Half-plant type pure-oil-based cutting oil and application thereof

A cutting oil, plant-based technology, applied in the direction of base material, petroleum industry, lubricating composition, etc., can solve the problems of large high-temperature oil mist, easy oxidation, inconvenient application, etc., achieve small wear resistance, prevent built-up edge, The effect of good permeability and heat dissipation

Inactive Publication Date: 2016-01-13

CHINA PETROLEUM & CHEM CORP

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] One of the technical problems to be solved by the present invention is that the prior art has the problems of easy oxidation, large high-temperature oil mist, and inconvenient storage and application at low temperature. A new semi-vegetable pure oil-based cutting oil is provided.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

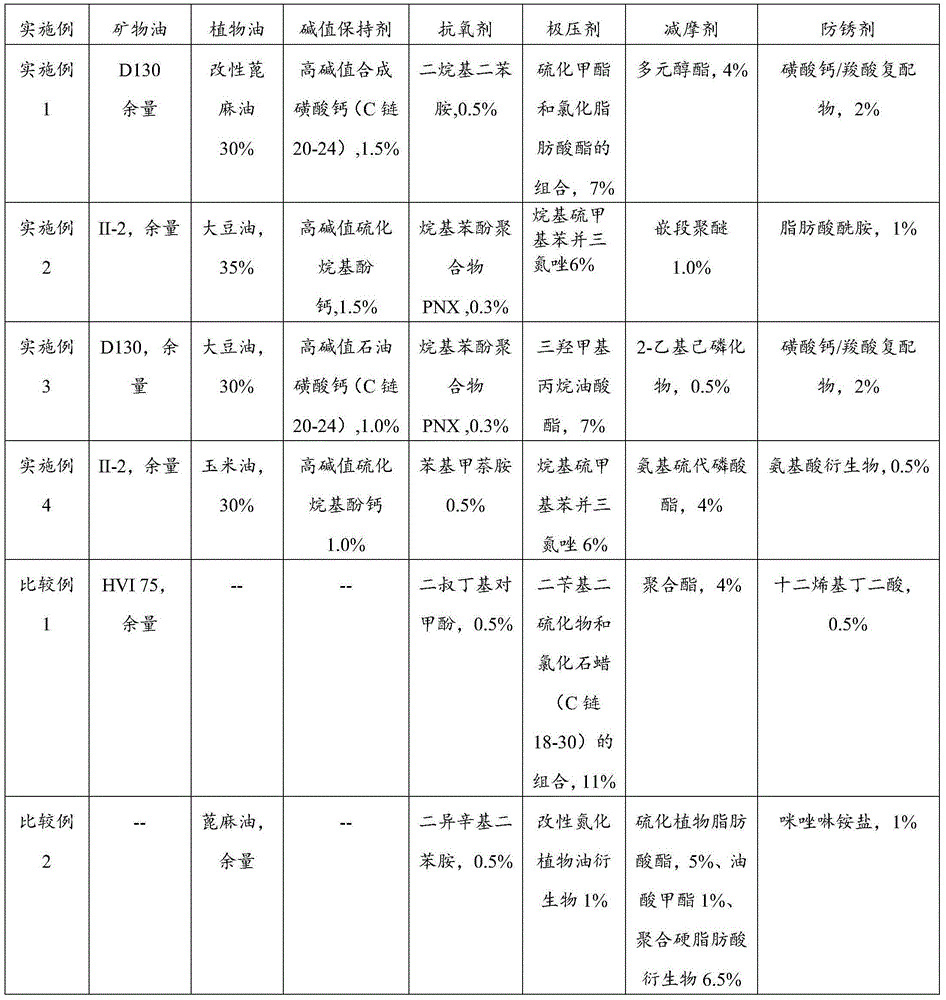

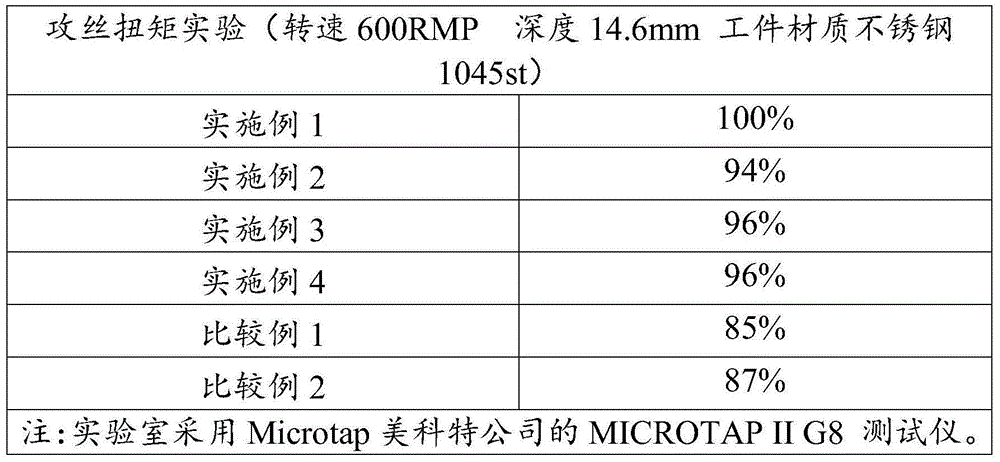

Embodiment 1~4

[0035] The base oil (mineral oil, vegetable oil) is added to the blending tank, and when the temperature is 28°C, various additives are added, and the mixture is fully stirred for 60 minutes until the blend is uniform and transparent to obtain the semi-vegetable cutting oil of the present invention. The composition and content of the cutting oil are shown in Table 1, and the properties are shown in Table 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to half-plant type pure-oil-based cutting oil and application thereof. The half-plant type pure-oil-based cutting oil mainly solves the problems that in the prior art, oxidation is prone to occurring, high-temperature oil mist is heavy, and low-temperature storage application is inconvenient. The half-plant type pure-oil-based cutting oil is prepared from, by weight, 45-60 parts of mineral oil, 30-45 parts of vegetable oil, 1-2 parts of base number retention agents, 0.2-0.5 part of antioxidants, 3-10 parts of extreme-pressure agents, 1-10 parts of anti-friction agents and 1-3 parts of antirust agents. According to the half-plant type pure-oil-based cutting oil and the application thereof, the problems are better solved, the higher tapping efficiency is achieved, and the half-plant type pure-oil-based cutting oil can be applied to a titanium alloy and stainless steel metal processing technology.

Description

Technical field [0001] The invention relates to a semi-plant type pure oil-based cutting oil and its use. Background technique [0002] Due to its high strength, high hardness and low density, titanium alloy materials have been used more and more in the fields of national defense, aerospace, and sports equipment and electronic accessories. Therefore, achieving high-efficiency cutting of titanium alloy materials has become one of the important research technologies in the industrial manufacturing industry. [0003] At present, titanium alloy-related cutting fluids are mainly water-based products, which have good heat dissipation and permeability, but there is still a certain gap in the performance of lubricating effect compared with pure oil-based products. Take emulsified oil as an example. The liquid contains part of the oil. Compared with pure oil-based products, the viscosity is too thin, and the mechanical strength of the film forming on the processed surface is not ideal. Add...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M169/04C10M101/00C10N30/12C10N30/06C10N30/08C10N30/10C10N40/22C10N40/24

Inventor 黄莉云李谨周勤祖曹长盛熊星

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com