Thick-specification FH690-grade ultrahigh-strength maritime work steel plate and preparation method thereof

A FH690, ultra-high-strength technology, applied in the direction of rolling force/roll gap control, etc., can solve the problem of not meeting the -60 °C impact standard, etc., and achieve the effect of excellent strength and toughness matching comprehensive performance, cost reduction, and large thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Another object of the present invention is to provide the preparation method of above-mentioned steel plate, specifically comprise following production process:

[0033] 1) Smelting and casting process: Converter smelting, out-of-furnace refining, vacuum treatment and continuous casting are used for production, the O content is controlled below 30ppm, the N content is controlled below 60ppm, the H content is controlled below 2ppm, and the tundish molten steel is passed Heat ≤ 25°C, use electromagnetic stirring and light pressure, protect the casting during the whole process, and obtain continuous casting slabs after continuous casting, the thickness of the continuous casting slabs is 250~350mm, and the width is 2000~2400mm. The internal low-magnification inspection results of continuous casting slabs meet: central segregation≤class C class 1.5, intermediate cracks≤1.0, and no other crack defects;

[0034] 2) Heating process: the billet heating temperature is 1220±30°C, ...

Embodiment 1

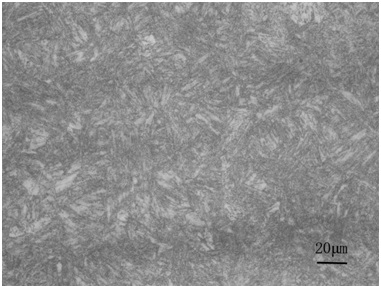

[0043] 100mm thick marine steel, continuous casting slab size 350mm thick x 2000mm wide x 3700mm long, rolled finished steel plate size 100mm thick x 2690mm wide x 9400mm long, cold-packed, heating temperature 1220 ℃ ~ 1250 ℃, heating time 425 minutes, Two-stand two-stage controlled rolling, rough rolling start temperature 1059°C, continuous rolling to 116mm thick intermediate billet, final rolling temperature 970°C, rough rolling final rolling reduction rate 24.5%. The finish rolling start temperature is 827°C, the finish rolling temperature is 805°C, laminar cooling after rolling, the cooling rate is 15.5°C / s, the redness temperature is 604°C, and then air-cooled to room temperature. The QT process is used for heat treatment, specifically: heating the hot-rolled steel plate that is air-cooled to room temperature to 880°C for full austenitization, 300 minutes in the furnace, and then quenching and cooling to room temperature; then heating the quenched steel plate to Tempering...

Embodiment 2

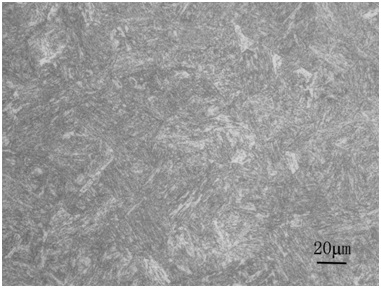

[0047] 50mm thick marine steel, continuous casting slab size 350mm thick x 2000mm wide x 2410mm long, rolled finished steel plate size 50mm thick x 2690mm wide x 13000mm long, cold-packed, heating temperature 1220 ℃ ~ 1250 ℃, heating time 422 minutes; Two-stand two-stage controlled rolling, rough rolling start temperature 1027°C, continuous rolling to 111mm thick intermediate billet, final rolling temperature 983°C, rough rolling final rolling reduction rate 19.95%. The finish rolling start temperature is 855°C, the finish rolling temperature is 845°C, laminar cooling after rolling, the cooling rate is 19.6°C / s, the redness temperature is 633°C, and then air-cooled to room temperature. The QT process is used for heat treatment, specifically: heating the hot-rolled steel plate that is air-cooled to room temperature to 880°C for full austenitization, and the furnace time is 150 minutes, strictly controlling the austenitization temperature and holding time to prevent abnormally co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com