Non-quenched and tempered steel for high-strength high-low-temperature impact toughness lifting hook and production process thereof

A technology of impact toughness, non-quenched and tempered steel, which is applied in the field of non-quenched and tempered steel for high-strength, high-low temperature impact toughness hooks and production technology, can solve the problem of insufficient impact toughness and plasticity of non-quenched and tempered steel, and toughness that is difficult to reach quenched and tempered steel. , low toughness and other problems, to achieve the effect of shortening the processing process, energy saving and environmental protection production cost, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

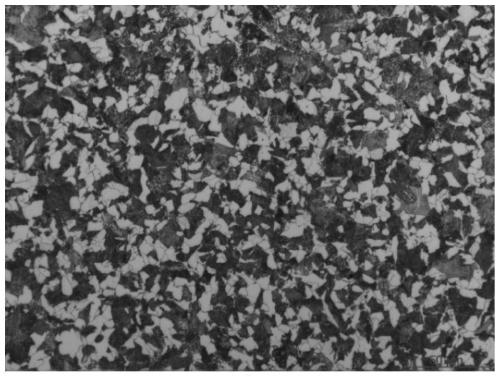

Image

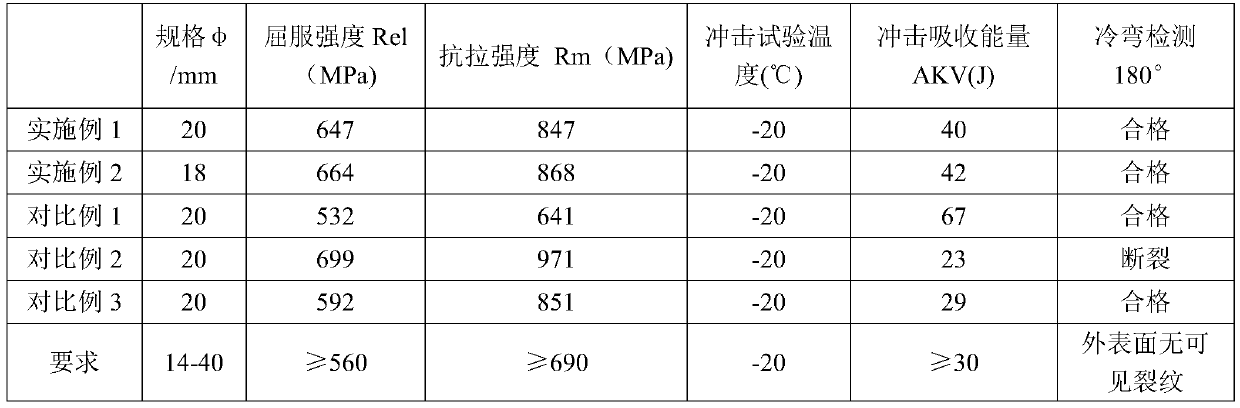

Examples

Embodiment 1

[0047]A non-quenched and tempered steel for high-strength high-low temperature impact toughness hooks, its chemical composition is calculated by weight percentage: C0.34%, Si 0.30%, Mn 1.61%, V 0.094%, Al 0.026%, P 0.009%, S 0.003%, H 1.0ppm, O 7ppm, the rest is Fe.

[0048] The tapping amount of the electric furnace is 100t, and the tapping P is 0.007%. During the tapping process, 80kg of aluminum particles, alloys, carburizers, and slag are added in sequence.

[0049] In the early stage of LF refining, the Al content was adjusted to 0.039%, silicon carbide was used for diffusion deoxidation, the slag basicity was 4.5, and the S content was 0.004% at the end of LF refining.

[0050] During the vacuum treatment process, the high vacuum (≤67Pa) time is 14 minutes; after the vacuum is broken, the target hydrogen is 1.0ppm, the molten steel is covered with carbonized rice husk, and the soft blowing time is 23 minutes.

[0051] The continuous casting section is 220mm×260mm, the c...

Embodiment 2

[0056] A non-quenched and tempered steel for high-strength high-low temperature impact toughness hooks, the chemical composition of which is calculated by weight percentage: C0.35%, Si 0.30%, Mn 1.63%, V 0.093%, Al 0.029%, P 0.009%, S 0.002%, H 1.0ppm, O 7ppm, the rest is Fe.

[0057] The tapping amount of the electric furnace is 100t, and the tapping P is 0.007%. During the tapping process, 80kg of aluminum particles, alloys, carburizers, and slag are added in sequence.

[0058] In the early stage of LF refining, the Al content was adjusted to 0.040%, silicon carbide was used for diffusion deoxidation, the slag basicity was 4.4, and the S content was 0.004% at the end of LF refining.

[0059] During the vacuum treatment process, the high vacuum (≤67Pa) time is 13 minutes; the target hydrogen concentration is 1.0ppm after the vacuum is broken, and the molten steel is covered with carbonized rice husks, and the soft blowing time is 25 minutes.

[0060] The cross-section of con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com