Steel for large heat input welding and method for improving toughness of heat-affected zone of steel

A large heat input welding and heat-affected zone technology, applied in the direction of process efficiency improvement, metal rolling, temperature control, etc., can solve the problem of low toughness of the zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

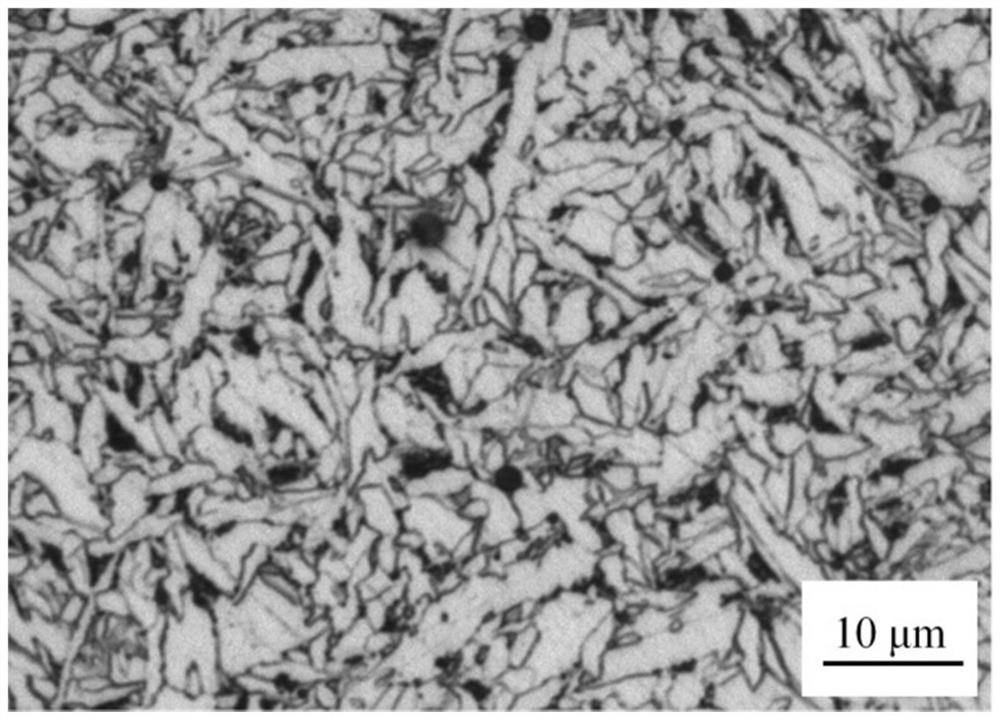

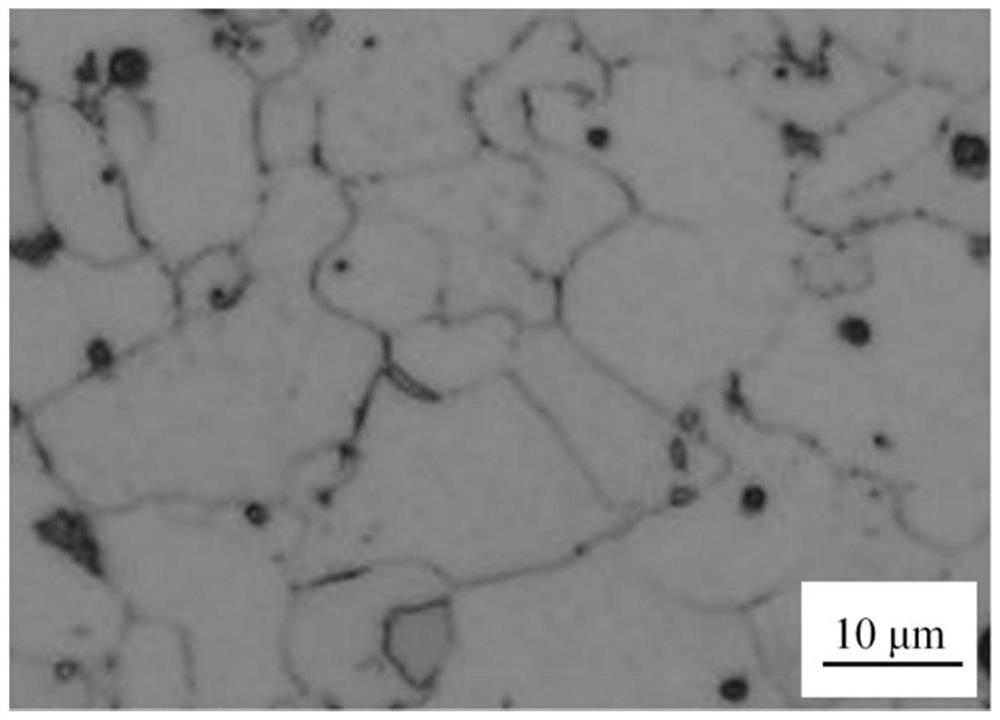

[0029] A method for improving the toughness of the heat-affected zone of steel for welding with large heat input, the chemical composition of which is as follows: C: 0.08%, Si: 0.23%, Mn: 1.80%, Al: 0.035%, P: ≤0.015%, S: ≤0.013 %, Ti: 0.07%, B: 0.002, and the balance is Fe, wherein the balance of Fe contains trace unavoidable impurities.

[0030] The above-mentioned method for improving the toughness of the heat-affected zone of steel for welding with large heat input, the specific steps are as follows:

[0031] (1) Smelting: According to the composition design of the high heat input welding steel, various raw materials are alloy smelted at 1600°C, molten steel is smelted, and steel ingots are obtained by pouring;

[0032] (2) Rolling: The steel ingot was heated to 1200 °C and held for 2 h. After fully austenitized, the steel ingot was subjected to 2 rough rolling passes. The initial rolling temperature of the rough rolling was 1100 °C, and the final rolling temperature was 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com