Ni micro-alloyed steel for petroleum drill collar and preparation method thereof

A micro-alloying and oil drilling technology, applied in the field of oil drilling steel, can solve problems such as complex drilling and production environment, and achieve the effects of process optimization, stability assurance, and high service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

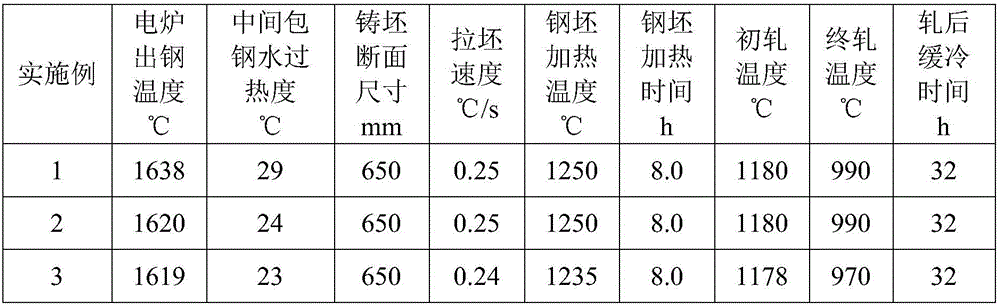

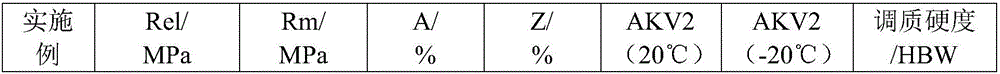

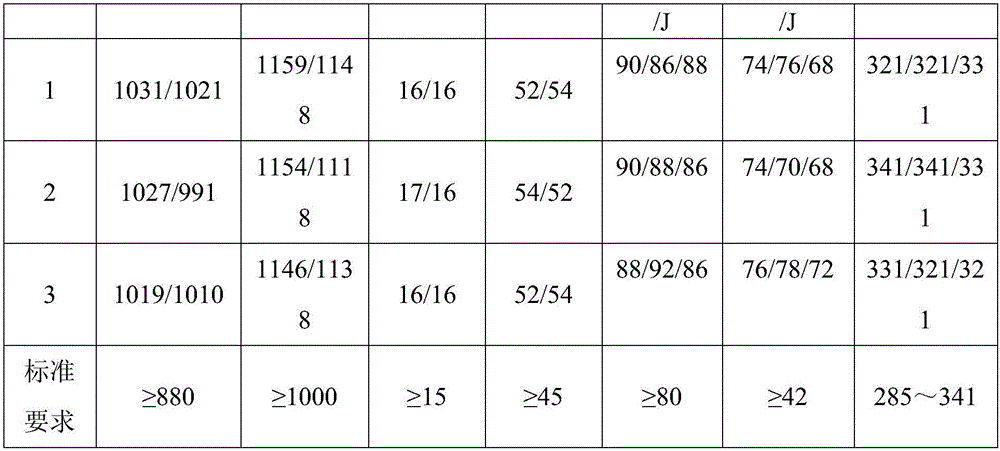

Embodiment 1-3

[0025] The preparation method of Ni microalloyed petroleum drill collar steel of the present invention comprises the following steps:

[0026] (1) Smelting

[0027] EBT ultra-high power 100-ton electric furnace is used for smelting. In order to effectively reduce the content of inclusions in steel, the amount of molten iron added in electric furnace smelting should be increased to more than 60%. High-phosphorus and high-sulfur scrap steel can only be smelted when the furnace body is in good condition, so as to ensure the best furnace condition and reduce the increase of gas content in the steel due to furnace body factors. The whole process of electric furnace smelting maintains foamy slag operation, uniform decarburization, reduces nitrogen absorption, and uses large amount of slag for deep decarburization to strengthen P removal, and the control end point [P]≤0.008wt%. High-temperature rapid decarburization, the control end point [C]≥0.10wt%, and the content of other residu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com