Multi-layer flexible printed circuit board and method of manufacturing the same

A flexible printing and manufacturing method technology, which is applied in multilayer circuit manufacturing, printed circuit components, semiconductor/solid-state device manufacturing, etc. Flatness, cheap and stable manufacturing, effect of reducing vias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

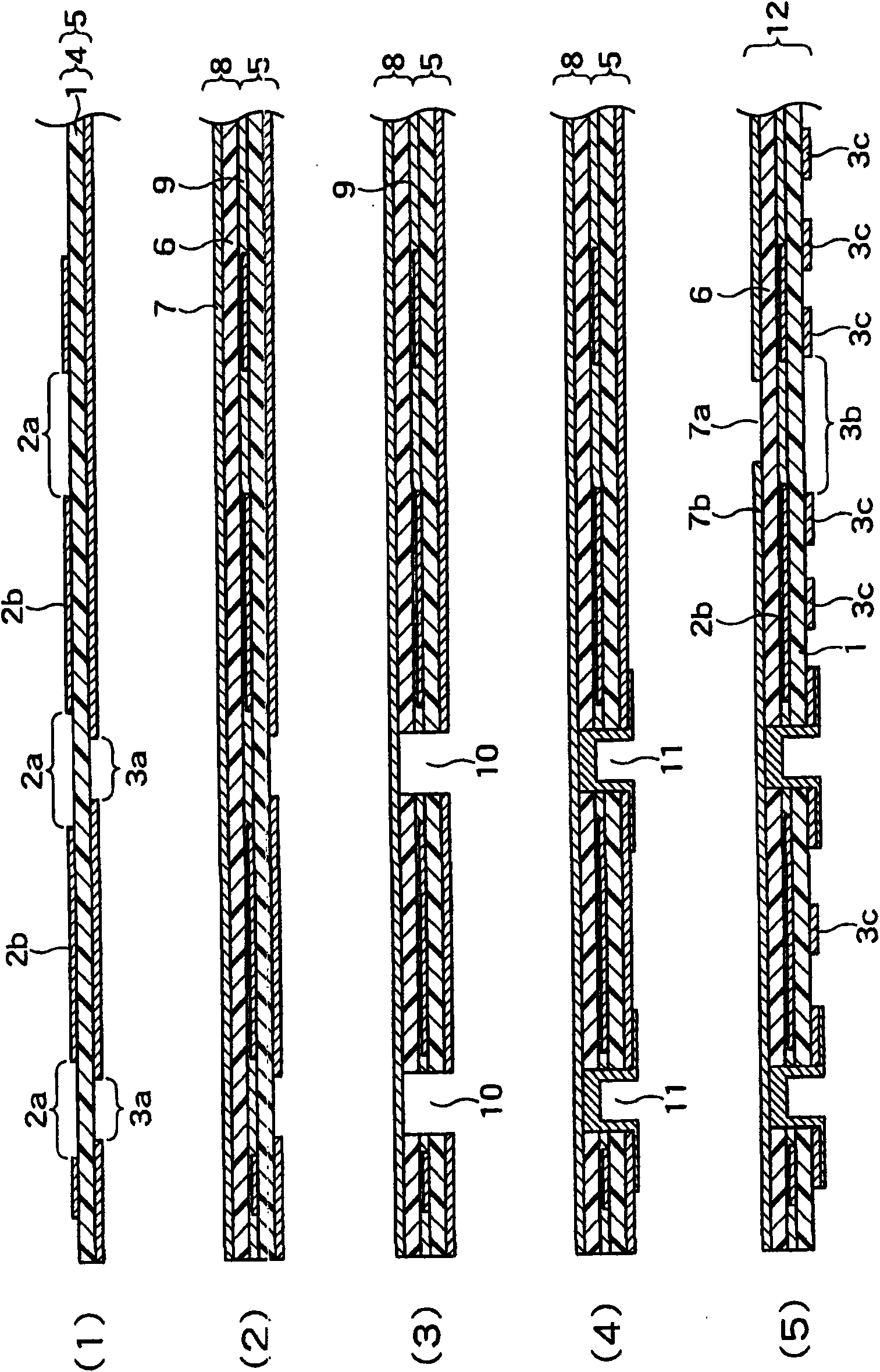

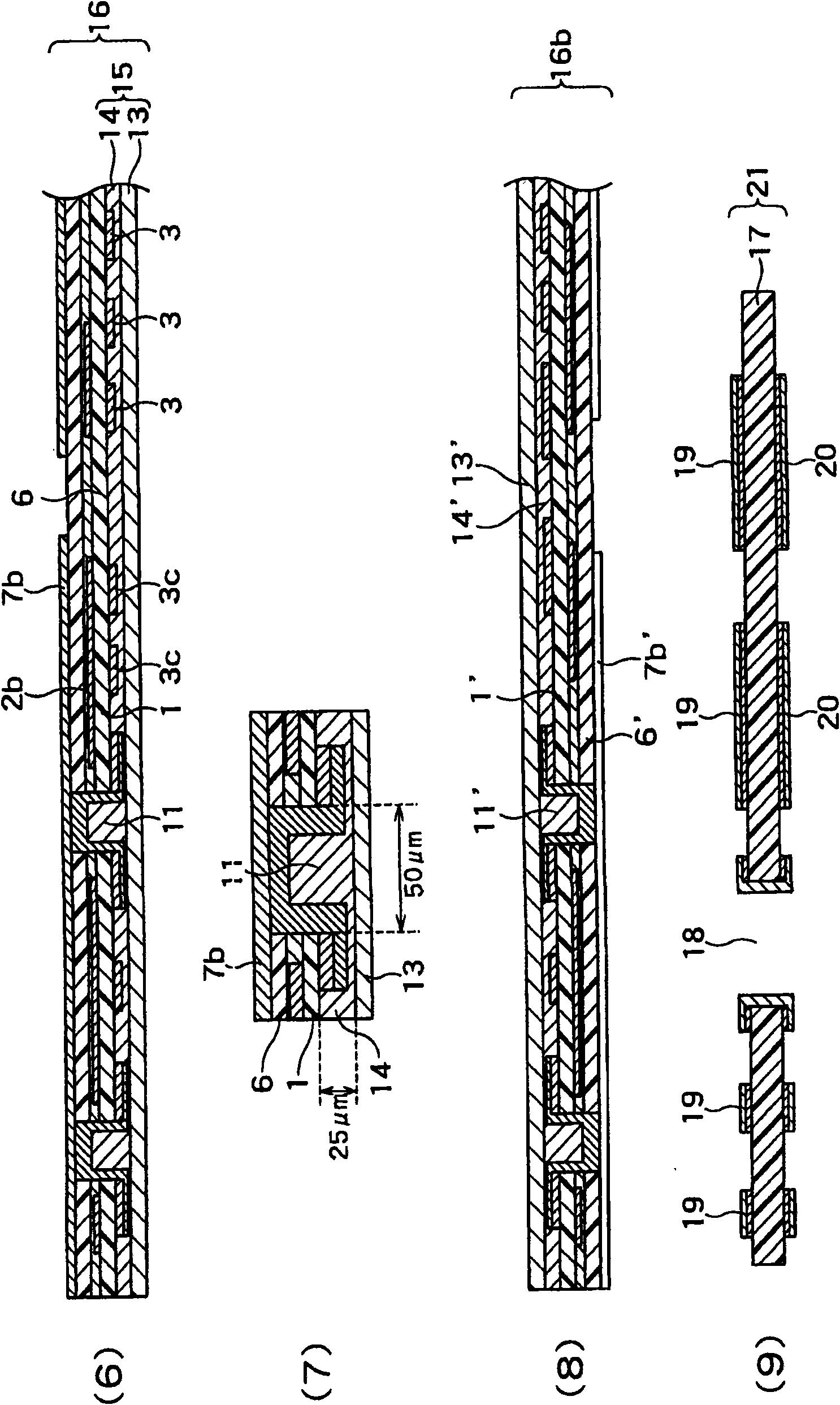

[0109] Figure 1A ~ Figure 1D It is a process drawing which shows the manufacturing method of this invention. A method of manufacturing a multilayer flexible printed wiring board having an 8-layer structure having a cable portion will be described with reference to this process diagram.

[0110] First, if Figure 1A As shown in (1), in the double-sided copper-clad laminate 4, a conformal mask 2a and a circuit pattern 2b are formed at the time of laser processing of the copper foil 2 on the inner layer side. As the double-sided copper-clad laminate 4, for example, a flexible insulating base material 1 (here, polyimide with a thickness of 12.5 μm) having copper foils 2 and 3 with a thickness of 12 μm on both sides of polyimide or the like is used. .

[0111] The conformal mask 2a and the circuit pattern 2b are formed by etching the copper foil 2 by metal surface photofabrication. Moreover, the conformal mask 3a at the time of laser processing is formed on the copper foil 3 u...

Embodiment 2

[0143] image 3 It is a sectional view showing the structure of the second embodiment of the present invention. as it should image 3 As shown, by changing the position where part of the build-up layer 16b was removed when producing the build-up layer 16b, the cable part of the outer layer can be formed on the circuit 35 of the second conductive layer in a single layer. Thus, an 8-layer flexible printed wiring board 37 having single-layer cables on the outer layer is obtained.

[0144] By employing such a cable structure, it can be suitably applied to a site requiring flexibility, such as a hinge portion of a mobile phone. Additionally, by image 3 Combining the through vias 38 in that way also enables direct connection of all layers.

Embodiment 3

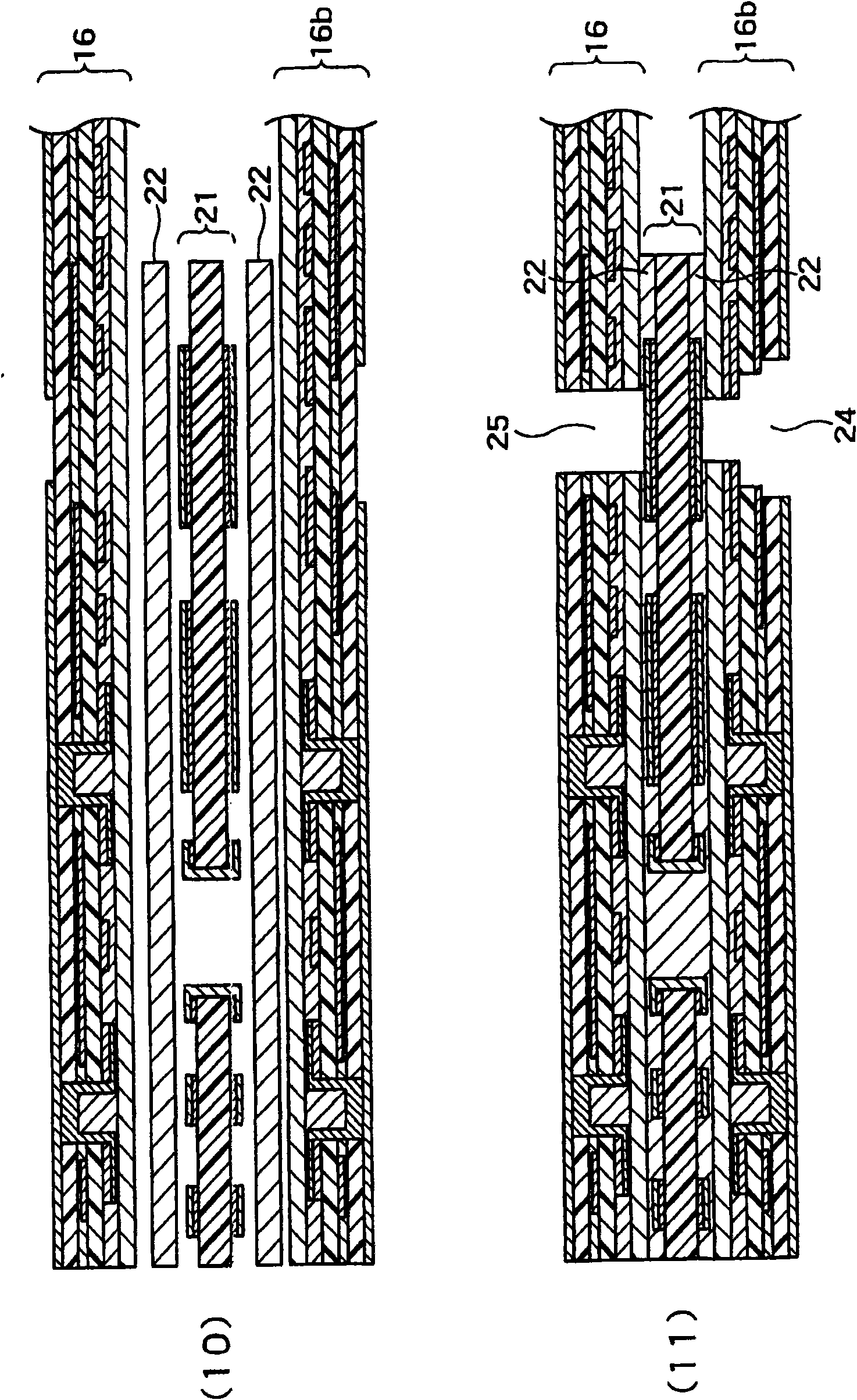

[0146] Figure 4 It is a sectional view showing the structure of the third embodiment of the present invention. as it should Figure 4 As shown, a part of the build-up layer remains and is stacked in a bent state, whereby the circuit 39 of the third conductive layer 3 can also be directly connected to the third conductive layer 3' on the opposite surface, and it can be effectively mounted. The signal of the third conductive layer 3 of the signal layer of the component on the first conductive layer 7 is connected to the third conductive layer 3 ′ (opposite signal layer) on the opposite side.

[0147] In addition, as an interlayer connection connecting four layers, a via hole 40 (connecting the first conductive layer 7 and the core substrate 21), a stepped via hole 41 (connecting the first conductive layer 7', the third conductive layer 3 'and the core substrate 21), stepped vias 27 (connecting the first conductive layer 7', the second conductive layer 2', the third conductive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com