Heat exchange water recoverer for waste steam of steaming cabinet and external connection structure thereof

A waste steam and recycler technology, which is applied in heat exchange equipment, heat exchanger shells, steam cooking utensils, etc., can solve the problem of wasting energy and water resources in steaming cabinets, prevent scale formation, save energy and water resources, The effect of reducing the risk of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

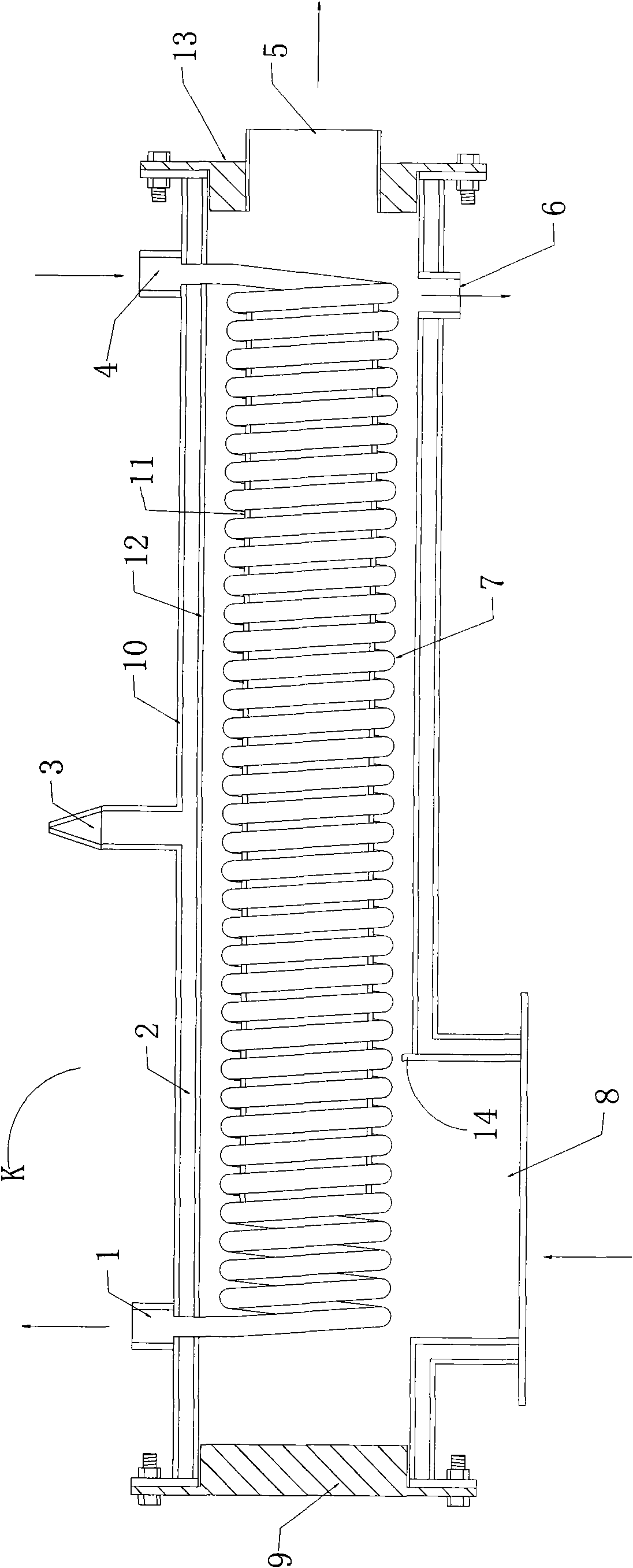

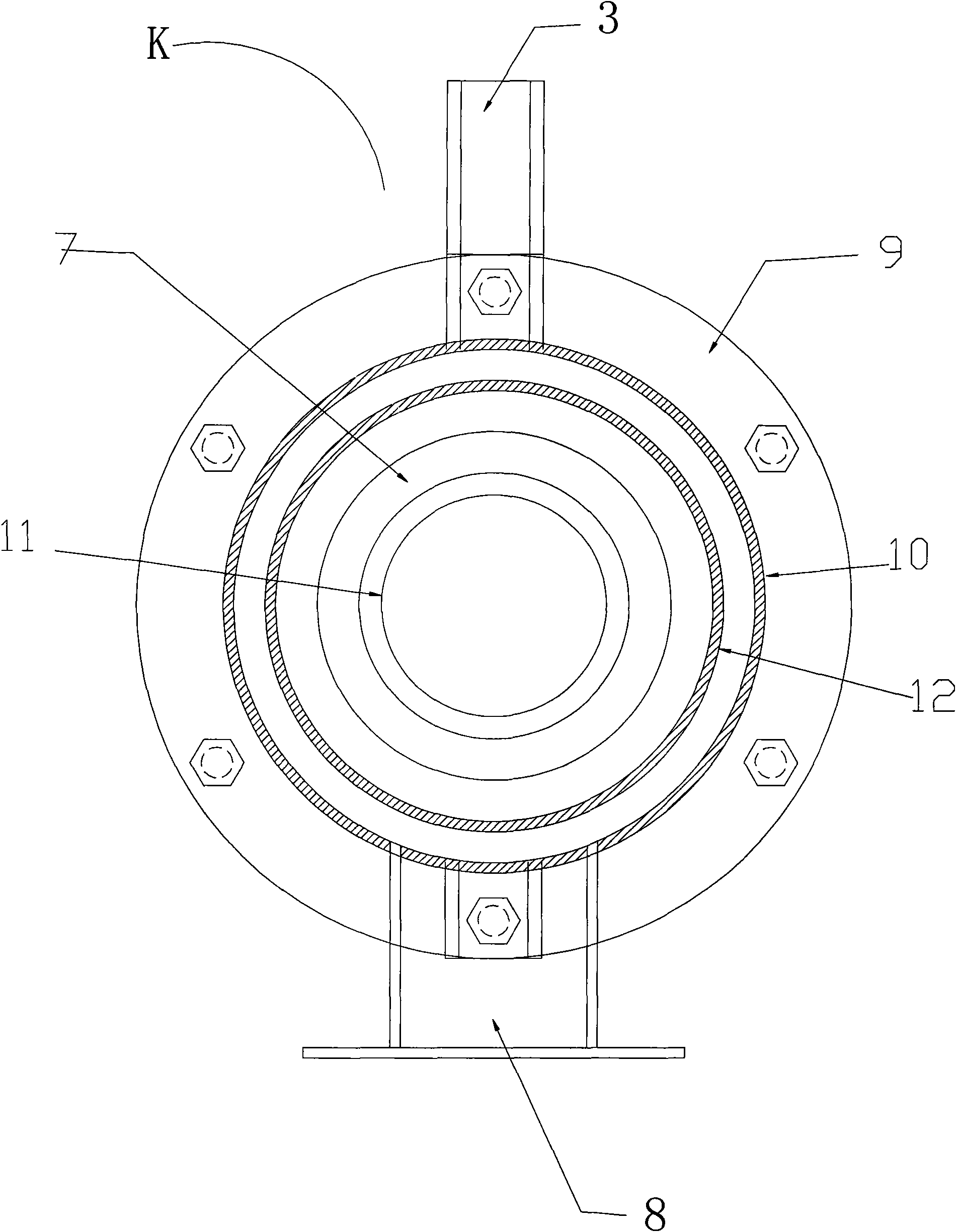

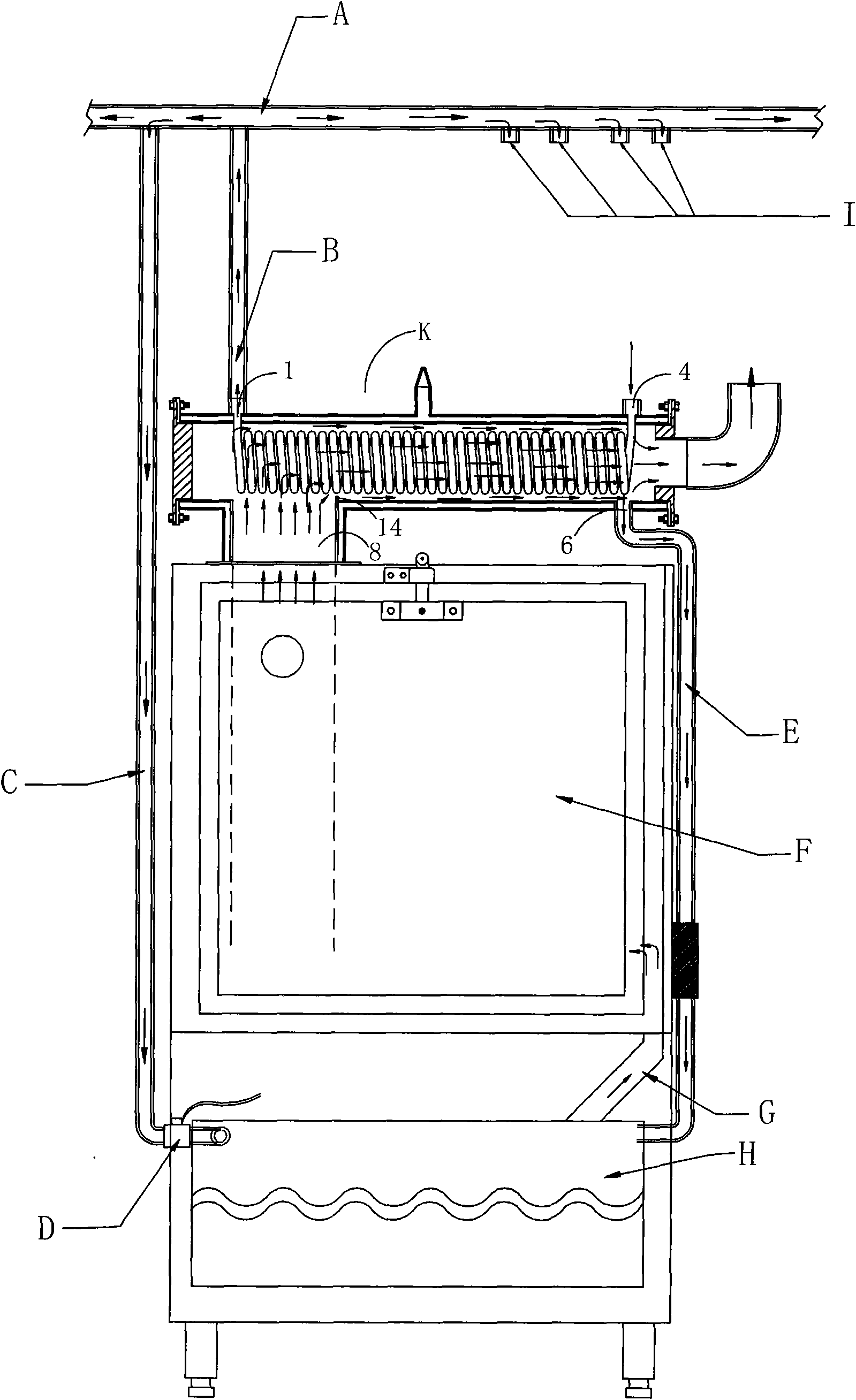

[0018] The specific embodiment of the present invention will now be described in detail in conjunction with the accompanying drawings.

[0019] Such as figure 1 and 2 As shown, a waste steam water heat exchange recoverer K of a steaming cabinet includes a shell, and the shell is provided with a recovery hot water outlet 1, a water inlet 4, an air inlet 8, an exhaust port 5, and a distilled water outlet 6. The water pipe 7 is installed in the housing, which can be made of aluminum, stainless steel, iron, copper, silver and plastic, etc. The water pipe 7 can be wound clockwise or counterclockwise, and can be regular or irregular after winding. Regular shape, in addition, the water pipe 7 can be a single pipe, or it can be formed by intertwining multiple branch water pipes. The range can be 0.3m ~ 50m, which can be determined according to the specific situation. The water inlet end of the water pipe 7 communicates with the water inlet 4 , and the water outlet end communicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com