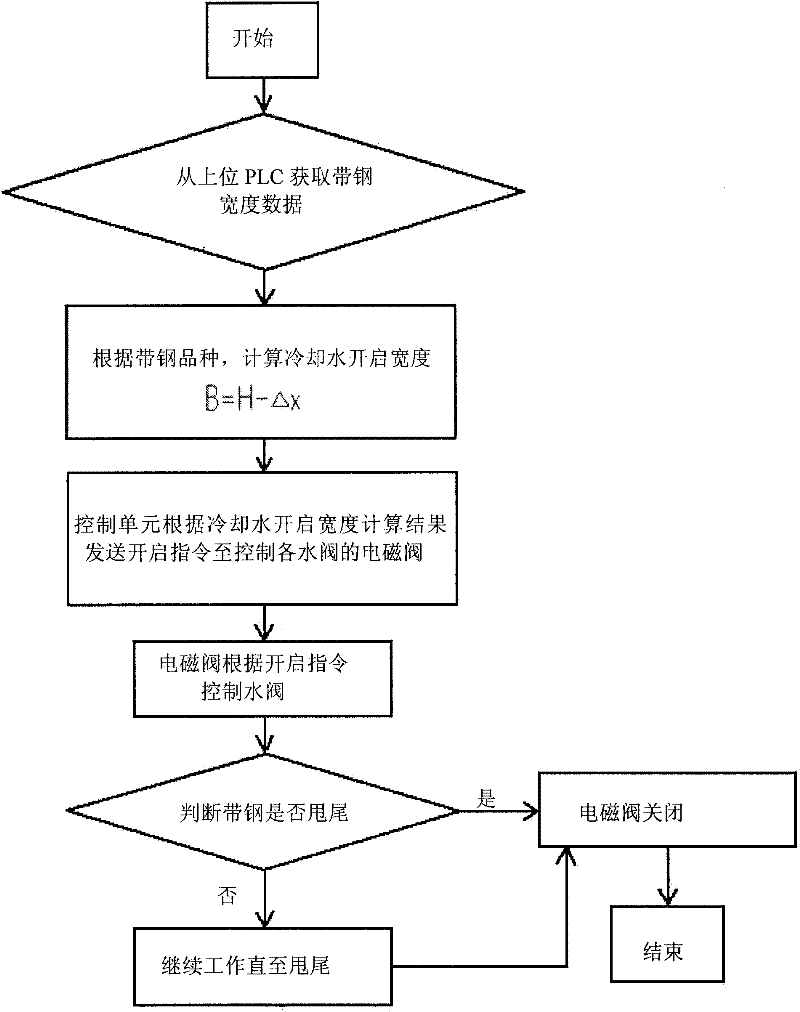

Laminar flow width-adjusting cooling device and control method thereof

A cooling device, laminar cooling technology, applied in the direction of spraying device, spraying device, rolling mill control device, etc., can solve the problems of waste of cooling water, unfavorable production resource saving, and reduce the temperature drop of the edge of the strip, so as to ensure the shape of the strip. , reduce temperature drop, avoid waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

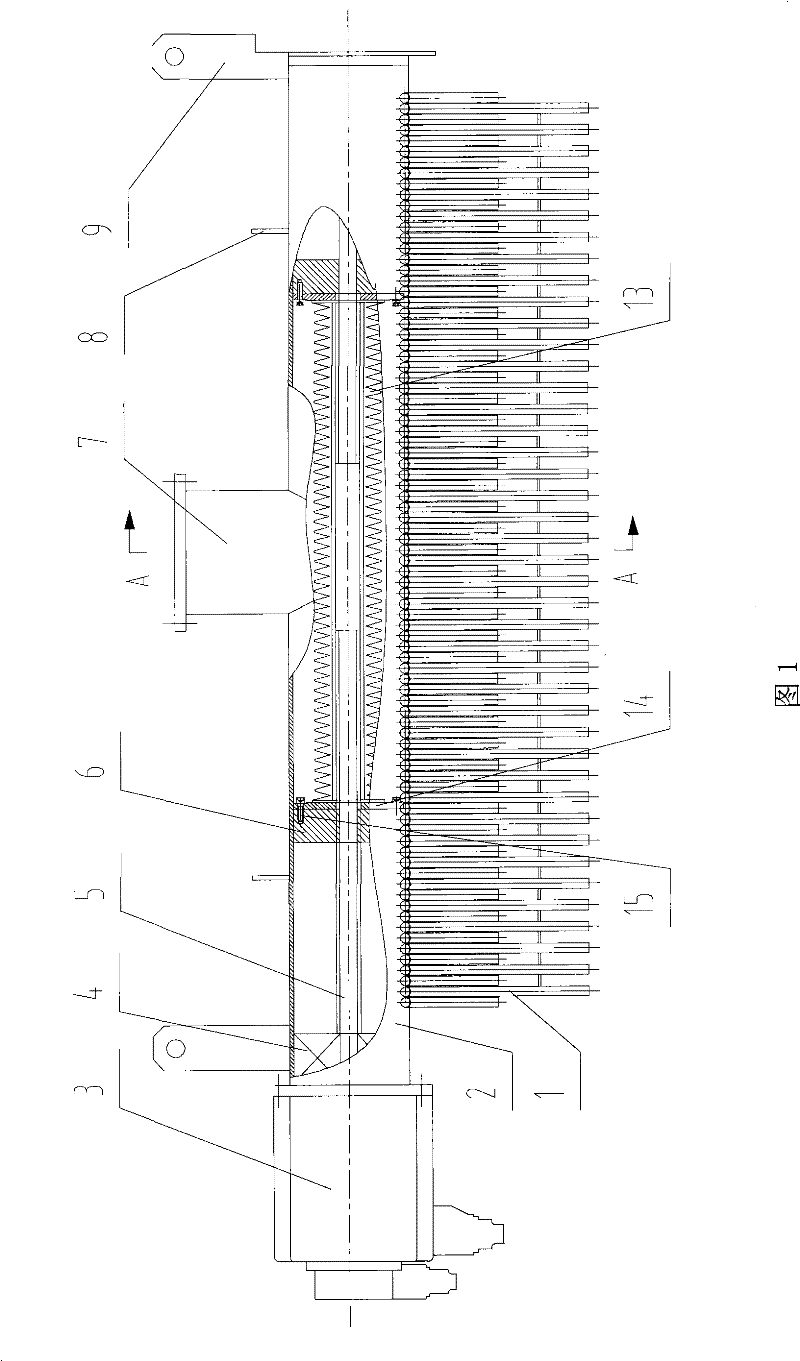

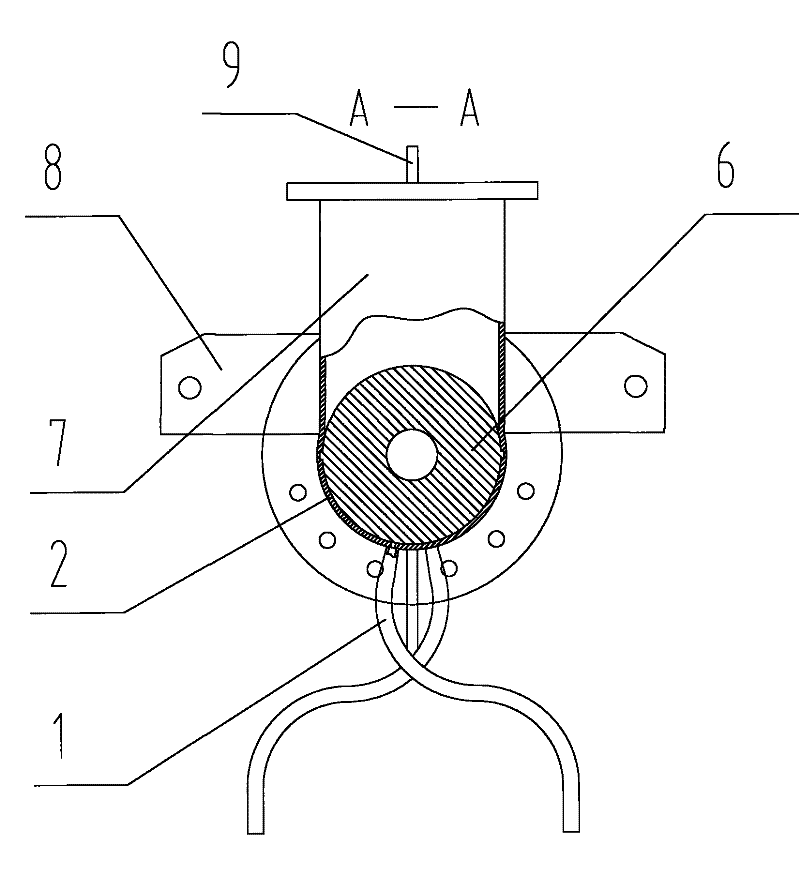

[0053] Such as figure 1 , 2 As shown, the laminar flow width adjustable cooling device of the present invention includes several groups of nozzle devices, each group of nozzle devices includes a header 2 fixedly arranged through a pair of mounting plates 9 along the vertical direction of strip steel running, and through the horizontal The reinforcing plate 8 enhances the stability of the nozzle device. The middle part of the header 2 is provided with a water inlet pipe 7, and a number of nozzles 1 are arranged on the header 2, which are evenly distributed on each header 2. The nozzles 1 are arranged at the bottom of the header 2 and arranged in the Straight line. The screw rod 5 is axially arranged in the center of the header pipe 2 through the bearing 4, and the screw rod 5 has double-ended reverse threads. The piston 6 is circular, and the outer diameter of the piston 6 matches the inner diameter of the manifold 2 . Two pistons 6 are arranged on the screw rod 5 respectiv...

Embodiment 2

[0057] Such as Figure 5 , 6 As shown, the laminar flow width adjustable cooling device of the present invention includes several groups of nozzle devices, and each group of nozzle devices includes a manifold 2 fixedly arranged through a pair of mounting plates 9 along the vertical strip running direction, and the middle part is arranged There are water inlet pipes 7, and a number of nozzles 1 are arranged on the headers 2, which are evenly distributed on each header 2. The nozzles 1 are arranged on the top of the headers 2, arranged in a staggered manner, and extend downward along the two sides of the headers 2. . The screw rod 5 is axially arranged in the center of the header pipe 2, and the screw rod 5 has double-ended reverse threads. The piston 6 is circular, and the outer diameter of the piston 6 matches the inner diameter of the manifold 2 . Two pistons 6 are arranged on the screw rod 5 respectively, and the pistons 6 have internal threads, which are connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com