Economic type diphasic stainless steel with good toughness and weldability and manufacturing method thereof

A technology of duplex stainless steel and weldability, which is applied in the field of economical duplex stainless steel and its manufacturing, can solve the problems of low-temperature toughness decline of welded joints, and achieve the effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

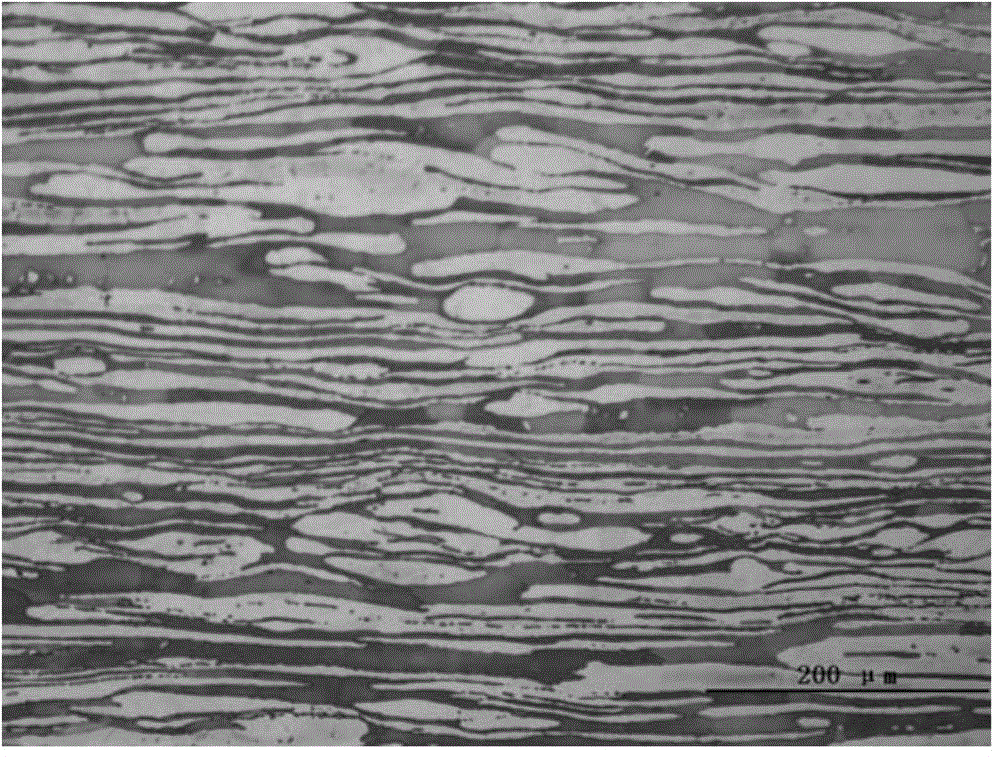

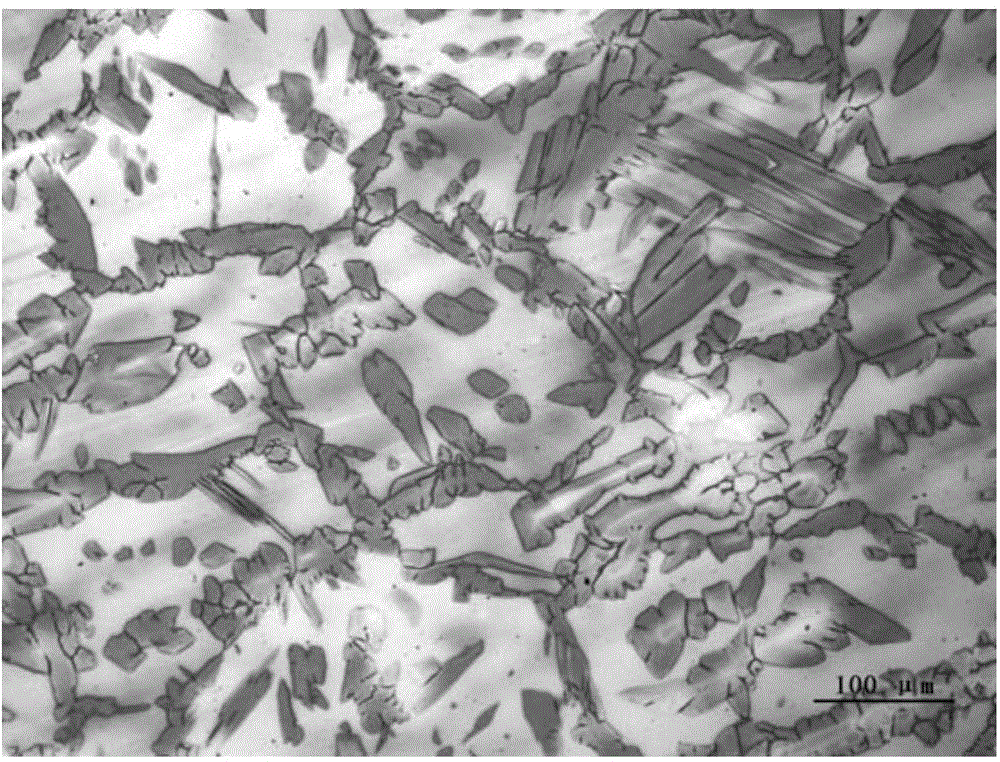

[0051] The metallographic structure of the alloy of embodiment 1 is as figure 1 shown. After the sample is ground and polished, electrolytic corrosion is performed, and the etchant is 40gKOH+100mlH 2 O, corrosion current 0.3~0.8A / cm 2 , and finally analyzed the proportion of austenite by quantitative metallographic method under metallographic microscope. In the figure, the black structure is ferrite, the white structure is austenite, and the austenite phase accounts for about 53%. The metallographic structure of embodiment 2 welding heat-affected zone is as figure 2 shown.

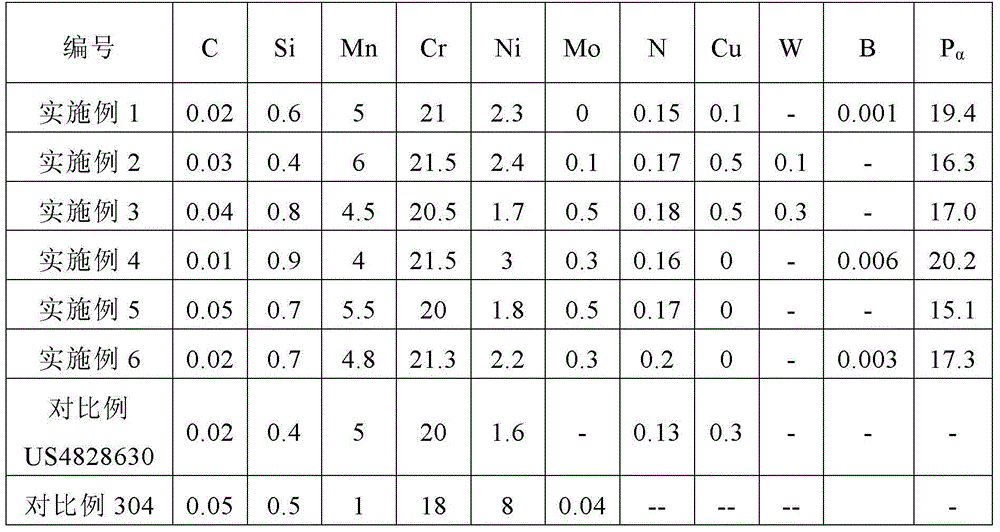

[0052] Table 1 Unit: % by weight

[0053]

[0054] Table 2

[0055]

[0056]

[0057] It can be seen from Table 1 and Table 2 that since the steel of the present invention uses Mn and N instead of Ni content, and contains no or only a small amount of alloying elements such as Mo and Cu, compared with 304 austenitic stainless steel, its alloy cost is significantly reduced. Compared with dup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com