Bipolar electrostatic chuck

An electrostatic chuck, bipolar technology, applied to the application of electrostatic attraction holding device, circuit, electrical components, etc., can solve the problems that it is difficult to remove the sample, cannot exert sufficient adsorption force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

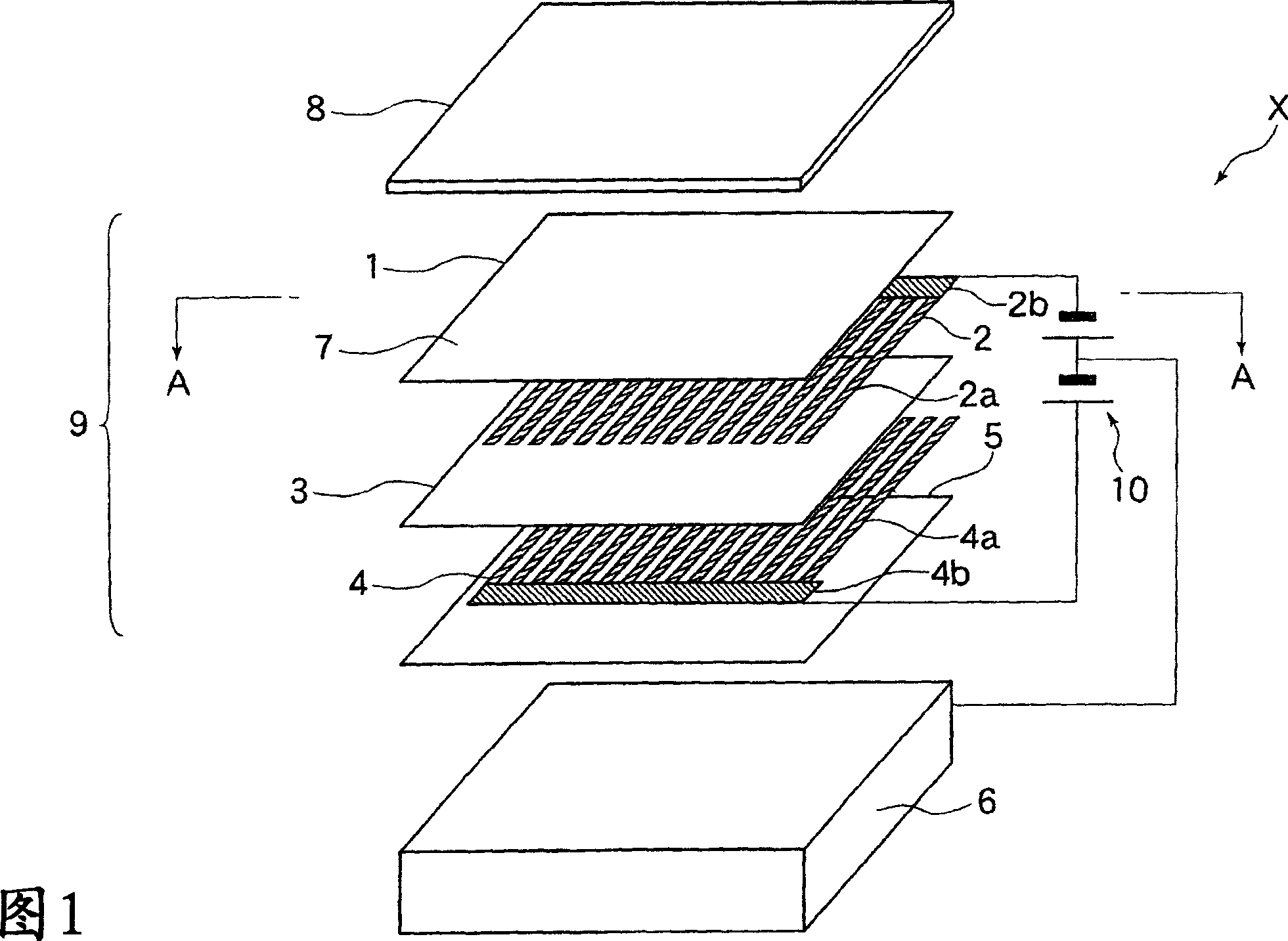

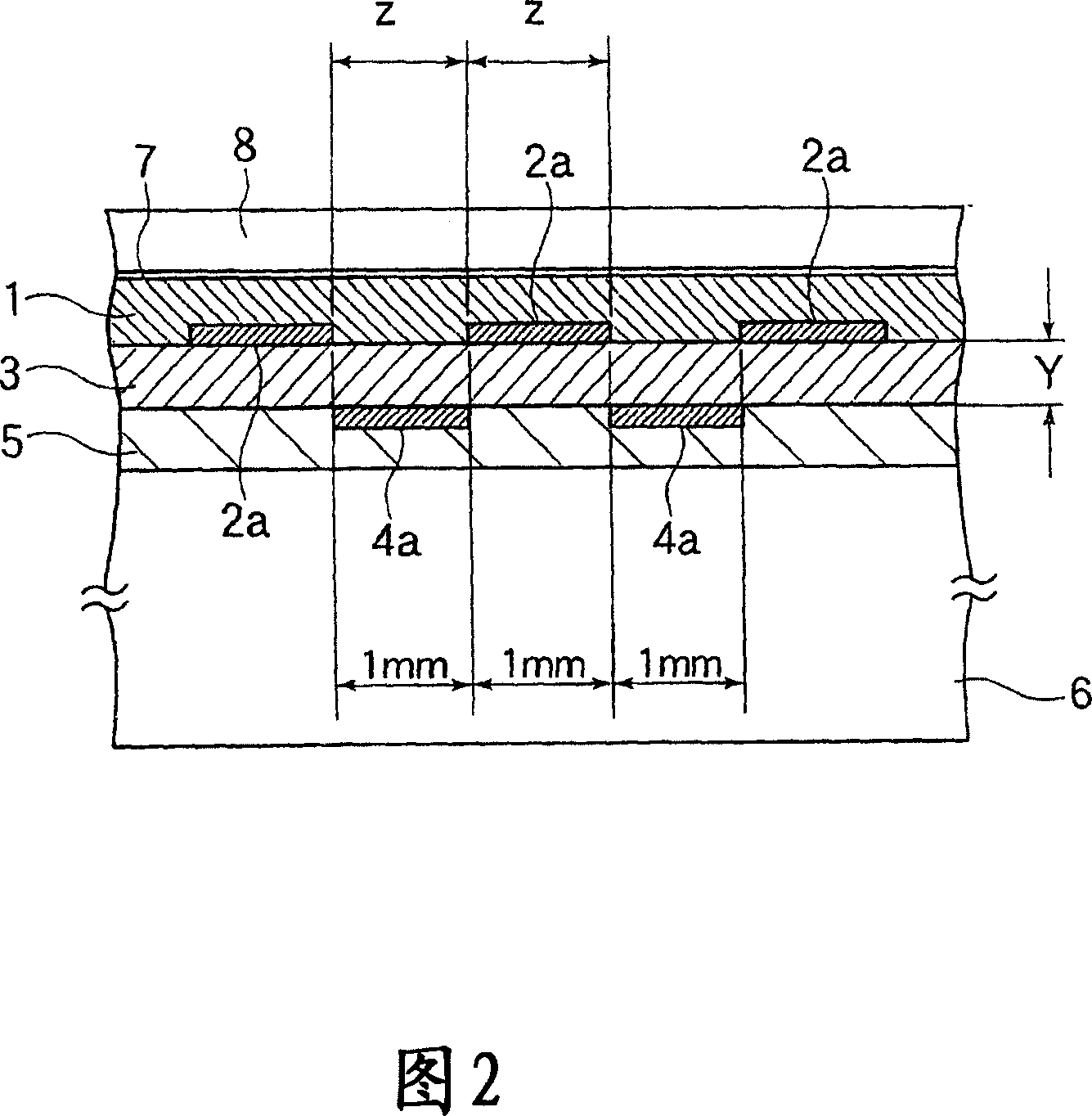

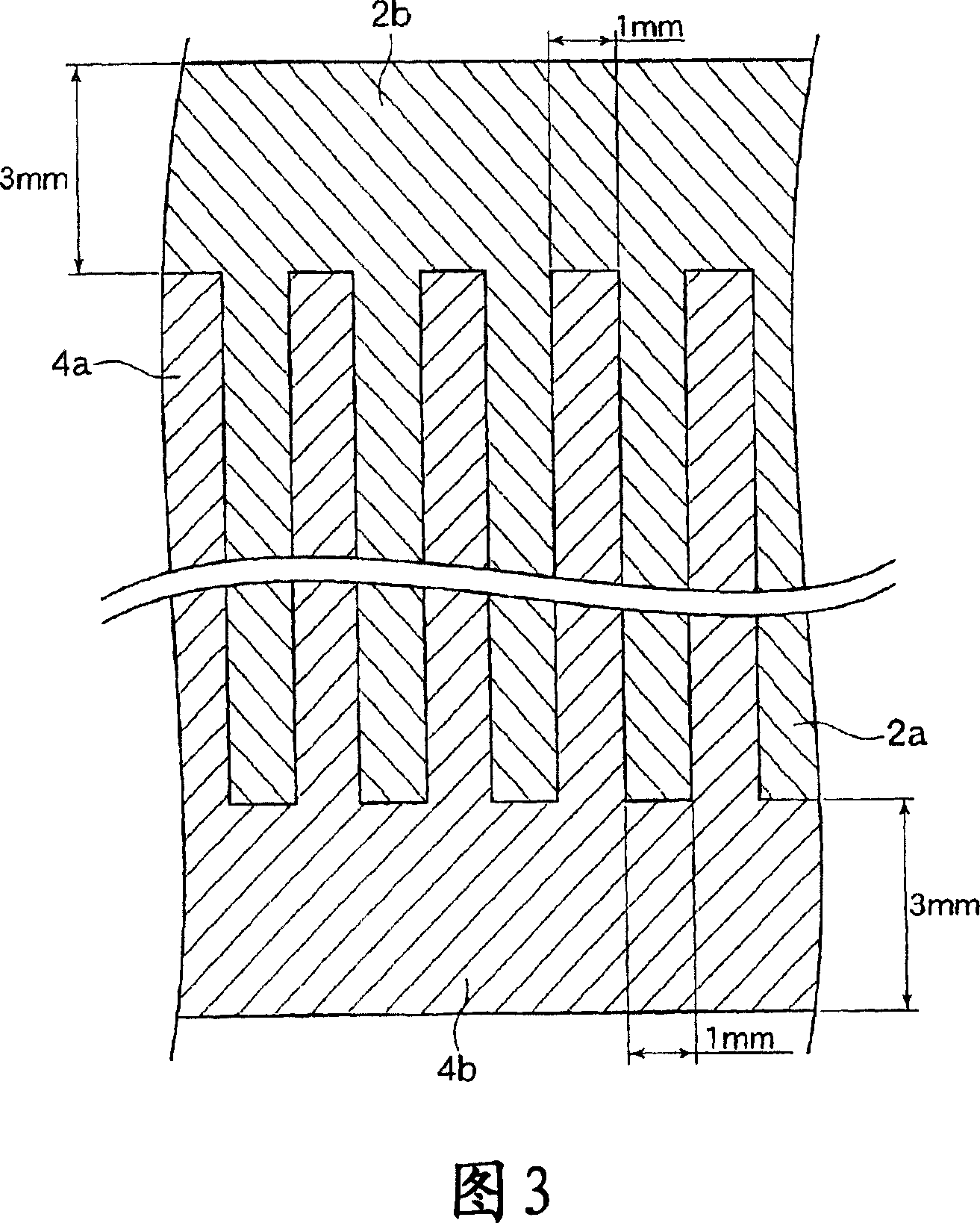

[0098] Fig. 1 shows the disassembled oblique view explanatory diagram of the bipolar electrostatic chuck of embodiment 1, this bipolar electrostatic chuck X comprises: length 100mm * width 100mm, film thickness 50μm and resistivity ε=3.5, has thermoplastic polymer on the lower surface An upper insulating layer 1 composed of a polyimide film of an imide film; a first electrode 2 composed of copper with a film thickness of 3 μm; a polyimide film with a length of 100 mm×width of 100 mm, a film thickness of 50 μm, and a resistivity ε=3.5 The inter-electrode insulating layer 3 composed; the second electrode 4 composed of copper with a film thickness of 3 μm; length 100 mm×width 100 mm, film thickness 50 μm and resistivity ε=3.5, polyimide with thermoplastic polyimide on the upper surface The lower insulating layer 5 is made of amine film; the metal substrate 6 is composed of aluminum with a length of 100 mm x a width of 100 mm x a thickness of 10 mm. In addition, in this bipolar el...

Embodiment 2

[0106] 4 is a cross-sectional explanatory diagram of the bipolar electrostatic chuck X of Example 2, and FIG. 5 is the normal line of the first electrode 1 and the second electrode 14 of the bipolar electrostatic chuck X of Example 2 along the sample adsorption surface 7. Partial plane explanatory diagram when viewed from the direction.

[0107] In the bipolar electrostatic chuck X of Embodiment 2, the electrode width of the strip-shaped portion 14a of the second electrode 14 is formed at 0.6 mm, and the strip-shaped portion 14a of the second electrode 14 is located on the strip-shaped portion formed by the first electrode 2. In the center of the gap (1 mm) formed by 2a, the strip-shaped comb teeth of the first electrode 2 and the strip-shaped comb teeth of the second electrode 14 are combined alternately, and the first electrode 2 and the strip-shaped comb teeth of the second electrode 14 are combined along the normal direction of the sample adsorption surface 7. The second e...

Embodiment 3

[0109] Fig. 6 is an exploded oblique view explanatory diagram of the bipolar electrostatic chuck X of embodiment 3, Fig. 7 is an explanatory diagram of a section (a part of section A-A in Fig. 6 ) of the bipolar electrostatic chuck X of embodiment 3, and Fig. 8 is an explanatory diagram of the embodiment 3 is a partial plan view of the first electrode 2 and the second electrode 24 of the bipolar electrostatic chuck X viewed along the normal direction of the sample adsorption surface 7 . The dotted area in FIG. 8 represents the portion where the second electrode 24 overlaps the first electrode 2 along the normal direction of the sample adsorption surface 7 .

[0110] The bipolar electrostatic chuck X of Example 3 was completed under the same conditions as in Example 1, except that the second electrode 24 was formed into a flat plate having a planar area of 80 mm in length and 80 mm in width.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com