Split high-altitude butt-joint installation method of offshore wind generating set

A technology for wind turbines and wind turbines, which is applied to wind turbine components, wind turbines, wind energy power generation and other directions, can solve the problems of difficult installation and construction, increased installation costs, and increased construction personnel, so as to reduce construction costs and reduce The effect of collision damage rate and safety guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

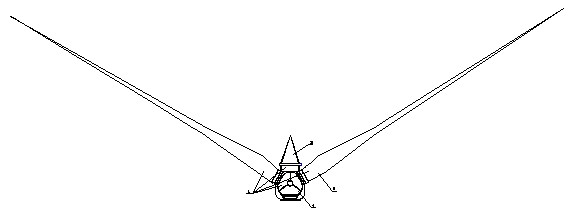

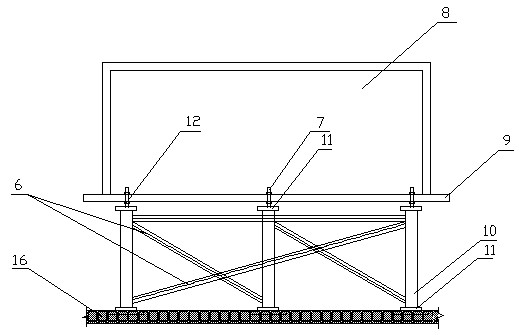

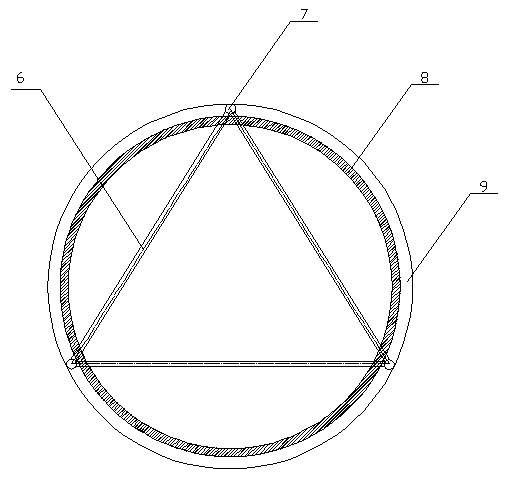

[0041] For a wind power generator project in an offshore wind farm in Jiangsu, a high-altitude docking installation method for offshore wind power generator components proposed by the present invention is used to install wind power generators. The installation steps are as follows:

[0042] 1. Assembly of the nacelle, hub and two blades of the wind turbine:

[0043] a) Hoisting machinery for wind turbines: the main crane 14 is a CC5800 1000t crawler crane installed on a large barge, and the working conditions are configured as follows: SSL working condition, main arm 90m, radius of gyration 26m, rated load 154t, auxiliary crane Machine 15 adopts 200t floating crane;

[0044] b), engine room hoisting:

[0045] Connect the special spreader to the engine room 3, and fix it on both sides of the engine room 3 with two hemp ropes to control the swing of the engine room 3, hoist the engine room 3 with the main crane 14, and lay it flat on the deck of the transport barge 13;

[0046...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com