Wrought aluminum alloy and heat treatment method thereof

A heat treatment method and a technology for deforming aluminum alloys, which are applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of rapid maintenance of aviation aircraft, insufficient mechanical properties, fracture toughness, and uneven three-dimensional mechanical properties. Avoid coarse precipitation of grain boundaries, improve intergranular corrosion ability, and improve the effect of bulk performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

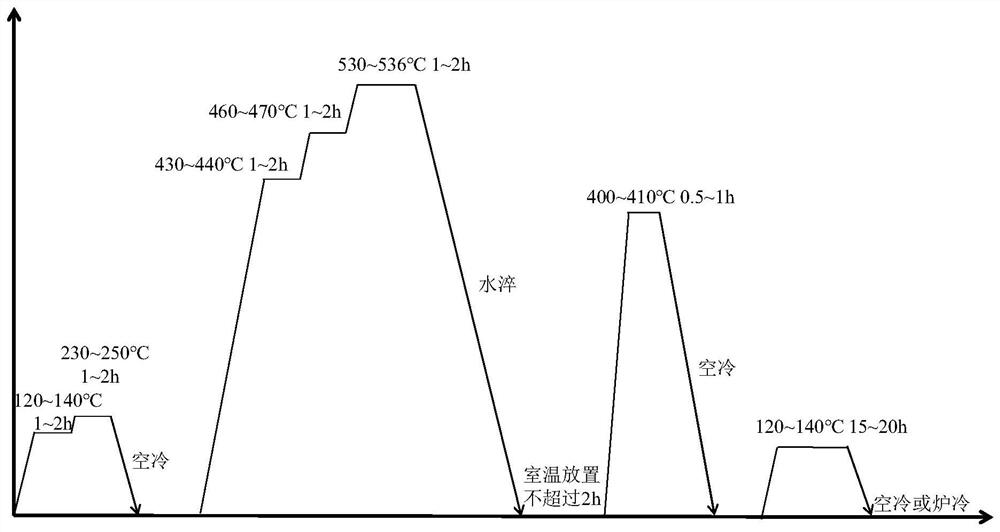

[0074] This embodiment provides a heat treatment method for deformed aluminum alloy, such as figure 1 shown.

[0075] The object of heat treatment is a semi-continuously cast rod or slab, and the composition of the semi-continuously cast rod or slab is as follows in terms of mass percentage:

[0076] Zn: 6.0%, Mg: 1.5%;

[0077] Y: 0.3%, Er: 0.04%; Zr: 0.06%; Ti: 0.07%; B: 0.018%;

[0078] The total content of impurities does not exceed 0.1%; of which Cu: 0.04%; Fe: 0.01%; Si: 0.02%;

[0079] The balance is aluminum.

[0080] Among them, W Y / (W Er +W Zr +W Ti ) = 1.76.

[0081] Described heat treatment method comprises the steps:

[0082] 1) Low temperature short time aging treatment:

[0083] At 120°C, aging treatment for 2 hours, continue to heat up to 240°C, aging treatment for 1 hour, and cool at room temperature;

[0084] 2) Multi-stage solid solution treatment:

[0085] Solution treatment at 430°C for 6 hours, continue to heat up to 460°C for solution treatm...

Embodiment 2

[0092] This embodiment provides a heat treatment method for deformed aluminum alloy.

[0093] The heat treatment object has the same composition as the semi-continuous cast rod or slab in Example 1, the only difference being the specific operating conditions of step 3) and step 4) in the heat treatment process.

[0094] Described heat treatment method comprises the steps:

[0095] 1) Low temperature short time aging treatment:

[0096] At 130°C, aging treatment for 1.5h, continue to heat up to 235°C, aging treatment for 1h, room temperature cooling;

[0097] 2) Multi-stage solid solution treatment:

[0098] Solution treatment at 440°C for 4 hours, continue to heat up to 470°C for solution treatment for 4 hours, continue to heat up to 531°C for solution treatment for 1 hour, water quenching, and the quenching transfer time is 5s;

[0099] 3) High temperature aging:

[0100] Aging at 405°C for 0.6h, air cooling;

[0101] 4) Low temperature aging:

[0102] Aging at 130°C fo...

Embodiment 3

[0106] This embodiment provides a heat treatment method for deformed aluminum alloy.

[0107] The heat treatment process is the same as in Example 1, but the composition of the heat treatment object semi-continuous cast rod or slab is as follows (mass percentage):

[0108] Zn: 6.8%, Mg: 1.7%;

[0109] Y: 0.25%, Er: 0.03%; Zr: 0.05%; Ti: 0.07%; B: 0.03%;

[0110] The total content of impurities is not more than 0.1%; Cu: 0.04%; Fe: 0.03%; Si: 0.01%;

[0111] The balance is aluminum.

[0112] Among them, W Y / (W Er +W Zr +W Ti ) = 1.66.

[0113] Described heat treatment method comprises the steps:

[0114] 1) Low temperature short time aging treatment:

[0115] At 120°C, aging treatment for 2 hours, continue to heat up to 240°C, aging treatment for 1 hour, and cool at room temperature;

[0116] 2) Multi-stage solid solution treatment:

[0117] Solution treatment at 430°C for 6 hours, continue to heat up to 460°C for solution treatment for 5 hours, continue to heat up ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com