Patents

Literature

42results about How to "Guaranteed low temperature impact toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Economic type diphasic stainless steel with good toughness and weldability and manufacturing method thereof

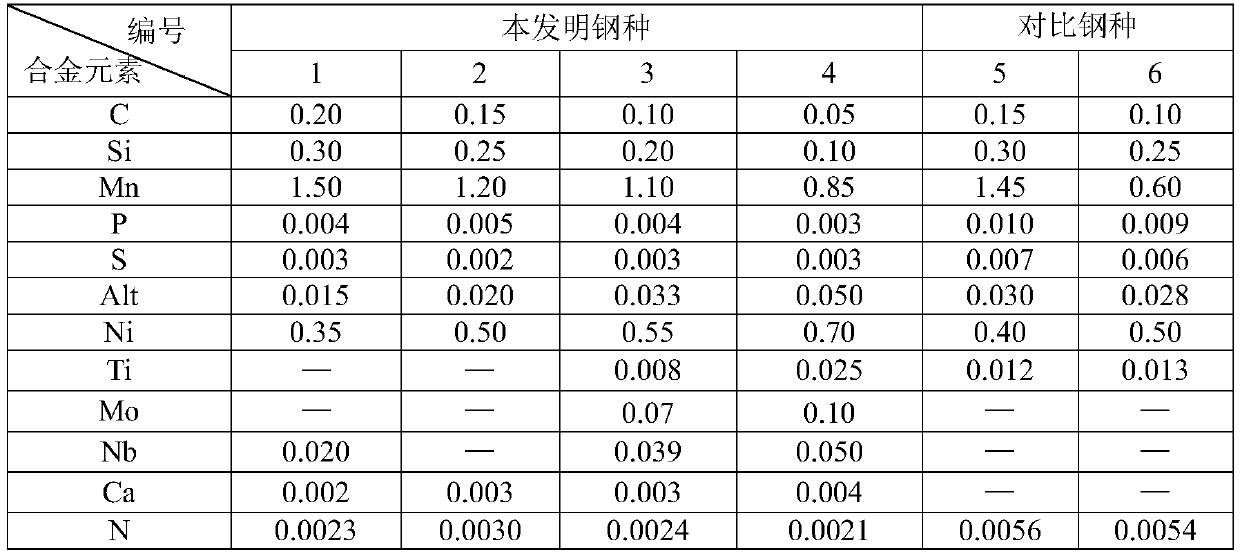

InactiveCN104131237ALow costGuaranteed low temperature impact toughnessHeat-affected zoneChemical composition

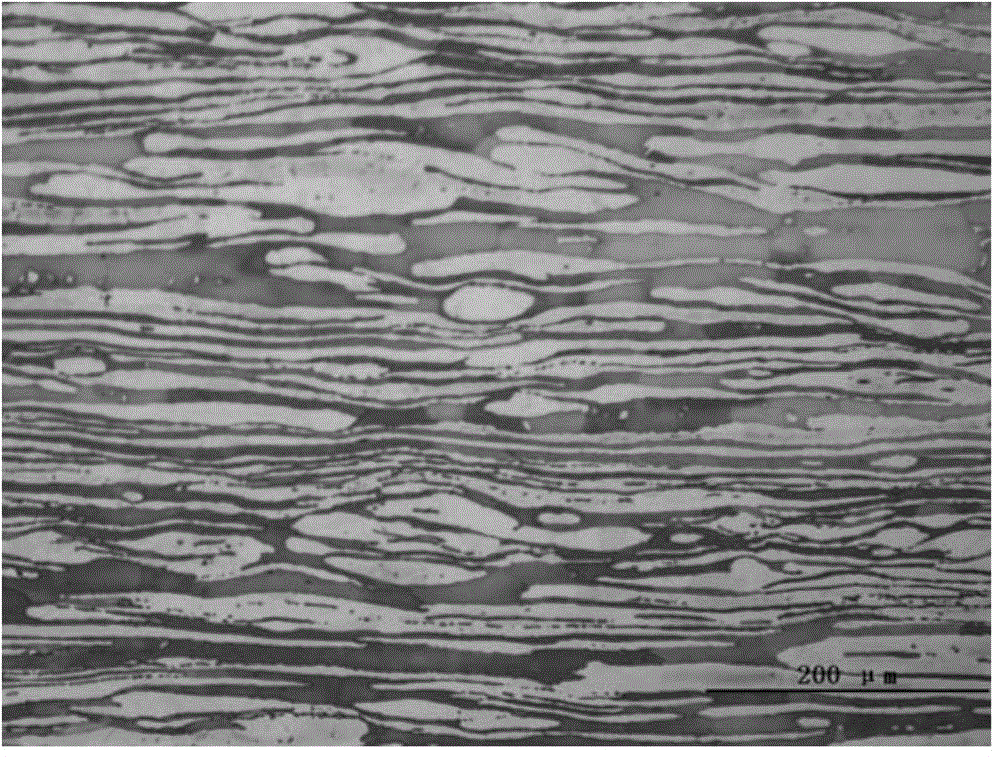

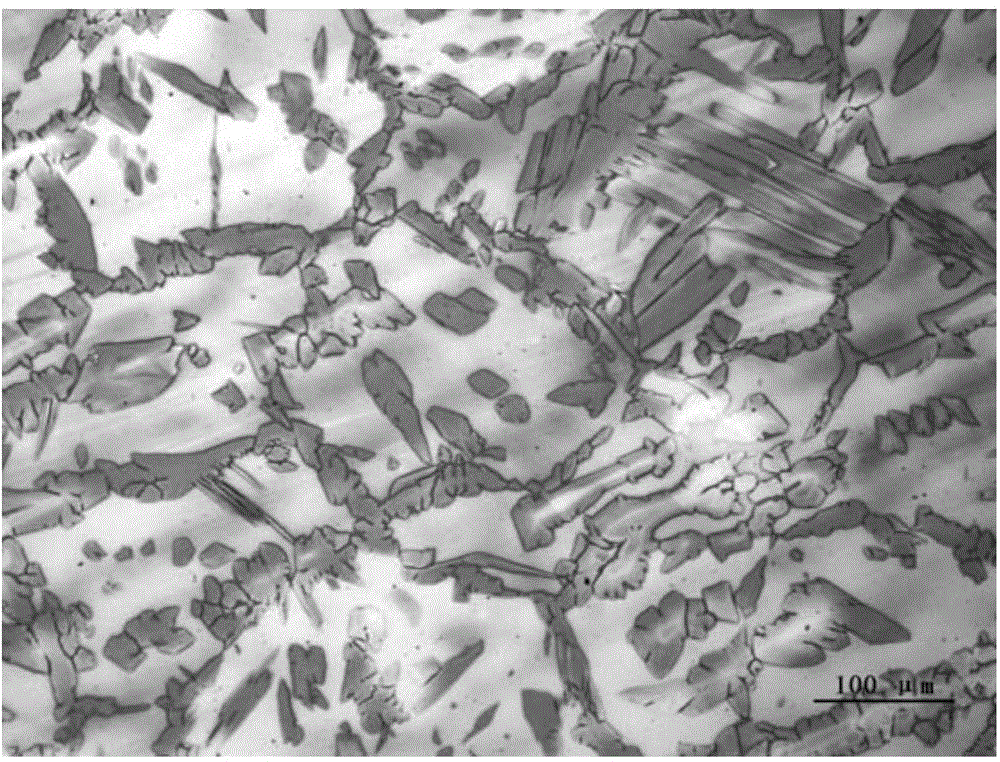

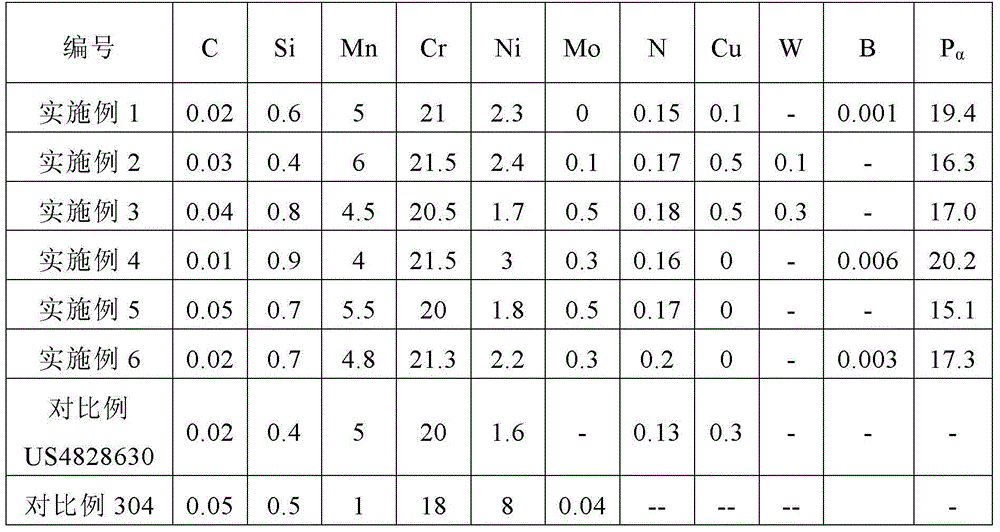

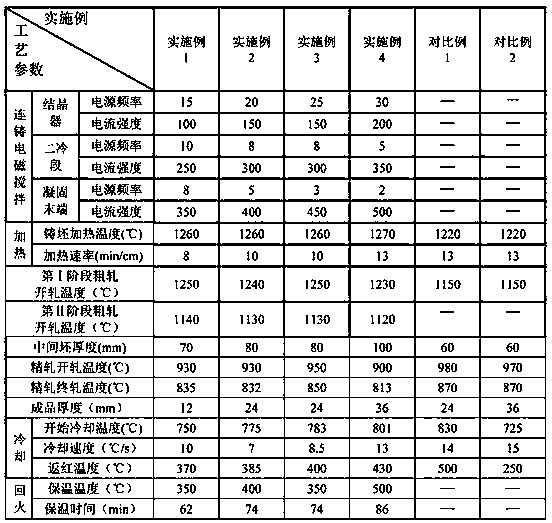

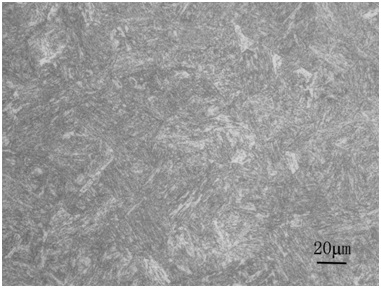

Disclosed are economic type diphasic stainless steel with good toughness and weldability and a manufacturing method thereof. The economic type diphasic stainless steel comprises the chemical components by the weight percentage: 0.01-0.05% of C, 0.2-1.0% of Si, 4.0-6.0% of Mn, 20.0-21.5% of Cr, 1.7-3.0% of Ni, 0.15-0.20% of N, not more than 0.5% of Mo, not more than 0.5% of W, not more than 0.5% of Cu, not more than 0.006% of B, and the balance Fe and inevitable impurities. The stainless steel mainly adopts 4.0-6.0% of Mn to replace Ni, at the same time, controls the contents of Mo and Cu in 0.5% or less, thereby significantly reducing alloy raw material costs; the content of Ni is controlled in 1.7-3.0%, the content of N is controlled in 0.15-0.2%, and the ferrite equivalent weight P[alpha] of a high-temperature heat affected zone is controlled in 20.5 or less, not only can the low temperature impact toughness of a parent metal be ensured, but also the good weldability can be obtained, and welded joints are allowed to have good low-temperature impact toughness. 304 austenitic stainless steel having the nickel content reaching up to 8% or more is replaced by the diphasic stainless steel under conditions of room temperature and low temperatures.

Owner:BAOSTEEL STAINLESS STEEL

Submerged arc welding flux and wire for welding ultra-low temperature high manganese steel and preparation methods

ActiveCN109530881ABeautiful weld shapeGood mechanical propertiesArc welding apparatusWelding/cutting media/materialsSlagSubmerged arc welding

The invention discloses a submerged arc welding flux for welding ultra-low temperature high manganese steel. The flux is prepared by the following components, by weight: 3-6 parts of SiO2, 30-50 partsof MgO, 30-40 parts of Al2O3, 10-20 parts of CaF2, 3-10 parts of TiO2, more than 0 and not more than 3.0 parts of Fe2O3, more than 0 and not more than 0.020 part of S and more than 0 and not more than 0.015 part of P. Compared with the prior art, the flux has the advantages of good welding processability, excellent slag removal, beautiful shape and better mechanical performance. The welding wireand flux of the invention can replace a nickel-based base material and welding material when welding ultra-low temperature high manganese having a manganese content of 13% or more and can meet the ultra-low temperature requirements of -196 DEG C.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

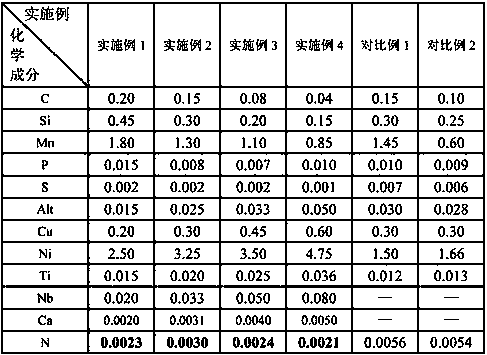

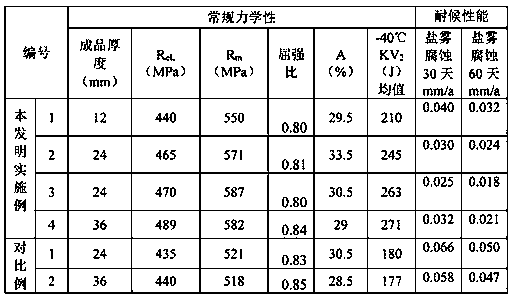

420 MPa grade low yield strength ratio resistance to marine atmospheric corrosion bridge steel and production method thereof

ActiveCN109136752AImprove low temperature impact toughnessImprove corrosion resistanceFurnace typesHeat treatment furnacesChemical compositionImpurity

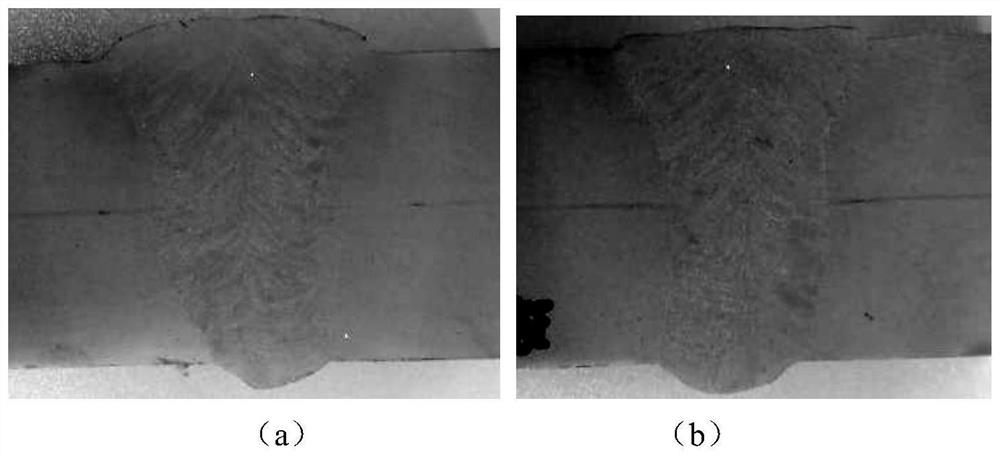

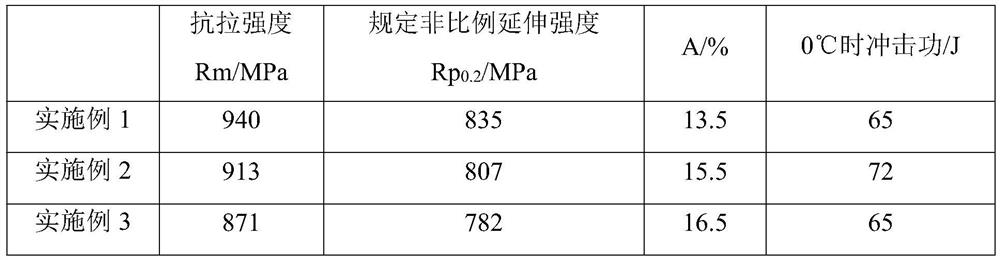

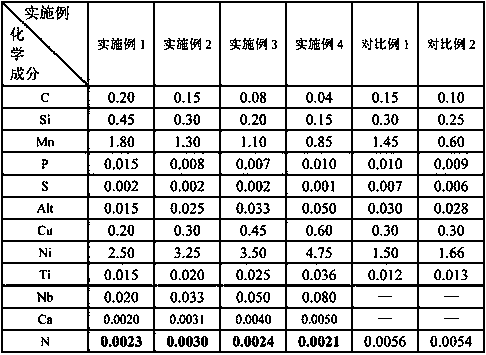

The invention discloses a steel 420MPa grade low yield ratio marine atmospheric corrosion resistant bridge and a production method thereof, the steel comprises the following chemical components in percentage by mass: 0.04-0.20% of C, 0.15-0.45% of Si, 0.85-1.80% of Mn, 0.015-0.050% of Alt, 2.50-4.75% of Ni, 0.20-0.60% of Cu, 0.020-0.080% of Nb, 0.015 to 0.036 percent of Ti, 0.0020 to 0.0050 percent of Ca, less than or equal to 0.020%of P, less than or equal to 0.002%of S, less than or equal to 0.004%of N and the balance of Fe and other inevitable impurities; after the steel of passes the composition design, the inclusion control, the controlled rolling , the controlled cooling and heat treatment, the steel has the advantages of high strength, low yield strength, and can be used for manufacturing various bridges under the ocean atmospheric environment, and the safety of use is greatly improved.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Submerged arc welding flux for welding SA-508Gr.3Cl.1 steel of third-generation nuclear power equipment and preparation method thereof

ActiveCN104551446ASimple welding processBeautiful shapeArc welding apparatusWelding/cutting media/materialsSlagNuclear power

The invention discloses a submerged arc welding flux for welding SA-508Gr.3Cl.1 steel of third-generation nuclear power equipment and a preparation method thereof. The submerged arc welding flux comprises the following components in parts by weight: 8-15 parts of SiO2 (silicon dioxide), 20-30 parts of MgO (magnesium oxide), 20-30 parts of CaF2 (calcium fluoride), 20-30 parts of Al2O3 (aluminum oxide), 6-10 parts of CaO (calcium oxide), 2-4 parts of MnO2 (manganese dioxide), 0.3-1 parts of BaO (barium oxide), 1-2 parts of rare earth oxides, 0.014-0.016 part of S (sulfur), 0.013-0.015 part of P (phosphor), and 22-24 parts of water glass. Compared with the prior art, the submerged arc welding flux has the advantages that the welding technological property is excellent, the slag removal property is excellent, the forming appearance is attractive, and the mechanical property is more excellent.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

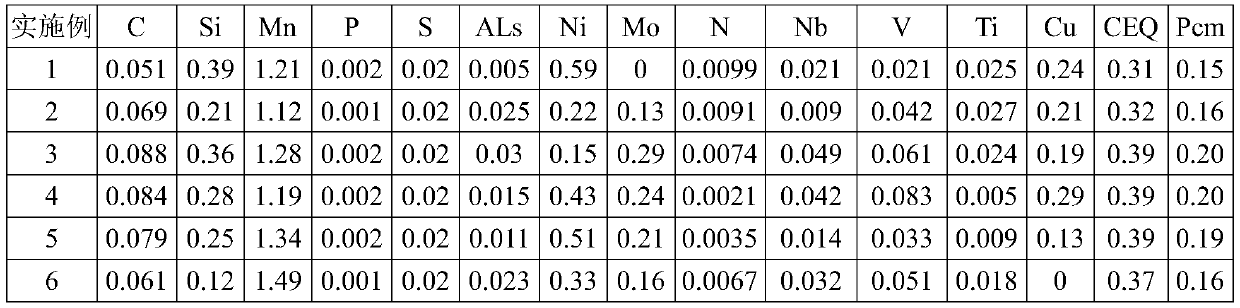

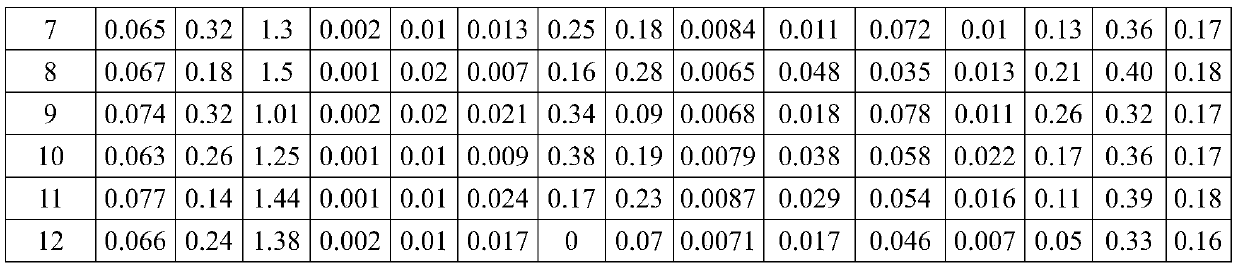

Low-yield-ratio marine steel plate with good welding performance and manufacturing method thereof

ActiveCN110791702ARaise the finishing temperatureHigh red temperatureMaterials preparationYield ratio

The invention belongs to the field of steel material preparation, and particularly relates to a low-yield-ratio marine steel plate with good welding performance and a manufacturing method thereof. Thelow-yield-ratio marine steel plate comprises the following components of, by weight, 0.05%-0.09% of C, 0.1%-0.4% of Si, 1.0%-1.5% of Mn, less than or equal to 0.02% of P, less than or equal to 0.02%of S, 0.005%-0.03% of Als, 0%-0.6% of Ni, 0%-0.3% of Cu, 0.008%-0.05% of Nb, 0.005%-0.03% of Ti, 0.002%-0.01% of N, 0.02%-0.08% of V, 0%-0.3% of Mo, and the balance Fe and inevitable impurities, wherein the yield ratio of the steel plate is less than or equal to 0.80, the carbon equivalent Ceq is less than or equal to 0.41, and Pcm is less than or equal to 0.21. According to the low-yield-ratio marine steel plate with the good welding performance and the manufacturing method thereof, a certain content of N element is added, and second phase dispersion precipitation of V, Ti element is matched,so that the high-heat input welding performance and the low-temperature impact toughness of the steel plate are improved; and chemical components and the processes of high finish rolling temperature,low water inlet high red returning temperature and low cooling speed are combined, so that the high service safety with the yield ratio being less than or equal to 0.8 can be obtained, and a corresponding production process is formed while the high-service safety steel plate which is easy to weld with high heat input is obtained.

Owner:ANGANG STEEL CO LTD

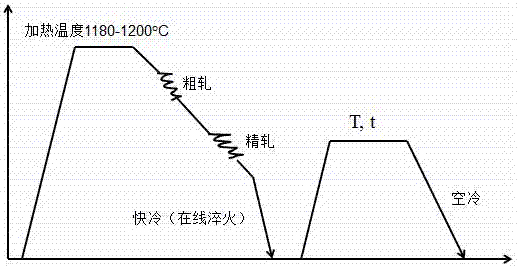

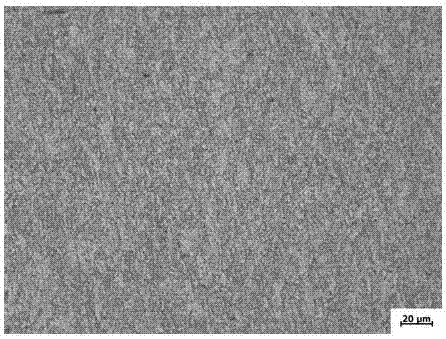

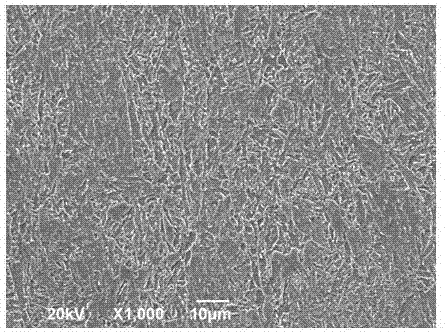

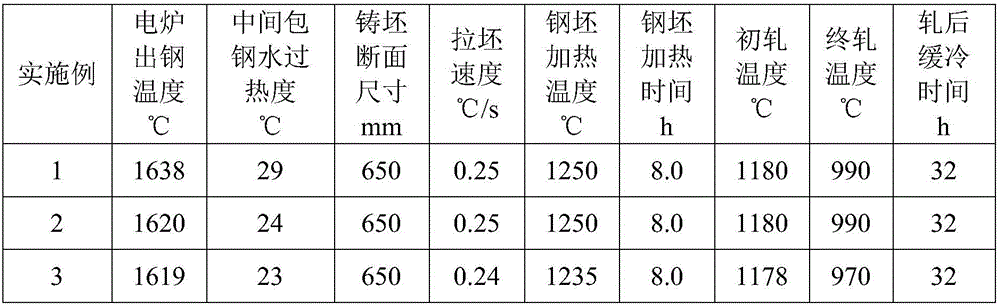

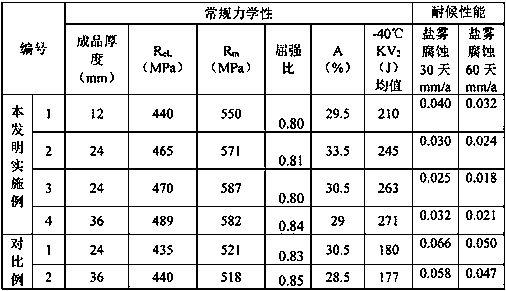

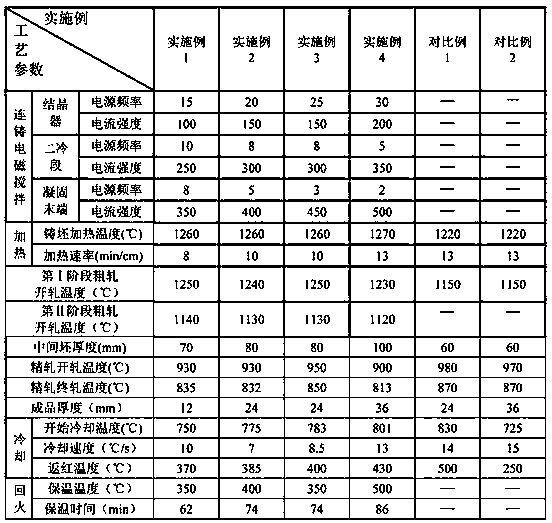

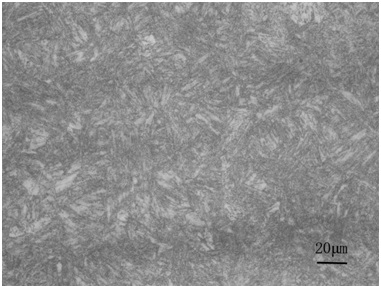

Production method for low-yield-ratio high-strength medium-thickness steel plate

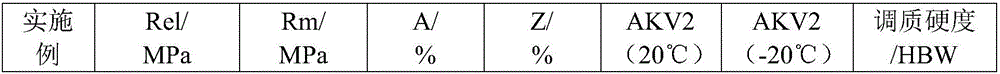

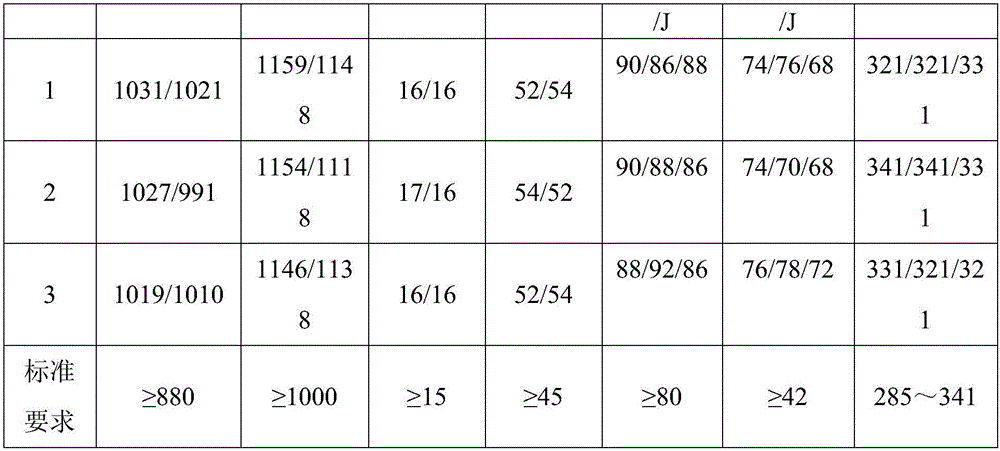

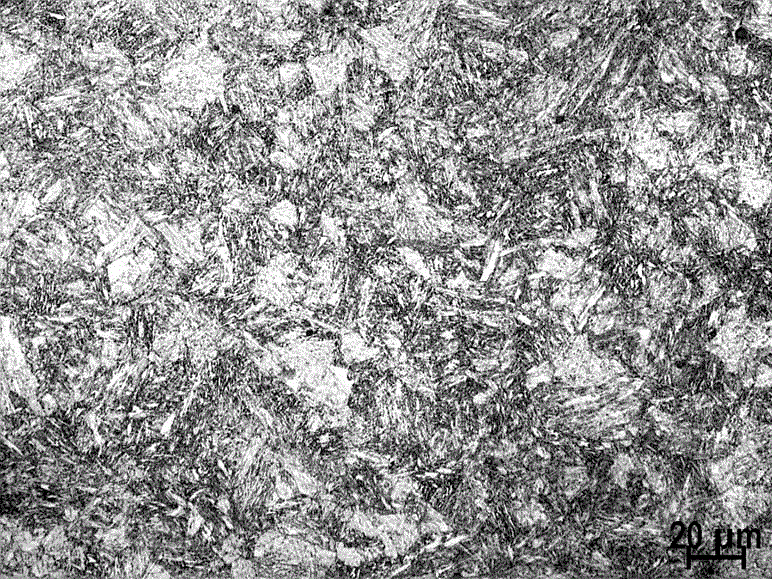

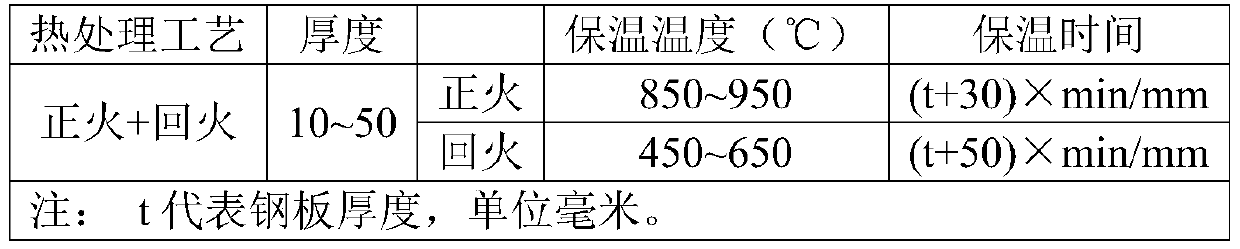

The invention discloses a production method of a low-yield ratio high-strength medium-thick steel plate. The chemical composition mass percentage of the steel is C=0.06-0.09, Si=0.2-0.4, Mn=1.3-1.8, Al=0.02-0.05, Cr=0.30~0.40, Nb≤0.05, Ti=0.015~0.025, Mo≤0.30, B≤0.0010, P<0.02, S<0.005, CEQ<0.45, Pcm<0.22, the process steps include rolling and heat treatment. The method of the present invention is used for rolling low-yield ratio high-strength medium-thick steel plates, especially high-strength steel medium-thick plates with a yield strength of 550 MPa for construction machinery, and finally obtains tempered strips through quenching and tempering process or TMCP+tempering process. The plate with bainite structure has a yield strength of more than 550MPa, a tensile strength of more than 680MPa, a yield ratio of less than 0.9, an elongation after fracture of more than 17%, and a full-thickness V-notch Charpy impact energy of more than 140J at -20°C. . And excellent performance after welding.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

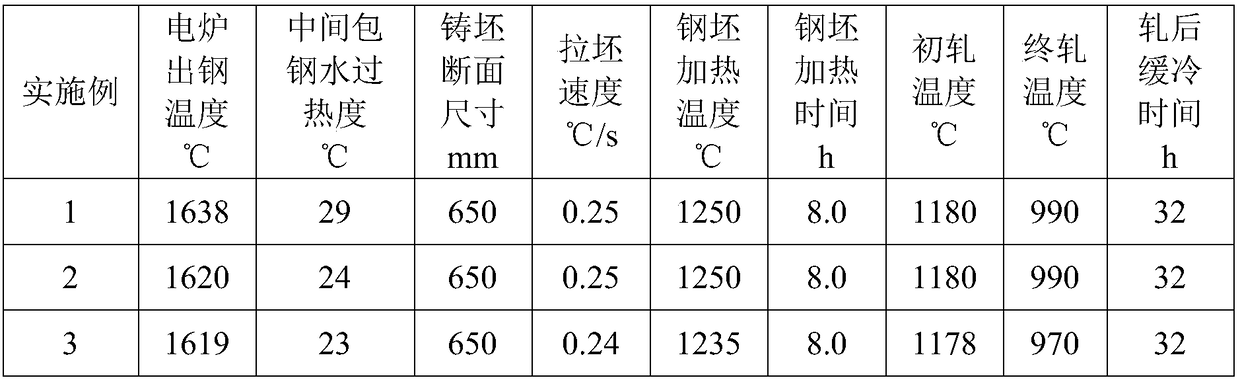

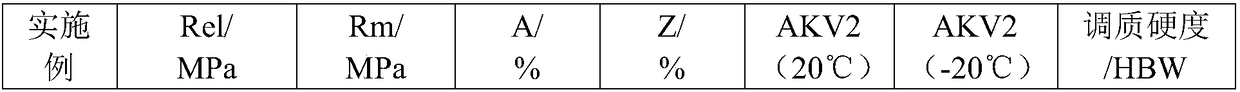

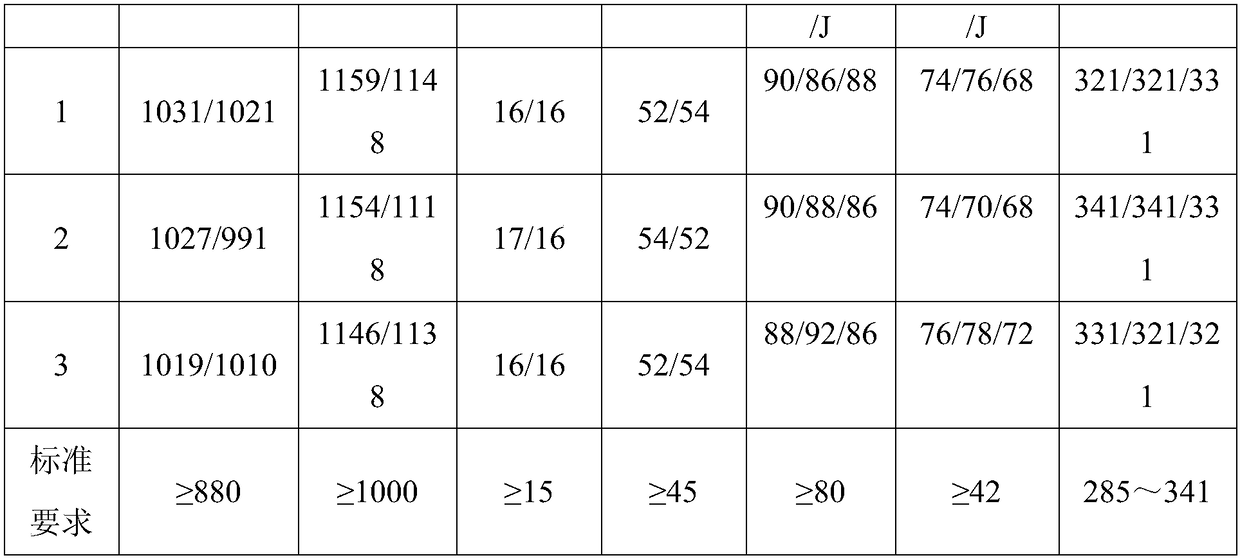

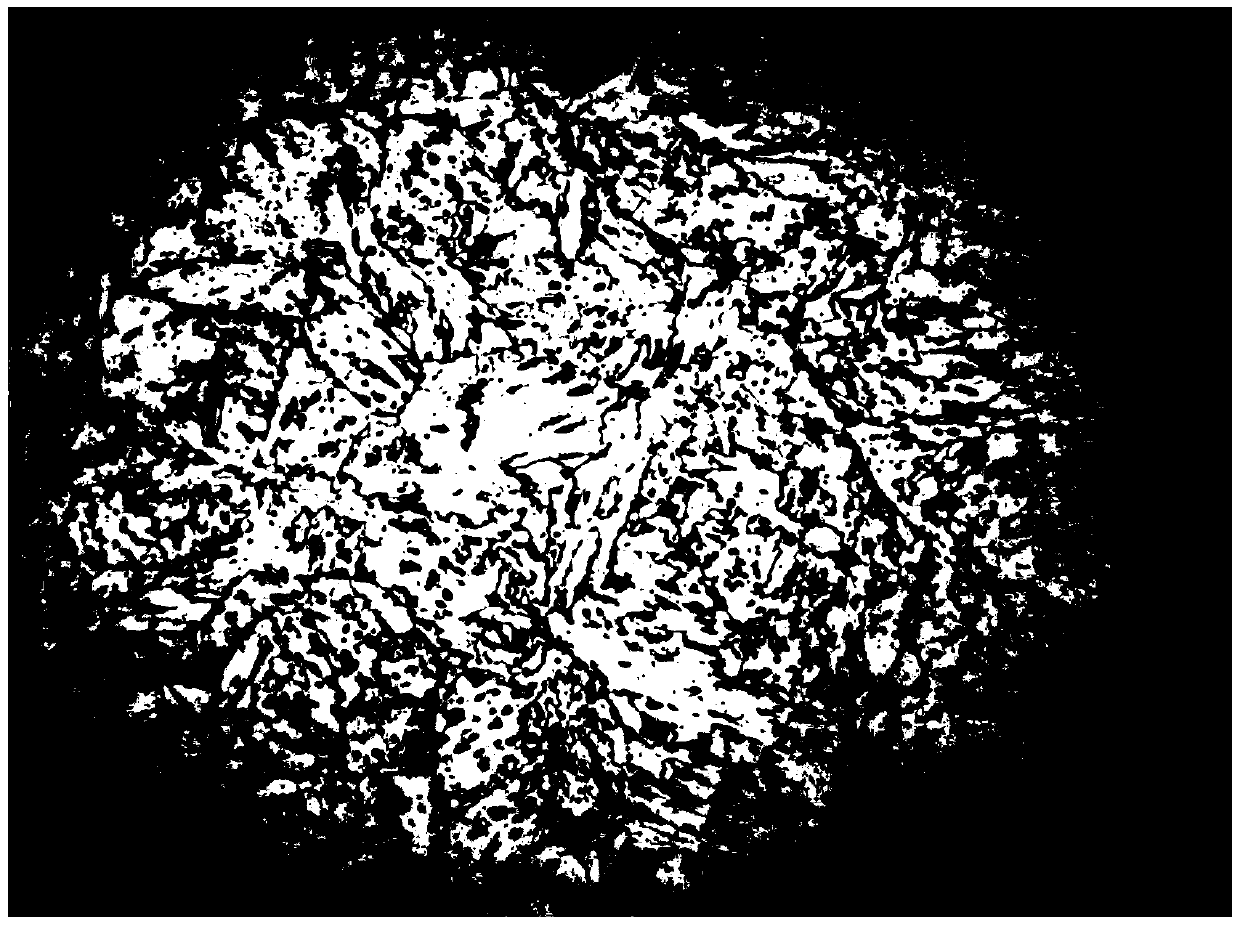

Ni micro-alloyed steel for petroleum drill collar and preparation method thereof

The invention discloses a Ni micro-alloyed steel for a petroleum drill collar and a preparation method of the Ni micro-alloyed steel. The Ni micro-alloyed steel for the petroleum drill collar comprises, by mass, 0.40%-0.48% of C, 0.15%-0.35% of Si, 1.00%-1.20% of Mn, 1.05%-1.30% of Cr, 0.20%-0.35% of Mo, 0.20%-0.40% of Ni, no more than 0.015% of P, no more than 0.010% of S and the balance iron and inevitable impurity elements. The preparation method of the Ni micro-alloyed steel comprises the procedures of smelting conducted through an electric furnace, external refining conducted through a ladle furnace, vacuum treatment conducted through a vacuum degassing furnace, continuous casting and rolling. The Ni micro-alloyed steel for the petroleum drill collar has good comprehensive mechanical performance and stable hardenability, and heat treatment stability is guaranteed. Because micro-alloying is achieved through the added Ni, the low-temperature impact toughness of the Ni micro-alloyed steel is improved.

Owner:SHANDONG IRON & STEEL CO LTD

High-hardenability and high-strength ultra-thick marine steel plate and production method thereof

The invention relates to a high-hardenability and high-strength ultra-thick marine steel plate. The high-hardenability and high-strength ultra-thick marine steel plate is 60-150 mm thick and is composed of the chemical components of, by weight percentage, 0.04-0.08% of C, 4-9% of Mn, 0.10-0.25% of Si, 0.01-0.03% of Als, 0.2-0.5% of Mo, 0.025-0.050% of Nb, less than or equal to 0.04% of S, less than or equal to 0.007% of P, and Fe and impurity elements as balance. The high-hardenability and high-strength ultra-thick marine steel plate can solve the phenomenon of non-uniformity of thickness direction texture and performance, expand the thickness specification to 150 mm with low-temperature toughness still meeting the operating requirements at -80 DEG C and obtain low yield ratio under equal yield strength conditions, specifically, the parts of 1 / 4 and 1 / 2 thickness of the steel plate reach a yield strength not lower than 690 MPa, a yield ratio not higher than 0.86, an elongation percentage not lower than 20%, and a -80 DEG C low-temperature impact energy greater than 100 J.

Owner:NANJING IRON & STEEL CO LTD

High-toughness low-yield ratio low-temperature steel for LPG ship storage tank and manufacturing method thereof

InactiveCN107974625ALow yield ratioGuaranteed low temperature impact toughnessSteel platesInclusion control

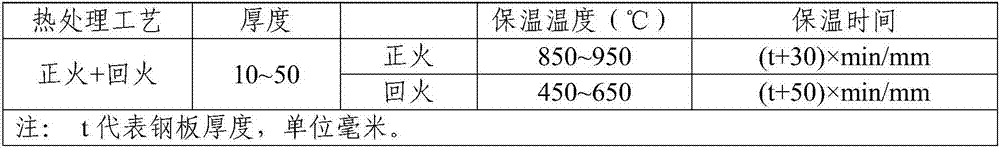

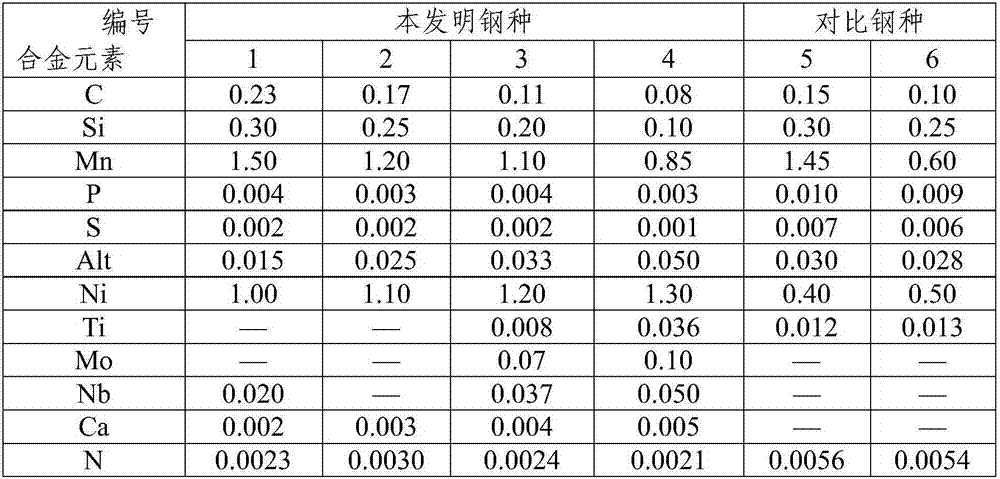

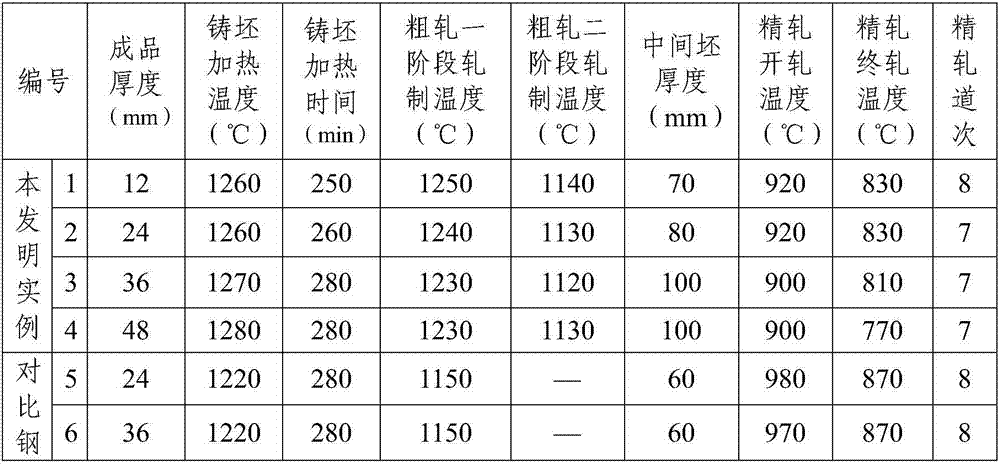

The invention belongs to the field of manufacturing of low alloy steel, and particularly relates to high-toughness low-yield ratio low-temperature steel for an LPG ship storage tank and a manufacturing method thereof. The low-temperature steel comprises the following raw material chemical components by mass percent: 0.08% to 0.23% of C, 0.30% or less of Si, 0.85% to 1.50% of Mn, 0.004% or less ofP, 0.002% or less of S, 0.015% to 0.050% of Alt, 1.00% to 1.30% of Ni and 0.004% or less of N, and further comprises at least one of 0.10% or less of Mo, 0.05% or less of Nb, 0.036% or less of Ti and0.005% or less of Ca, and the balance being Fe and unavoidable impurities. The method for manufacturing the low-temperature steel comprises a steel-making technology, a steel rolling technology and aprocessing and thermal treatment technology. According to the high-toughness low-yield ratio low-temperature steel, through component design, inclusion control, rolling and thermal treatment, a steelplate has excellent low-temperature toughness and good welding performance, the yield ratio is relatively low, the steel plate can be utilized to manufacture the storage tank for an LPG ship, and utilization safety performance is greatly improved.

Owner:武汉钢铁有限公司

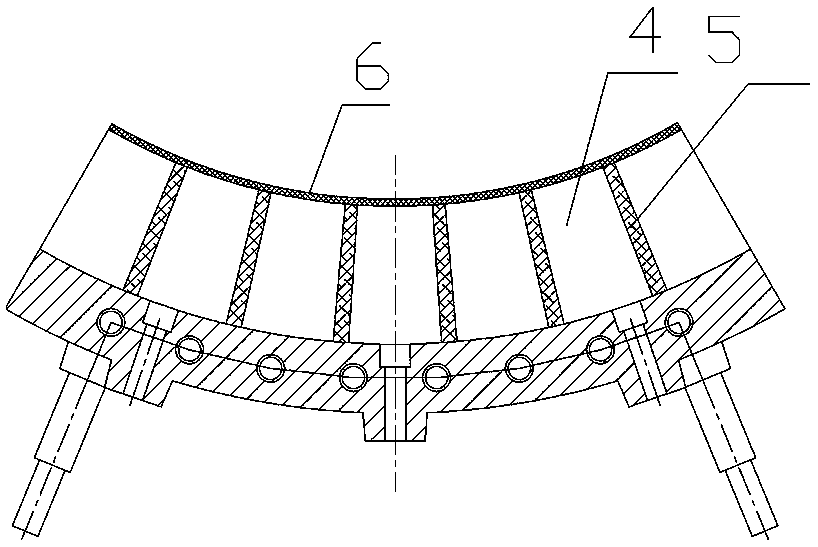

Soldering flux for submerged arc horizontal position welding of steel containment, preparation method and welding method

InactiveCN103737192ASimple welding processBeautiful shapeArc welding apparatusWelding/cutting media/materialsNuclear powerSlag

The invention relates to a soldering flux and discloses a soldering flux for submerged arc horizontal position welding of a steel containment. The soldering flux for submerged arc horizontal position welding of the steel containment comprises the following components of, by mass, 6-18% of SiO2, 22-40% of MgO, 12-28% of Al2O3, 15-30% of sigma CaO, 0.5-4% of MnO, 0.5-2% of Na2O, 0.2-2% of K2O, 0<TiO2<=3%, 0<Fe2O3<=3.0%, 0<S<=0.030%, and 0<P<=0.030%. Compared with soldering fluxes in prior art, the submerged arc soldering flux for submerged arc horizontal position welding of the steel containment is special for welding the steel containment for nuclear power and has the advantages of good welding manufacturability, slag removal effects and mechanical properties and attractive shaping.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

K65 control-rolled steel plate and longitudinal submerged arc welded pipe used in frigid zone and manufacturing method of longitudinal submerged arc welded pipe

ActiveCN105624584AGuaranteed low temperature impact toughnessImprove low temperature impact toughnessArc welding apparatusSteel tubeSteel plates

The invention discloses a K65 control-rolled steel plate and a longitudinal submerged arc welded pipe used in a frigid zone and a manufacturing method of the longitudinal submerged arc welded pipe, and belongs to the technical field of manufacturing of submerged arc welded pipes. The K65 control-rolled steel plate comprises the following various components in percentages by mass: 0.04-0.08% of C, 1.50-1.75% of Mn, 0.20-0.35% of Si, less than or equal to 0.006% of S, less than or equal to 0.010% of P, less than or equal to 0.23% of Ni, less than or equal to 0.009% of Mo, less than or equal to 0.020% of Ti, 0.025-0.050% of Al, 0.06-0.09% of Nb, less than or equal to 0.01% of N, less than or equal to 0.25% of Cu, 0.10-0.30% of Cr, less than or equal to 0.0005% of B, 0.085-0.224% of V+Nb+Ti, and the balance Fe; Ceq is less than or equal to 0.43, and Pcm is less than or equal to 0.20; and in a microscopic structure of the K65 control-rolled steel plate, the content of bainite is 45-65%, and the content of ferrite is 35-55%. Alloy ingredients and rolling technology parameters of the K65 control-rolled steel plate are optimized, so that the K65 control-rolled steel plate has good low-temperature impact toughness and DWTT performance, and is suitable for manufacturing a K65 steel longitudinal submerged arc welded pipe which is used in the frigid zone, and has the diameter phi equal to 1,422 mm and the wall thickness being 23-27.7 mm, and safe use of the steel pipein the frigid zone is ensured.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

High-strength high-tenacity rare earth-containing steel material for Z-type steels

InactiveCN102392196AHigh strengthGuaranteed low temperature impact toughnessNiobiumAtmospheric corrosion

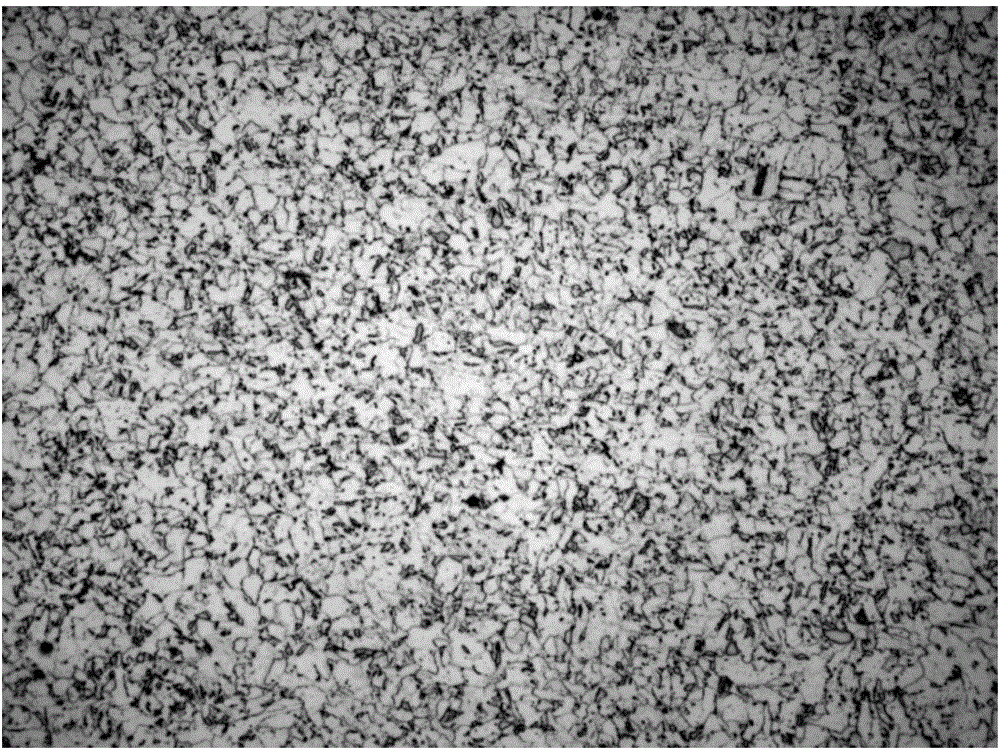

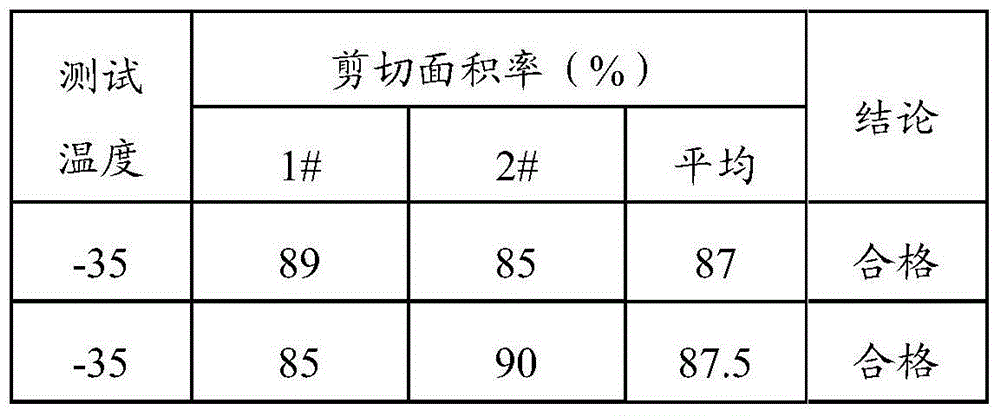

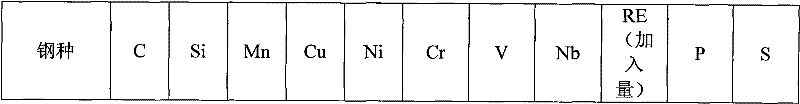

The invention relates to a high-strength high-tenacity rare earth-containing steel material for Z-type steels, which is characterized by comprising the following components in percentage by weight: 0.06-0.12% of carbon, 0.20-048% of silicon, 1.20-1.65% of manganese, 0.2-0.4% of copper, 0.2-0.4% of nickel, 0.2-1.0% of chromium, 0.03-0.14% of vanadium, 0.020-0.055% of niobium, 0.02-0.04% of rare earth, less than or equal to 0.025% of phosphorus, less than or equal to o.o15% of sulfur and the rest of iron and unavoidable impurities. The high-strength high-tenacity rare earth-containing steel material for Z-type steels has the advantages of being reasonable in composition proportion, integrating a plurality of excellent properties such as high strength, atmospheric corrosion resistance, favorable low-temperature impact tenacity, favorable welding property and the like and according with the mechanical property requirements of Z-type steels.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Manufacturing method of marine 5Ni steel plate with low remanence and excellent surface quality

ActiveCN111440990AGuaranteed hardenabilityGuaranteed low temperature impact toughnessFurnace typesQuenching agentsTemperingSurface cleaning

The invention relates to a manufacturing method of a marine 5Ni steel plate with low remanence and excellent surface quality. The technological process is converter smelting -> LF refining -> RH highvacuum degassing -> Ca treatment -> continuous casting -> casting blank slow cooling treatment -> casting blank surface cleaning -> heating -> rolling -> quenching twice -> tempering. According to component design, low carbon, low silicon and 5% of Ni are adopted, and V and Nb are added, so that hardenability is improved, low-temperature toughness is improved, austenitic amorphous starting temperature is raised, the steel plate can be subjected to high-temperature rolling and high-temperature quenching, then the shape of the steel plate is remarkably improved, and the steel plate is suitable for production of thin specification products. According to the manufacturing method, optimization is performed from the perspectives of element design, technology control, base material organization,center segregation, quenching and tempering temperature and time and the like, and therefore it is guaranteed that the steel plate has good ductility, -130 DEG C low-temperature impact toughness, excellent surface quality and low remanence while high strength of the 5Ni steel plate is realized.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

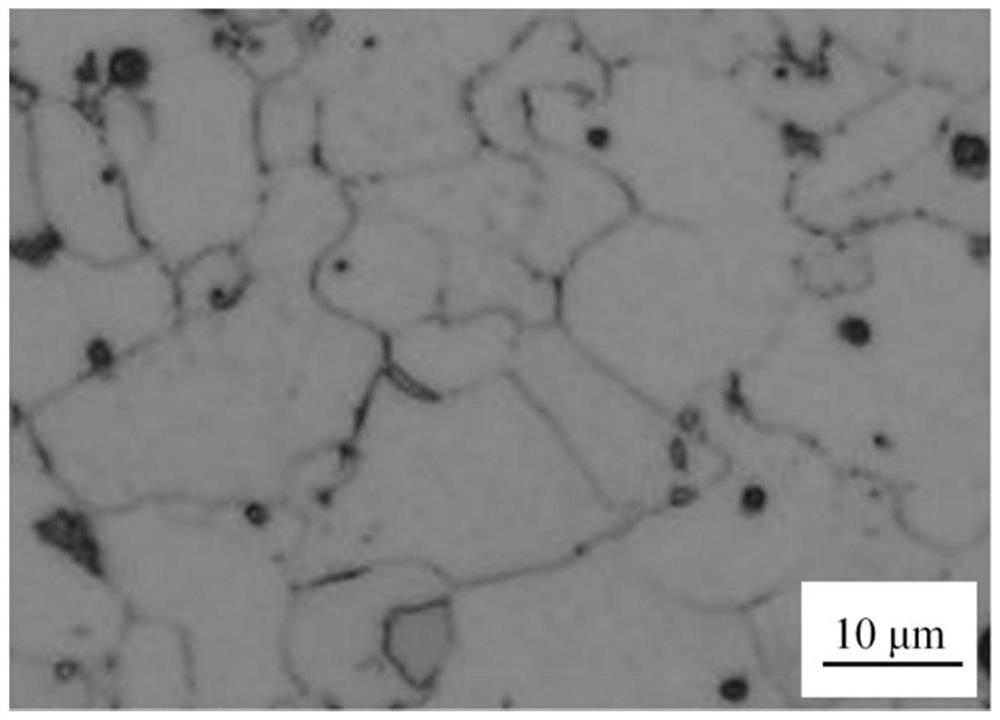

Manufacturing method of ultra-large-section low-temperature high-toughness ferrite spheroidal graphite iron casting

ActiveCN108866427AMeet technical requirementsShorten the setting timeFoundry mouldsFoundry coresNuclear powerDuctile iron

The invention discloses a manufacturing method of an ultra-large-section low-temperature high-toughness ferrite spheroidal graphite iron casting. The spheroidal graphite iron casting is more than 50 tons in weight, is 400mm or more in wall thickness, and is prepared from the following components: 3.6 to 3.7 percent of C, 0.9 to 1.0 percent of Si<original>, 1.9 to 2.0 percent of Si<final>, less than or equal to 0.1 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.01 percent of S, 0.03 to 0.08 percent of Mg, 0.01 to 0.02 percent of RE, 0.6 to 0.8 percent of Ni and0.003 to 0.005 percent of Sb. During manufacturing, the technical measures of ''high-temperature pure base iron melt, water-cooled metal mold, cold iron, spheroidizing agent 5800, compound strengthening inoculation, alloying and low-temperature box beating'' are adopted, so that the prepared ultra-large-section low-temperature high-toughness ferrite spheroidal graphite iron casting can meet the quality standard of a spheroidal graphite iron casting of which the license number is QT400-18, and can meet the technical requirements of ultra-large-section spheroidal graphite iron castings applied to wind power, nuclear power and the like.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Steel plate with thickness of S355G10+N for marine structure and production method thereof

ActiveCN111455271AImprove low temperature toughnessGood welding performanceChemical compositionToughness

The invention discloses a steel plate with a thickness of S355G10+N for a marine structure, and relates to the technical field of steel smelting. The maximum thickness of the steel plate is 150 mm. The chemical composition comprises, by mass percentage, 0.08%-0.14% of C, 1.30%-1.65% of Mn, 0.10%-0.50% of Si, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.015%-0.030% of Nb,less than or equal to 0.03% of V, 0.10%-0.020% of Ti, 0.020%-0.055% of Alt, 0.10%-0.50% of Ni, less than or equal to 0.43% of CEV, less than or equal to 0.21% of Pcm and balance of Fe and unavoidableimpurities. The 150mm extra-thick steel plate has excellent low temperature toughness, especially the impact is greater than 100J at -40 DEG C at 1 / 2 thickness, the welding performance is good, and the use and service requirement of an offshore structure are better met.

Owner:NANJING IRON & STEEL CO LTD

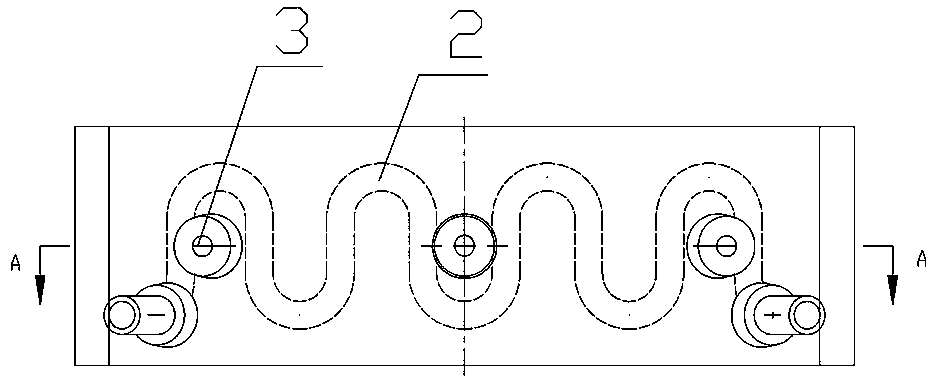

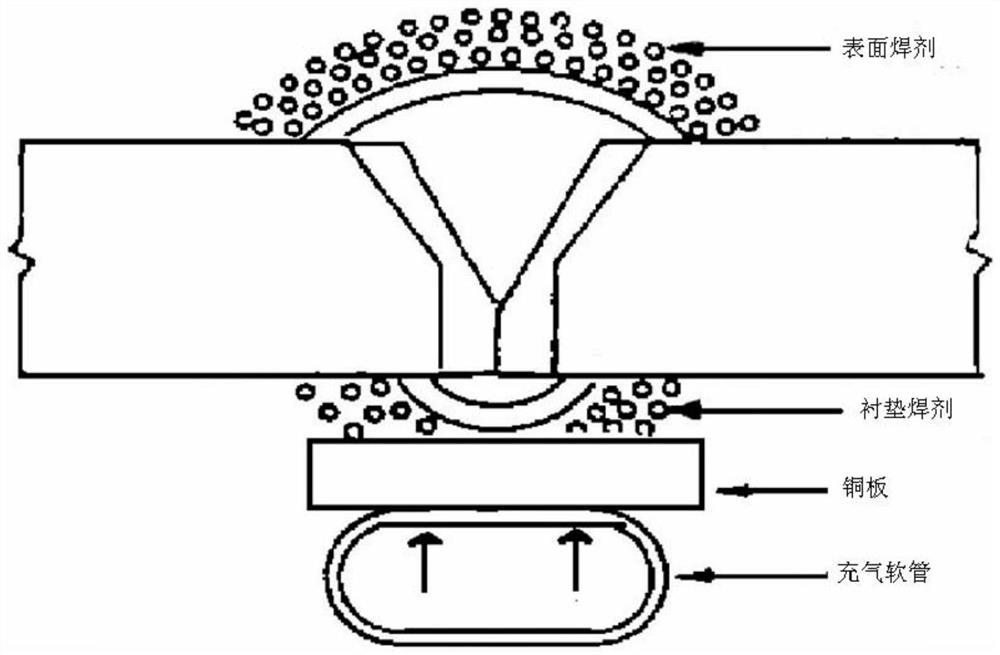

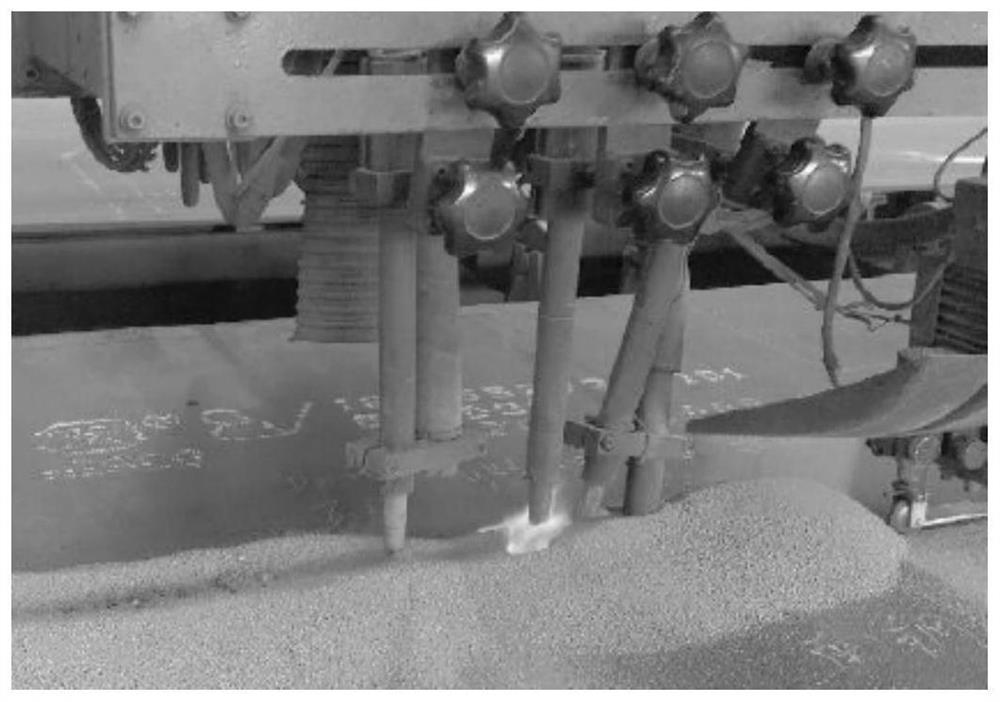

Solid welding wire for FCB method and high-heat input submerged-arc welding and preparation method and application of solid welding wire

ActiveCN112404671AInhibit grain coarseningGuaranteed StrengthArc welding apparatusWelding/cutting media/materialsHigh heatSolder material

The invention discloses a solid welding wire for an FCB method and high-heat input submerged-arc welding and a preparation method and application of the solid welding wire, and belongs to the technical field of welding materials. The welding wire comprises the following chemical components in percentage by weight: 0.06-0.09% of C, 0.12-0.28% of Si, 1.52-2.0% of Mn, 0.0001-0.3% of A and the balanceof Fe and inevitable impurities, wherein the element A is one or more of Mg, Ca, Zr, RE and B. The chemical components of the solid welding wire further contain Ti, Ni and Cu (or contain Ti and V). After the welding wire is used for welding at the online energy of 60-300kJ / cm, the strength and the low-temperature impact toughness, which are matched with those of base metal, of a welding joint canbe guaranteed. The welding wire is suitable for the FCB method of a structural steel plate with the thickness smaller than 40 mm and high heat input welding of other submerged-arc welding machines.

Owner:李素坤

High-strength S420 NL-Z35 low-temperature toughness steel plate and manufacturing method thereof

The invention discloses a high-strength S420 NL-Z35 low-temperature toughness steel plate and a manufacturing method thereof, and relates to the technical field of steel smelting. The steel plate comprise the following chemical components of, in percentage by mass, 0.13%-0.15% of C, 1.40%-1.60 of Mn, 0.30%-0.45% of Si, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.020%-0.030% of Nb, 0.040%-0.060% of V, 0.020%-0.050% of Alt, less than or equal to 0.45% of CEV, and the balance Fe and inevitable impurities. A low carbon content design is adopted, the process of rolling, the special normalizing heat treatment and the like are controlled, the S420 NL-Z35 steel plate with the maximum thickness 100 mm is developed, the product quality is excellent, the production cost is controlled to be appropriate, and the comprehensive cost ratio is high.

Owner:NANJING IRON & STEEL CO LTD

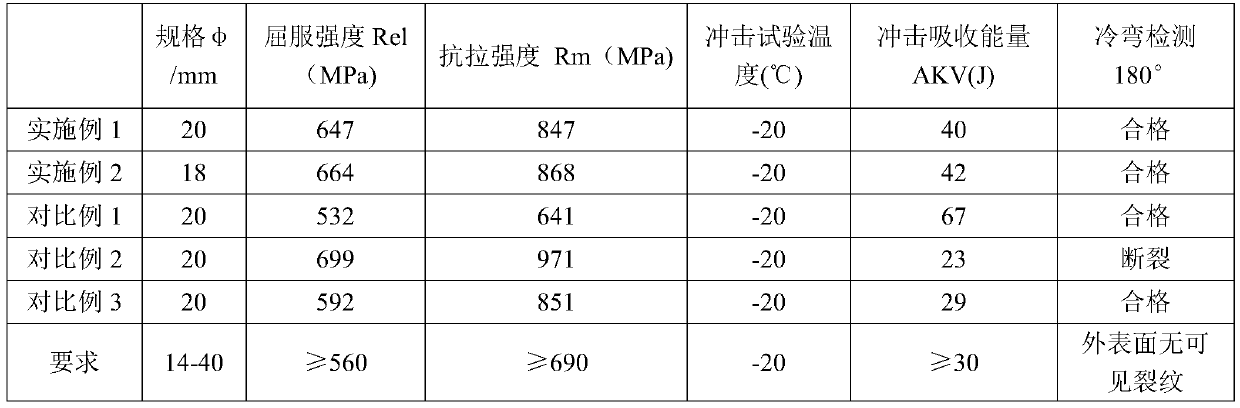

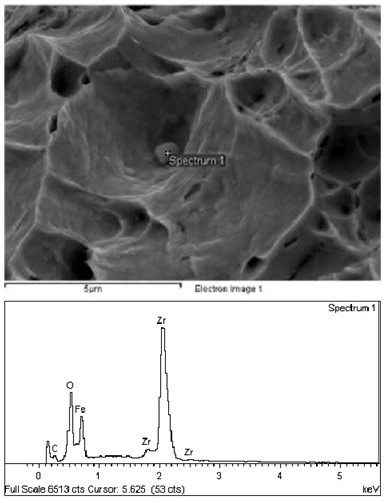

High-toughness titanium alloy and method for preparing bar by using titanium alloy

The invention discloses a high-toughness titanium alloy. The high-toughness titanium alloy comprises the following chemical components of, in percentage by mass, 4.0%-6.0% of Al, 1.0%-3.0% of Mo, 1.0%-3.0% of Zr, 0.5%-1.0% of Fe, 0.2%-0.5% of V and the balance Ti and inevitable impurities. The method for preparing the bar by using the high-toughness titanium alloy comprises the following steps that aluminum titanium, molybdenum titanium, iron nails, titanium-vanadium intermediate alloy, pure zirconium sponge and titanium sponge are correspondingly weighed, mixed and pressed into an electrode bar, and the electrode bar is smelted in a vacuum consumable electro-arc furnace for two times to obtain a titanium alloy cast ingot; the surface of the titanium alloy cast ingot is coated with a puretitanium plate with the thickness of 1.0-2.0 mm, an anti-oxidation coating is brushed on the surface of the pure titanium plate, and the titanium alloy cast ingot is aired for later use; the titaniumalloy cast ingot is placed in a heating furnace to be heated to 930-1150 DEG C, and heat preservation is conducted; and the ingot heated by a radial forging machine is forged to obtain a forging blank; and the forging blank is straightened by using a press machine by using waste heat, and finally machining is conducted to obtain the bar. According to the high-toughness titanium alloy and the method for preparing the bar by using the titanium alloy, the bar prepared from the titanium alloy is high in strength, high in plasticity, high in low-temperature impact toughness and good in corrosion resistance, and the application requirements of severe working conditions of oil and gas wells are met.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Low-temperature impact resistance high-elongation Q345 hot rolled strip steel and production method

The invention discloses a low-temperature impact-resistant high-elongation Q345E hot-rolled strip steel and a production method. The chemical composition and mass percentage of the hot-rolled strip steel are: C: 0.15-0.18%, Mn: 0.4-0.7%, S≤0.015%, P≤0.025%, Si≤0.03%, Als≥0.015%, N≤0.0060%, the rest is iron and unavoidable impurities; production methods include steelmaking, heating, rolling and cooling processes. The invention applies the principle of controlled rolling and controlled cooling bainite phase transformation strengthening, reduces the cost of the alloy, improves the strength and low-temperature impact toughness, and the surface quality and adhesion of the low-silicon and low-phosphorus hot-dip galvanized zinc layer are strong, and the corrosion resistance is strong. , to meet the needs of photovoltaic brackets, power towers, power towers, engineering construction scaffolding and other hot-dip galvanized structural steel in cold regions, which is conducive to increasing market share and can generate great economic benefits.

Owner:TANGSHAN STAINLESS STEEL +1

A kind of 420mpa grade low yield strength ratio steel for marine atmospheric corrosion resistant bridge and production method thereof

ActiveCN109136752BLow yield ratioGood weather resistanceFurnace typesHeat treatment furnacesChemical compositionUltimate tensile strength

The invention discloses a steel 420MPa grade low yield ratio marine atmospheric corrosion resistant bridge and a production method thereof, the steel comprises the following chemical components in percentage by mass: 0.04-0.20% of C, 0.15-0.45% of Si, 0.85-1.80% of Mn, 0.015-0.050% of Alt, 2.50-4.75% of Ni, 0.20-0.60% of Cu, 0.020-0.080% of Nb, 0.015 to 0.036 percent of Ti, 0.0020 to 0.0050 percent of Ca, less than or equal to 0.020%of P, less than or equal to 0.002%of S, less than or equal to 0.004%of N and the balance of Fe and other inevitable impurities; after the steel of passes the composition design, the inclusion control, the controlled rolling , the controlled cooling and heat treatment, the steel has the advantages of high strength, low yield strength, and can be used for manufacturing various bridges under the ocean atmospheric environment, and the safety of use is greatly improved.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Non-quenched and tempered steel for high-strength high-low-temperature impact toughness lifting hook and production process thereof

The invention discloses non-quenched and tempered steel for a high-strength high-low-temperature impact toughness lifting hook and a production process thereof. The steel comprises the following chemical components in percentage by weight, 0.25-0.40% of C, 0.20-0.40% of Si, 1.50-1.80%% of Mn, 0.07-0.10% of V, 0.020-0.040% of Al, smaller than or equal to 0.010% of P, smaller than or equal to 0.010%of S, smaller than or equal to 2 ppm of H, smaller than or equal to 10 ppm of O, and the balance Fe. By combining the group distribution ratio with a controlled rolling and controlled cooling process, the required performance level can be achieved without quenching and tempering treatment, and meanwhile, the low-temperature toughness at minus 20 DEG C meets the use requirement of the product, theproduction cost and the production difficulty are reduced, and the advantages of economy, energy conservation and environmental protection are achieved. The steel can be suitable for lifting hooks for buildings in cold areas.

Owner:ZENITH STEEL GROUP CORP +1

High-toughness 35Kg-grade steel plate for building structure and production method of high-toughness 35Kg-grade steel plate

PendingCN114525456AImprove securityImprove efficiencySolid waste managementLaminar coolingRolling mill

The invention belongs to the field of medium-thickness plate manufacturing, and provides a high-toughness 35Kg-grade steel plate for a building structure and a production method of the high-toughness 35Kg-grade steel plate. The production method comprises the steps of blast furnace molten iron preparation, molten iron pre-desulfurization, converter smelting, deoxidation alloying, LF refining, VD refining, slab continuous casting, slab reheating, slab descaling, 3500 rolling mill rolling, straightening, laminar cooling, straightening, air cooling, finished product sampling inspection and warehousing. According to the method, the 35Kg-grade building structure steel plate with the thickness of 8-60 mm can be produced by adopting a continuous casting billet with the thickness of 250 mm, the highest carbon content of the steel plate is 0.14 wt%, it can be guaranteed that the strength of the steel plate meets the requirement, the yield ratio is smaller than or equal to 0.80, it can be guaranteed that the low-temperature impact toughness at the temperature of-40 DEG C is larger than or equal to 120 J and far exceeds the basic requirement of the national standard, and the thickness direction performance, the flaw detection performance and the welding performance of Z35 can also be guaranteed.

Owner:天津市新天钢钢铁集团有限公司

High-strength, high-toughness, low-yield-ratio low-temperature steel for -70°C and manufacturing method thereof

ActiveCN106467951BLow yield ratioGuaranteed low temperature impact toughnessChemical compositionHigh intensity

The invention discloses a low-temperature steel having high strength, high toughness and low yield ratio used at 70 DEG C and a manufacture method thereof. The low-temperature steel comprises the following chemical components by weight percentage: 0.05-0.20% of C, less than or equal to 0.30% of Si, 0.85-1.50% of Mn, less than or equal to 0.005% of P, less than or equal to 0.003% of S, 0.015-0.050% of Alt, 0.35-0.70% of Ni, and less than or equal to 0.004% of N, and also contains any one or more of less than or equal to 0.10% of Mo, less than or equal to 0.05% of Nb, less than or equal to 0.025% of Ti, and less than or equal to 0.005% of Ca, and the balance of Fe and the unavoidable impurity. The low-temperature steel is manufactured by a steel-making technology, a steel rolling technology and a heat treatment technology, The content of the C and Mn elements can be controlled on component design, so that the yield ratio of a steel plate is reduced, a certain amount of the Ni element is added for guaranteeing the low-temperature impact toughness, the microalloy elements such as Ti, Mo, and Nb are added for improving the welding performance, the contents of P, S and N are strictly controlled, the Ca-Si processing is carried out, and the steel has excellent low-temperature toughness and has low yield ratio.

Owner:武汉钢铁有限公司

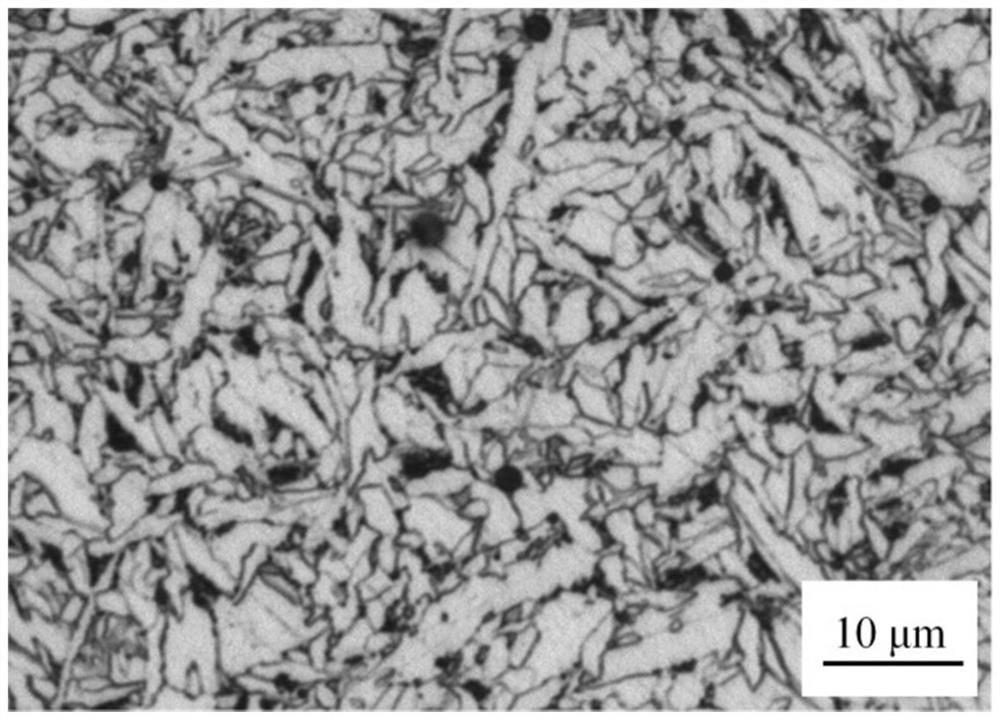

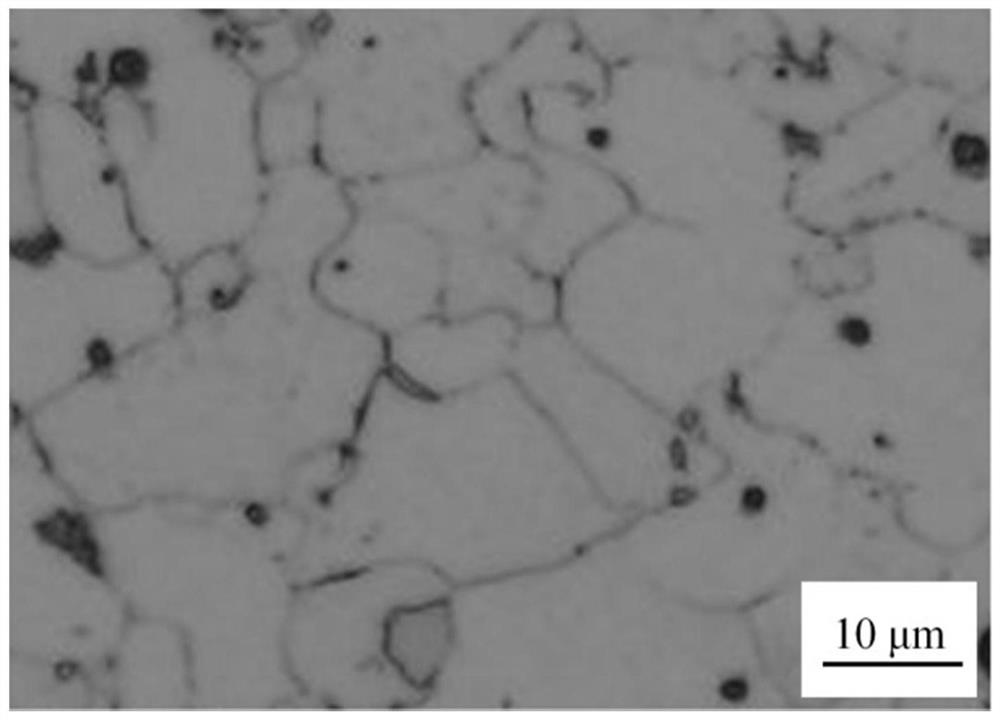

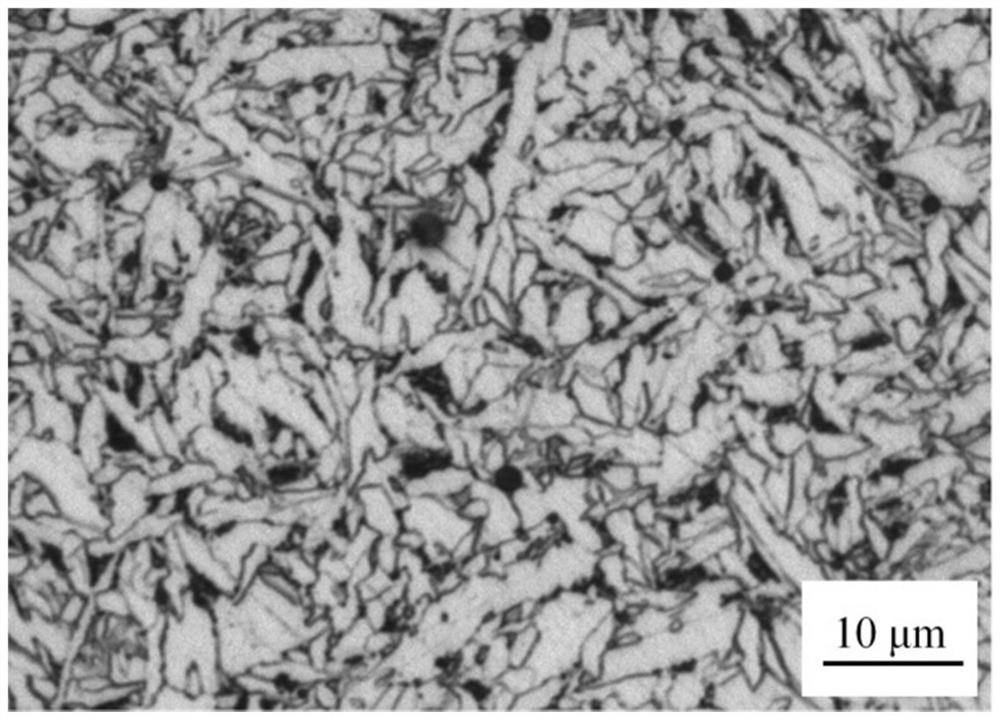

Steel for welding with large heat input and method for improving toughness of heat affected zone

ActiveCN112139242BImprove mechanical propertiesStable mechanical propertiesTemperature control deviceProcess efficiency improvementHeat-affected zoneMechanical property

The invention discloses a steel for welding with large heat input and a method for improving the toughness of the heat affected zone. The scheme is controlled by reasonable component design, pouring, rolling and cooling process links, so that it forms fine and dispersed particles in the base metal. The inclusions of (Ti, Si, Al, Mn)O and MnS types are mostly between 0.5 μm and 2 μm in size, and with such inclusions as the core, a large number of elongated acicular ferrite (AF) are formed. structure, so that the base metal has higher mechanical properties. After welding with a large heat input of 200~800kJ / cm, the AF structure in the weld-affected zone (HAZ) was transformed into an equiaxed ferrite structure. The low-temperature impact toughness of HAZ at ‑40℃ did not decrease, but increased slightly, and the HAZ toughness Not affected by welding heat input, HAZ also has stable mechanical properties while greatly improving welding efficiency.

Owner:LONGYAN UNIV

Thick-specification FH690-grade ultrahigh-strength maritime work steel plate and preparation method thereof

PendingCN114672726AUniform tissueUniform and stable tissueRoll force/gap control deviceUltimate tensile strengthMechanical property

The invention discloses a thick-specification FH690-grade ultrahigh-strength maritime work steel plate and a preparation method thereof. The thick-specification FH690-grade ultrahigh-strength maritime work steel plate is prepared from 0.08%-0.16% of C, 0.15%-0.35% of Si, 0.80%-1.50% of Mn, 0.40%-0.60% of Cr, 1.00%-1.65% of Ni, 0.20%-0.50% of Mo, 0.10%-0.35% of Cu, 0.02%-0.04% of Nb, 0.04%-0.06% of V, 0.01%-0.03% of Zr, 0.001%-0.002% of B, 0.02%-0.05% of Alt, smaller than or equal to 0.015% of P, smaller than or equal to 0.005% of S, smaller than or equal to 0.006% of N and the balance Fe. The produced steel plate has good obdurability matching and excellent comprehensive mechanical properties, meets the requirements of classification society on FH690-grade steel plates, and is simple in manufacturing process and wide in adaptability.

Owner:MINMETALS YINGKOU MEDIUM PLATE

Steel for large heat input welding and method for improving toughness of heat-affected zone of steel

ActiveCN112139242AImprove mechanical propertiesStable mechanical propertiesTemperature control deviceProcess efficiency improvementHeat-affected zoneMechanical property

The invention discloses steel for large heat input welding and a method for improving the toughness of a heat-affected zone of the steel. According to the scheme, through reasonable component design,pouring, rolling and cooling process link control, fine and dispersed (Ti, Si, Al, Mn) O and MnS type inclusions are formed in a base metal, the size mostly ranges from 0.5 [mu]m to 2 [mu]m, and a large number of slender acicular ferrite (AF) structures are generated with the inclusions used as cores, so that the base metal has the relatively-high mechanical properties. After large heat input welding of 200-800 kJ / cm, the AF structures in the welding affected zone (HAZ) are converted into equiaxed ferrite structures, the subzero-40-DEG C low-temperature impact toughness of the HAZ is not reduced but slightly increased, the toughness of the HAZ is not affected by welding heat input, the welding efficiency is substantially improved, and meanwhile, the HAZ has the stable mechanical properties.

Owner:LONGYAN UNIV

A kind of Ni microalloyed steel for petroleum drill collar and preparation method thereof

The invention discloses a Ni micro-alloyed steel for a petroleum drill collar and a preparation method of the Ni micro-alloyed steel. The Ni micro-alloyed steel for the petroleum drill collar comprises, by mass, 0.40%-0.48% of C, 0.15%-0.35% of Si, 1.00%-1.20% of Mn, 1.05%-1.30% of Cr, 0.20%-0.35% of Mo, 0.20%-0.40% of Ni, no more than 0.015% of P, no more than 0.010% of S and the balance iron and inevitable impurity elements. The preparation method of the Ni micro-alloyed steel comprises the procedures of smelting conducted through an electric furnace, external refining conducted through a ladle furnace, vacuum treatment conducted through a vacuum degassing furnace, continuous casting and rolling. The Ni micro-alloyed steel for the petroleum drill collar has good comprehensive mechanical performance and stable hardenability, and heat treatment stability is guaranteed. Because micro-alloying is achieved through the added Ni, the low-temperature impact toughness of the Ni micro-alloyed steel is improved.

Owner:SHANDONG IRON & STEEL CO LTD

A welding third-generation nuclear power equipment sa-508gr. 3cl. 1 Submerged arc flux for steel and its preparation method

ActiveCN104551446BSimple welding processBeautiful shapeArc welding apparatusWelding/cutting media/materialsNuclear powerSlag

The invention discloses a submerged arc welding flux for welding SA-508Gr.3Cl.1 steel of third-generation nuclear power equipment and a preparation method thereof. The submerged arc welding flux comprises the following components in parts by weight: 8-15 parts of SiO2 (silicon dioxide), 20-30 parts of MgO (magnesium oxide), 20-30 parts of CaF2 (calcium fluoride), 20-30 parts of Al2O3 (aluminum oxide), 6-10 parts of CaO (calcium oxide), 2-4 parts of MnO2 (manganese dioxide), 0.3-1 parts of BaO (barium oxide), 1-2 parts of rare earth oxides, 0.014-0.016 part of S (sulfur), 0.013-0.015 part of P (phosphor), and 22-24 parts of water glass. Compared with the prior art, the submerged arc welding flux has the advantages that the welding technological property is excellent, the slag removal property is excellent, the forming appearance is attractive, and the mechanical property is more excellent.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

A kind of k65 controlled rolling steel plate, straight seam submerged arc welded pipe and its manufacturing method for alpine regions

ActiveCN105624584BImprove low temperature impact toughnessSolve the problem of poor toughnessArc welding apparatusSheet steelCold area

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Thickness s355g10+n steel plate for marine structure and its production method

The invention discloses a steel plate with a thickness of S355G10+N for marine structures, which relates to the technical field of iron and steel smelting. The maximum thickness of the steel plate is 150mm, and the chemical composition and mass percentage are as follows: C: 0.08%-0.14%, Mn: 1.30%-1.65%, Si: 0.10%~0.50%, P≤0.015%, S≤0.005%, Nb: 0.015%~0.030%, V≤0.03%, Ti: 0.10%~0.020%, Alt: 0.020%~0.055%, Ni: 0.10 %~0.50%, CEV≤0.43%, Pcm≤0.21%, the balance is Fe and unavoidable impurities. The 150mm extra-thick steel plate has excellent low-temperature toughness, especially the ‑40°C impact at 1 / 2 of the thickness is greater than 100J, and the welding performance is good, which better meets the use and service requirements of offshore structures.

Owner:NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com