Array substrate, preparation method, display panel and display device

A technology for array substrates and display panels, which is applied in the fields of preparation methods, array substrates, display panels, and display devices, and can solve problems such as uneven lighting brightness of electroluminescent devices and decreased material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

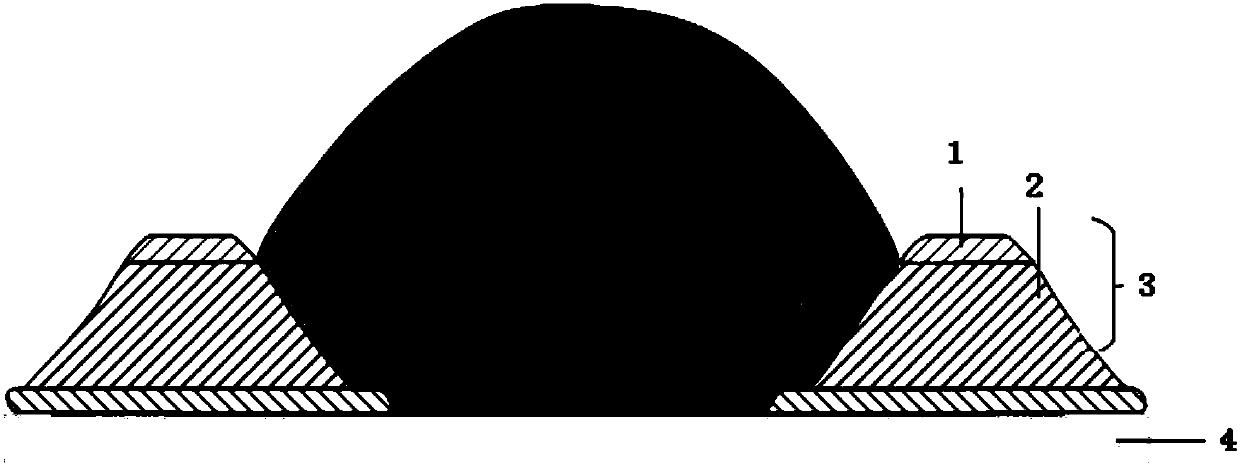

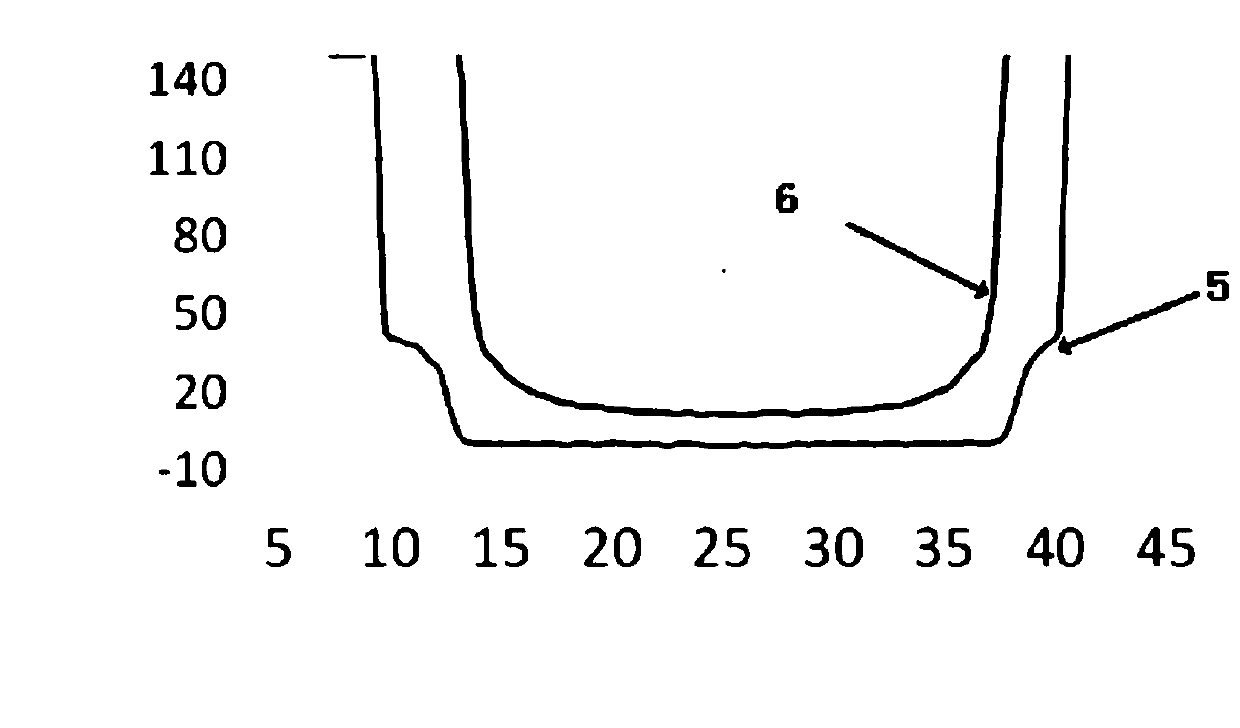

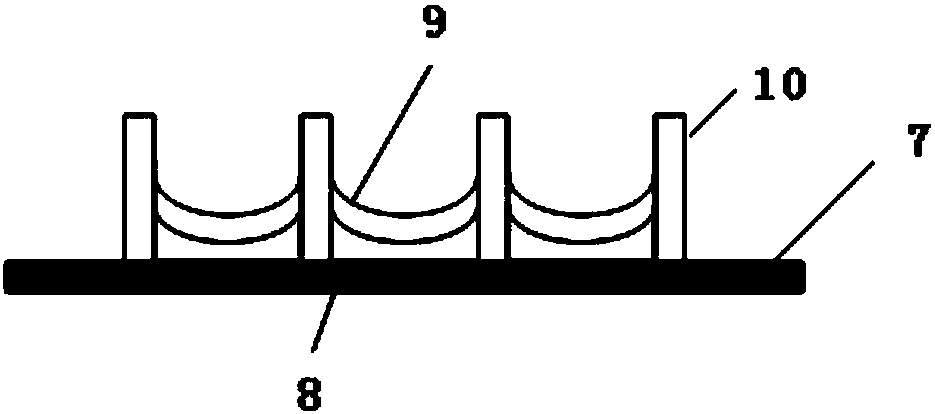

[0035] refer to image 3 , shows a schematic structural view of an array substrate provided by an embodiment of the present invention. As shown in the figure, the array substrate may include a substrate 7 and an array of anode layers 8 arranged on the substrate 7, wherein, at a distance from each anode layer 8 Within the preset distance range from the edge, the thickness of each anode layer 8 gradually increases along the direction from the center to the edge of each anode layer 8 .

[0036] In the prior art solution, the wet film forming process needs to remove excess solvent through a subsequent process, so as to dry and form the required film. In the drying process, when the ink drop falls into the substrate or pixel, due to the shape of the ink drop, the evaporation rate of the central part with a smaller volume / unit area ratio and the edge part with a larger volume / unit area ratio in the ink droplet different, so the ink dries faster at the edges. With the continuous vo...

Embodiment 2

[0053] refer to Figure 5 , which shows a flow chart of the steps of a method for preparing a substrate provided in an embodiment of the present invention, which may include the following steps:

[0054] Step 101: providing a substrate.

[0055] In the embodiment of the present invention, before the preparation of the anode layer is completed, a substrate needs to be provided first, and the substrate may be, but not limited to, an insulating substrate such as a glass substrate or a plastic substrate.

[0056] The substrate includes a substrate, and the preparation method of the substrate mainly includes: sequentially forming a gate layer, a gate insulating layer, a semiconductor layer, a source and drain layer, a passivation layer and a flat layer on the substrate.

[0057] The method for preparing the substrate provided in the embodiment of the present invention is an improvement on the process of the anode layer. The method for preparing the substrate is the same as that co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com