High-toughness titanium alloy and method for preparing bar by using titanium alloy

A titanium alloy and high toughness technology, which is applied in the field of high toughness titanium alloy and the use of this titanium alloy to prepare rods, can solve problems such as insufficient impact performance, stress corrosion resistance, inability to meet material performance requirements, and complex stress conditions , to achieve the effect of ensuring low temperature impact toughness, reducing material cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

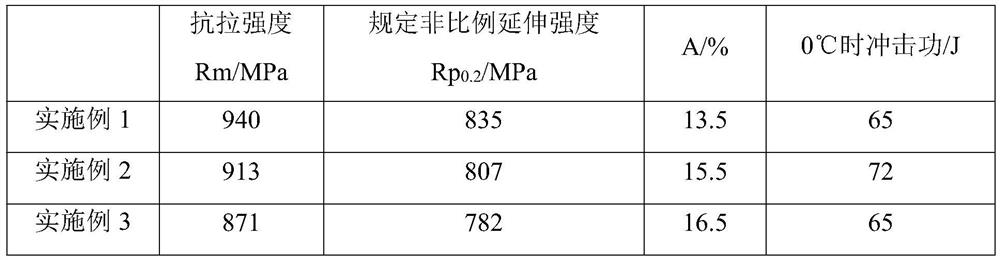

Embodiment 1

[0033] Aluminum-titanium, molybdenum-titanium, iron nails, titanium-vanadium master alloy, pure sponge Zr, and sponge Ti were smelted twice into titanium alloy ingots with a diameter of Φ720 through mixing, pressing electrode rods, and vacuum self-consumption. The results of the alloy element detection of the ingots Al5.8%, Mo2.6%, Zr1.3%, Fe0.8%, V0.33%, alloy transformation point 985 ℃. The 1.8mm TA1 plate is used to cover the titanium alloy ingot, and then the surface is coated with DGH-9 anti-oxidation coating, and it is dried for later use. After the ingot is kept at 1150°C for 360 minutes, it is forged into a Φ224 forging billet with a radial forging machine twice, and the surface temperature of the billet is not lower than 850°C during the process. After forging, it is straightened by a press, air-cooled to room temperature and machined into a Φ220 bar.

Embodiment 2

[0035] Aluminum-titanium, molybdenum-titanium, iron nails, titanium-vanadium master alloy, pure sponge Zr, and sponge Ti are smelted twice through mixing, pressing electrode rods, and vacuum self-consumption into diameters. Alloy ingots, the detection results of alloy elements in ingots are Al5.1%, Mo2.15%, Zr2.7%, Fe0.6%, V0.35%. The alloy transformation point is 976°C. Use 1.5mm TA1 plate to cover the ingot, and then coat the surface with DGH-9 anti-oxidation coating, and let it dry for later use. The cast ingot is heat-preserved at 1150°C, and forged into a Φ154 forging billet by two rounds of forging with a radial forging machine. The surface temperature of the billet during the process is not lower than 850°C. After forging, it is straightened by a press, air-cooled to room temperature and machined into a Φ150mm bar.

Embodiment 3

[0037] Aluminum-titanium, molybdenum-titanium, iron nails, titanium-vanadium master alloy, pure sponge Zr, and sponge Ti are smelted twice through mixing materials, pressing electrode rods, and vacuum self-consumption. Alloy ingot, the detection results of alloy elements in the ingot are Al4.2%, Mo1.2%, Zr2.8%, Fe0.7%, V0.44%. The alloy transformation point is 972°C. Use 1.2mm TA1 plate to cover the ingot, and then coat the surface with DGH-9 anti-oxidation coating, and let it dry for later use. The cast ingot is heat-preserved at 1050°C, and is forged into a Φ118.5mm billet with a radial forging machine twice, and the surface temperature of the billet is not lower than 850°C during the process. After forging, it is straightened by a press, air-cooled to room temperature and machined into a Φ114.5mm bar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com