Process for producing SiC single crystal

A manufacturing method and single crystal technology, which are applied in the directions of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems that polycrystallization cannot be reliably prevented, and SiC single crystal cannot be produced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

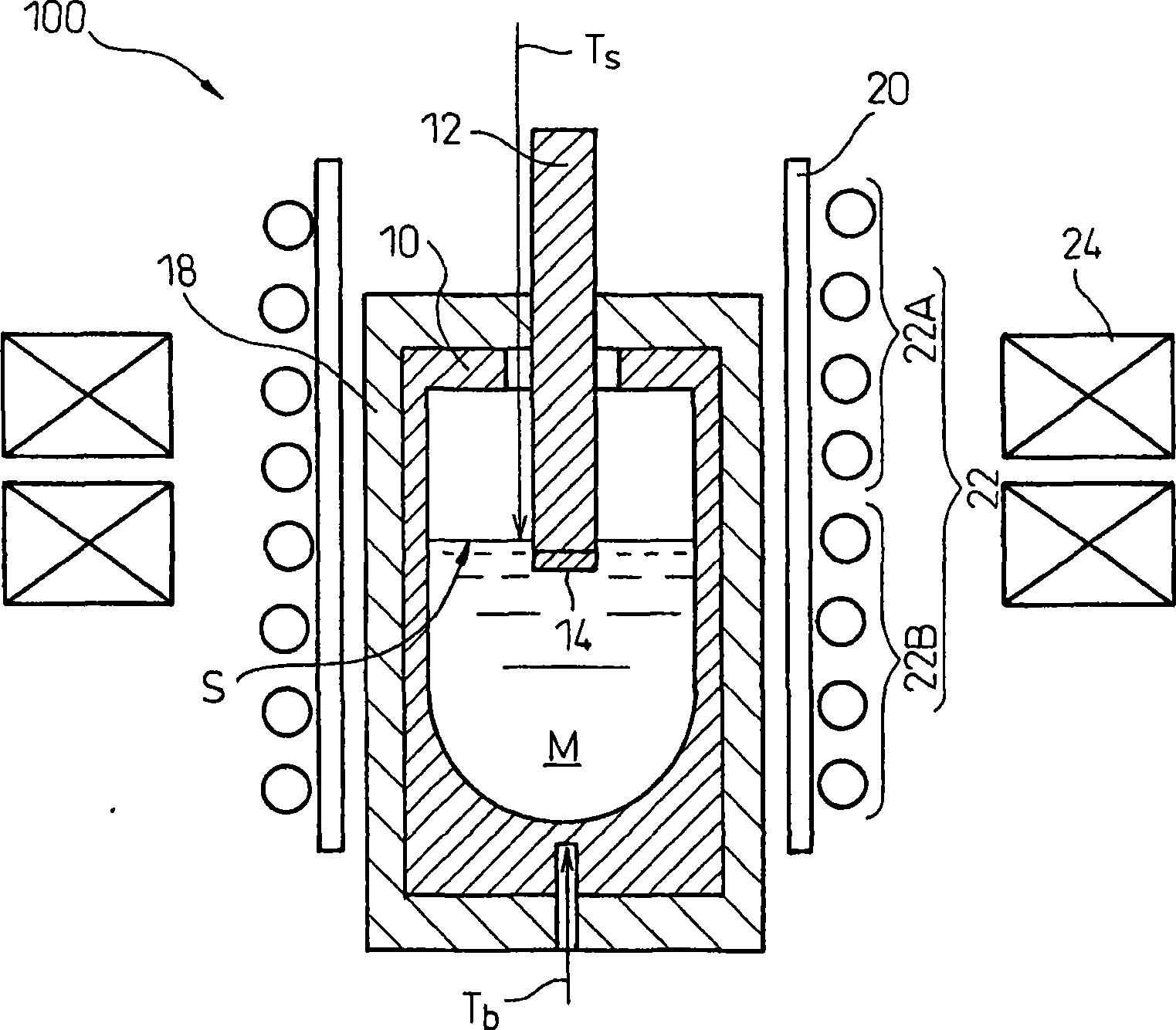

[0039] use image 3 The SiC single crystal production furnace 100 of the present invention is suitable for producing SiC single crystals by the solution method with the deviation angle θ of the present invention.

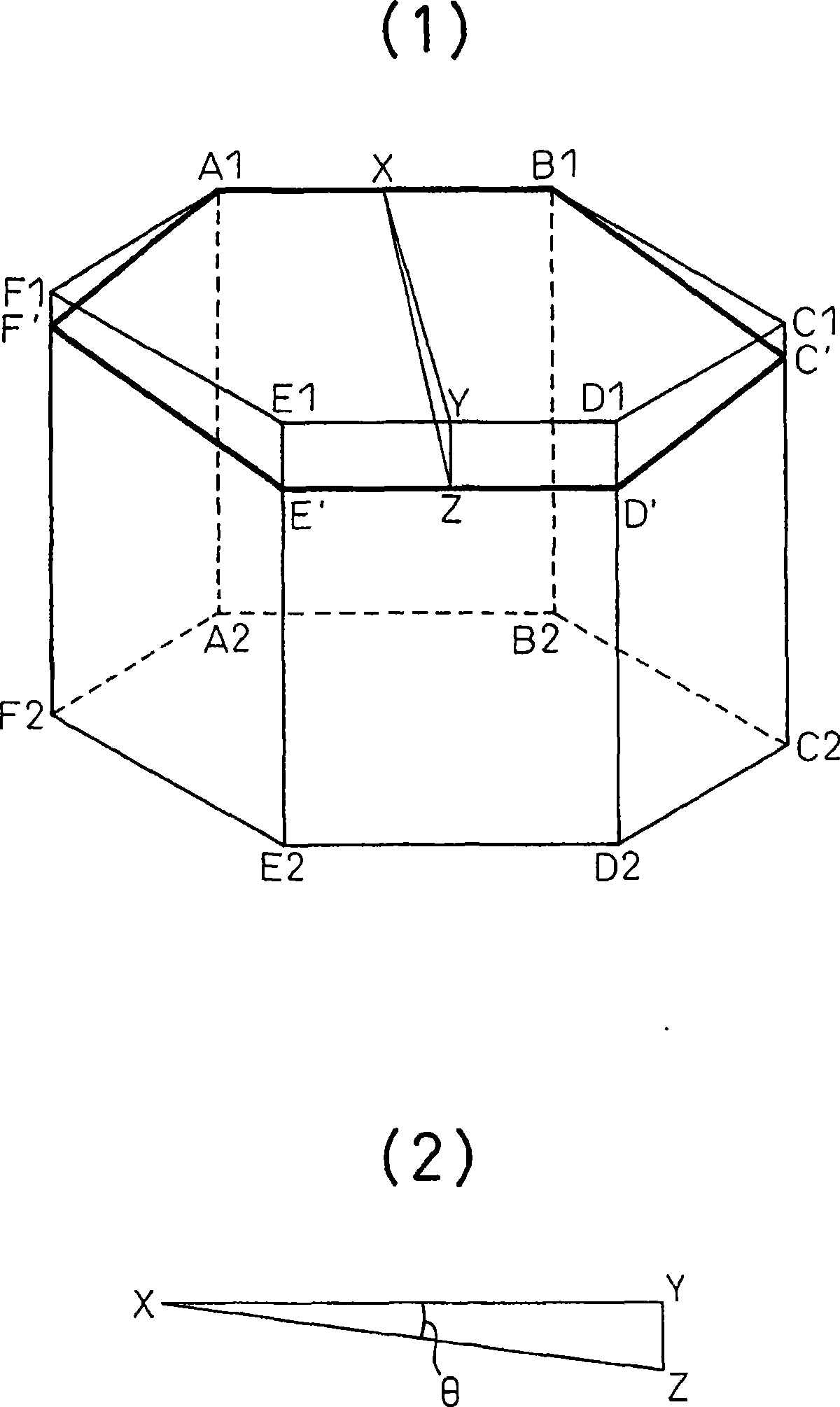

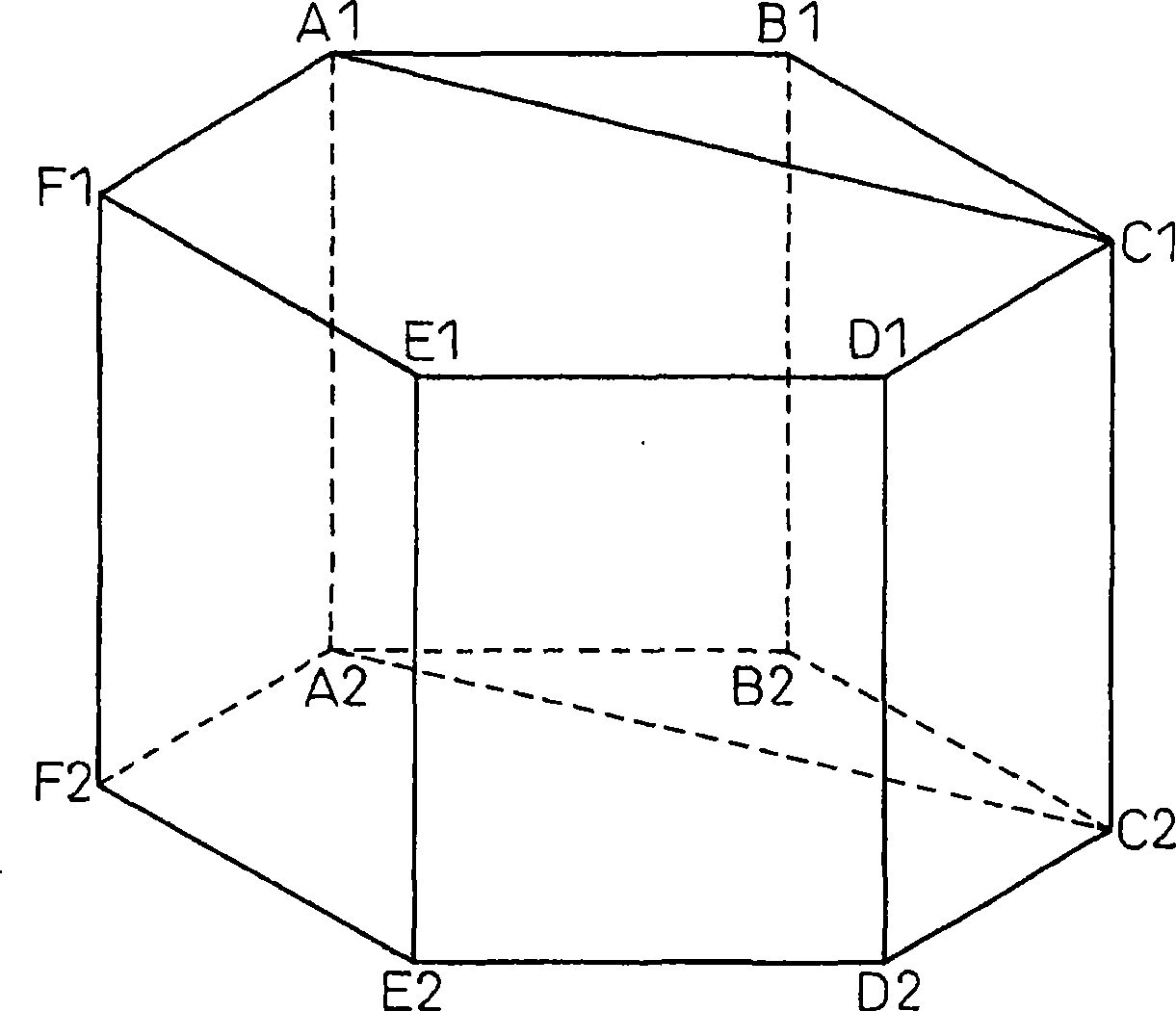

[0040] In this embodiment, the SiC seed crystal 14 whose growth surface is inclined at an angle of θ=4° relative to the (0001) plane [1-100] direction is installed on the lower end of the graphite rod 12 and inserted into the positive side of the Si melt surface S. Below, a SiC single crystal was grown under the following growth conditions.

[0041] [growth conditions]

[0042] The melt surface temperature Ts of the Si melt temperature is 1800°C, and the temperature gradient from the bottom of the crucible to the melt surface S temperature is set at 20°C / cm. The atmosphere in the crucible is Ar gas and maintained at normal pressure. In order to stabilize the planar growth, Al, which is one of the additive elements already proposed by the present applicant in JP-A...

Embodiment 2

[0045] Install the SiC seed crystal 14 whose growth surface is the (1-100) plane (that is, the deviation angle θ=90° relative to the (0001) direction [1-100] direction) on the lower end of the graphite rod 12, and insert it into the Si melt surface Directly below S, a SiC single crystal was grown under the same growth conditions as in Example 1.

[0046] Figure 5 (1) A photograph showing a section including the growth axis from the graphite rod 12 through the seed crystal 14 to the single crystal growth layer G. SiC single crystals grow with very high planarity on SiC seeds.

[0047] At this time, and then as Figure 5 As shown in the schematic diagram showing the growth surface profile in (2), the diameter of the SiC single crystal grown from the SiC seed crystal (the outline is shown by a dotted rectangle) is approximately doubled or more. There is also a portion where the expansion is terminated due to the multinucleated portion N occurring around a portion, but this ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com