Solid welding wire for FCB method and high-heat input submerged-arc welding and preparation method and application of solid welding wire

A solid welding wire and submerged arc welding technology, which is applied in welding equipment, welding equipment, arc welding equipment, etc., can solve the problem of not having the supply capacity of welding materials for steel for large heat input welding, and achieve the suppression of grain coarsening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]Converter smelting-LF furnace refining-continuous casting process is adopted. When the molten steel reaches the LF furnace for refining, the oxide metallurgy process is adopted to control the oxygen content to 45ppm through weak deoxidation of silicon and manganese, and then add Ti, Mg, Al, Ca and B in sequence. Elements, each element is added at an interval of 8 minutes, and then LF furnace slagging, desulfurization and alloying are carried out. After the LF furnace refining is completed, the molten steel enters the continuous casting process to cast a 150×150mm square billet. The chemical composition of the slab by mass percentage is: C 0.08%, Si 0.21%, Mn1.57%, P 0.010%, S 0.003%, Ni 0.22%, Cu0.20%, Ti 0.015%, Mg 0.003%, Ca0. 003%, Al T 0.02%, B 0.002%, N 0.004%, O 0.003%, and the balance is Fe and unavoidable impurities.

[0033] After the continuous casting billets are stacked for about 24 hours, they are heated to 1100°C by a walking heating furnace. The rolling ...

Embodiment 2

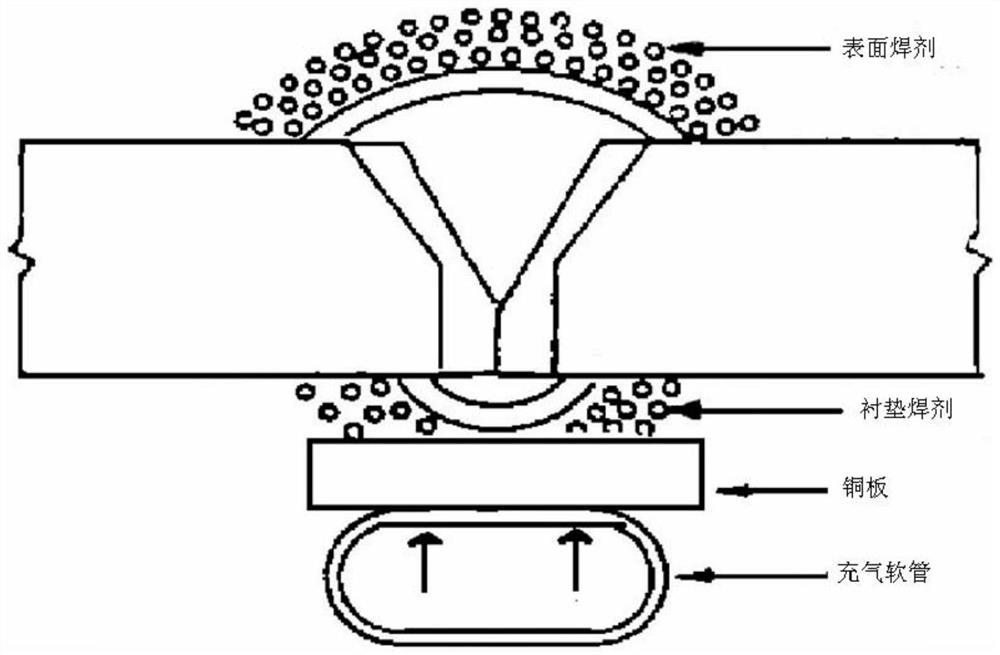

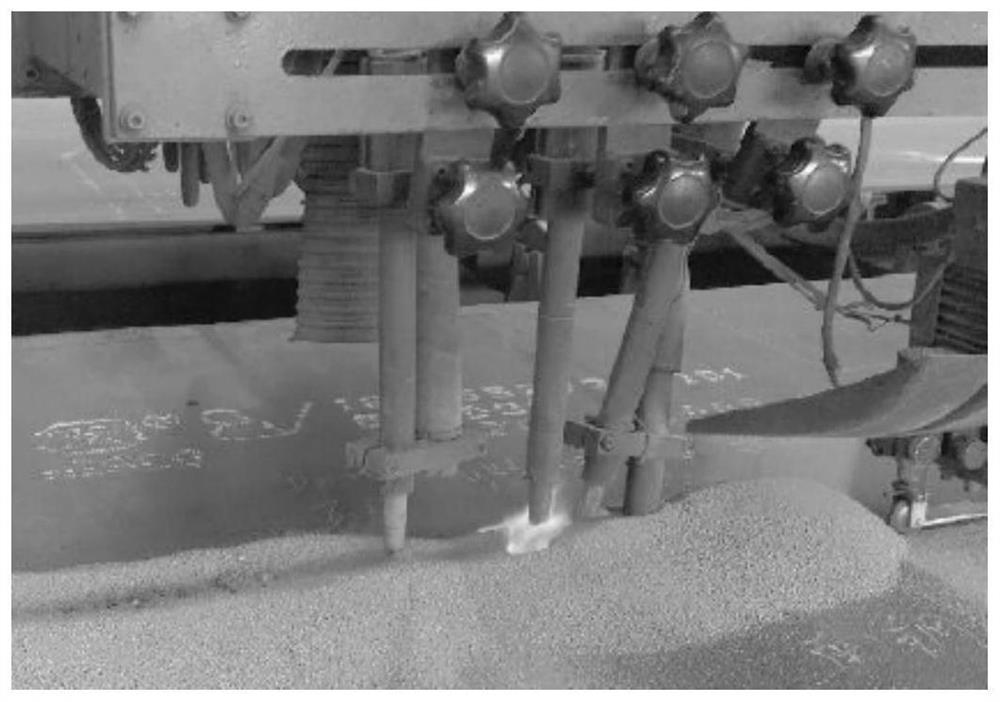

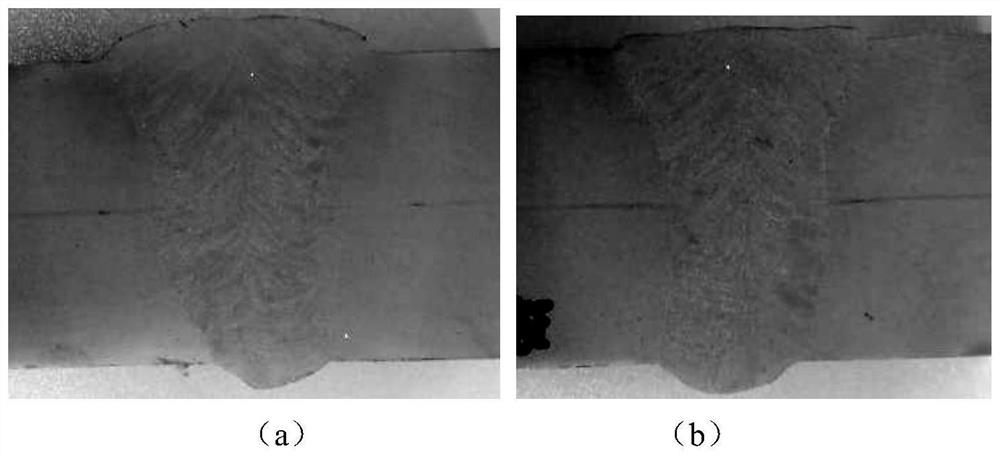

[0044] The 4.8mm diameter welding wire obtained in Example 1 and Comparative Example 1 was respectively placed on the L pole and T1 pole of the FCB method submerged arc automatic welding machine, and the 6.4mm diameter welding wire was placed on the T2 pole, and the domestic 34mm thick EH36 shipbuilding steel plate was used to match Japan. Nippon Steel (strain) imported flux NSH-1RM / NSM-50M, under the parameter conditions shown in table 3, carry out the FCB method large input energy submerged arc welding comparative test of embodiment 1 and comparative example 1 welding wire, as a reference, also in the meantime Under the same parameter conditions shown in table 3, the comparative test of the welding wire of embodiment 1 and the imported Y-DL welding wire of Nippon Steel (strain) was carried out. The macroscopic metallographic photograph of comparative example 1 welded joint is as image 3 shown. From the data in Table 4, it can be seen that the cold bending performance of th...

Embodiment 3

[0050] The diameter 4.8mm welding wire that embodiment 1 and comparative example 1 obtains is used as the first two wires (L pole and T1 pole) of FCB submerged arc welding machine, and the diameter 6.4mm welding wire is used as the rear wire (T2 pole) of FCB submerged arc welding machine, Using the 30mm thick Q420C steel plate used in the "deep and middle channel" immersed tube currently under construction to match the domestic TGF-55E / TGF-B flux, the comparative test of the FCB method large-line energy submerged arc welding was carried out under the parameters shown in Table 5. The mechanical properties of the joints are shown in Table 6, and the macroscopic metallographic photos of the welded joints are shown in Table 6. Figure 4 shown. From the data in Table 6, it is not difficult to find that when the welding wire of Example 1 is matched with the domestic flux for welding low-alloy high-strength structural steel plates with a yield strength of 420MPa, the strength and tou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com