A kind of hrb500 anti-seismic steel bar and its production process

A technology of anti-seismic steel bars and molten steel, applied in the field of metallurgy, to achieve the effects of improving welding performance, inhibiting grain coarsening, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

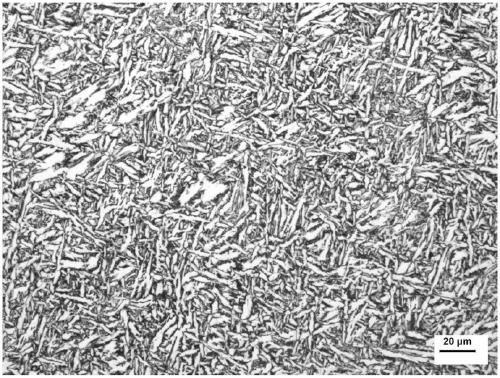

[0034]This embodiment provides a kind of HRB500 anti-seismic steel bar, which contains calcium-based composite particle precursors in the anti-seismic steel bar, wherein: the molten steel of the steel bar is composed of the following elements in terms of mass fraction: C is 0.21%, and Si is 0.58 %, Mn is 1.34%, S is 0.038%, P is 0.022%, the balance is Fe, and the sum of the percentages of elements is 100%.

[0035] The production process of the HRB500 anti-seismic steel bar in this embodiment is as follows: the molten steel of the steel bar is smelted in molten steel, and when the steel is tapped, silicon-manganese is first added to the ladle for alloying, and then ferrosilicon or aluminum alloy is added for pre-deoxidation, and the molten steel is poured into the tundish Finally, add calcium carbide to the crystallizer for final deoxidation, control the amount of calcium carbide added so that the oxygen content in the molten steel of the steel bar drops to 32ppm, and produce c...

Embodiment 2

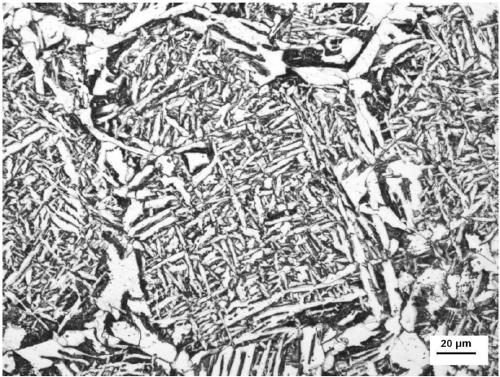

[0056] This embodiment provides a 500MPa earthquake-resistant steel bar, which contains calcium-based composite particles.

[0057] Among them: the molten steel of the steel bar is composed of the following elements in terms of mass fraction: C is 0.22%, Si is 0.61%, Mn is 1.34%, S is 0.036%, P is 0.022%, and the balance is Fe, the mass of the element The sum of the percentages is 100%.

[0058] Production process: the production method of this embodiment is the same as that of embodiment 1, the only difference being that in this embodiment, the amount of calcium carbide added is controlled so that the oxygen content in the molten steel of the steel bar is reduced to 41ppm.

[0059] After testing, the calcium-based composite particles are composed of the following elements in terms of mass fraction: 14.8% Ca, 12.7% Si, 2% Al, 32% Mn, 4.5% S, and 34% O.

[0060] In the steel bars prepared in this example, the number of calcium-based composite particles with a size of 0.5-3 μm ...

Embodiment 3

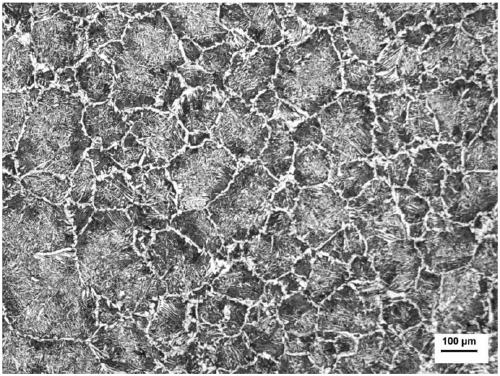

[0062] This example provides a 500MPa earthquake-resistant steel bar, which contains calcium-based composite particles. Among them: the molten steel of the steel bar is composed of the following elements in terms of mass fraction: C is 0.23%, Si is 0.8%, Mn is 1.2%, S is 0.045%, P is 0.045%, and the balance is Fe, the mass of the element The sum of the percentages is 100%.

[0063] Production process: the production method of this embodiment is the same as that of embodiment 1, the only difference is that in this embodiment, the amount of calcium carbide added is controlled so that the oxygen content in the molten steel of the steel bar is reduced to 36ppm.

[0064] After testing, the calcium-based composite particles are composed of the following elements in terms of mass fraction: 15% Ca, 13% Si, 3% Al, 35% Mn, 4% S, and 30% O.

[0065] In the steel bars prepared in this example, the number of calcium-based composite particles with a size of 0.5-3 μm reaches 2600 / mm 2 . T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| carbon equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com