Multilayer printed wiring board

A multi-layer printing and circuit board technology, which is applied in the fields of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problems of increasing the rigidity of the insulating substrate, reducing the rigidity of the mounting substrate, and easily reducing the resistance, so as to prevent the conductor circuit from breaking or Disconnection, decrease in reliability reduction, effect of reducing reliability reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0133] (1) First, a circuit board as a unit constituting a multilayer printed circuit board is produced. This circuit board is a substrate that is the center of lamination among a plurality of insulating layers to be laminated. A prepreg sheet that is made into a B-stage by impregnating epoxy resin on glass cloth is laminated with copper foil and heated. The double-sided copper-clad laminate 10 obtained by pressing was used as a raw material (refer FIG. 9A).

[0134] The thickness of the insulating base material 12 is 60 μm, and the thickness of the copper foil 14 is 12 μm. If a copper foil thicker than 12 μm is used as the copper foil of the laminate, the thickness of the copper foil can also be adjusted to 12 μm by etching the copper foil.

[0135] (2) Carbon dioxide gas laser irradiation is performed on the double-sided circuit board 10 having the copper foil 14, and the copper foil 14 and the insulating base material 12 are penetrated to form the opening 16 for forming a ...

Embodiment 2

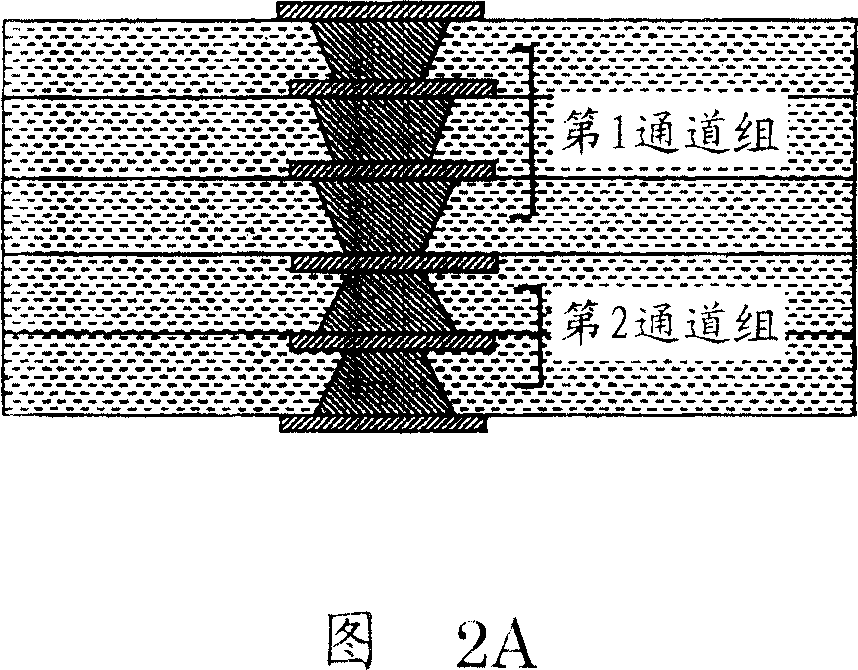

[0193] Each via hole constituting the first channel group and the second channel group formed on the insulating layer laminated on the surface and the back surface of the above-mentioned double-sided circuit board respectively, as shown in FIG. A multilayer printed wiring board was manufactured in substantially the same manner as in Example 1 except that the position was formed at a distance of about 1 / 2.

Embodiment 3

[0195] Each via hole that constitutes the first channel group formed on the above-mentioned double-sided circuit board and the insulating layer stacked above it, and the second channel group formed on the insulating layer stacked below the double-sided circuit board, as shown in the figure As shown in 3B, a multilayer printed wiring board was manufactured in substantially the same manner as in Example 1, except that the via hole diameters were substantially shifted from each other.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com