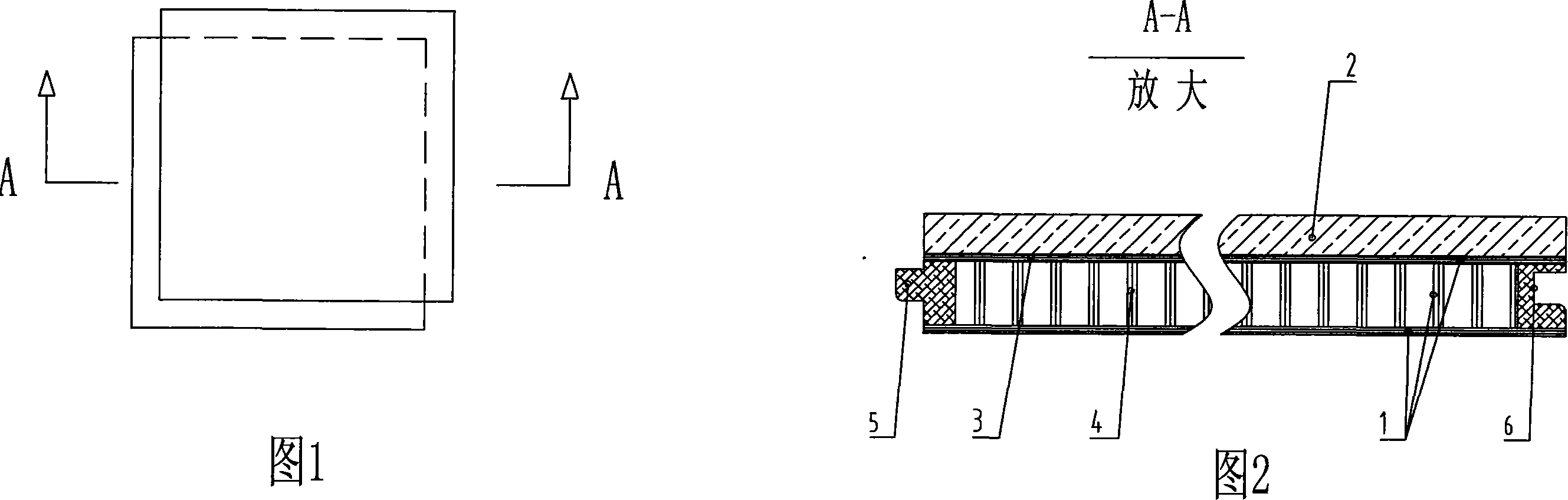

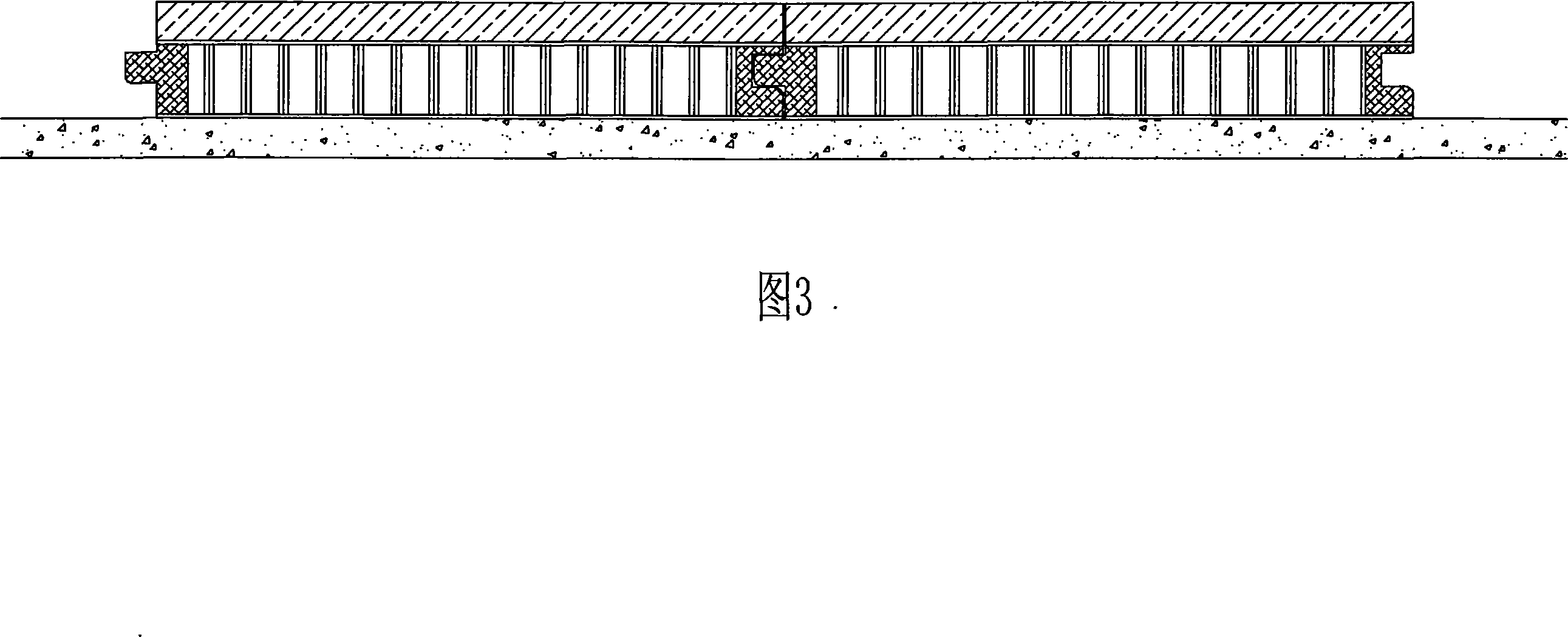

[0015] As shown in Figure 2, the mobile mosaic type natural stone composite floor has an aluminum honeycomb reinforced board 1 and a stone panel 2, and the aluminum honeycomb reinforced board 1 is pasted by glass fiber cloth 3, aluminum honeycomb core 4, and glass fiber cloth 3 in sequence The aluminum honeycomb reinforced board 1 is bonded to the stone panel 2, and the four sides around the floor have connecting blocks made of epoxy adhesive, wherein the connecting blocks on two adjacent sides have tenon 5, and the other two There are grooves 6 on the connecting blocks of two adjacent sides.

[0016] The manufacturing process adopted by the mobile mosaic type natural stone composite floor, the steps are as follows:

[0017] a. Material preparation: glass fiber cloth, aluminum honeycomb core, stone panel, high-strength epoxy adhesive;

[0018] b. Production of aluminum honeycomb reinforced board: put two pieces of glass fiber cloth into epoxy adhesive to soak, then sandwich t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com