Display substrate and manufacturing method thereof, and display device

A technology for displaying substrates and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as different thicknesses, improve uniformity, reduce the probability of thin edges and thick edges in the middle, and ensure The effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

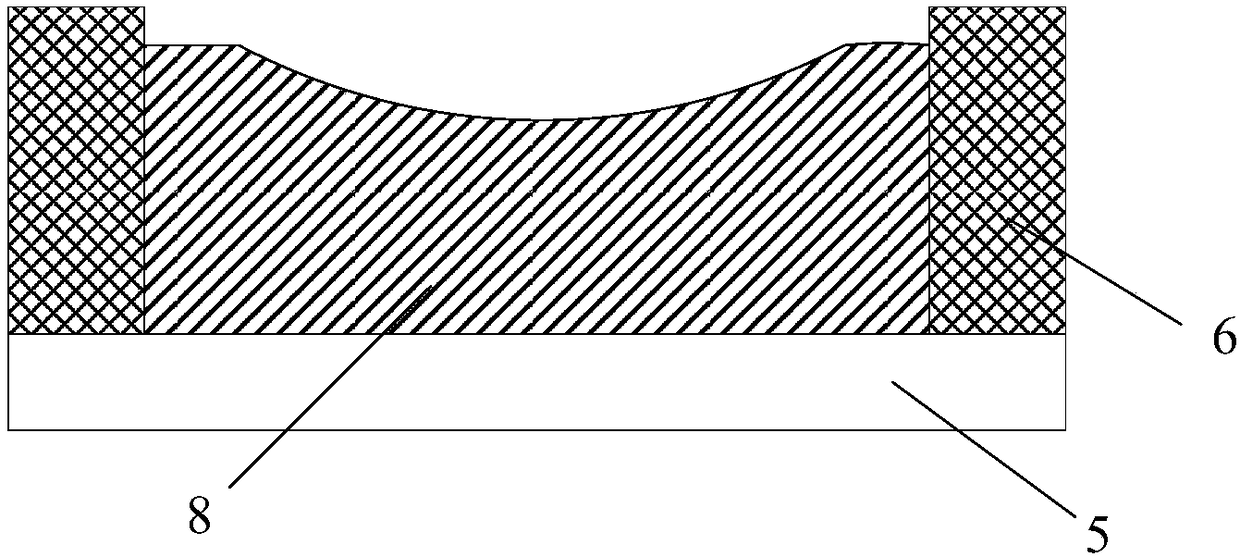

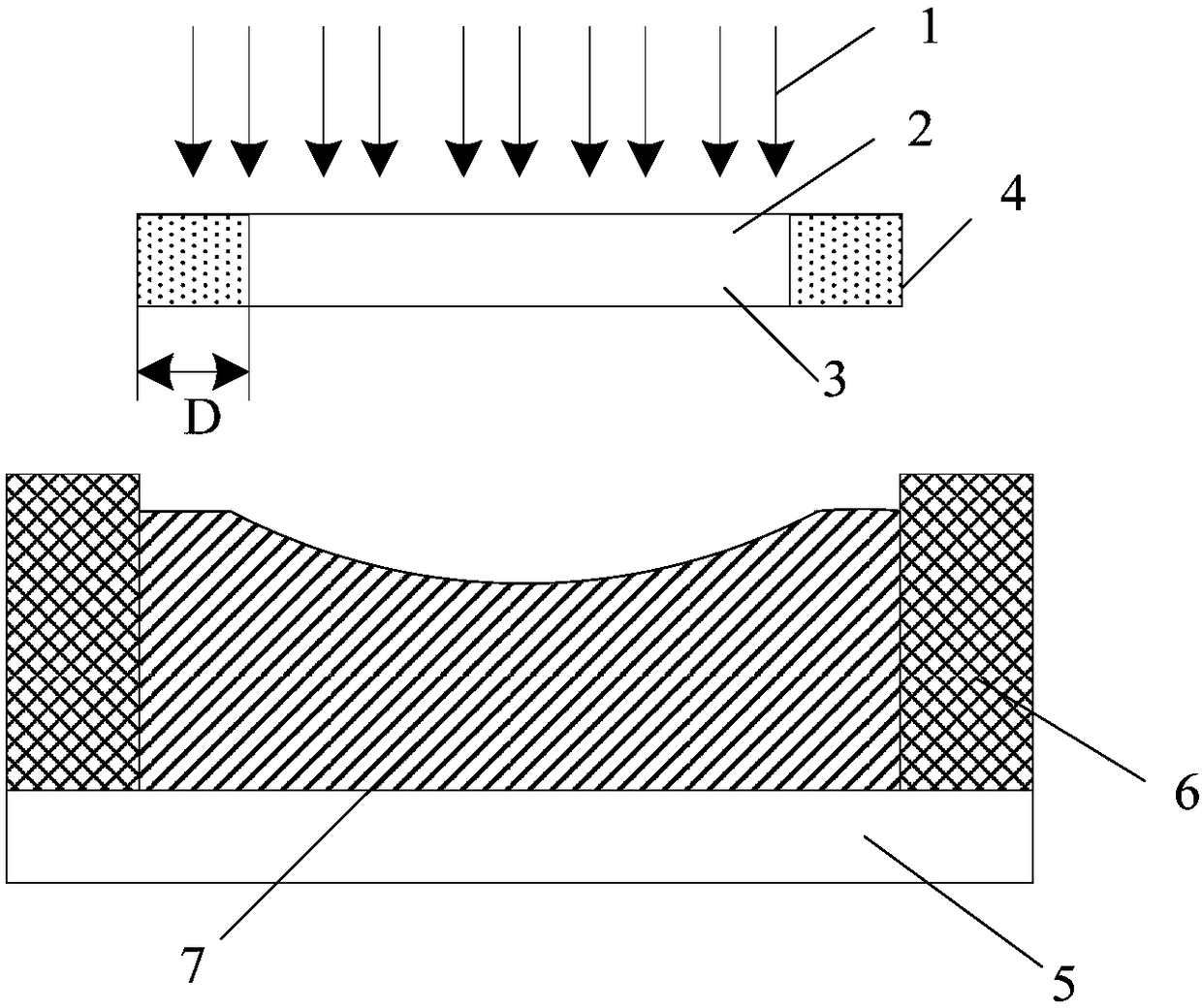

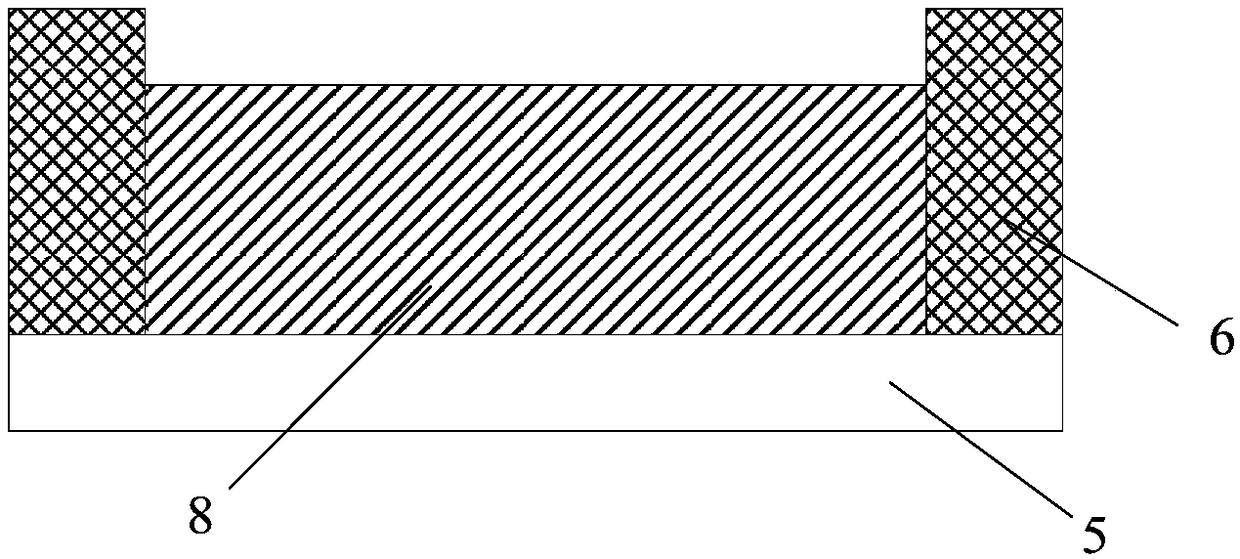

[0038] The formation of droplets in the inkjet printing process includes the process of droplet falling, spreading, and drying. After the droplet falls, the vapor pressure at the edge of the droplet is small, resulting in a faster evaporation rate of the solvent at the edge of the droplet, and the final solute is constantly in contact. The phenomenon that the thickness of the functional film layer at the peripheral part of the sub-pixel area deposited on the line is relatively large, and the thickness of the functional film layer at the middle part of the sub-pixel area is small, such as figure 1 This phenomenon is called the coffee ring effect. The coffee ring effect will make it difficult to ensure the flatness of the functional film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com