Hydro-generator box sleeve type all-insulation isolation protection device

A technology for hydroelectric generators and protective devices, which is applied in hydroelectric power generation, cable inlet sealing devices, and cable installation, etc. It can solve the problems of main lead-out line body deformation and damage, increase loss, increase operating temperature, etc., and reduce the risk of corrosion The probability of improving insulation stability and the effect of improving safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

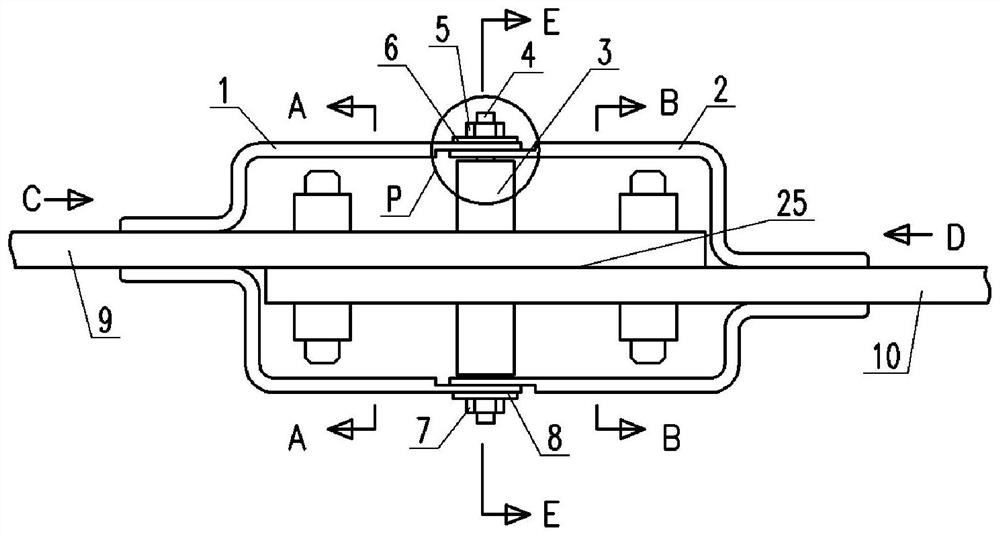

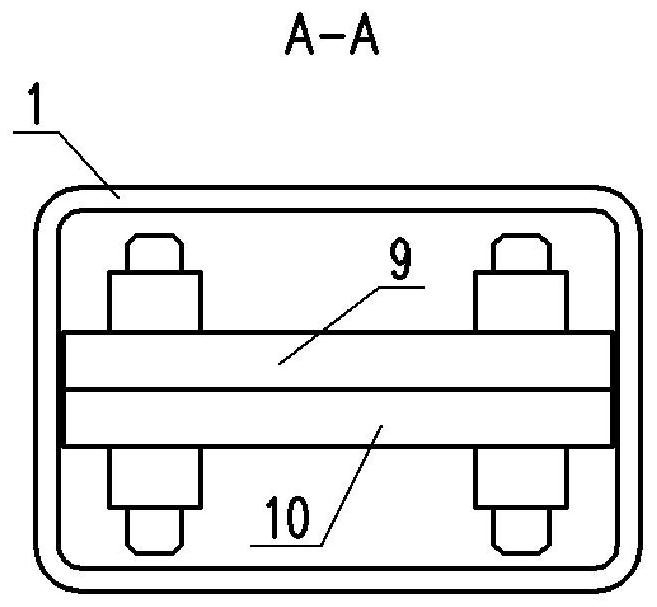

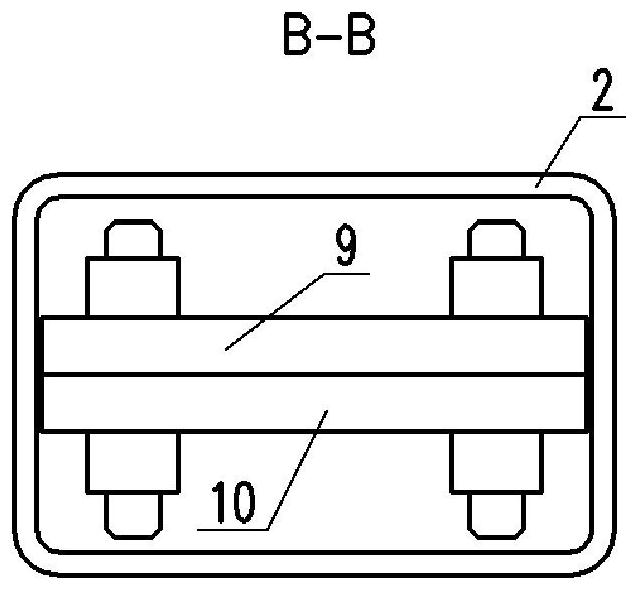

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown in the figure, a casing-type fully insulating isolation protection device for a hydro-generator consists of an upper insulating shell 1, a lower insulating shell 2, an insulating sleeve 3, an insulating stud 4, a lock nut A5, and an insulating washer A6, lock nut B7, and insulating gasket B8 form a whole, and the insulating sleeve 3 is vertically passed through the upper main lead wire 9 and the lower main lead wire 10, and then the lower insulating shell 2 is placed on the lower main lead wire from right to left. On the lead wire 10, put the upper insulating shell 1 on the upper main lead wire 9 from left to right, and then use the insulating double-ended stud 4 to pass through the upper insulating shell 1 and the lower insulating shell from top to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com