Laminar flow water cooling device and control method

A technology of cooling device and control method, which is applied in the directions of temperature control, metal rolling, manufacturing tools, etc., can solve the problems of wasting cooling water, reducing the temperature drop at the edge of strip steel, unfavorable production resource saving, etc., so as to ensure the plate shape, Avoid waste and reduce the effect of temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

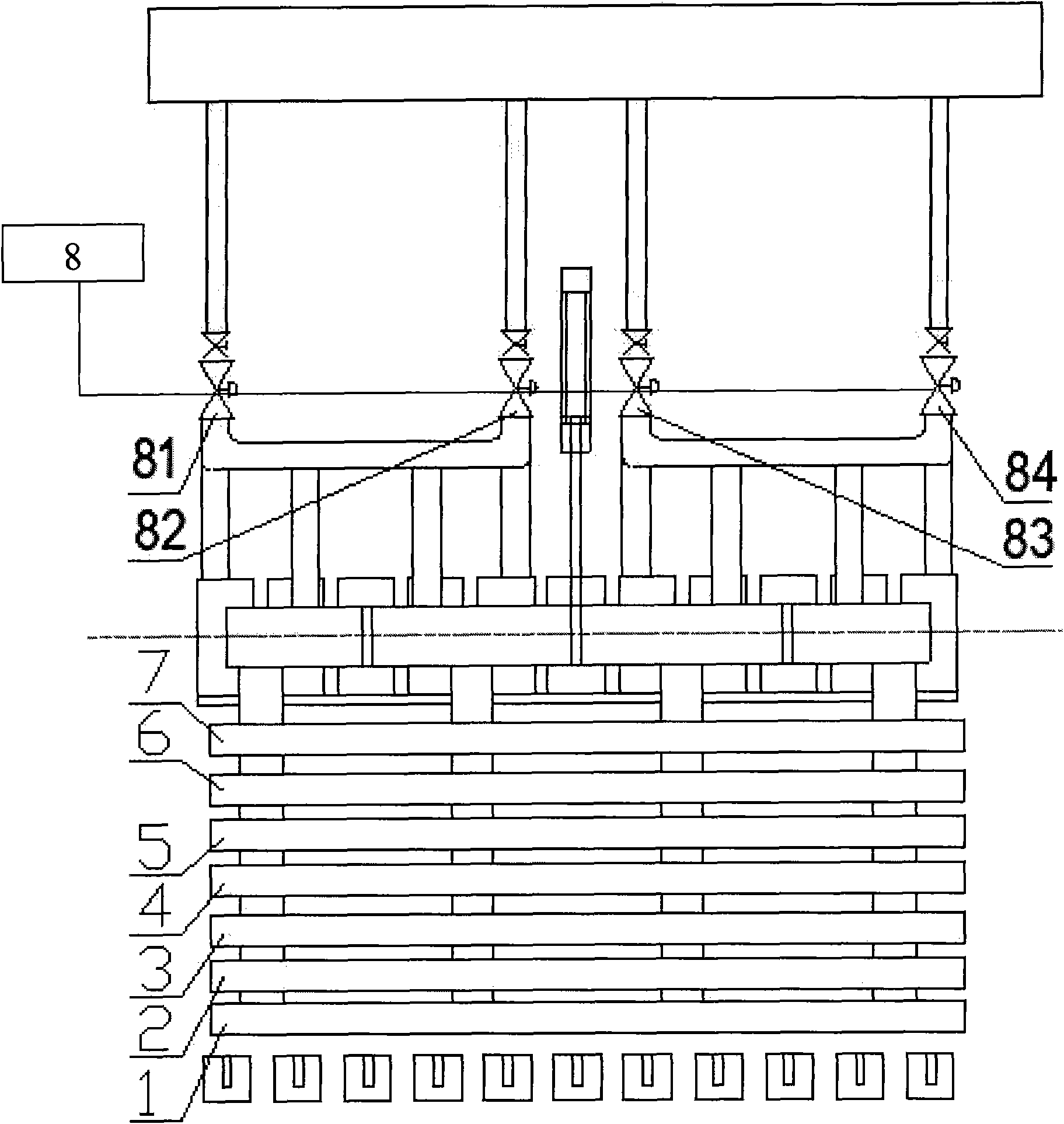

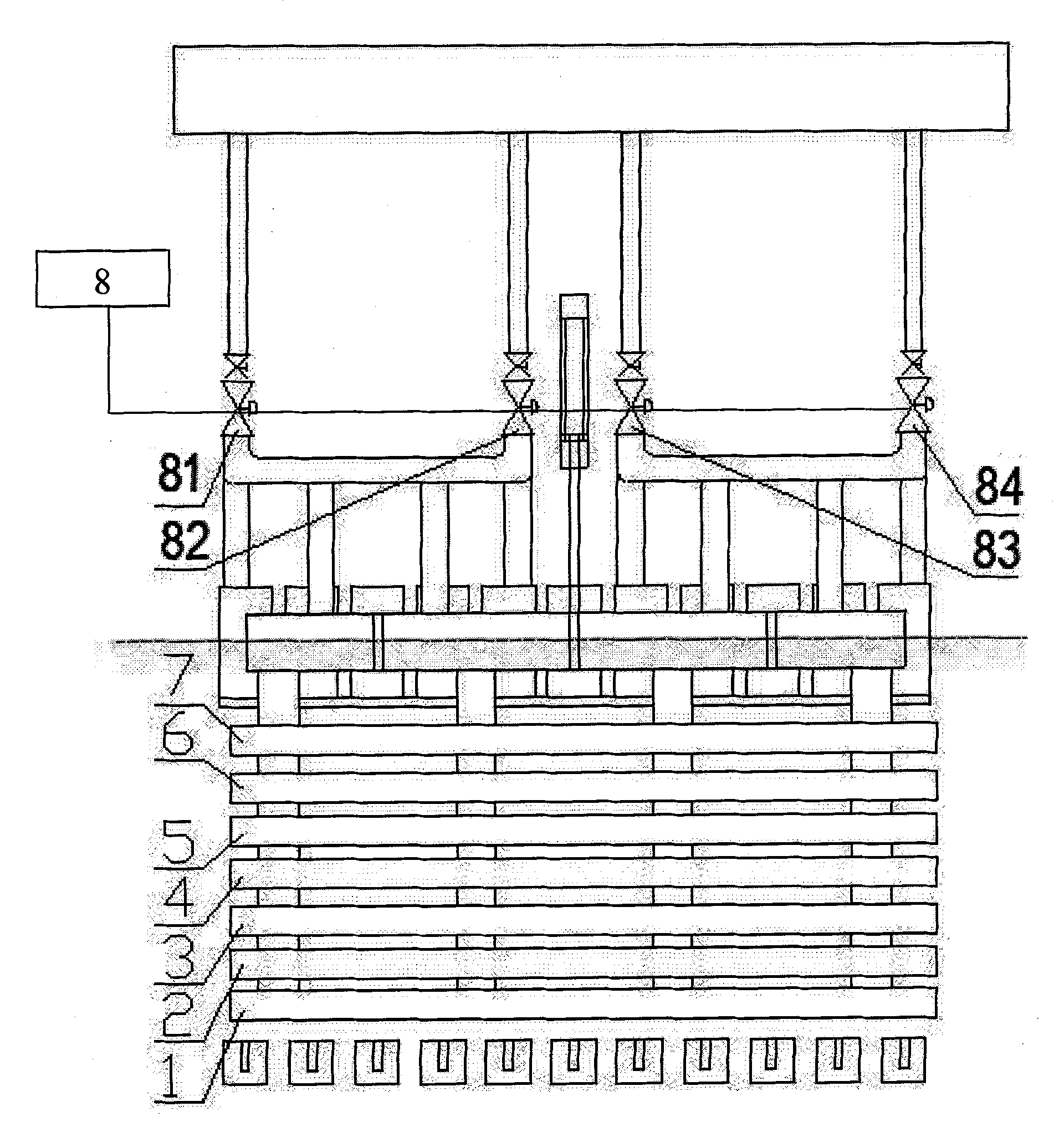

[0047] A preferred embodiment of the present invention will be specifically introduced below in conjunction with accompanying drawings 1-4.

[0048]As shown in Figure 1, the present invention is installed vertically on the steel strip advancing direction, and the water storage pipes 1-7 are equally spaced, and the central water storage pipe 4 is controlled by a water valve 81, and the water storage pipes 3, 5 is controlled by a water valve 82 at the same time, the water storage pipes 2 and 6 near the outside of the water storage pipes 3 and 5 are controlled by a water valve 83 at the same time, and the water storage pipes 1 and 7 near the outside of the water storage pipes 2 and 6 are simultaneously controlled by a water valve 84 . A control unit 8 is respectively connected to the water valves 81-84 to control the opening and closing of each water valve.

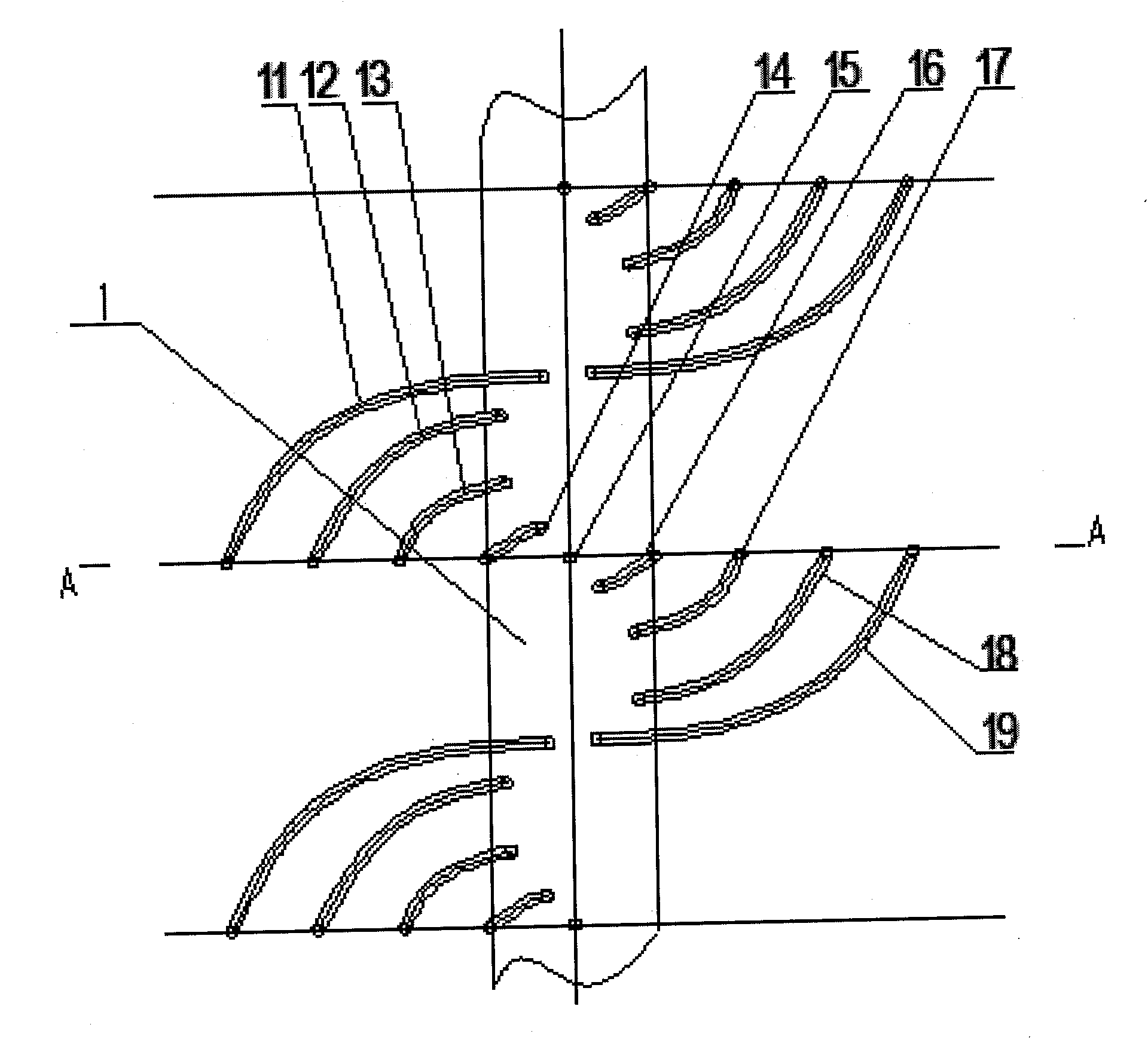

[0049] As shown in Figures 2 and 3, several groups of goosenecks are spirally connected on both sides of each water stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com