Guide cylinder used in single crystal furnace

A guide tube and single crystal furnace technology, applied in the field of solar photovoltaics, can solve the problems of small flow resistance, radial oxygen content, resistivity, excessive fluctuation of native defects, and poor uniformity of response parameters of silicon wafers. Achieve the effect of improving thermal insulation effect and maintaining flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

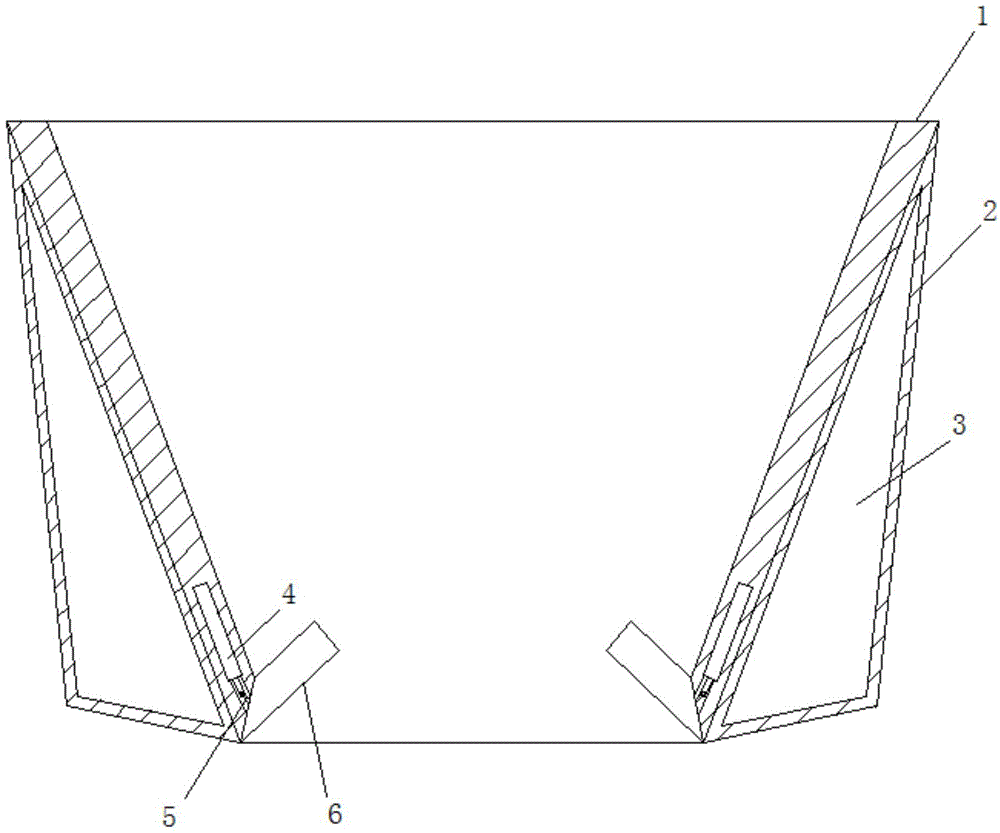

[0012] like figure 1 As shown, the guide cylinder of the single crystal furnace includes a cylinder body 1 whose diameter gradually decreases from top to bottom. The cylinder body 1 is made of multi-layer composite carbon fiber material. There are several rotatable gas regulating devices, an outer cylinder 2 is arranged on the outer peripheral surface of the cylinder, and an insulating space is provided between the outer cylinder 2 and the cylinder body 1, and an insulating material layer 3 is arranged in the insulating space.

[0013] The regulating part includes an oil cylinder 4 arranged in the barrel and a connecting rod 5 connected with the gas regulating device, and the connecting rod 5 is also connected with the cylinder rod of the oil cylinder 4 .

[0014] The gas regulating device is a regulating plate 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com