Steel for welding with large heat input and method for improving toughness of heat affected zone

A technology of large heat input welding and heat affected zone, which can be used in the improvement of process efficiency, metal rolling, temperature control, etc., and can solve problems such as low toughness in the zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

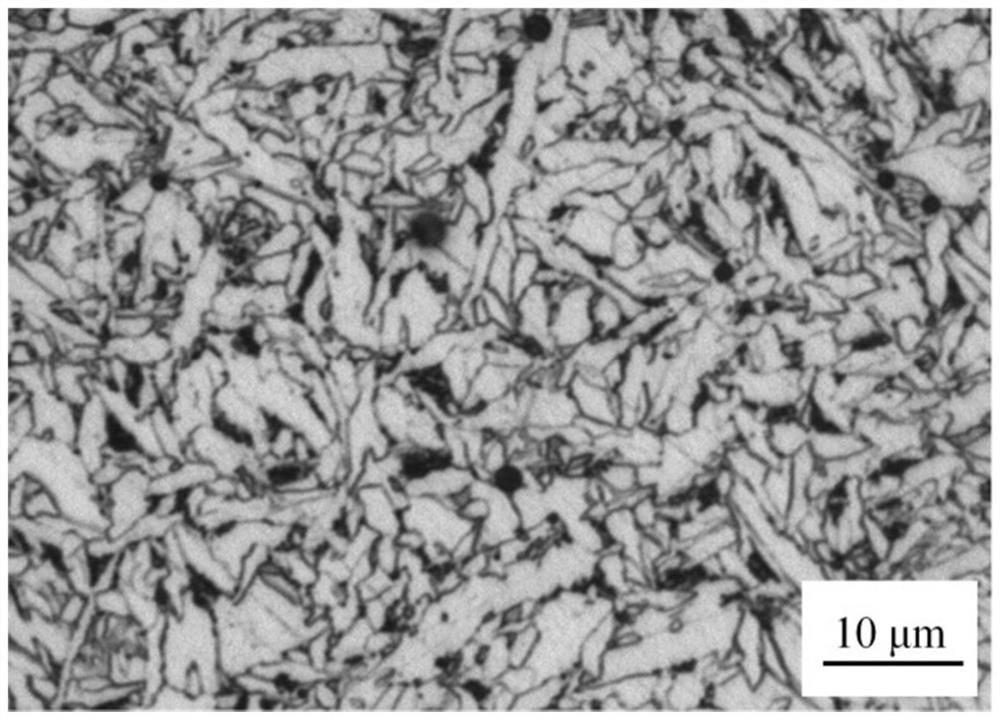

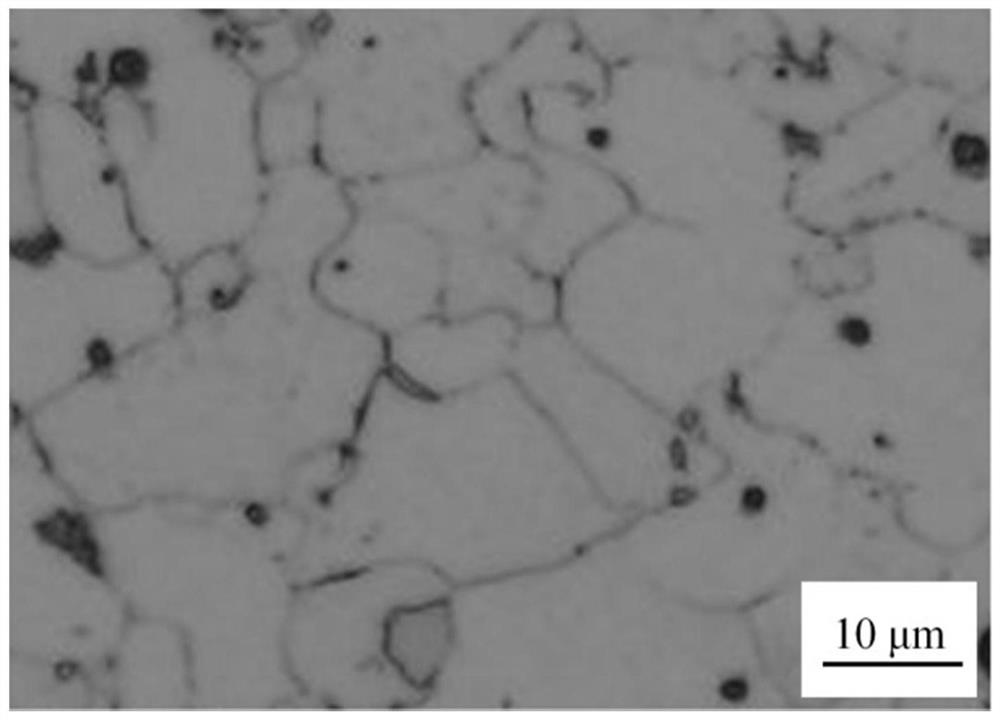

[0029] A method for improving the toughness of the heat-affected zone of steel for welding with large heat input, the chemical composition of which is as follows: C: 0.08%, Si: 0.23%, Mn: 1.80%, Al: 0.035%, P: ≤ 0.015%, S: ≤ 0.013 %, Ti: 0.07%, B: 0.002, the balance is Fe, and the balance of Fe contains a small amount of inevitable impurities.

[0030] The above-mentioned method for improving the toughness of the heat-affected zone of steel for welding with large heat input, the specific steps are as follows:

[0031] (1) Smelting: According to the design of the components contained in the welding steel with large heat input, various raw materials are alloyed at 1600 ° C, molten steel is smelted, and ingots are obtained by pouring;

[0032] (2) Rolling: The steel ingot was heated to 1200 °C and kept for 2 h. After fully austenitizing, the steel ingot was subjected to 2 passes of rough rolling. The rough rolling temperature was 1100 °C and the final rolling temperature was 1050...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com