High-toughness 35Kg-grade steel plate for building structure and production method of high-toughness 35Kg-grade steel plate

A technology of building structure and production method, applied in the field of medium and heavy plate manufacturing, can solve problems such as difficulty, and achieve the effects of uniform cooling, stable performance and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

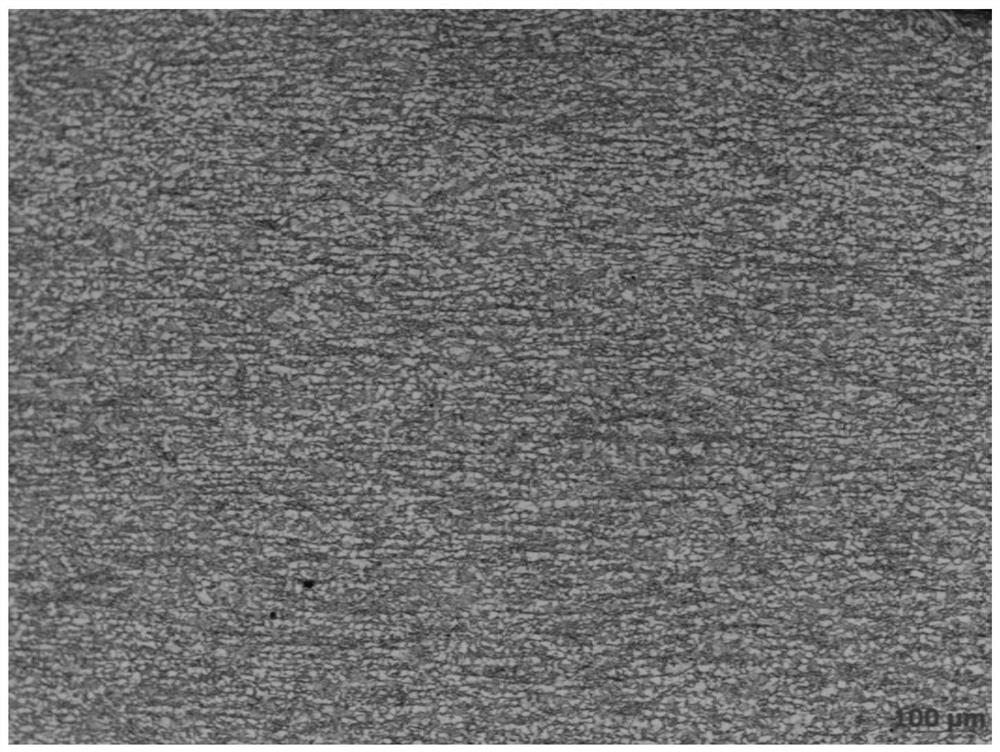

Embodiment 1

[0040] The production process of the steel plate in this embodiment is: blast furnace molten iron → molten iron pre-desulfurization → converter smelting → deoxidation alloying → LF refining → VD refining → slab continuous casting → slab reheating → slab descaling → 3500 mill rolling → straightening Straightening → laminar cooling → straightening → air cooling → finished product sampling inspection → storage.

[0041] Specifically: molten steel is smelted on a 120t converter, and the molten steel is cast into a slab with a thickness of 250mm; the continuous casting slab is reheated to a temperature of 1162 °C; rolling after the continuous casting slab is released: the rough rolling temperature is 1141 °C, and the final rolling temperature is 1036 °C , the thickness of the intermediate billet is 70mm; the finishing rolling temperature is 906 ℃, the final rolling temperature is 854 ℃, and the steel plate is rolled into a 20mm;

[0042] The chemical quality components of the finis...

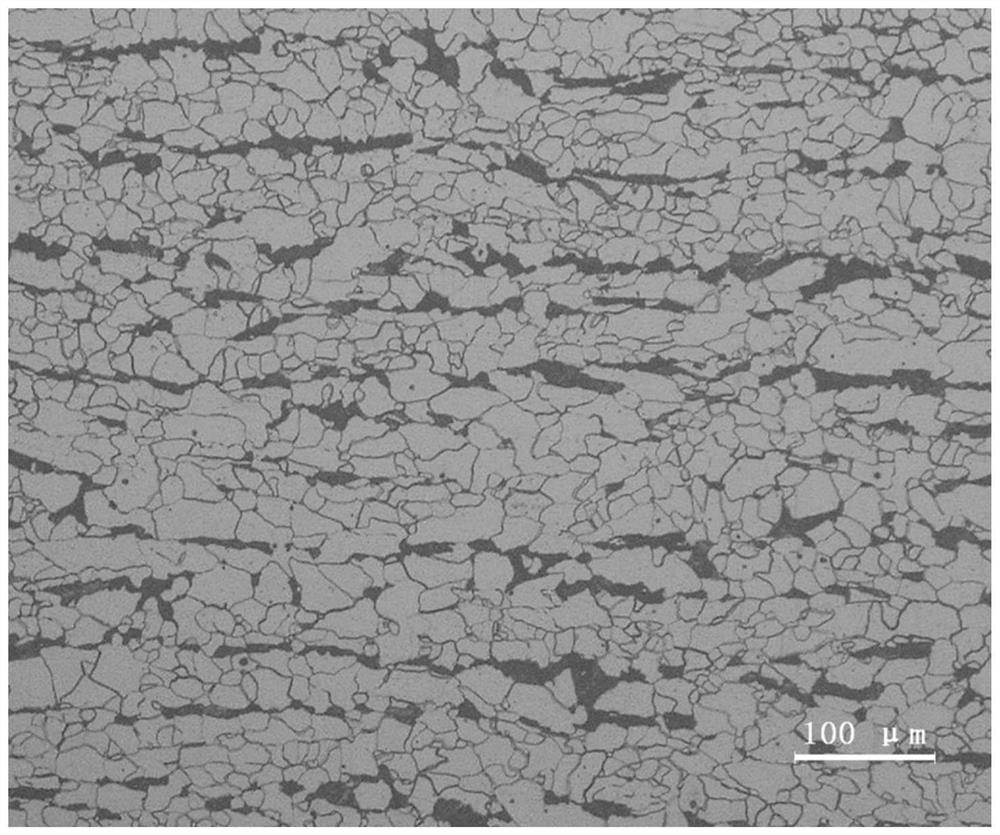

Embodiment 2

[0048] The production process of the steel plate in this embodiment is: blast furnace molten iron → molten iron pre-desulfurization → converter smelting → deoxidation alloying → LF refining → VD refining → slab continuous casting → slab reheating → slab descaling → 3500 mill rolling → straightening Straightening → laminar cooling → straightening → air cooling → finished product sampling inspection → storage.

[0049] Specifically: molten steel is smelted on a 120t converter, and the molten steel is cast into a slab with a thickness of 250mm; the continuous casting slab is reheated and the temperature is 1164 °C; the rolling after the continuous casting slab is released: the rough rolling temperature is 1149 °C, and the final rolling temperature is 1051 °C , the thickness of the intermediate billet is 82mm; the finishing rolling temperature is 862℃, the final rolling temperature is 838℃, and the steel plate is rolled into 36mm;

[0050] The chemical quality components of the fi...

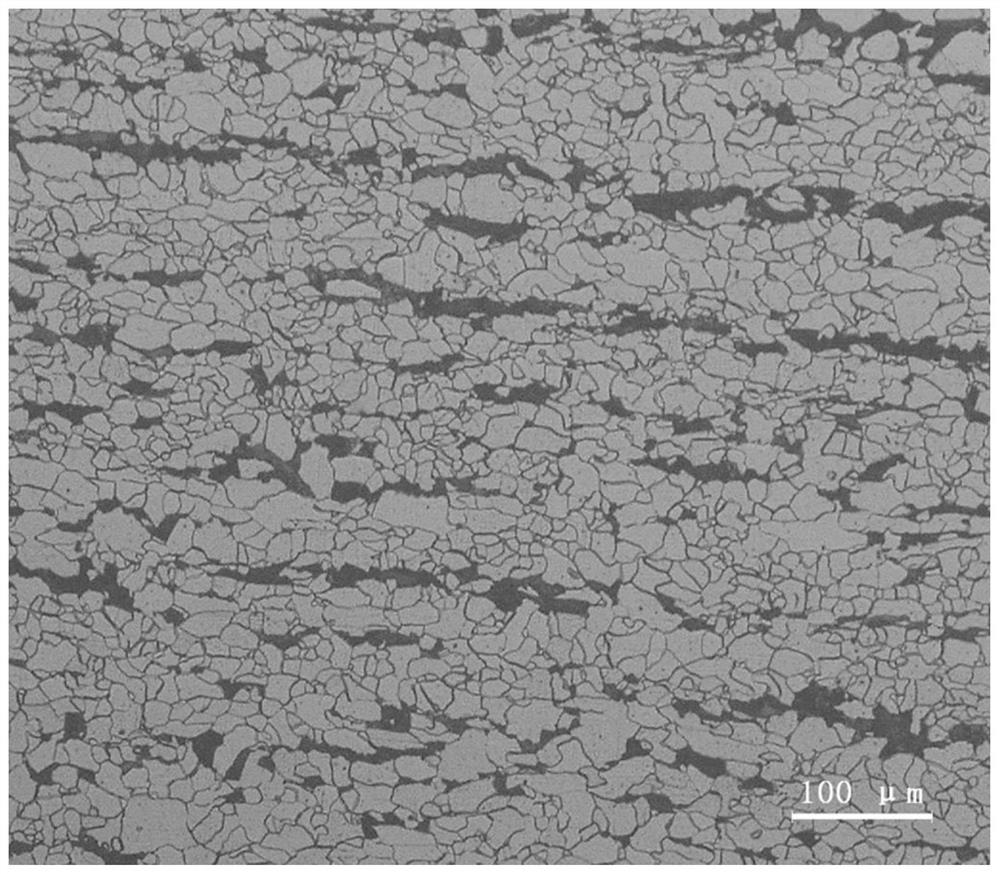

Embodiment 3

[0055] The production process of the steel plate in this embodiment is: blast furnace molten iron → molten iron pre-desulfurization → converter smelting → deoxidation alloying → LF refining → VD refining → slab continuous casting → slab reheating → slab descaling → 3500 mill rolling → straightening Straightening → laminar cooling → straightening → air cooling → finished product sampling inspection → storage.

[0056] Specifically: molten steel is smelted on a 120t converter, and the molten steel is cast into a slab with a thickness of 250mm; the continuous casting slab is reheated to a temperature of 1164 °C; rolling after the continuous casting slab is released: the rough rolling temperature is 1145 °C, and the final rolling temperature is 1043 °C , the thickness of the intermediate billet is 110mm; the finishing rolling temperature is 831 ℃, the final rolling temperature is 826 ℃, and the steel plate is rolled into a 60mm;

[0057] The chemical quality components of the fini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com