Patents

Literature

89results about How to "Solve problems such as waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum electrolyzed waste carbon residue innocent treatment system and method thereof

ActiveCN103831285AAdvanced technologyInnovative design ideasSolid waste disposalCarbon preparation/purificationExhaust gasHeating furnace

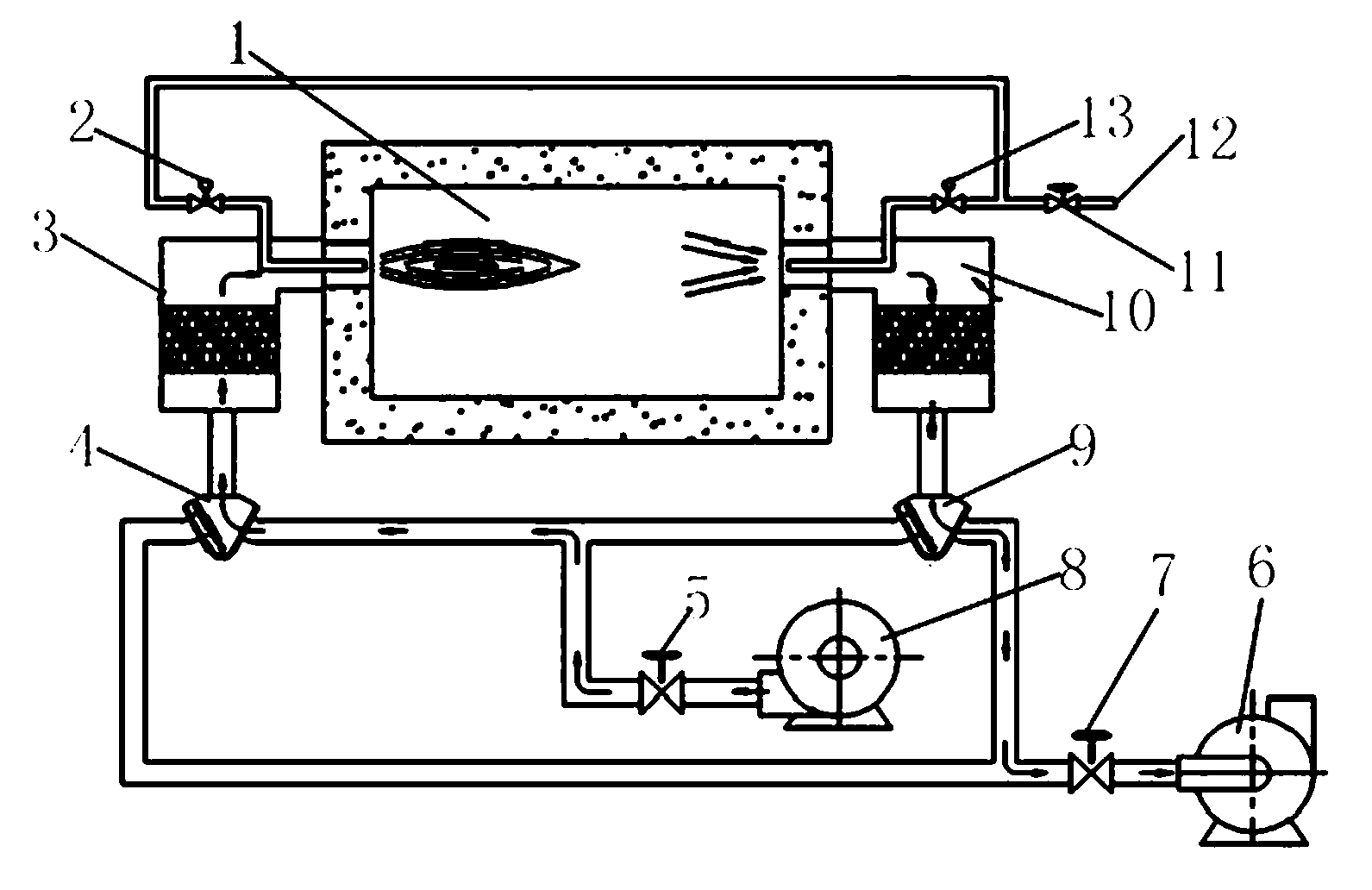

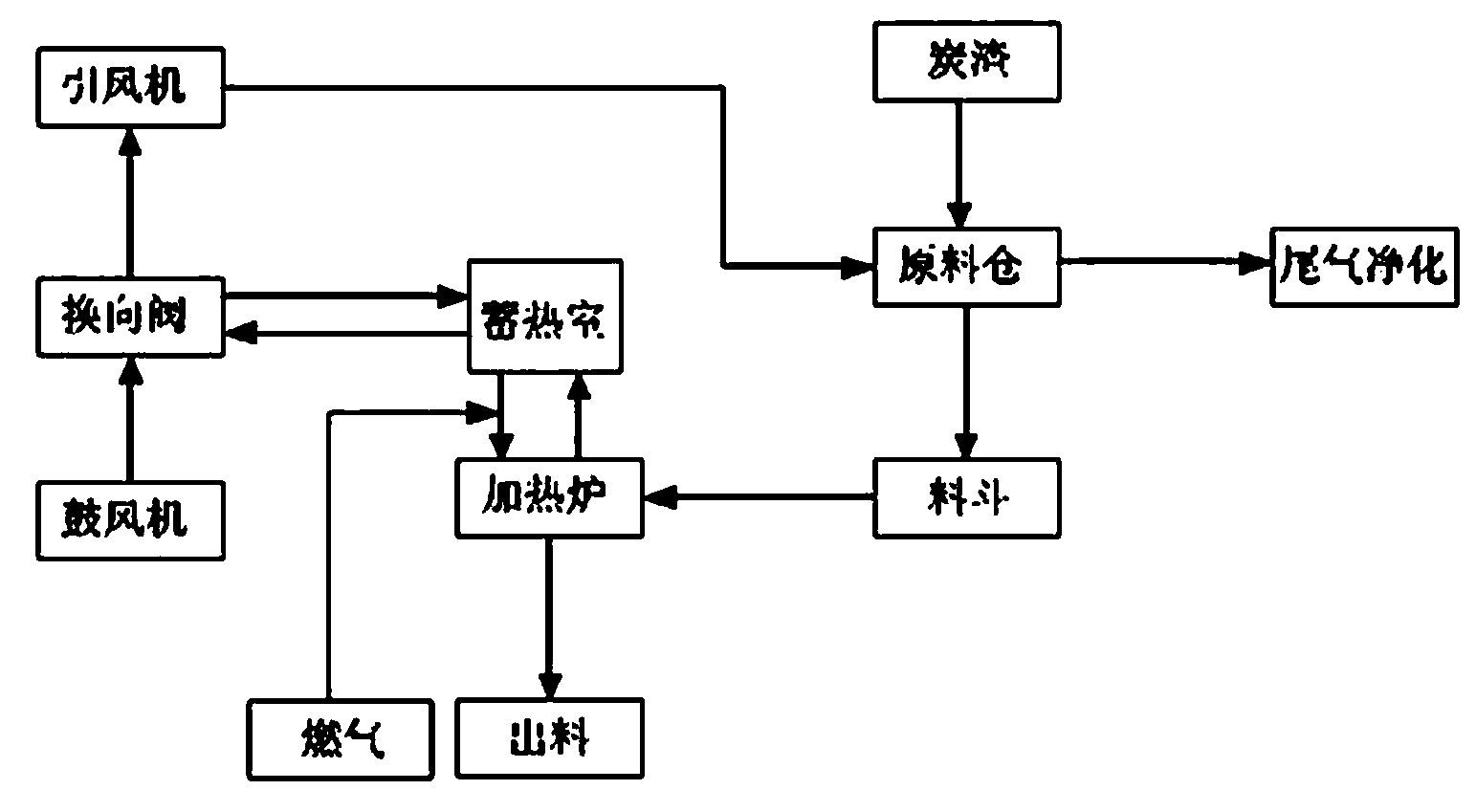

The invention discloses an aluminum electrolyzed waste carbon residue innocent treatment system and a method thereof, and aims at solving the technical problems of low carbon residue reclaiming utilization and environmental pollution in current electrolytic aluminum industry. The system comprises a heating furnace, a heating circulation device, a tail gas purification device, a hopper correspondingly communicated with the heating furnace and a raw material bin correspondingly communicated with the hopper, wherein the heating circulation device is respectively and correspondingly communicated with the heating furnace and the raw material bin; a tail gas outlet communicated with the tail gas purification device is formed in the raw material bin. According to the aluminum electrolyzed waste carbon residue innocent treatment system, the problems that accumulation or landfill of waste slot liner carbon residues pollutes environment, massive raw materials are wasted and the like, which trouble the electrolytic aluminum industry for years, can be effectively solved.

Owner:ZHENGZHOU JINGWEI TECH & IND

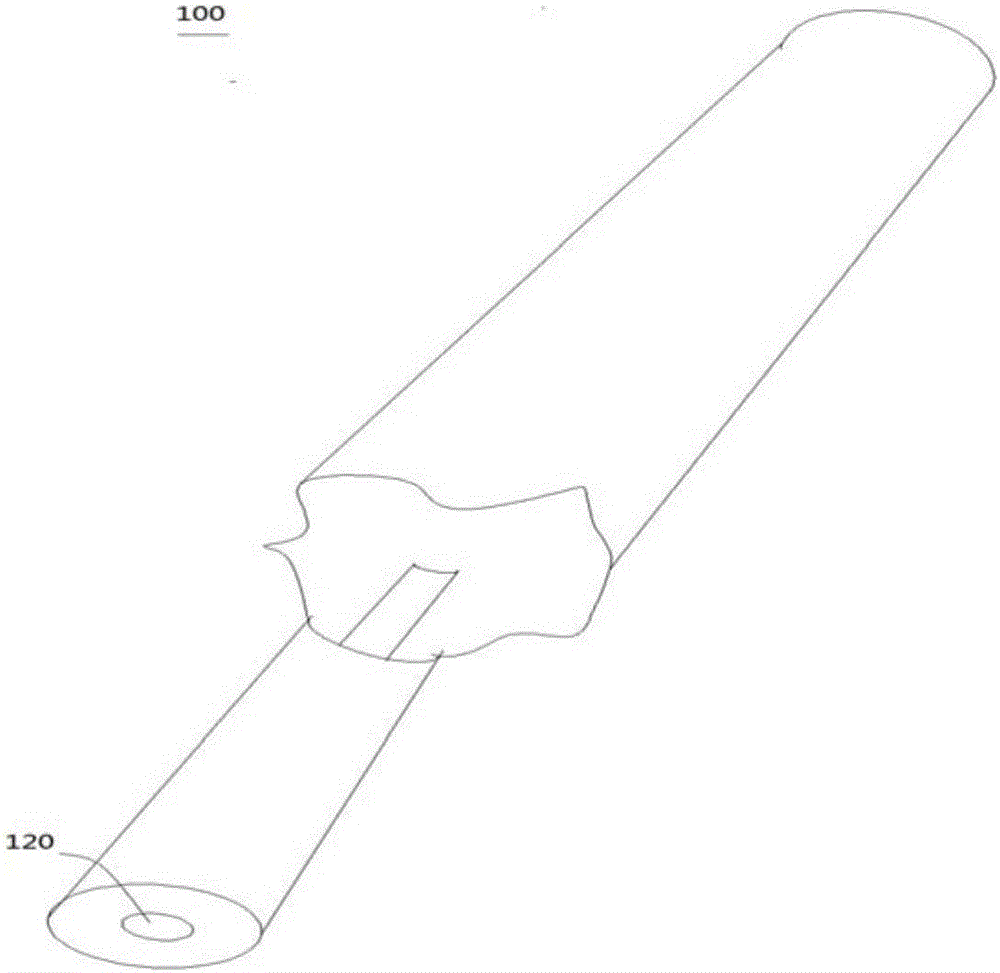

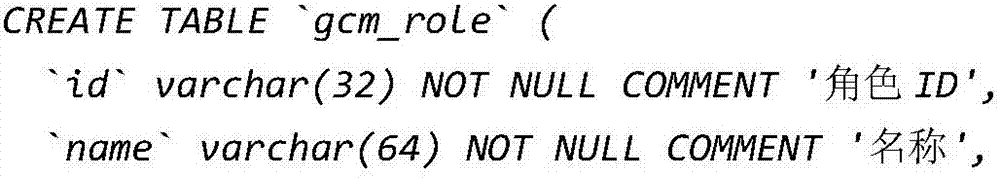

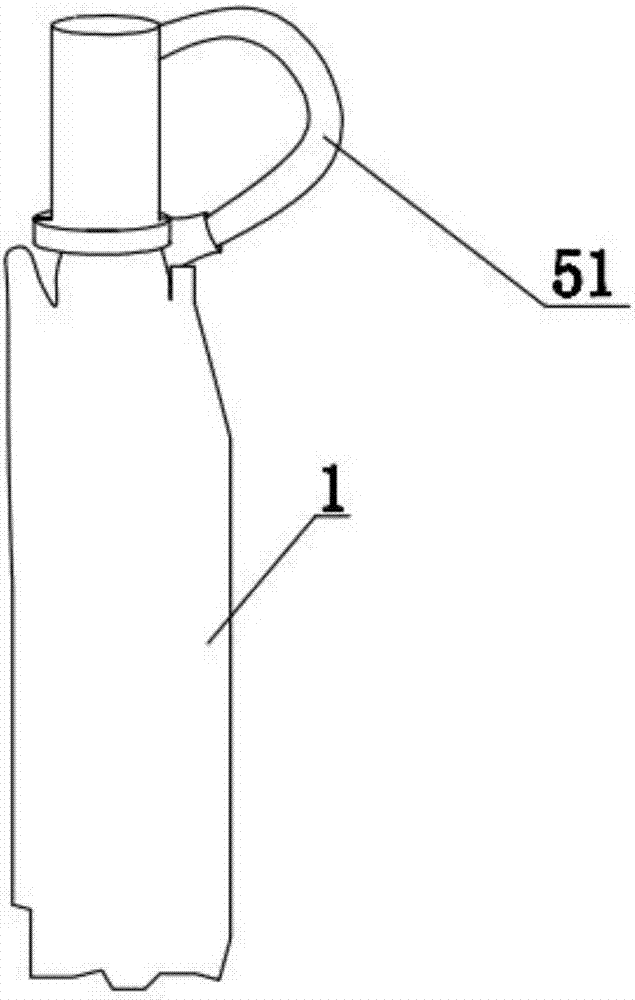

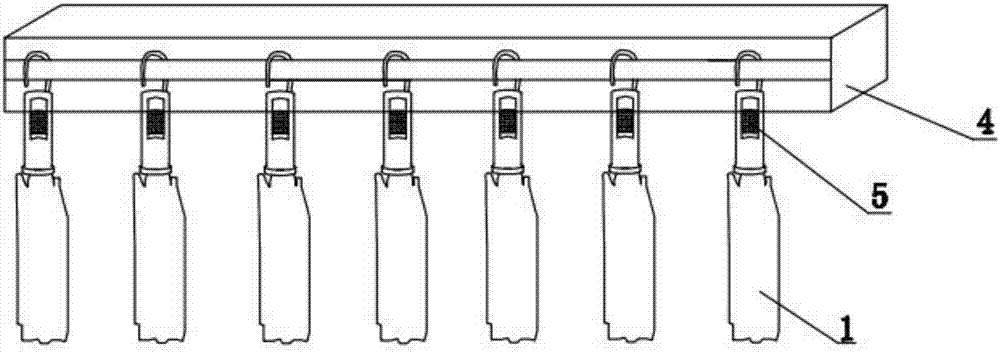

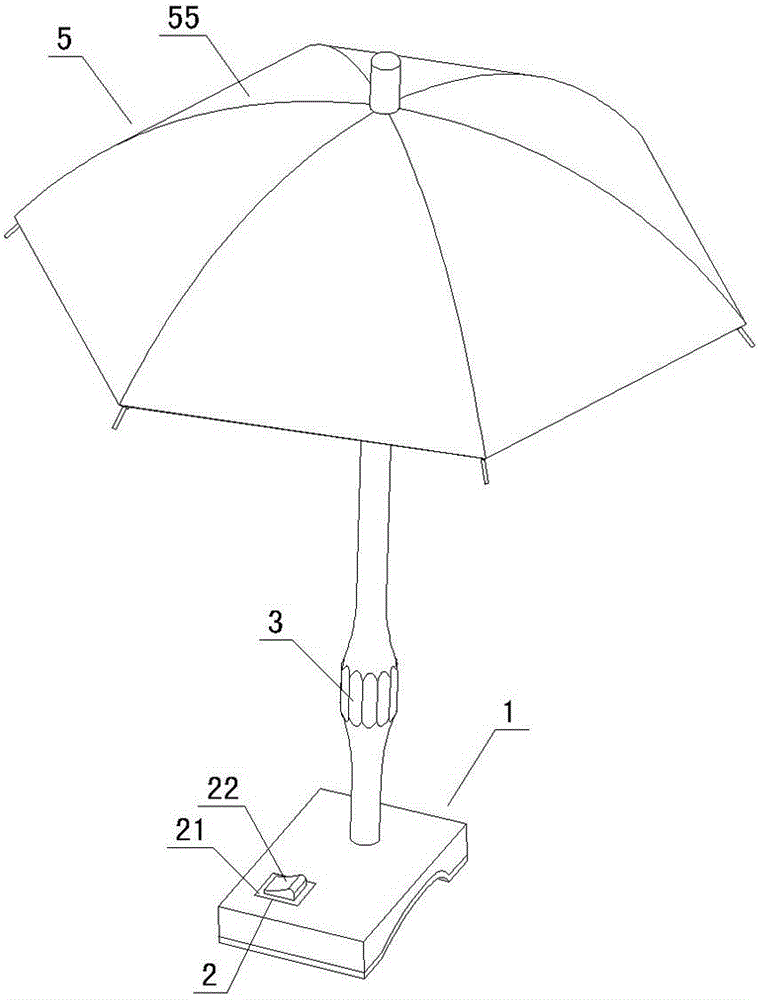

Umbrella sharing system, method and device

InactiveCN106355775AImprove efficiencyImprove convenienceApparel holdersApparatus for meter-controlled dispensingComputer terminalManagement system

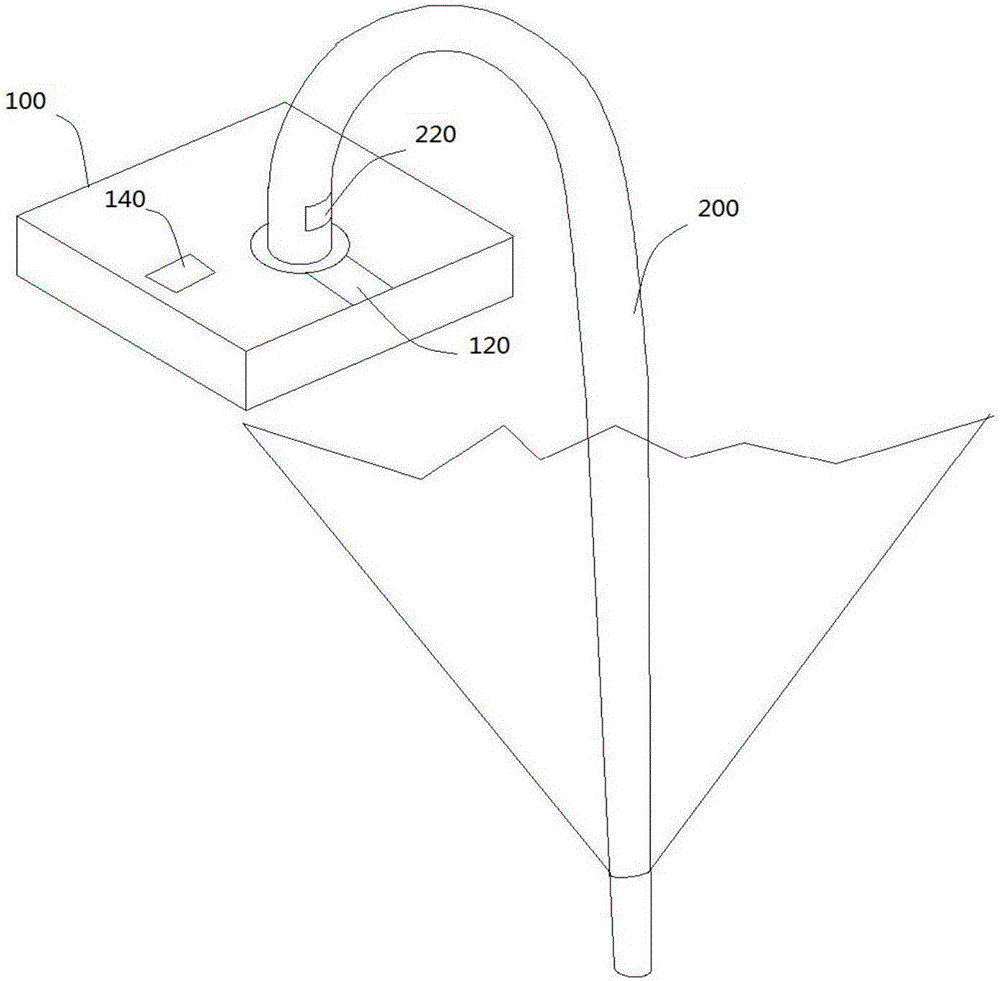

The invention provides an umbrella sharing system, method and device, and relates to the technical field of control management, wherein the system comprises an umbrella, a base for containing the umbrella, an electronic lock for locking the umbrella at the base, and an umbrella management system, wherein an recognizing device and first recognition code for marking the identity information of the electronic lock are arranged on the base; the umbrella is provided with second recognition code for marking the umbrella identity information; the umbrella management system comprises a processing device used for controlling the electronic lock to be unlocked, a user terminal used for scanning the first recognition code to obtain the identity information of the electronic lock and a server end used for sending an electronic lock unlocking instruction to a processing device according to the identity information of the electronic lock. Through the design of the umbrella sharing system, the problems that people get wet in the rain when not bringing the umbrella in a rainy day, the space resource waste is caused when people carry the umbrella in a day without the rain, and the like can be solved.

Owner:谢明

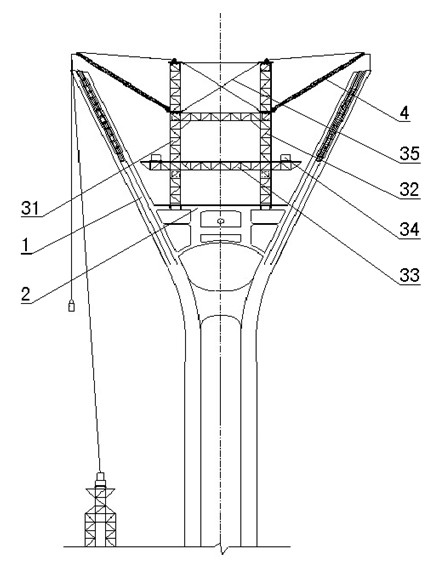

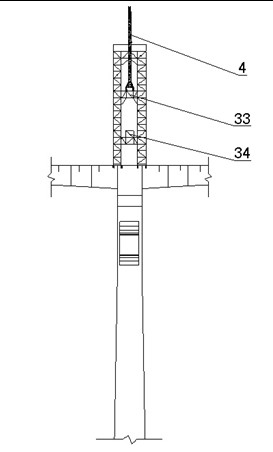

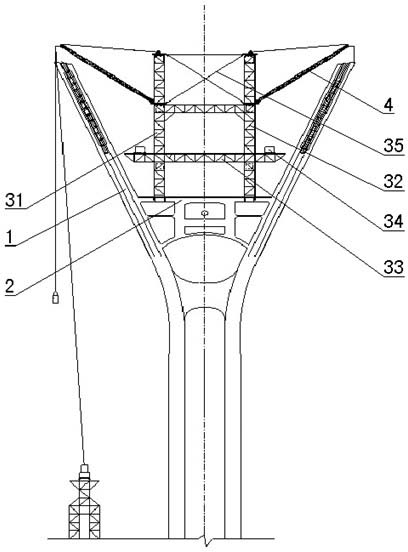

Construction method of steel-concrete mixed Y-shaped tower of low-pylon cable-stayed bridge

InactiveCN102168405AAvoid wastingStrong flexibility and adaptabilityBridge structural detailsBridge erection/assemblyLift systemCable stayed

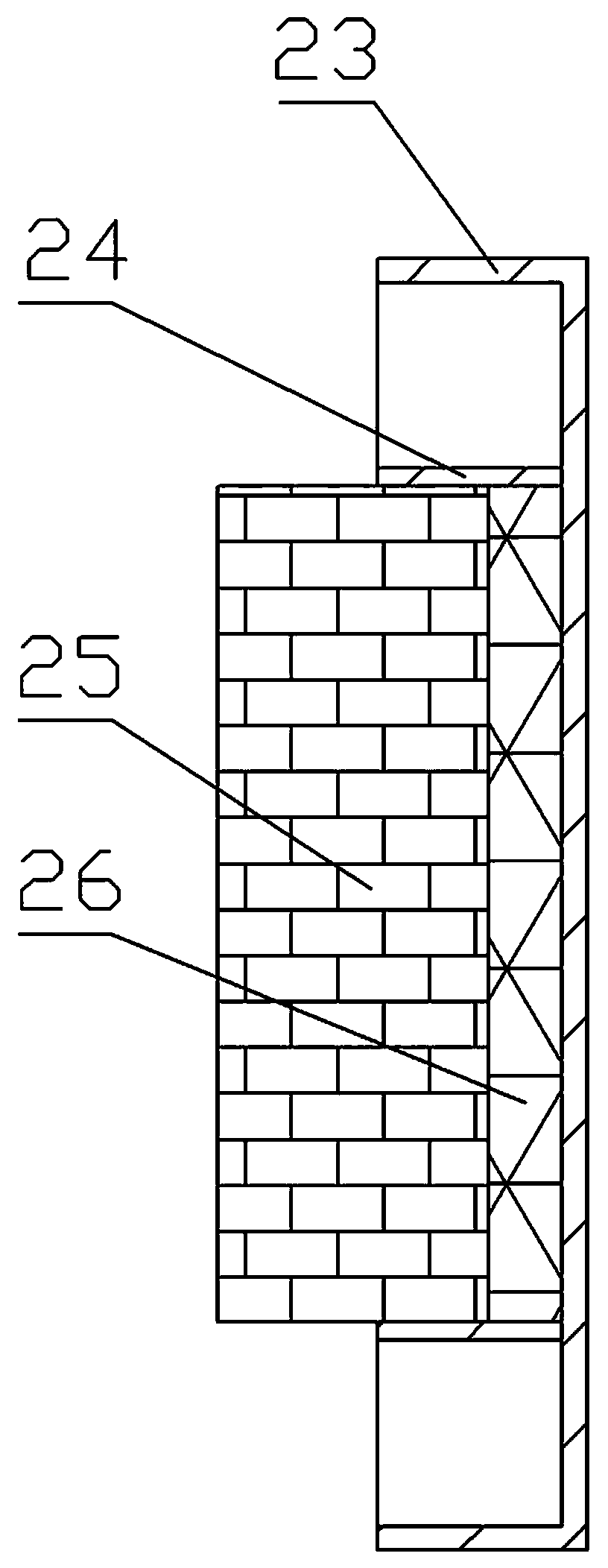

The invention discloses a construction method of a steel-concrete mixed Y-shaped tower of a low-pylon cable-stayed bridge. The invention relates to the construction method of architectural details of a bridge structure, also relates to a lifting device used in the construction method, and aims at solving the problems of waste and the like caused by adoption of a super-tonnage tower crane in the prior art. The construction method comprises the following steps of: manufacturing a segment steel anchor box, and arranging a rod piece support lifting system on a girder at the root part of a pylon of the Y-shaped tower; lifting and fixing the segment steel anchor box by using the rod piece support lifting system, and carrying out concrete construction on the segment steel anchor box after lifting and fixing; and removing the rod piece support lifting system. Compared with the prior art, the rod piece support lifting system is adopted for lifting the steel box girder so that the waste caused by usage of the super-tonnage tower crane is avoided, and the construction method has extremely strong adaptability and flexibility.

Owner:CHONGQING URBAN CONSTR HLDG GRP +1

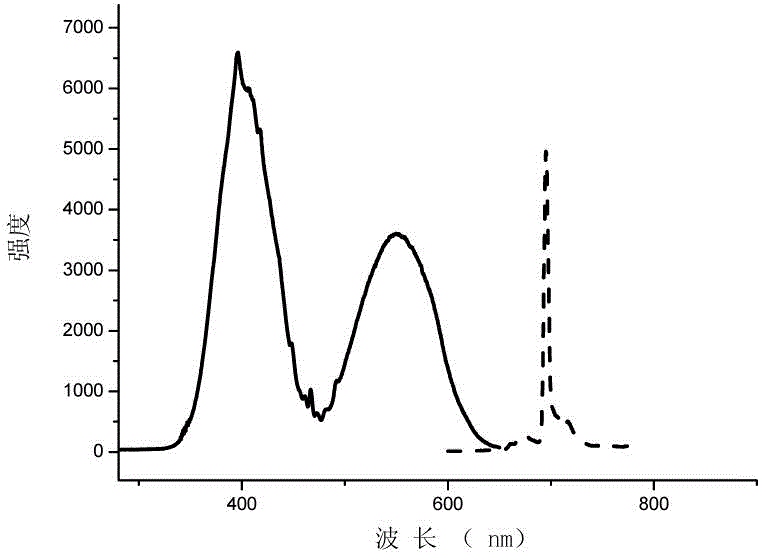

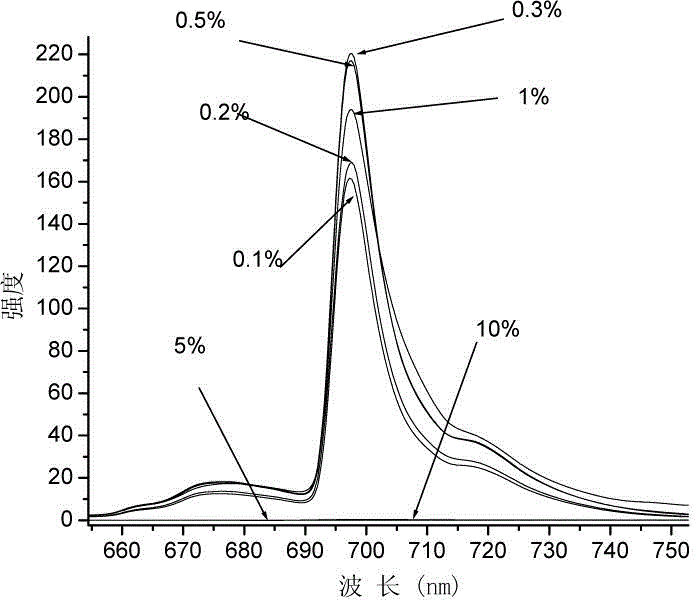

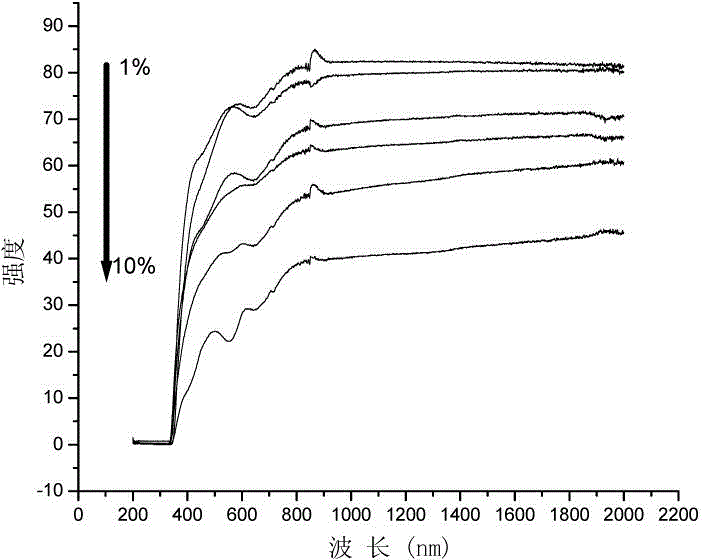

Cr<3+>-activated alumina glass-ceramic for agricultural greenhouse and its preparation method and use

ActiveCN103332863ASolve pollutionSolve problems such as wasteLuminescent compositionsGrowth plantGreenhouse

The invention discloses a Cr<3+>-activated alumina glass-ceramic for an agricultural greenhouse and its preparation method and use. The Cr<3+>-activated alumina glass-ceramic is obtained by doping 1-10wt% of a mixture of Al2O3 and Cr2O3 in a low-melting point glass material, wherein the mixture of Al2O3 and Cr2O3 comprises 0.1-1mol% of Cr2O3. The Cr<3+>-activated alumina glass-ceramic can realize selective absorption and permeation of light. The Cr<3+>-activated alumina glass-ceramic can be used for the agricultural greenhouse, has a long service life, solves the problem that a film-type light replacement product produces pollution and waste, and is in accordance with development tendency of a light conversion material for plant growth.

Owner:HEBEI UNIVERSITY

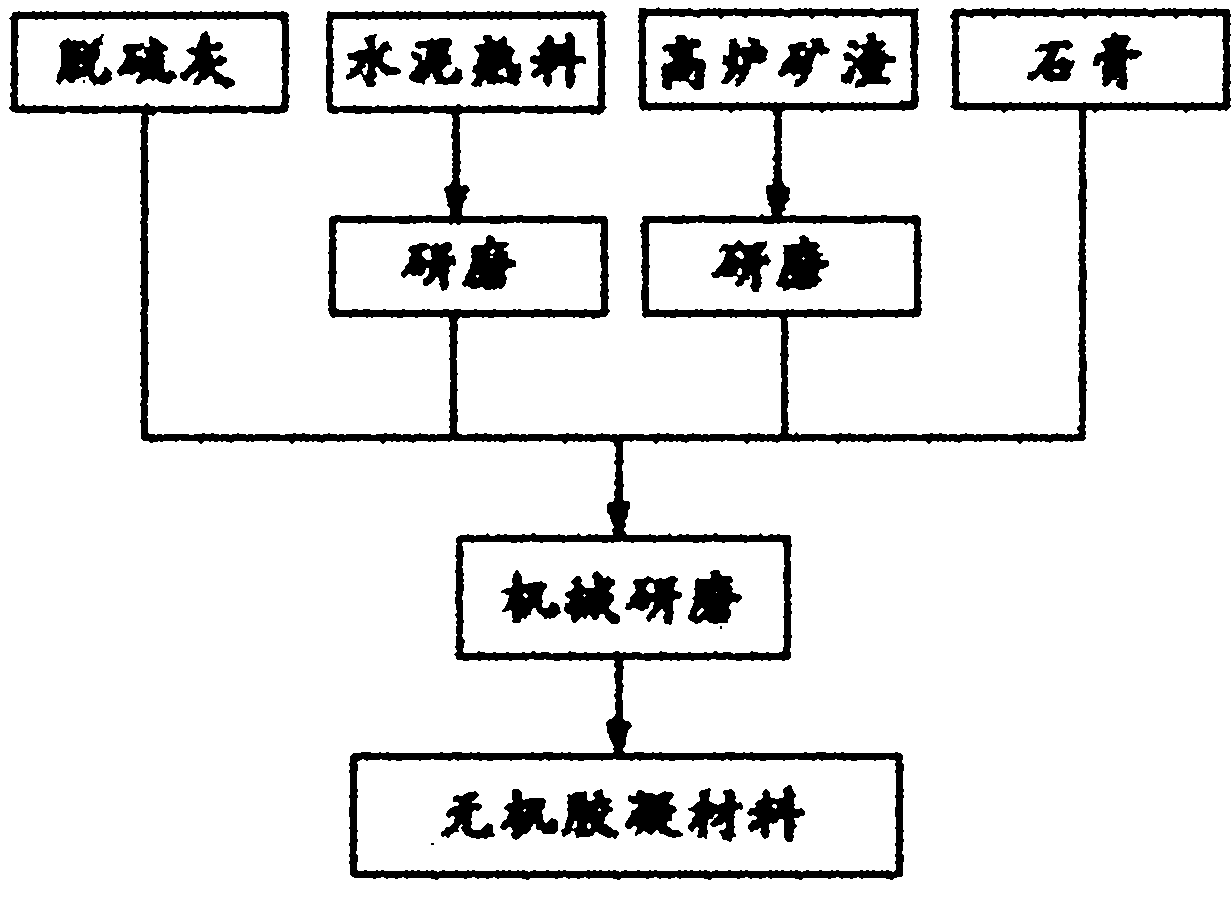

Flue gas desulfurization byproduct-based inorganic gelled material and preparation method thereof

InactiveCN101973719AIncrease profitSolve secondary pollutionClinker productionNatural resourceHigh energy

The invention discloses a flue gas desulfurization byproduct-based inorganic gelled material and a preparation method thereof. In the material, desulfurization ash generated in flue gas desulfurization treatment of a coal fired power plant is used as a main material; and slag, gypsum and cement clinker are mixed and ground with the main material to form the inorganic gelled material. The inorganic gelled material comprises the following components in percentage by weight: 30 to 40 percent of desulfurization ash, 45 to 55 percent of slag, 3 to 5 percent of gypsum and 8 to 12 percent of cement clinker. Because the desulfurization ash is used as a raw material for preparing the inorganic gelled material, no or little natural resource is used, and secondary pollution of the desulfurization ash is reduced. The preparation method comprises the steps of raw material selection, pre-grinding, mixing and grinding. Because the mechanical means is adopted, the raw materials do not need high-temperature calcination treatment, the manufacturing process is very compact, the production cost is extremely low, high energy consumption and high pollution caused by calcination can be avoided, the energy can be greatly saved, and the requirements of energy conservation and emission reduction are met. By detection, various inspection indexes of the inorganic gelled material meet the requirement of 22.5 strength level in GB / T3183-2003 Masonry Cement, and the inorganic gelled material can fully replace the traditional product.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

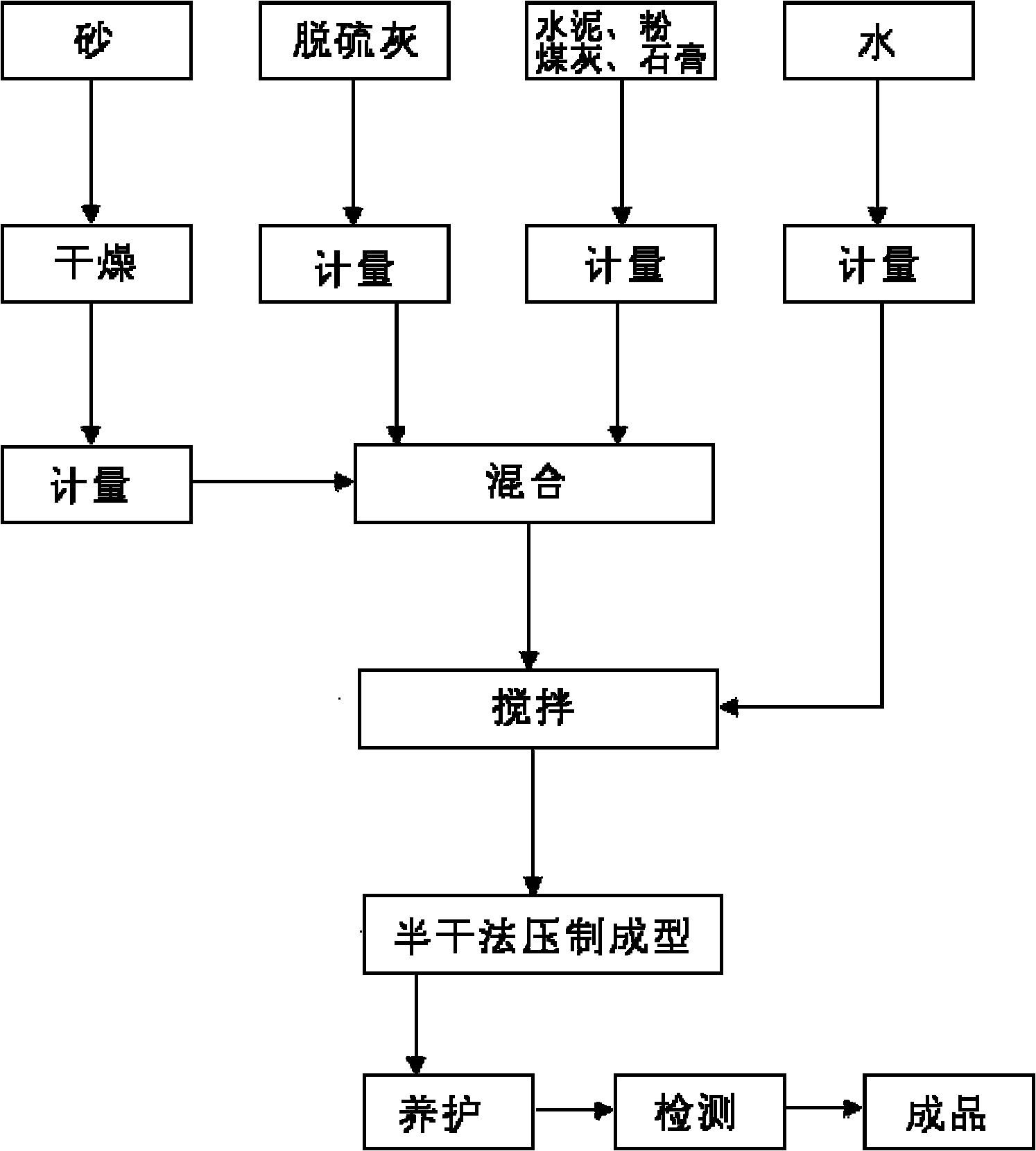

Non-sintered brick based on flue gas desulfurization byproduct and preparation method thereof

InactiveCN101973749AIncrease profitAvoid destructionSolid waste managementEcological environmentLand resources

The invention relates to a non-sintered brick based on a flue gas desulfurization byproduct and a preparation method thereof. The brick is prepared by the following steps: desulfurated ash produced by desulfuration treatment on flue gas generated in a coal fired power plant is taken as a main material, cement, fly ash, gypsum and sand are taken as auxiliary materials, water is added into the main material and the auxiliary materials, the mixture is evenly stirred and then is subject to compression moulding to obtain the brick, wherein the solid raw materials contain the following components by weight percent: 30-35% of the desulfurated ash, 10-15% of the cement, 5-10% of the fly ash, 3-5% of the gypsum and 40-50% of the sand; and the adding amount of the water accounts for 10-12% of the total weight of the solid raw materials. Because the brick takes the desulfurated ash as the raw material instead of solid clay, and natural resources are not used or used as little as possible, which avoids the damage on land resources owing to taking clay and reduces secondary pollution of the desulfurated ash. The preparation method comprises the steps of taking raw materials, mixing the raw materials, carrying out compression moulding and carrying out later-period consevation. The brick is not subject to high temperature sintering treatment, thus energy consumption is greatly reduced, and the protection and the improvement on ecological environment can be achieved more easily. Tests indicate that the non-sintered brick has strength grade greater than or equal to MU 10 grade, and can fully replace the traditional solid clay brick.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

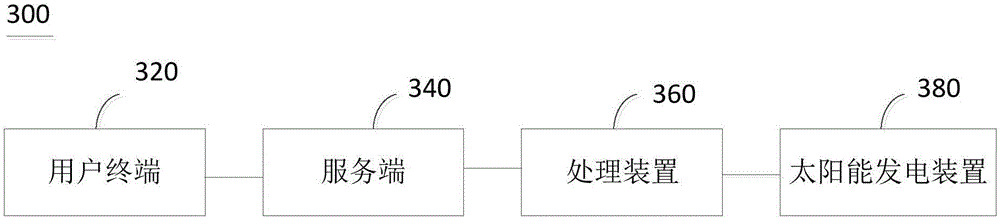

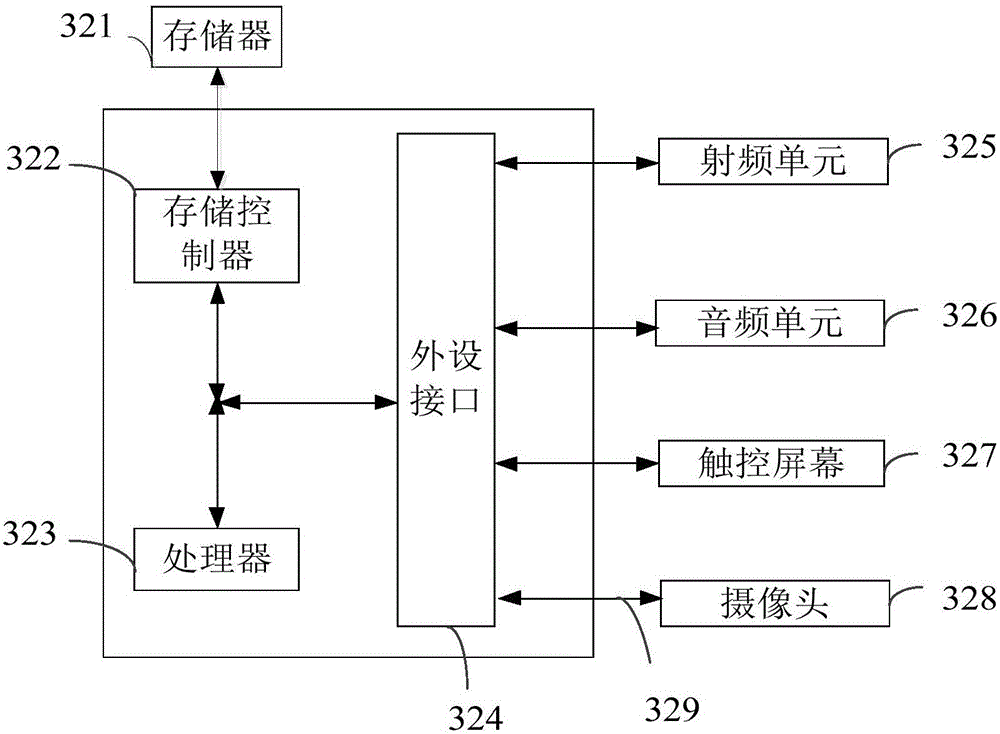

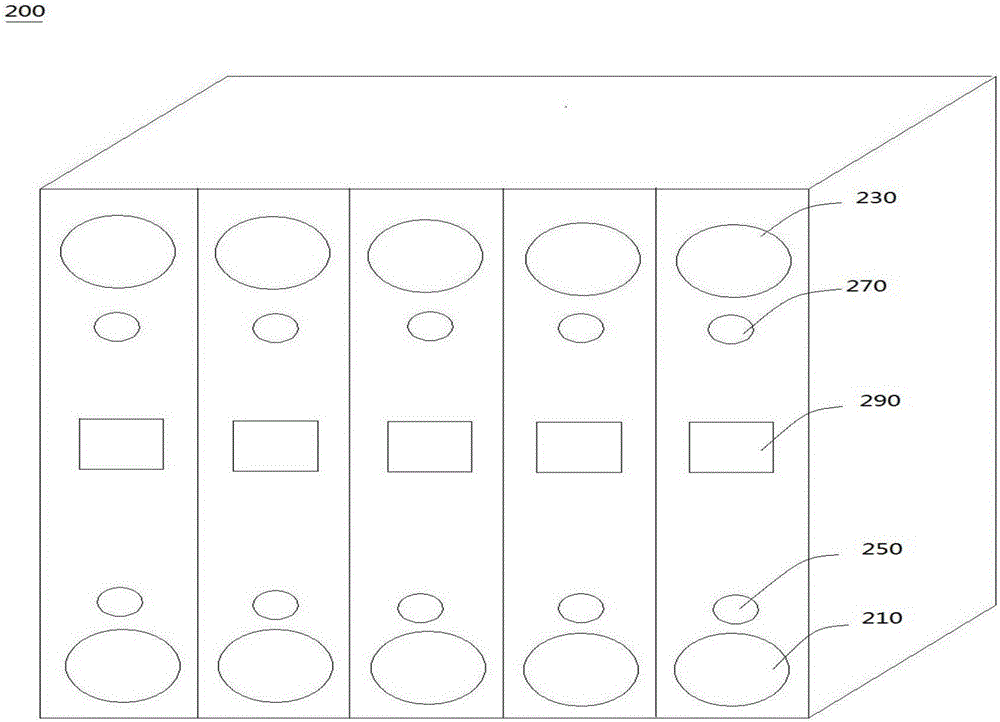

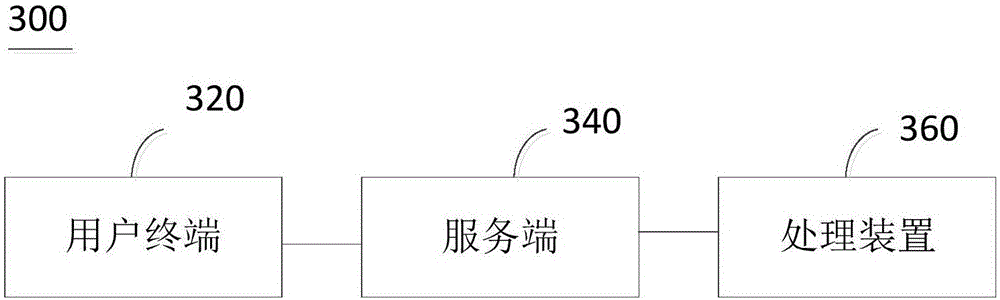

Umbrella sharing system, method and device

PendingCN106355774AImprove efficiencySolve problems such as wasteApparatus for meter-controlled dispensingComputer scienceManagement system

The invention provides an umbrella sharing system, method and device, and relates to the technical field of control management, wherein the system comprises an umbrella, a box body for containing the umbrella and an umbrella management system, wherein first recognition code with umbrella identity information is arranged on the umbrella; an umbrella inlet, an umbrella outlet, a first recognizer for recognizing the first recognizing code, a second recognizer and second recognizing code with umbrella outlet identity information are arranged on the box body; the umbrella management system comprises a user terminal, a server end and a processing device; the user terminal is used for obtaining the umbrella outlet identity information through scanning the second recognition code; the server end is used for sending an umbrella outlet opening instruction to the processing device according to the umbrella outlet identity information; the processing device is used for controlling the opening of the umbrella outlet according to the umbrella outlet opening instruction. Through the design of the umbrella sharing system, the problems that people get wet in the rain when not bringing the umbrella in a rainy day, the space resource waste is caused when people carry the umbrella in a day without the rain, and the like can be solved.

Owner:谢明

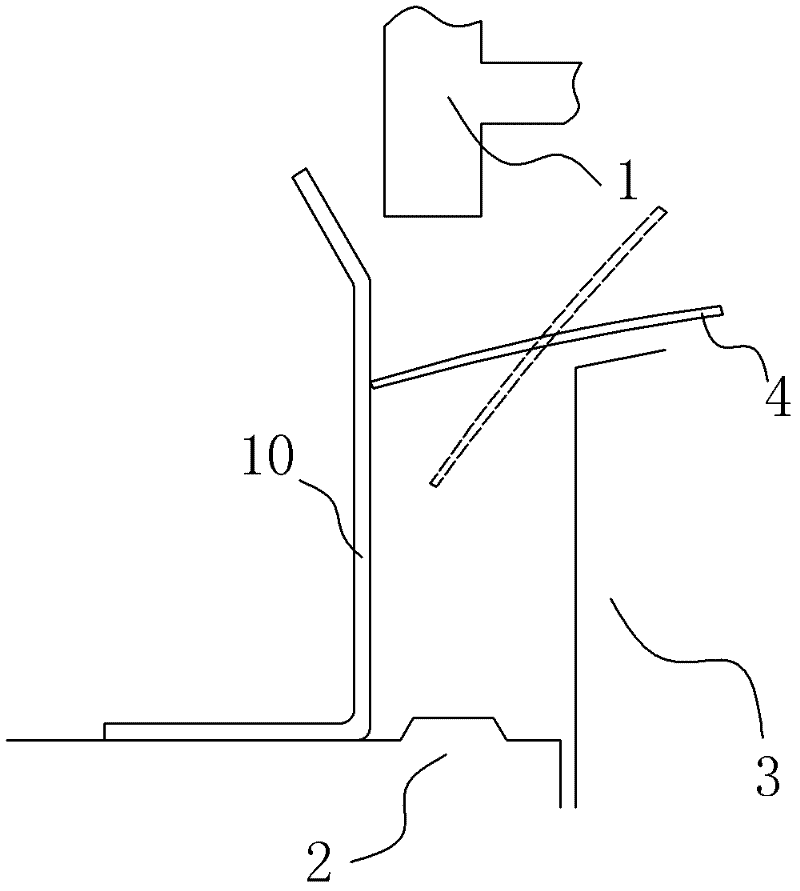

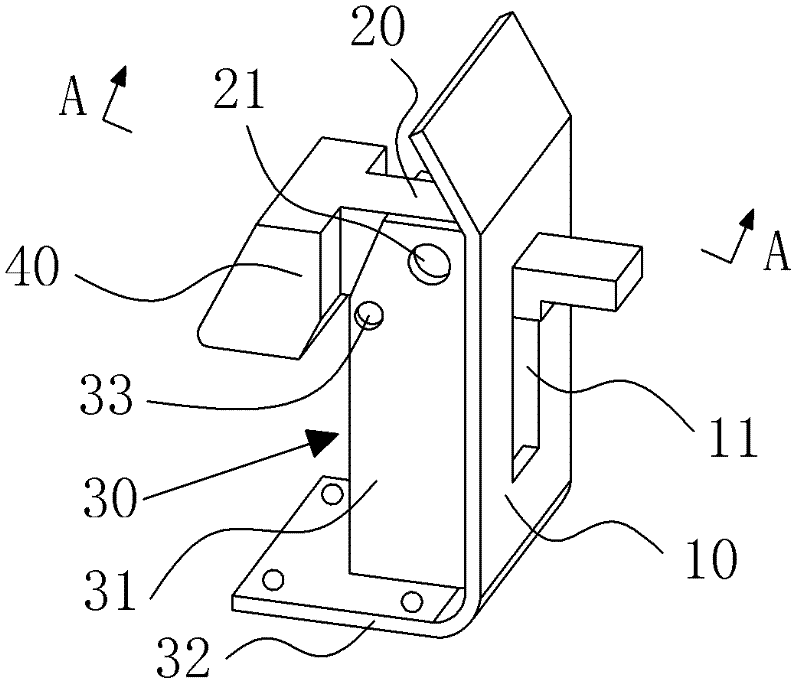

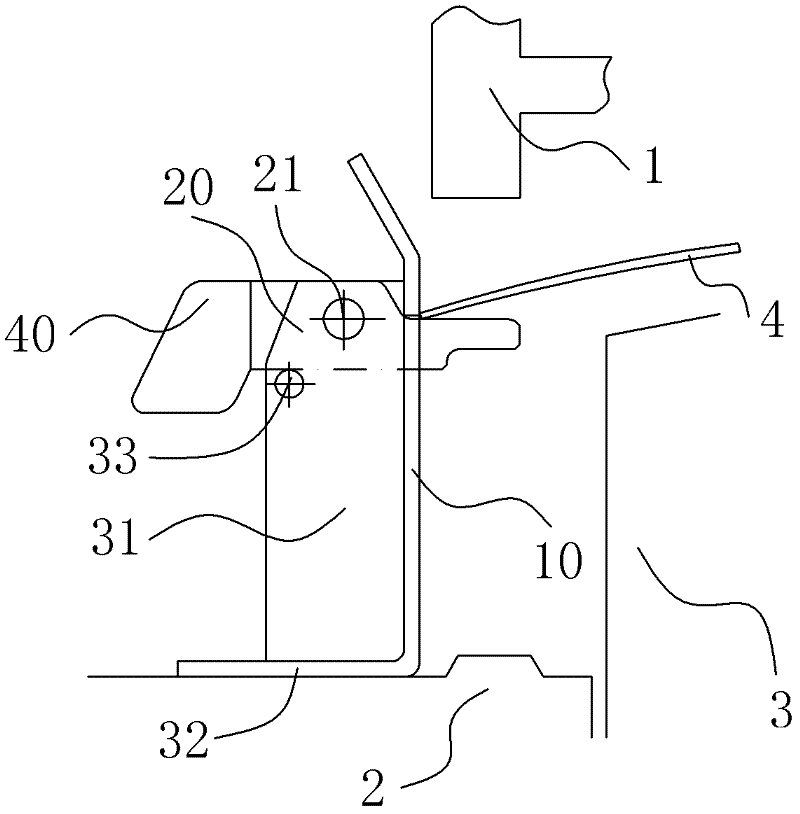

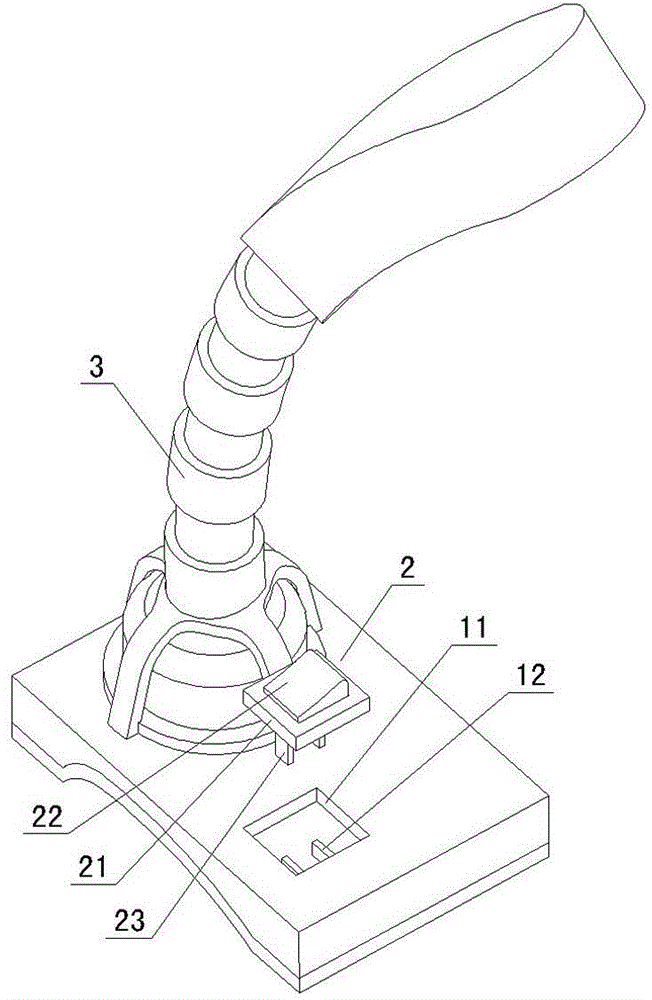

Positioning mechanism

InactiveCN102327989APrevent slippingSolve problems such as wasteShaping toolsMetal-working feeding devicesPunchingEngineering

The invention discloses a positioning mechanism. The positioning mechanism comprises limiting plates which are vertically arranged on a blank holder and a movable member; the movable member has two states, one is a protruding state, namely the movable member protrudes to the front of the limiting plate and the other is a retraction state, namely the movable member retracts to the position at least flush with the plate surface of the limiting plate. The invention is characterized by arranging the movable member; the movable member is in the protruding state, namely protrudes to the front of the limiting plate to fix the position of a material plate and prevent the a suspended end of the material plate from sliding off when the material plate enters into a mould; when the material plate is punched by the mould, the movable member is in the retraction state, namely retracts to the position which is flush with the plate surface of the limiting plate at least, so that the material plate which enters into the mould can be better positioned and the punching of the material plate is not affected. The positioning mechanism is reliable in positioning, simple in structure and convenient in operation, and the problem of material waste and the like because the positioning is realized through the large-sized material plate in a single action drawing mould can be solved effectively.

Owner:CHERY AUTOMOBILE CO LTD

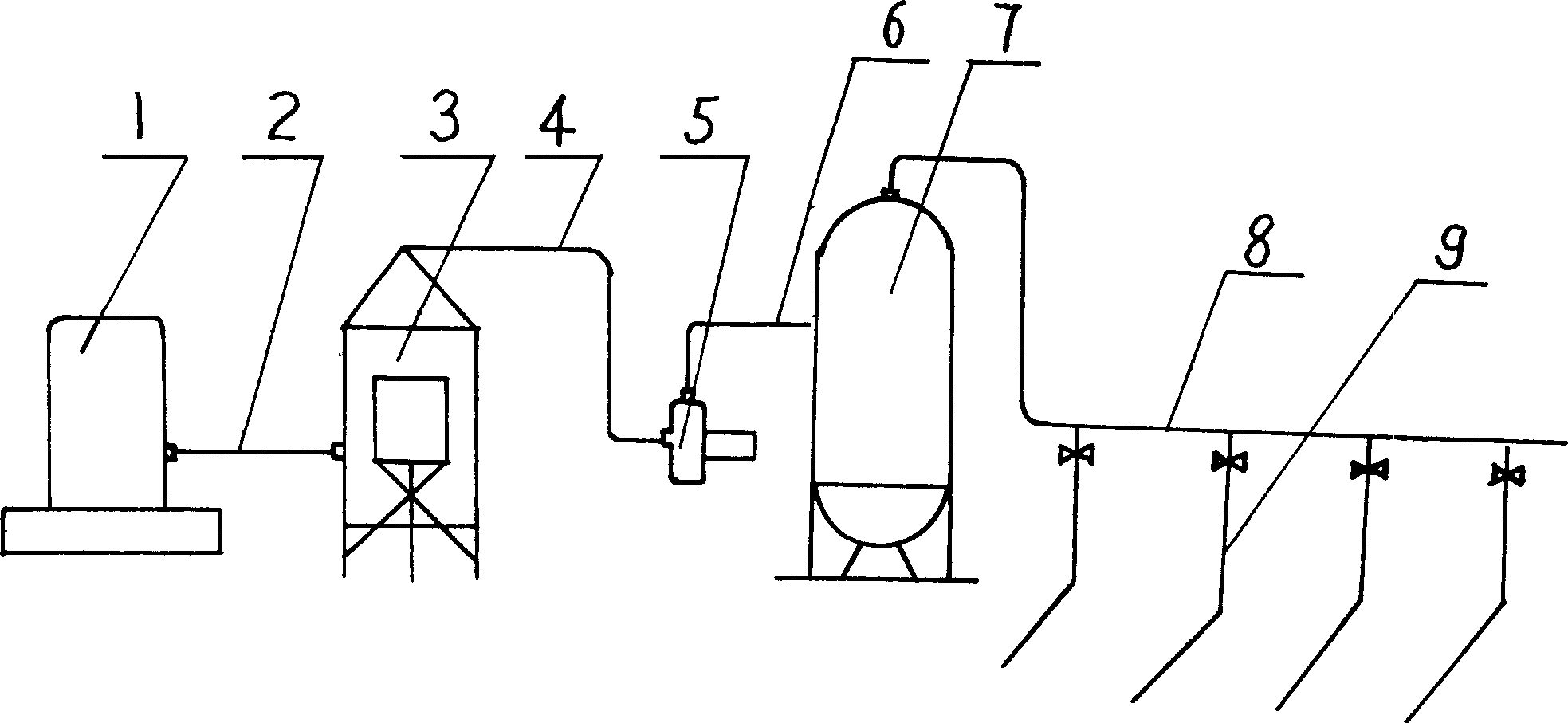

Process and apparatus for supplying environment protection Spirulina ultivating carbon source

InactiveCN1793313AImprove qualityIncrease productionUnicellular algaeWater sourceAtmospheric pollution

The invention relates to an environmental protection type spiral alga breeding carbon source replenishing method and its device. Its main features are as follows: adopting carbon dioxide gaseous fertilizer replenishing method in breeding and drying course; and adding corresponding device; the carbon dioxide gaseous fertilizer is waste flue gas, injected spiral alga raising pond after purifying; the device includes waste gas collecting purifying device, booster pump, surge tank, and carbon dioxide gas injecting device. The invention fully utilizes waste flue gas to form carbon dioxide gaseous fertilizer and uses to replenish carbon source. Thus it can effectively solve the problem of atmospheric and water source pollution. The replenishing course is simple and safe. Thus it can improve growth condition for spiral alga, increase product quality and quantity, and greatly reduce breeding cost.

Owner:梁建国

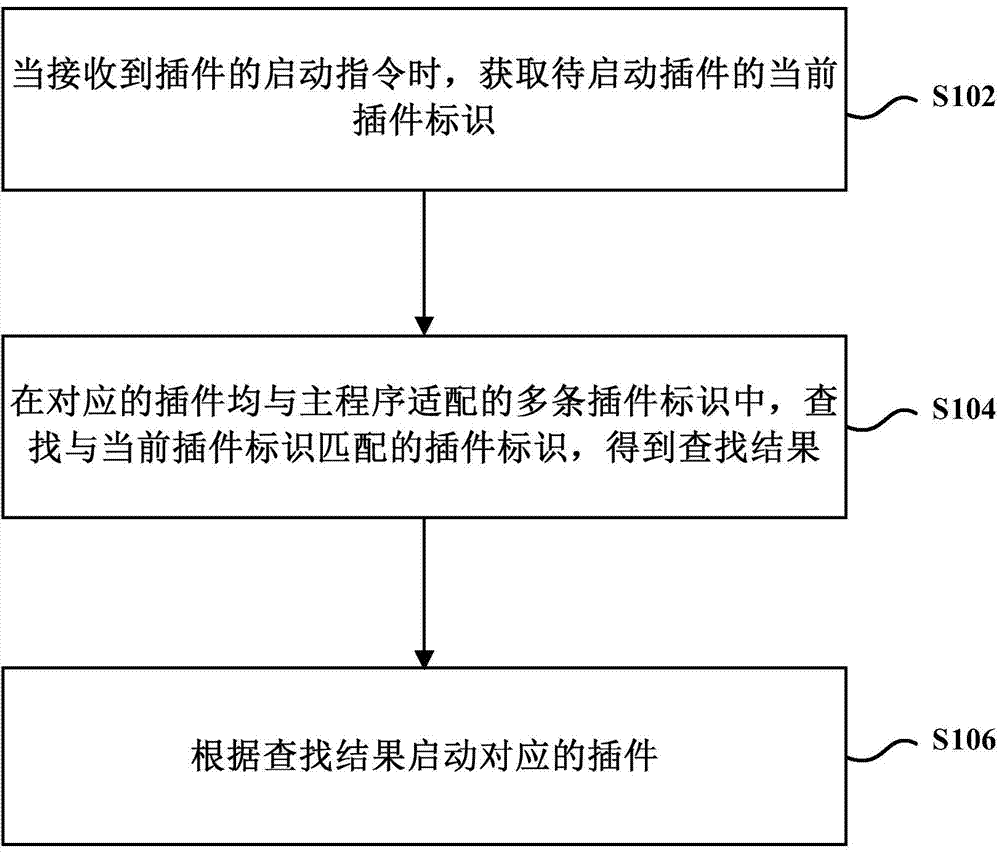

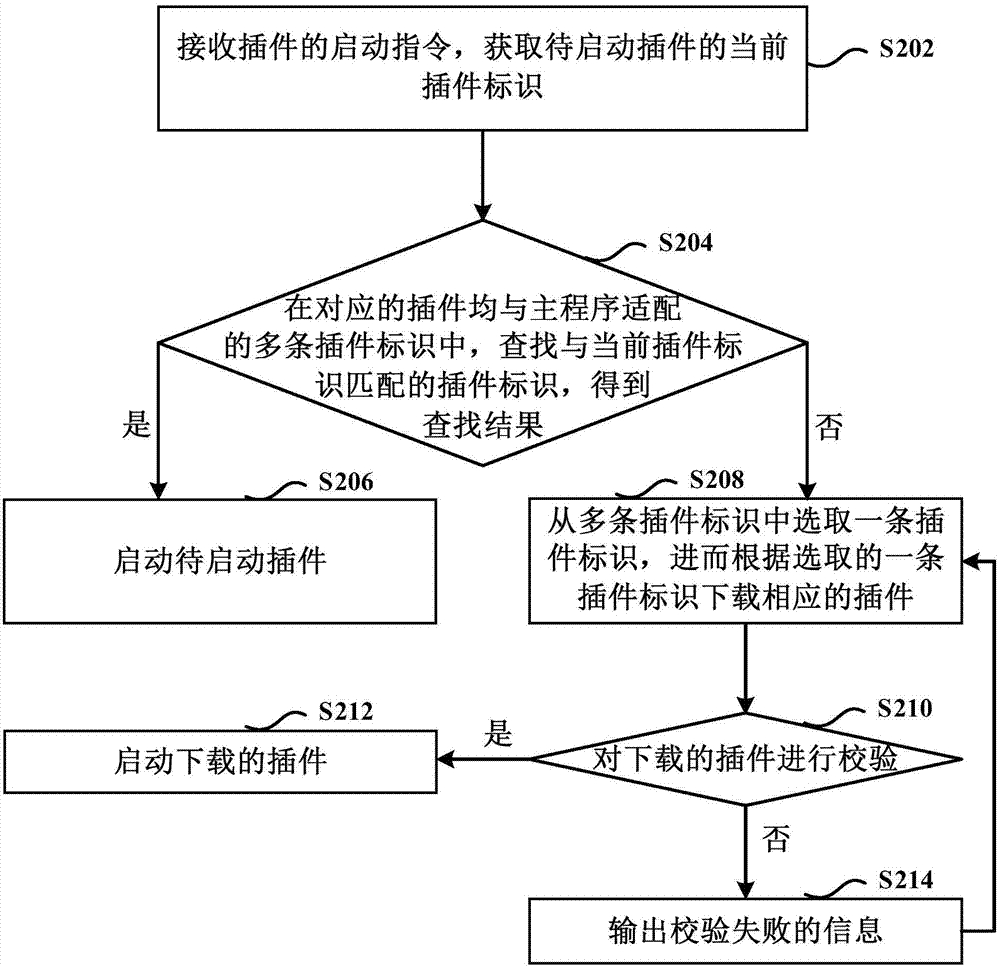

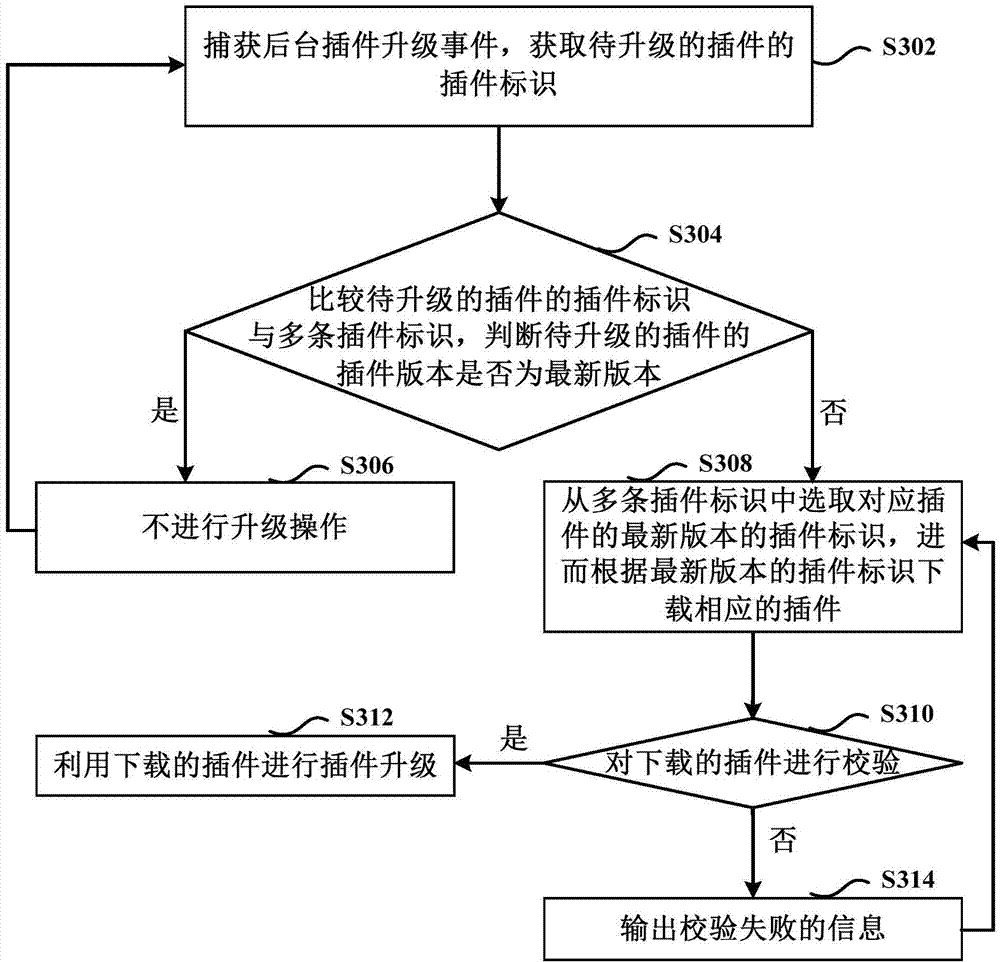

Method and device for starting plug-in in main program

ActiveCN104731623AImprove match rateSolve problems such as wasteProgram loading/initiatingComputer engineering

The invention provides a method and device for starting a plug-in in a main program. The method comprises the steps of acquiring current plug-in identification of the plug-in to be started when receiving a plug-in startup command; in multiple plug-in identification of the corresponding plug-in which are all adaptive to the main program, searching for the plug-in identification matched with the current plug-in identification, and obtaining a search result; according to the search result, starting the corresponding plug-in. By means of the technical scheme of the method and device for starting the plug-in in the main program, the matching ratio of the plug-in identification can be raised, and the aims to be compatible with an old version and raise the processing efficiency can be achieved.

Owner:BEIJING QIHOO TECH CO LTD

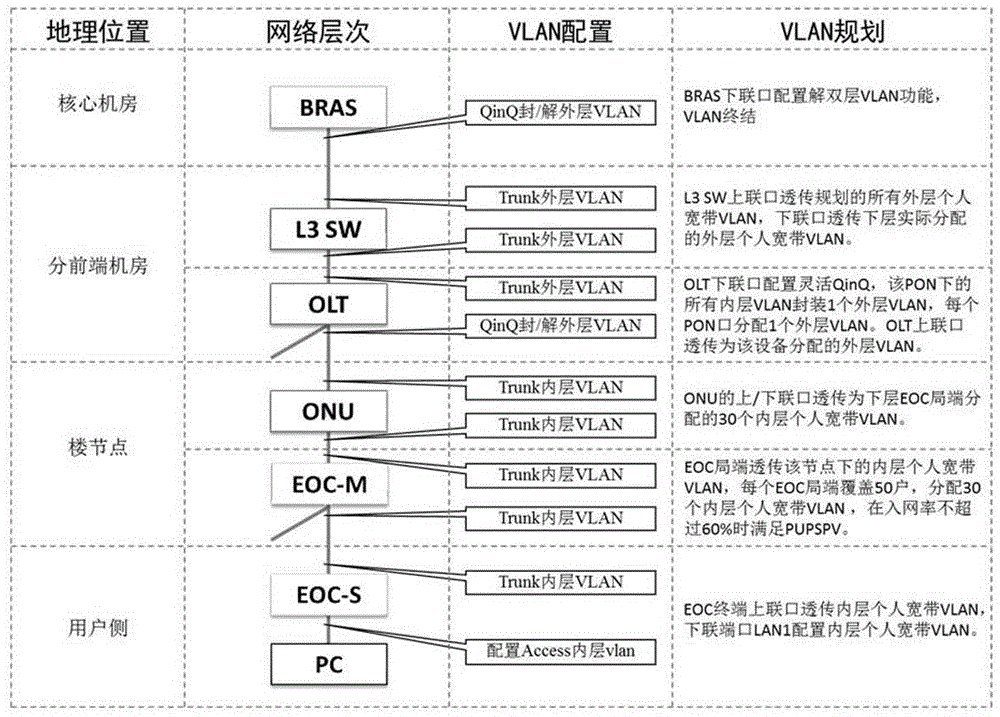

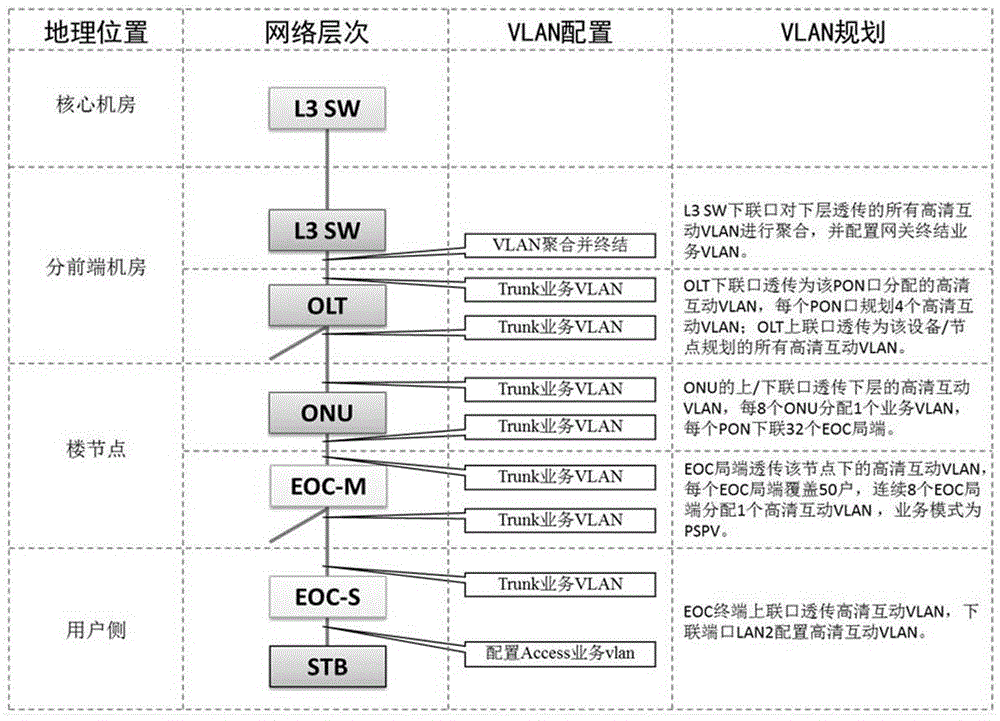

VLAN (Virtual Local Area Network) distribution method for different terminal services

InactiveCN105530200AAchieving identifiabilityFulfillment requirementsNetworks interconnectionAccess networkDistribution method

The invention discloses a VLAN (Virtual Local Area Network) distribution method for different terminal services, belonging to the field of communication; the method comprises the following steps: (1) in a PON (Passive Optical Network) plus EOC (Ethernet Over Cable) / LAN (Local Area Network) environment, starting a QinQ at a PON port of an OLT (Optical Line Terminal) device and ending the QinQ at the port of a BRAS (Broadband Remote Access Server), namely deploying an internal layer VLAN below the PON of the OLT, simultaneously arranging an external layer VLAN at the PON, and transparently passing the external layer VLAN above the PON; (2) from the OLT to a network end-point, deploying a service VLAN; (3) planning continuous thirty internal layer VLANs for one building node; and (4) planning one service VLAN for continuous eight building nodes. By combining with technological methods such as QinQ and the like in VLAN planning to carry out reasonable extension on VLAN resources to meet use requirements of the services: through taking the external layer VLAN of the QinQ as a sub-front end identifier or an access device identifier for planning and taking the internal layer VLAN as a user or service identifier for planning, the problems of conflict, waste and the like of resource use occurred in a bidirectional access network are effectively solved, and the requirements on precise recognition and safety isolation of the services are realized. According to the VLAN distribution method for the different terminal services disclosed by the invention, the implementation steps are simple, so the method is easy for promotion and use.

Owner:SHAANXI BROADCAST & TV NETWORK INTERMEDIARY GRP CO LTD

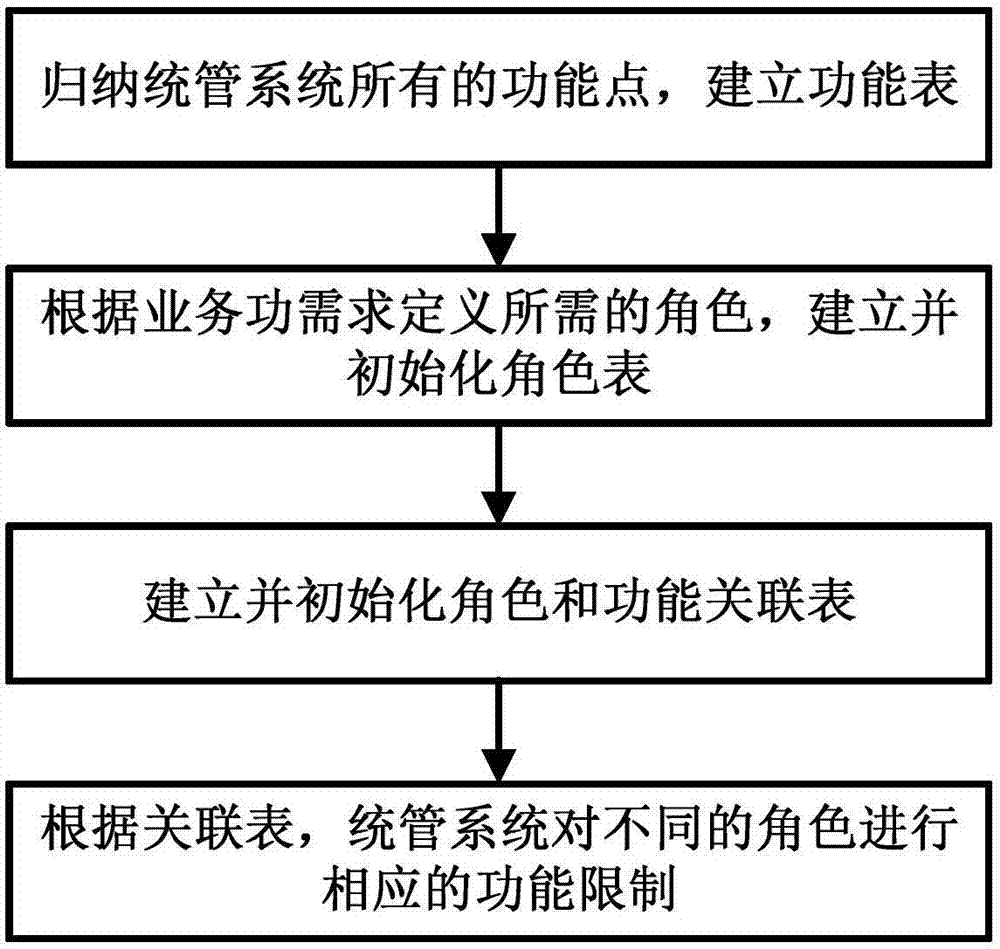

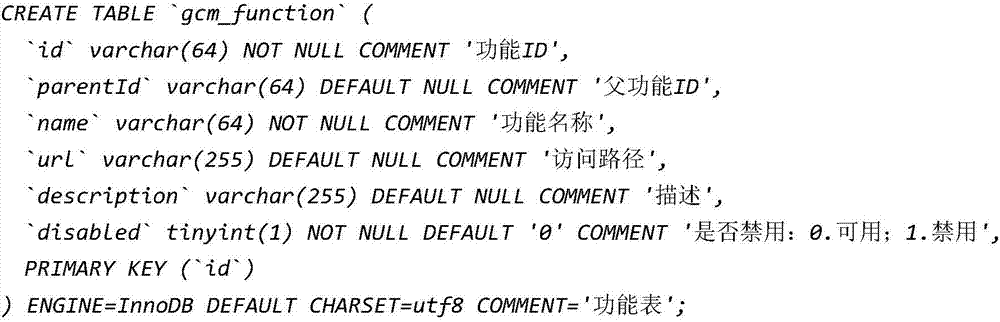

Limits of authority control method based on multiple cloud platforms

InactiveCN107992767ASimplified access controlReduce investmentDigital data protectionAuthority controlManagement environment

The invention relates to the technical field of management of multiple cloud platforms, in particular to a limits of authority control method based on the multiple cloud platforms. The method refers to that a unified management system is arranged and the multiple cloud platforms uniformly perform limits of authority control on the unified management system; the method comprises the specific stepsthat step 1, all functional points of the unified management system are summarized, and a function table is established and initialized; step 2, required roles are defined according to business function requirements, and a role table is established and initialed; step 3, a role and function association table is established and initialed; step 4, according to the association table, the unified management system limits the authority corresponding to different roles. The method solves the problems that the limits of authority of the multiple cloud platforms are complicated to control, the limitsof authority of the multiple cloud platforms cannot be arranged uniformly, and human resources are wasted; the system can be applied to a unified management environment of the limits of authority of the multiple cloud platforms.

Owner:G CLOUD TECH

Portable shared umbrella system

The invention provides a portable shared umbrella system, which includes an umbrella body, an umbrella handle, and an umbrella handle. The lower part of the umbrella body is connected with an umbrella handle, and the lower part of the umbrella handle is connected with an umbrella handle. Lock or intelligent lock or electronic lock, the beneficial effects of the present invention are: simple structure, reasonable design, easy to use; through the air enters from the air inlet and then sprays out from the high-speed air outlet, the air umbrella provides an air curtain for the user, which The air curtain can act as an umbrella cover to block rainwater. The operation is simple, and the user can control the size of the air curtain; when consumers riding bicycles or sharing bicycles need to use umbrellas in rainy days or in the sun, the fixed seat It can be installed on the handlebar bar of a bicycle or shared bicycle or motorcycle or tricycle or on the rear of a bicycle or shared bicycle or motorcycle or tricycle.

Owner:王祖玉

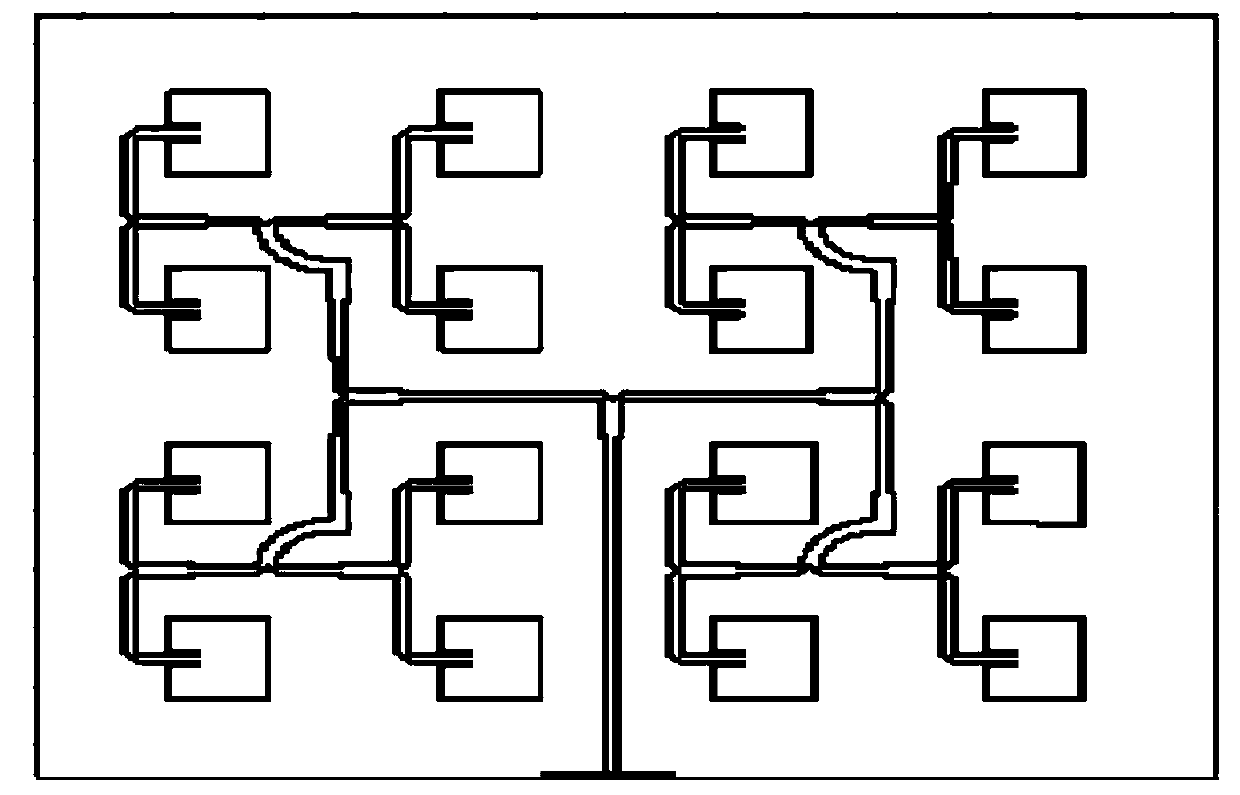

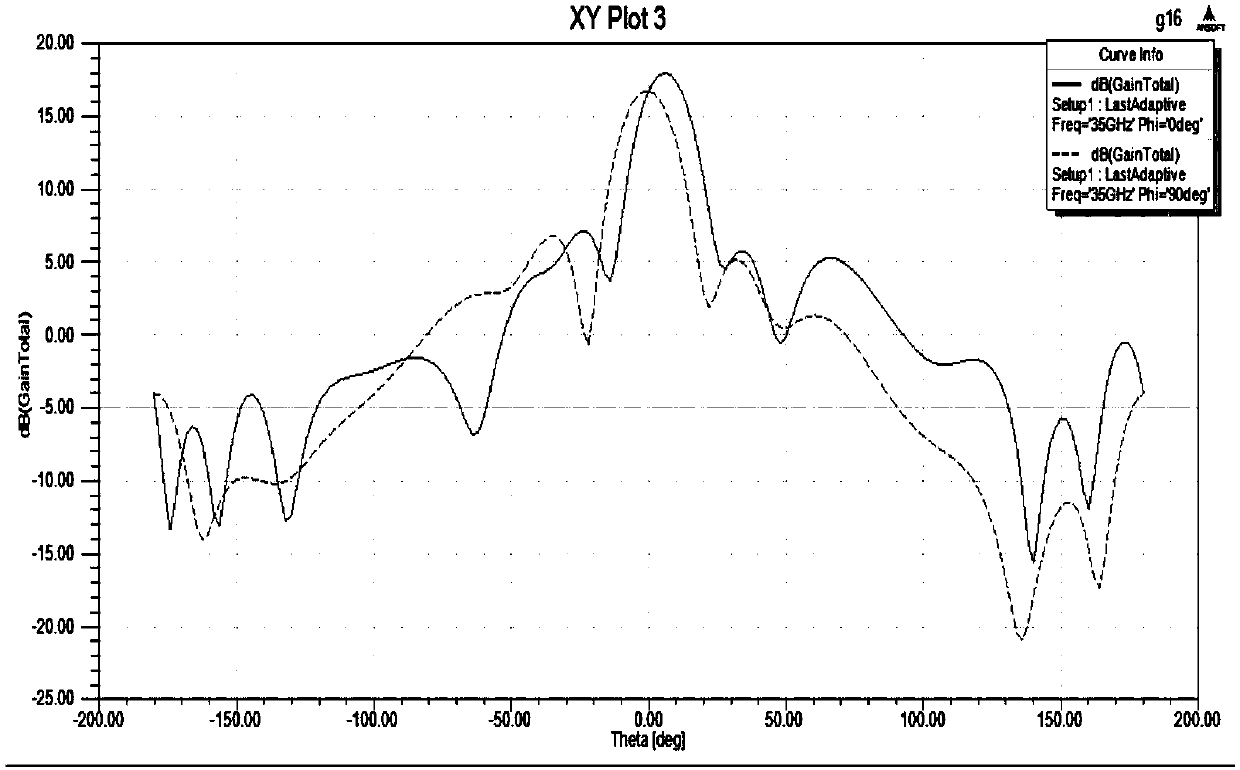

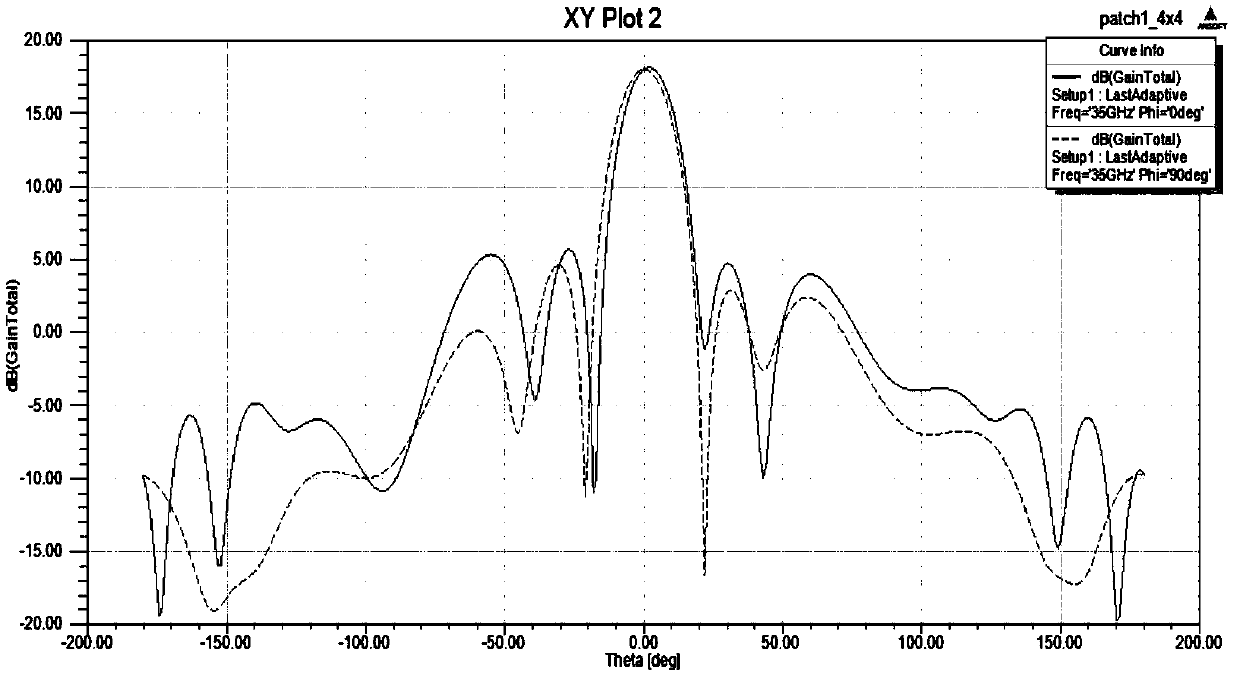

Microstrip array antenna

InactiveCN107645067AHigh gainSmall footprintIndividually energised antenna arraysMicrostrip array antennaAntenna gain

The invention discloses a microstrip array antenna which comprises a dielectric substrate and eight groups of radiating elements arranged on the dielectric substrate. Each group of radiating elementscomprises two sub-radiating elements with the same frequency band. The sixteen radiating elements are arranged on the dielectric substrate along the same direction according to a 4*4 way, and are connected with the entire feed network in a cascaded way in order to ensure 16-equal divisions. The microstrip array antenna changes the design of the feed network, increases antenna gain, and well solvesbeam deviation and a waste of overall antenna space caused by just using a single T-junction power divider.

Owner:NANJING UNIV OF SCI & TECH

Sintered ceramsite adopting tailings generated during germanium extraction of lignite as main raw material and preparation method of sintered ceramsite

InactiveCN103819174ASolve pollutionSolve resource problemsCeramic materials productionClaywaresKaolin clayMuffle furnace

The invention discloses a sintered ceramsite adopting tailings generated during germanium extraction of lignite as a main raw material and a preparation method of the sintered ceramsite. The sintered ceramsite comprises the components of tailings generated during germanium extraction of lignite, kaolin and water; the tailings are ground; kaolin and water are fed into the ground tailings; the mixture is stirred to be uniform; ageing is carried out for pelletizing; the finished balls are placed in a muffle furnace for preheating and calcining to obtain the sintered ceramsite. The preparation is simple in technology, low in energy consumption, relative high in waste utilization, and good in product performance.

Owner:LINCANG TEACHERS COLLEGE

Sintered brick adopting germanium-extracted lignite tailings as main material and preparation method of sintered brick

InactiveCN103964812ARealize resource development and environmental protectionAchieve energy saving and emission reductionSolid waste managementMuffle furnaceMetallurgy

The invention discloses a sintered brick adopting germanium-extracted lignite tailings as a main material and a preparation method of the sintered brick. The sintered brick is prepared from the raw materials of the germanium-extracted lignite tailings, kaolin, fly ash, and water. The preparation method comprises the following steps: grinding the germanium-extracted lignite tailings; adding the kaolin, fly ash and water; uniformly stirring; forming through extrusion; cutting to obtain adobe; placing the adobe in a thermostatic drying box for drying to obtain dried adobe; placing the dried adobe in a muffle furnace for preheating and calcining; naturally cooling to obtain the sintered brick. The technology is simple, the tailing utilization ratio is high, and the product performance is high.

Owner:LINCANG TEACHERS COLLEGE

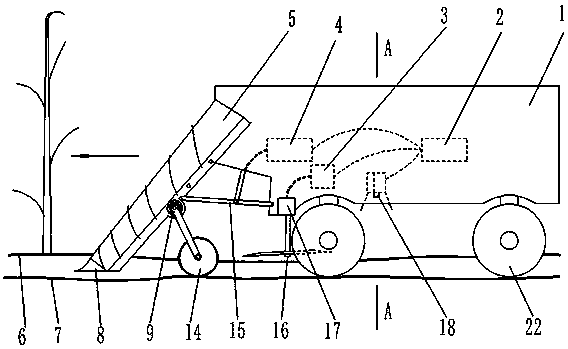

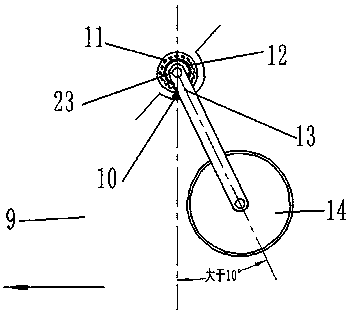

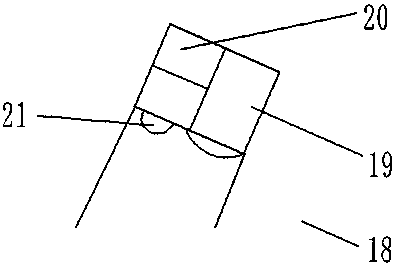

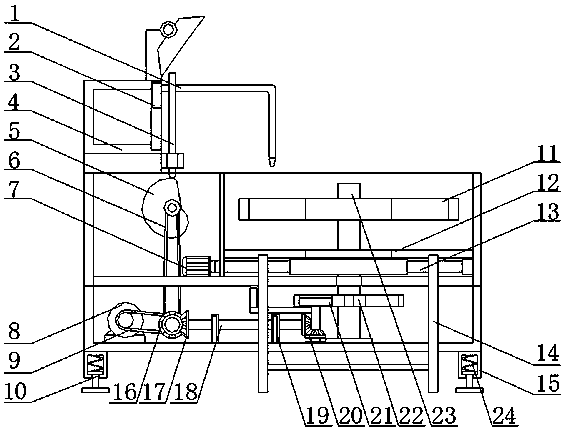

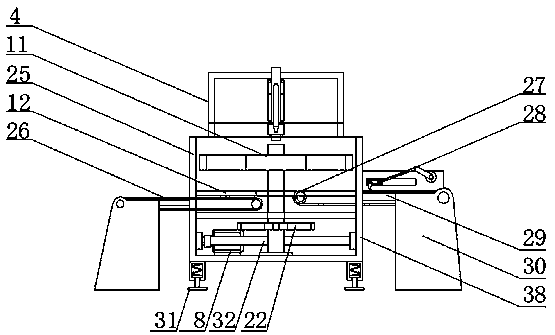

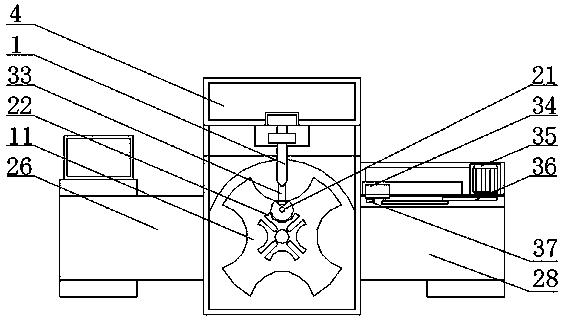

Automatic copying follow-up system of sugarcane harvester and control method thereof

ActiveCN110352707ASolve the problem of excessive perennial rootsSolve problems such as wasteHarvestersFluid-pressure actuator componentsAgricultural engineeringClosed loop

The invention discloses an automatic copying follow-up system of a sugarcane harvester and a control method thereof. The automatic copying follow-up system comprises a displacement sensor device whichis installed directly behind a sugarcane supporting mechanism, the sugarcane supporting mechanism is fixed to the front end of a sugarcane supporting mechanism lifting device which is installed at the front end of a cart and is connected with a sugarcane-supporting hydraulic control device, a root cutting device is installed in the center of the front lower part of the cart and is connected witha root-cutting hydraulic control device, and a ridge height detection device used for detecting the height change between the cutter at the bottom of the root cutting device and the sugarcane ridge inreal time is installed at the middle bottom of the cart. The automatic copying follow-up system is a closed-loop control system and can be used for automatically copying and carrying out sugarcane harvesting operation, so that the head breaking rate of sugarcane is greatly reduced, and the waste is reduced.

Owner:柳州市孚桂智能科技有限公司

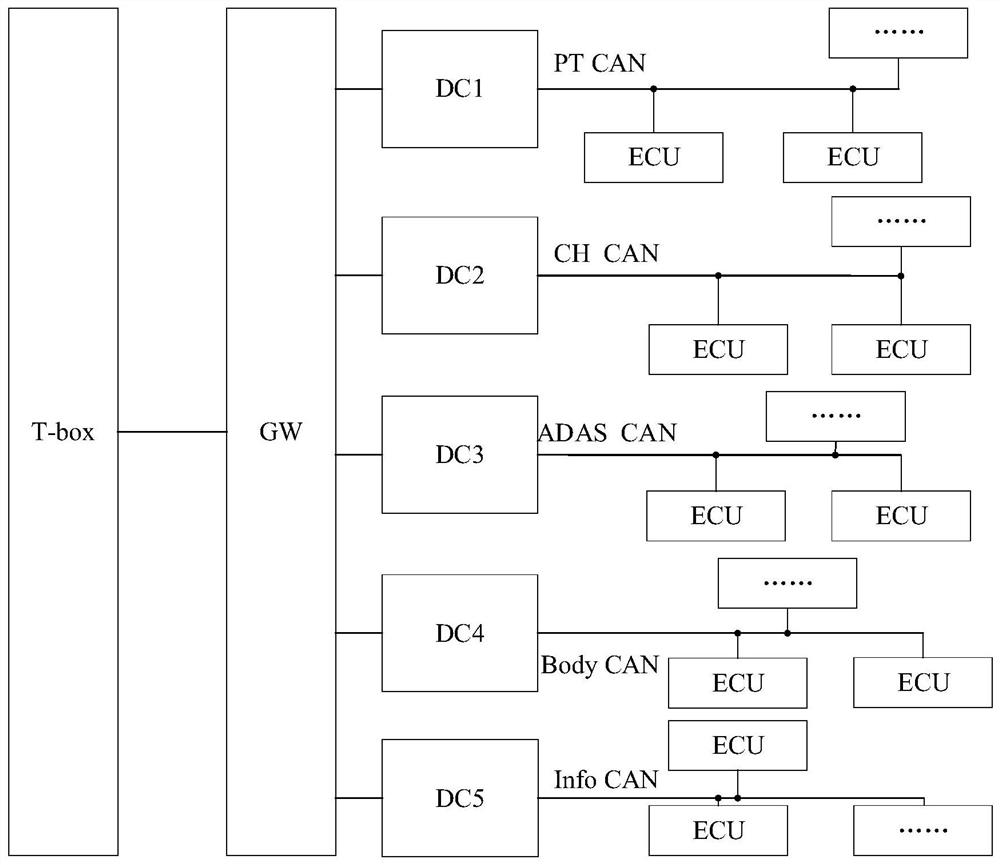

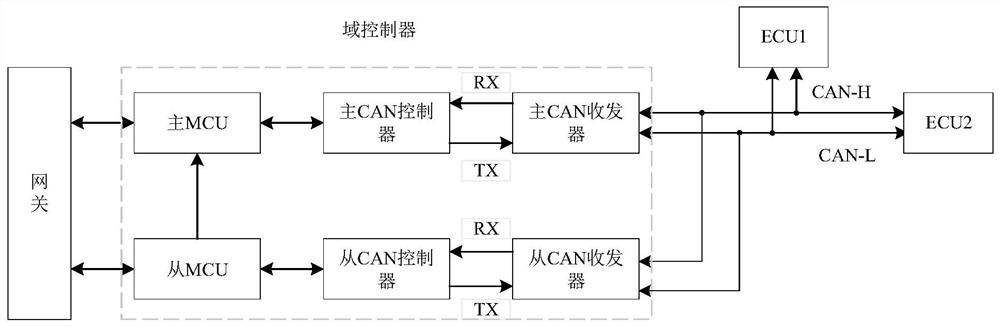

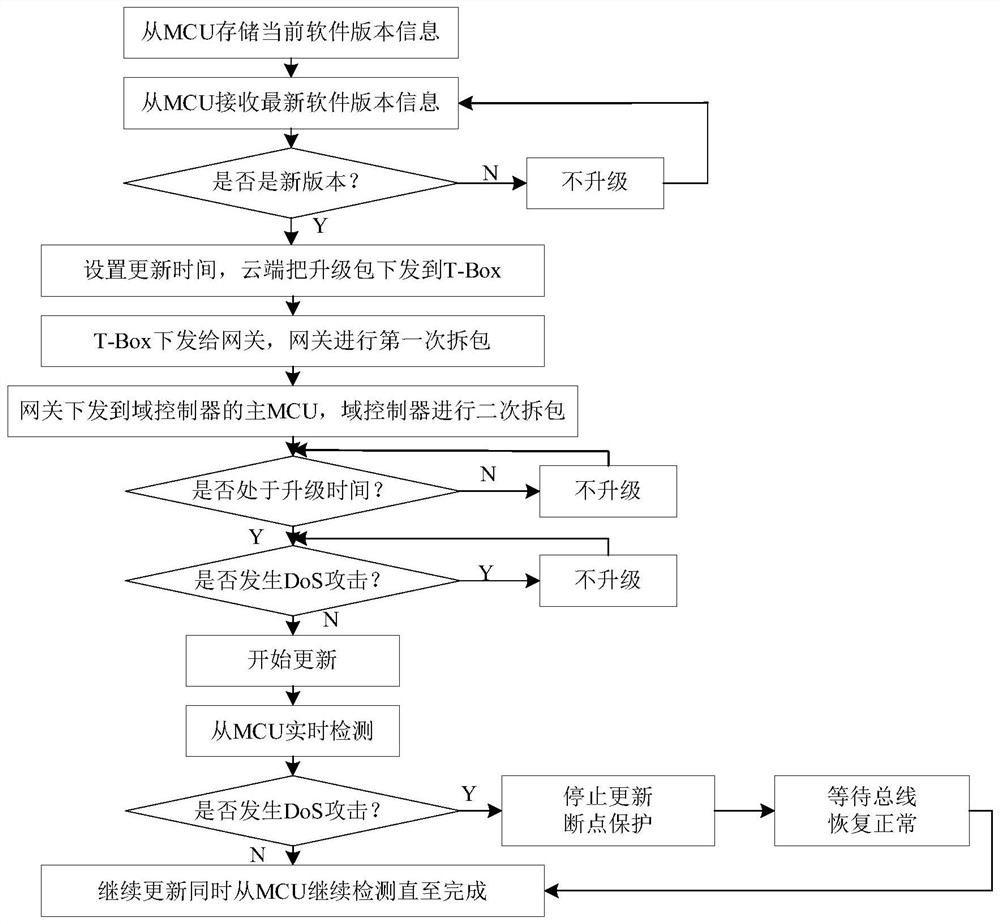

OTA upgrading method for vehicle-mounted domain architecture CAN bus DoS attack

ActiveCN112187744AEfficient and safe upgradeEnsure normal communication statusComputer security arrangementsBus networksTransceiverAttack

The invention discloses an OTA upgrading method for a vehicle-mounted domain architecture CAN bus DoS attack. The OTA upgrading method comprises the following steps that 1, version information of current upgrading software is stored in a slave MCU of a domain controller; 2, the packaged upgrade package is issued to the TBox from the cloud; 3, in the OTA upgrading process, the TBox issues the software package to a gateway; 4, the gateway issues the packets corresponding to the domain controllers to the corresponding domain controllers; 5, before the domain controller issues the upgrade package;6, the slave MCU detects whether the CAN network is subjected to DoS attack or not through a slave CAN controller and a slave CAN transceiver; 7, in the updating process, the slave MCU detects the flow of the CAN bus in real time all the time so as to judge whether DoS attacks happen to the bus or not; and 8, OTA issuing is completed. By means of the upgrading method, whether DOS attacks occur ornot in the upgrading process can be judged, and then whether upgrading occurs or not is judged.

Owner:北京小墨数智科技有限公司

Indoor decoration design method based on BIM

PendingCN108763754ASolve problems such as wasteAvoid mistakes, omissions, etc.Geometric CADSpecial data processing applicationsTime costDesign methods

The invention discloses an indoor decoration design method based on BIM. The method comprises the following steps of S1, building a three-dimensional model through BIM software, wherein the three-dimensional model comprises a ceiling model, a floor model, a wall body model and furniture part, and giving a material corresponding to each three-dimensional model; S2, simulating to enter a construction site to carry out acceptance check, checking whether the design of each three-dimensional model is consistent with a design scheme or not, and adaptively adjusting a non-conformance term according to design requirements; S3, rendering a drawing of the three-dimensional model; and S4, outputting the drawing. According to the method, a problem can be found and the design scheme can be adjusted timely in a dynamic simulation process based on the BIM, and the construction drawing can also be correspondingly adjusted in a design scheme adjustment process, so that the situations of wrong modification, modification missing and the like can be avoided, and the two-way performance is achieved, and thus the modification time cost is directly saved; after all aspects of the design scheme based on the BIM are perfected, the problems of material waste and the like in construction are indirectly solved, so that the construction can be carried out rapidly and accurately.

Owner:广东天元建筑设计有限公司

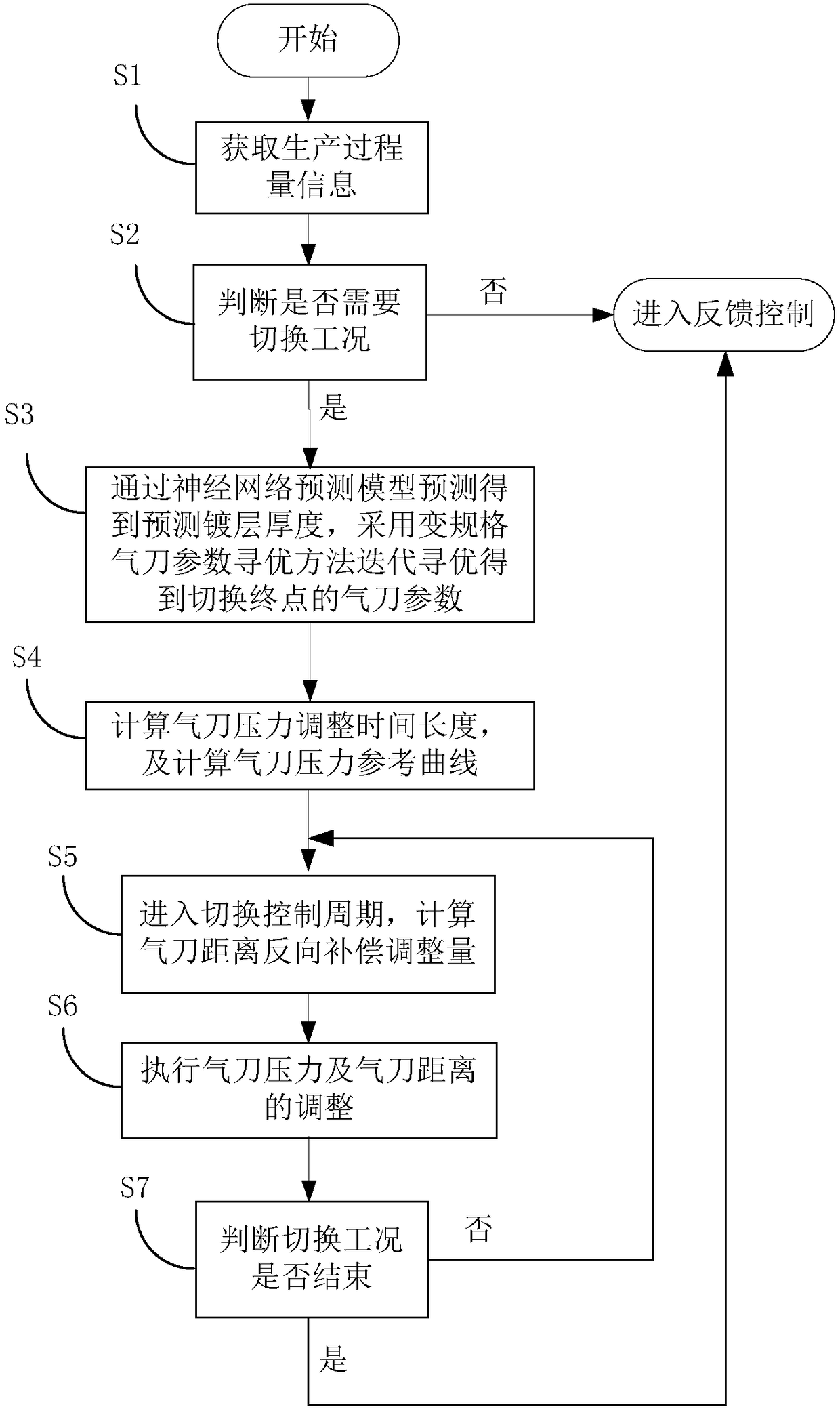

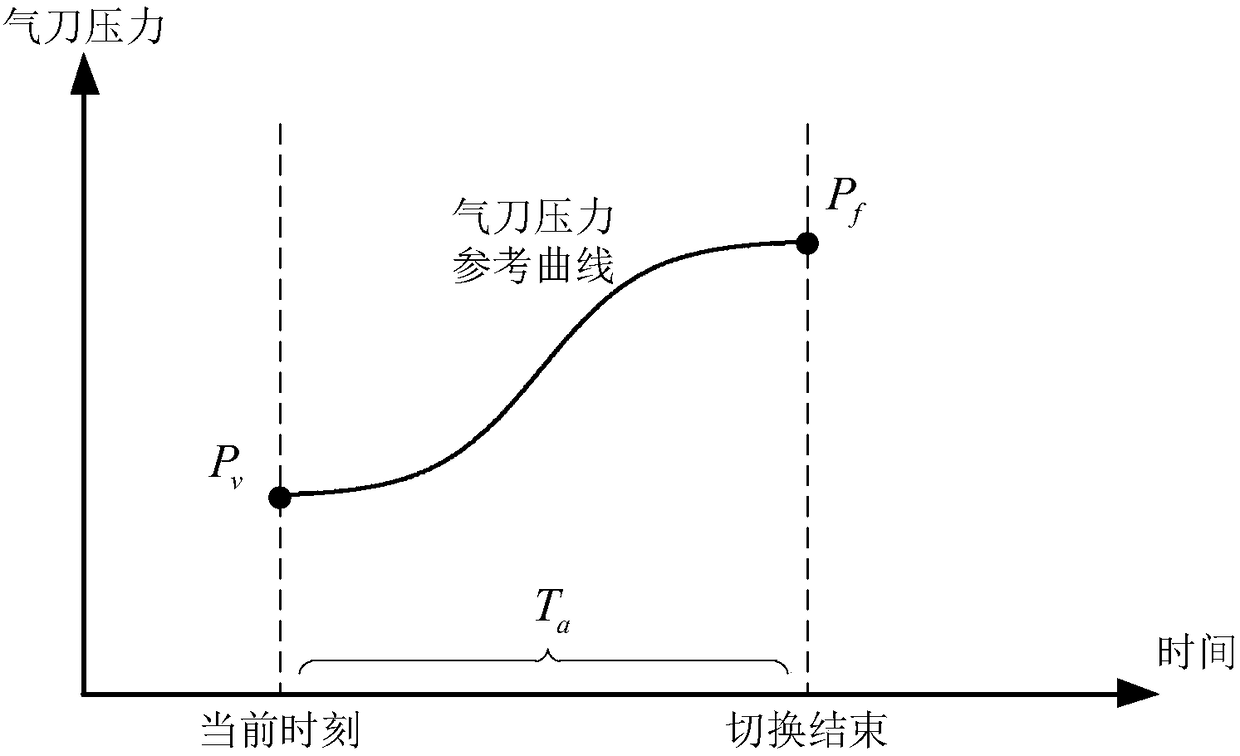

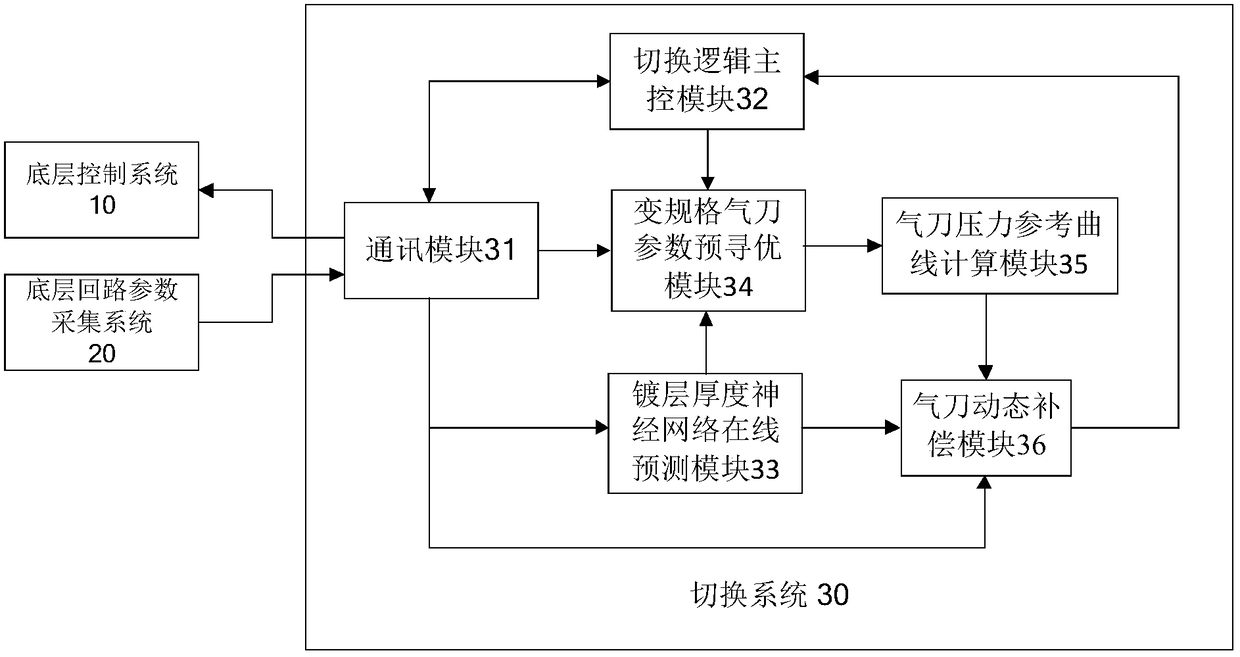

Method and system for rapid switching of hot-dip galvanized coating thickness based on dynamic compensation of tool distance

ActiveCN106167887BHigh precisionOvercoming nonlinearityHot-dipping/immersion processesEngineeringWeld seam

The invention provides a method for rapidly switching the hot dip galvanized coating thickness based on knife distance dynamic compensation. The method comprises: S1: obtaining production process quantity information; S2: judging whether the working condition is required to be switched, if not, entering feedback control, and if so, entering a step S3; S3: obtaining a predicted coating thickness through a neural network prediction model, and carrying out iterative optimization on air knife parameters by using a specification optimization variable air knife parameter optimization method to obtain the air knife parameters (the air knife distance Df and the air knife pressure Pf) of the switching terminal point; S4: calculating the air knife pressure adjustment time length and the calculating the air knife pressure reference curve; S5: entering a switching control period, obtaining the current air knife pressure Pi, and calculating the current air knife distance Di adjusted through reverse compensation; S6: outputting Pi and Di, and executing the air knife parameter adjustment; and S7: detecting the weld seam position, judging whether the switching ends, if so, outputting the air knife distance Df and ending the switching, and otherwise, returning to the step S5. With the method of the present invention, the transition time of the system switching between the products having different specifications can be effectively reduced, and the number of transition products in the transition period can be reduced.

Owner:ZHEJIANG SUPCON RES

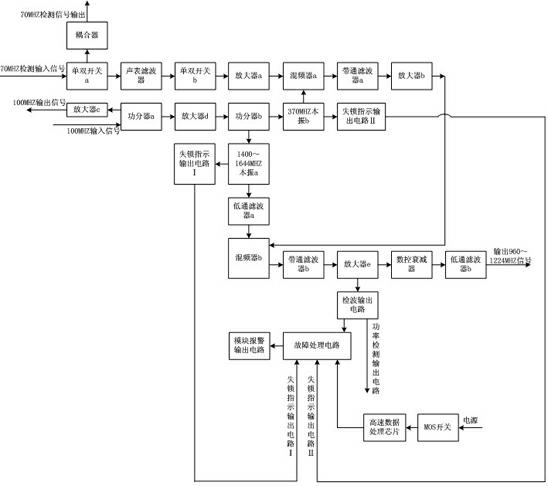

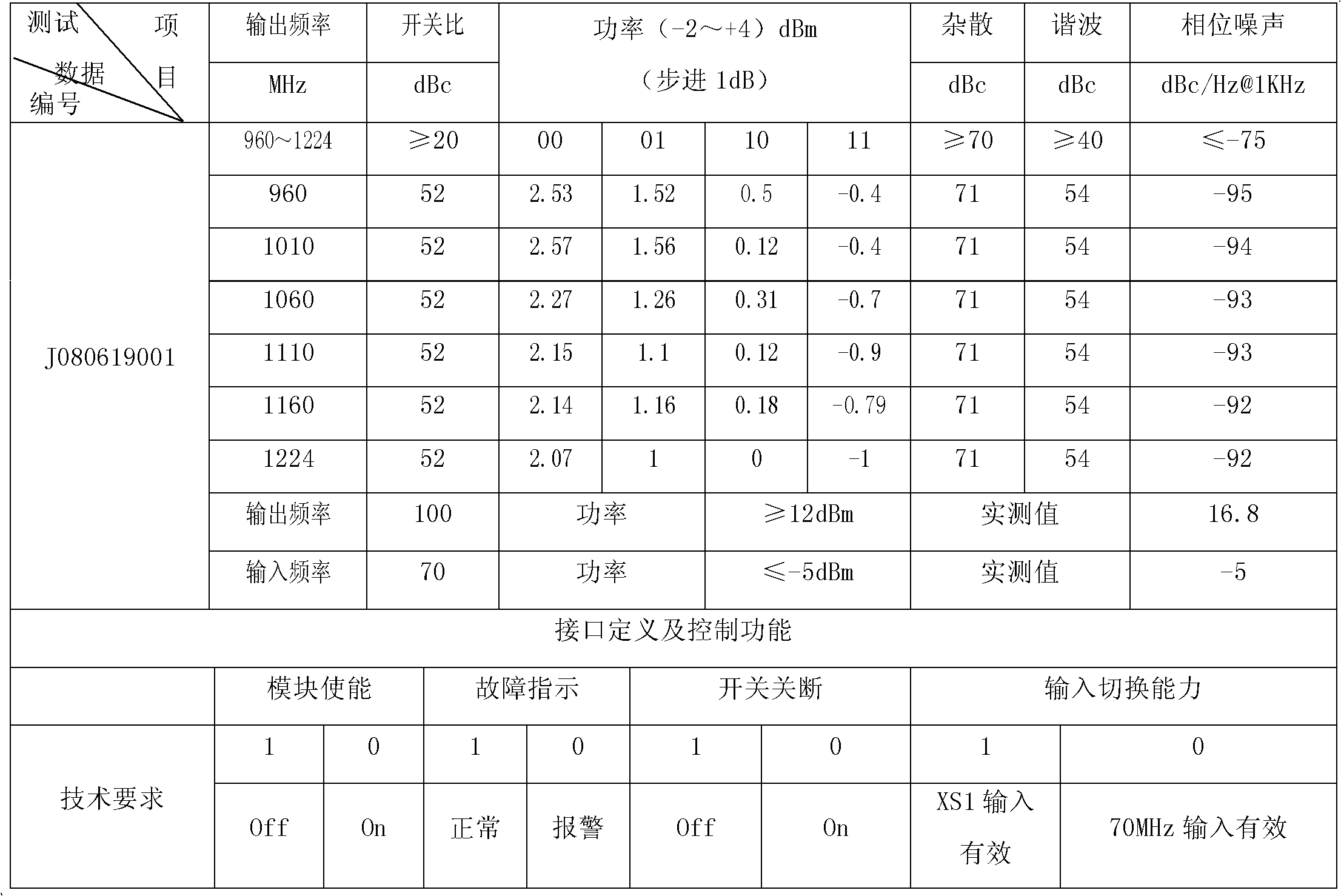

Miniature airborne up-converter and manufacturing process thereof

ActiveCN102664592AImproved Spurious Suppression RatioResolve inhibitionMulti-frequency-changing modulation transferenceFrequency changerLocal oscillator signal

The invention discloses a miniature airborne up-converter which is composed of three parts of a local oscillator circuit, a frequency conversion channel circuit and a power control circuit. An output end of the local oscillator circuit and the power control circuit are connected with the frequency conversion channel circuit respectively. Manufacturing processes include steps of circuit design, circuit wiring, circuit electric fitting, final assembly and multi-channel quality test. Stray rejection ratio of local oscillator signals is improved greatly, and power dissipation of the whole machine is reduced, meanwhile, broadband phase discrimination is used, phase discrimination frequency is improved, rapid capture broadband is added, frequency agility time is increased, and problems of miscellaneous inhibition capacity, frequency agility time and the like of local oscillator signals are solved; a mixer with high compression is used as frequency spectrum flitting, secondary frequency conversion is used, needed broadband signals are produced through the secondary frequency conversion and output by amplification of filtering waves, stray is effectively restrained, and anti-interference capability is enhanced; and multi-channel quality test is used in the manufacturing process, checks are performed at all levels, and product yield and product quality are greatly improved.

Owner:CHENGDU TIGER MICROWAVE TECH

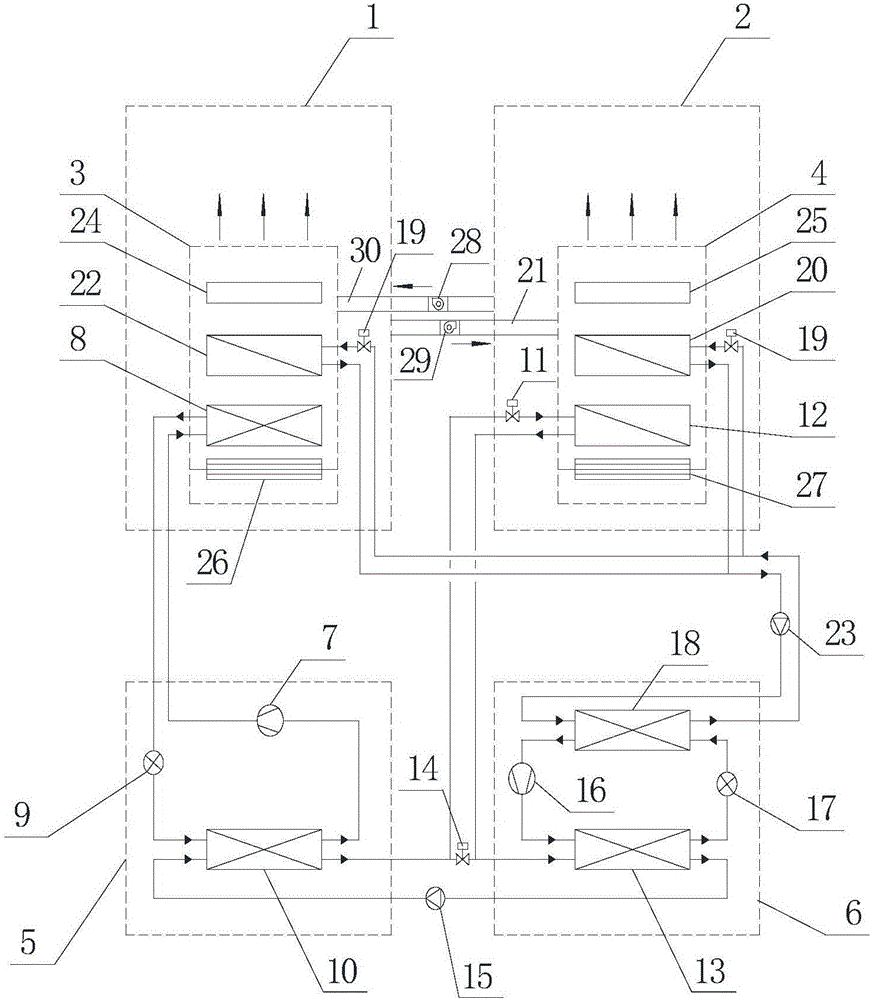

Air conditioner system

InactiveCN105135552ARealize rational utilizationSolve problems such as wasteHeating and refrigeration combinationsAir conditioning systemsEngineeringRefrigeration

The invention discloses an air conditioner system. The air conditioner system comprises a heat supply end air conditioner unit, a heat pump unit, a cold supply end air conditioner unit and a refrigeration unit. The heat supply end air conditioner unit comprises a first cooling, dehumidifying and heat exchange coil and a first condenser. The heat pump unit comprises a first evaporator. The cold supply end air conditioner unit comprises a second cooling, dehumidifying and heat exchange coil and a cold supply end air conditioner unit heat exchange coil. The refrigeration unit comprises a second evaporator and a second condenser. The first condenser is connected with the first evaporator. The second condenser is connected with the second evaporator. One part of cooling water output by the first evaporator sequentially passes the cold supply end air conditioner unit heat exchange coil and the second condenser and then flows back to the first evaporator. One part of freeze water output by the second evaporator passes the first cooling, dehumidifying and heat exchange coil and then flows back to the second evaporator, and the other part of the freeze water output by the second evaporator passes the second cooling, dehumidifying and heat exchange coil and then flows back to the second evaporator. By means of the reasonable connection of the heat pump unit and a water way of a water chilling unit, waste heat is recycled, and the problems of resource waste and the like are solved.

Owner:GREE ELECTRIC APPLIANCES INC

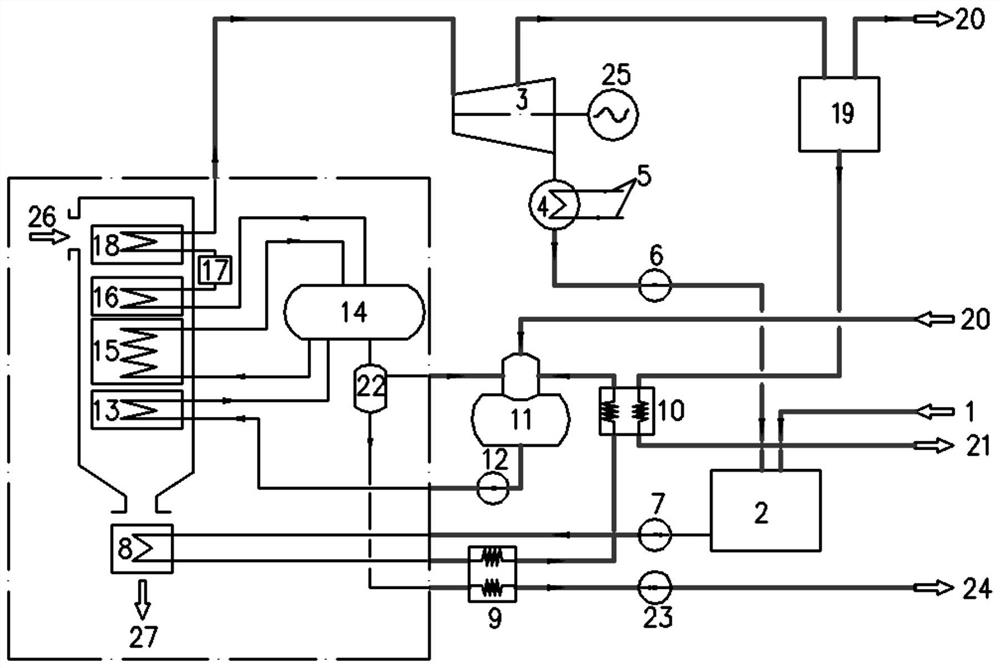

Low-grade waste heat recovery system and process of coking production system

PendingCN112610941ASolve problems such as wasteImprove waste heat utilizationLiquid degasificationFeed water supplyBoiler feedwater pumpCoke

The invention relates to a low-grade waste heat recovery system and process of a coking production system. The coking production system comprises a coke dry quenching boiler, a steam extraction and condensing steam turbine, a condenser, a condensate pump, a dynamo, a crude benzene distillation unit, a deaerator, a deoxidizing feed pump, a demineralized water tank, a demineralized water station, a boiler feed pump, a continuous blowdown expander, a blowdown pump and a coke dry quenching device water seal tank; and the low-grade waste heat recovery system comprises a first-stage water-water heat exchanger and a second-stage water-water heat exchanger. By means of the low-grade waste heat recovery system and process, low-grade waste heat of condensed water and flash steam of the crude benzene distillation unit, continuous blowdown water and secondary steam of the coke dry quenching boiler and the like in the coking production process can be effectively recycled, and the system is simple in composition, and operation and control are convenient.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

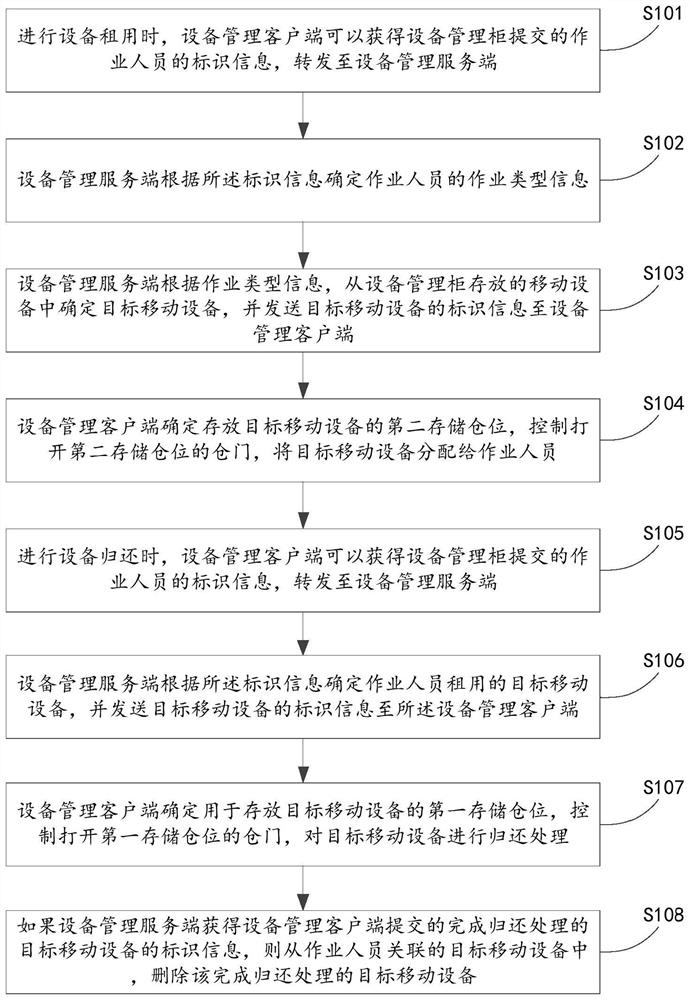

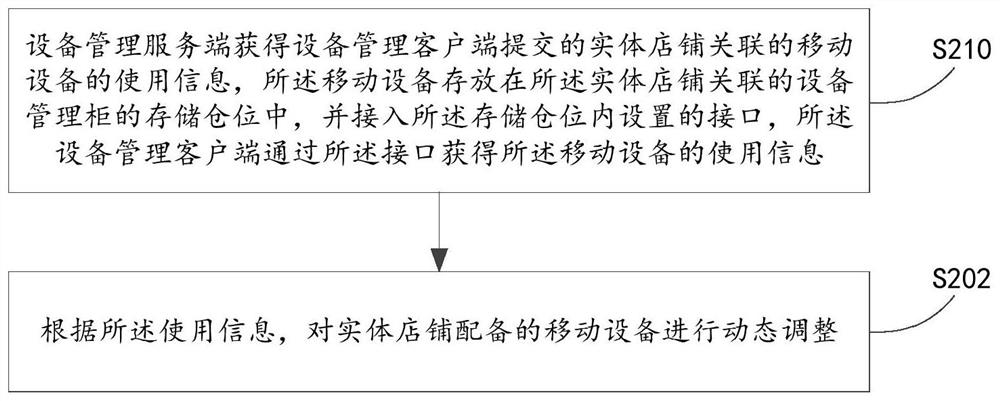

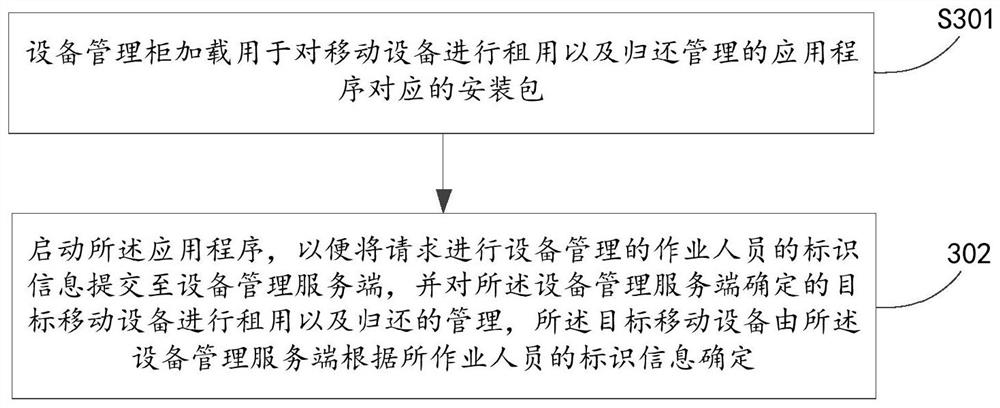

Mobile equipment management system, method and device and electronic equipment

PendingCN112633959AImplement lease managementSolve management confusionApparatus for meter-controlled dispensingBuying/selling/leasing transactionsMobile deviceComputer science

The embodiment of the invention discloses a mobile device management system, method and device and electronic equipment. The method comprises the steps that an equipment management server obtains identification information, submitted by an equipment management client, of an operator, wherein the identification information is collected by an equipment management cabinet and submitted to the equipment management client, the equipment management cabinet comprises a plurality of storage bins, and the storage bin is used for storing mobile equipment in a physical store associated with the equipment management cabinet; renting and returning management of the mobile equipment is carried out on the operating personnel with the identification information. According to the scheme, the mobile equipment stored in the equipment management cabinet can be automatically rented and returned, and the problems of disordered equipment management, equipment resource waste and the like can be solved.

Owner:HEMA (CHINA) CO LTD

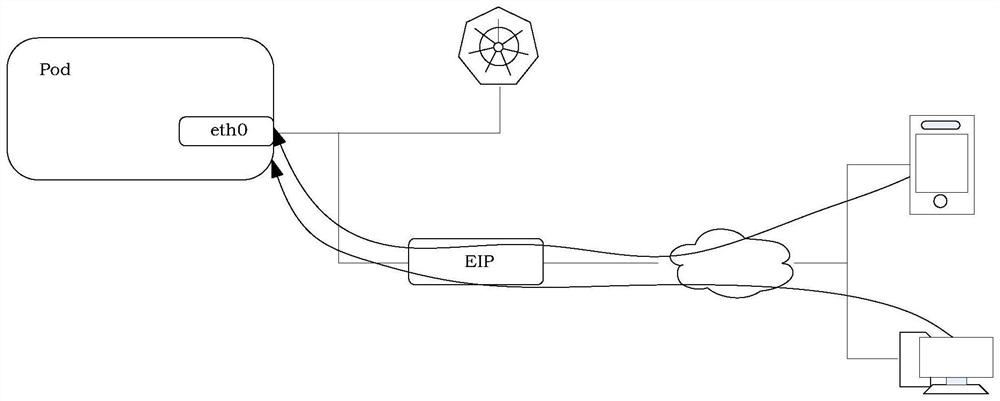

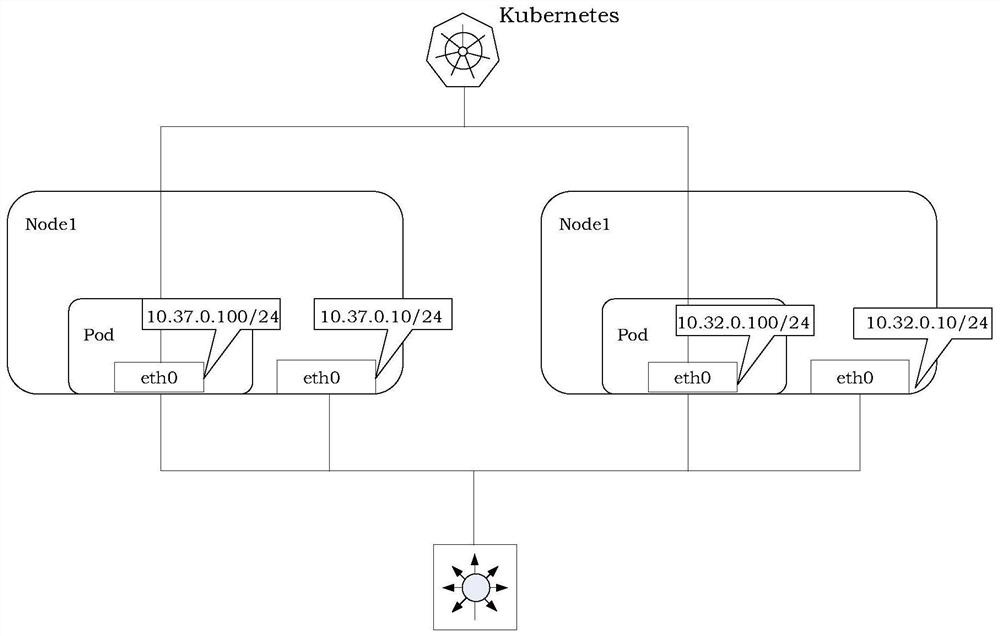

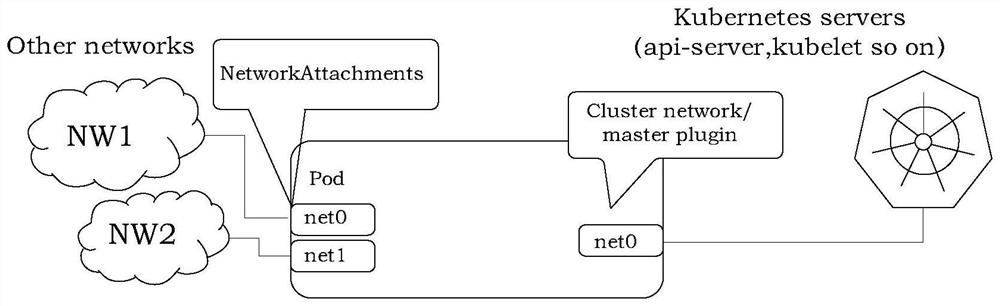

Response method and device of access request and storage medium

The invention discloses an access request response method and device, and a storage medium, and the method comprises the steps: obtaining a to-be-allocated extranet segment corresponding to a container cloud, the to-be-allocated extranet segment comprising a plurality of to-be-allocated extranet IP addresses; according to a node IP address of a target node, determining a target network segment located in the same network segment as the node IP address in the external network segments to be allocated; the external network IP address to be distributed in the target network segment is distributed to the target node; and under the condition that a first POD in the target node receives an access request sent by an external network, selecting a target IP address from a plurality of external network IP addresses to be allocated in the target network segment, and responding to the access request through the target IP address, by adopting the technical scheme, the problem that the IP is allocated to a main network of the POD by using macvlan or ipvlan cni is solved, and the access efficiency is improved. And IP address waste can be caused.

Owner:ZHEJIANG DAHUA TECH CO LTD

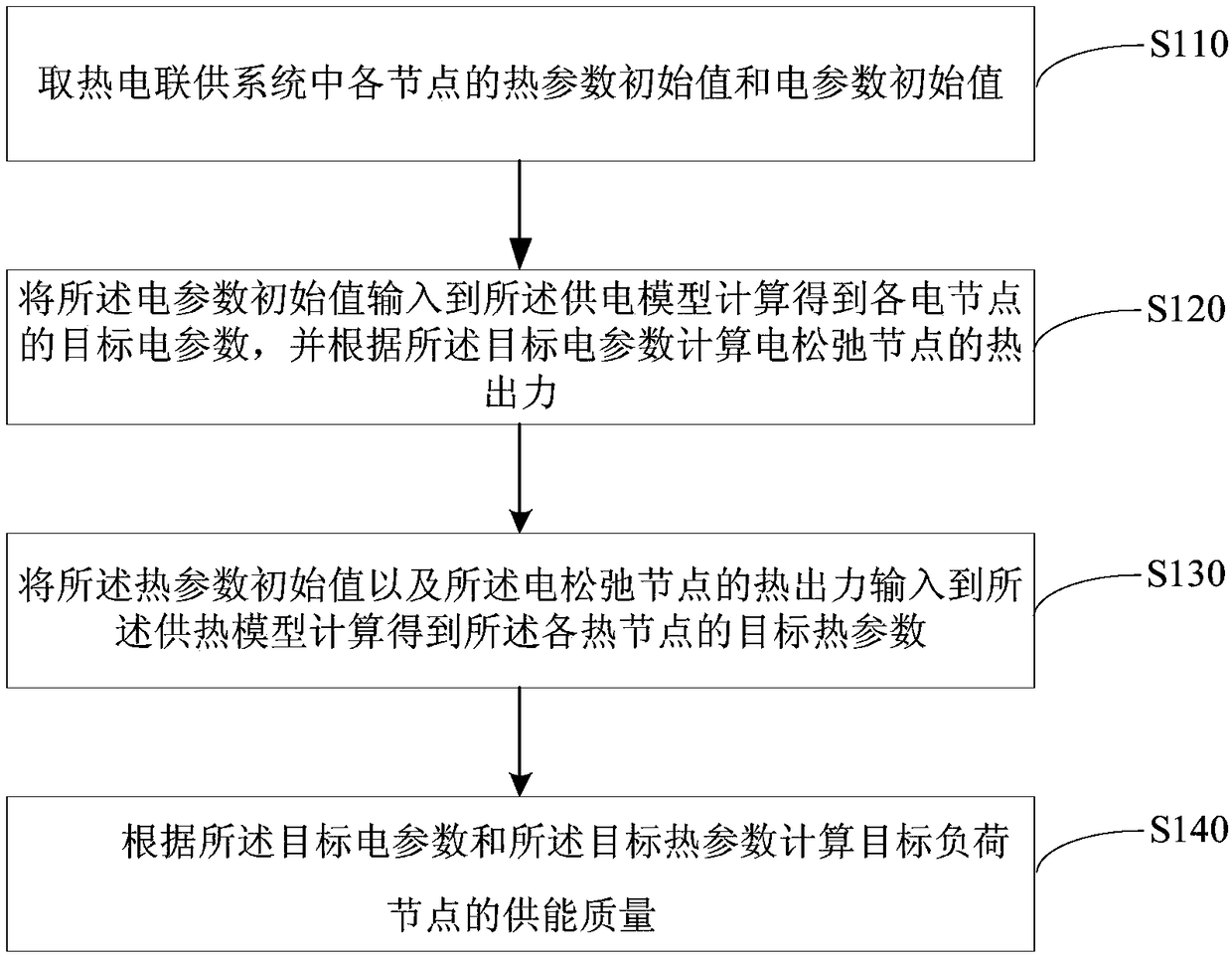

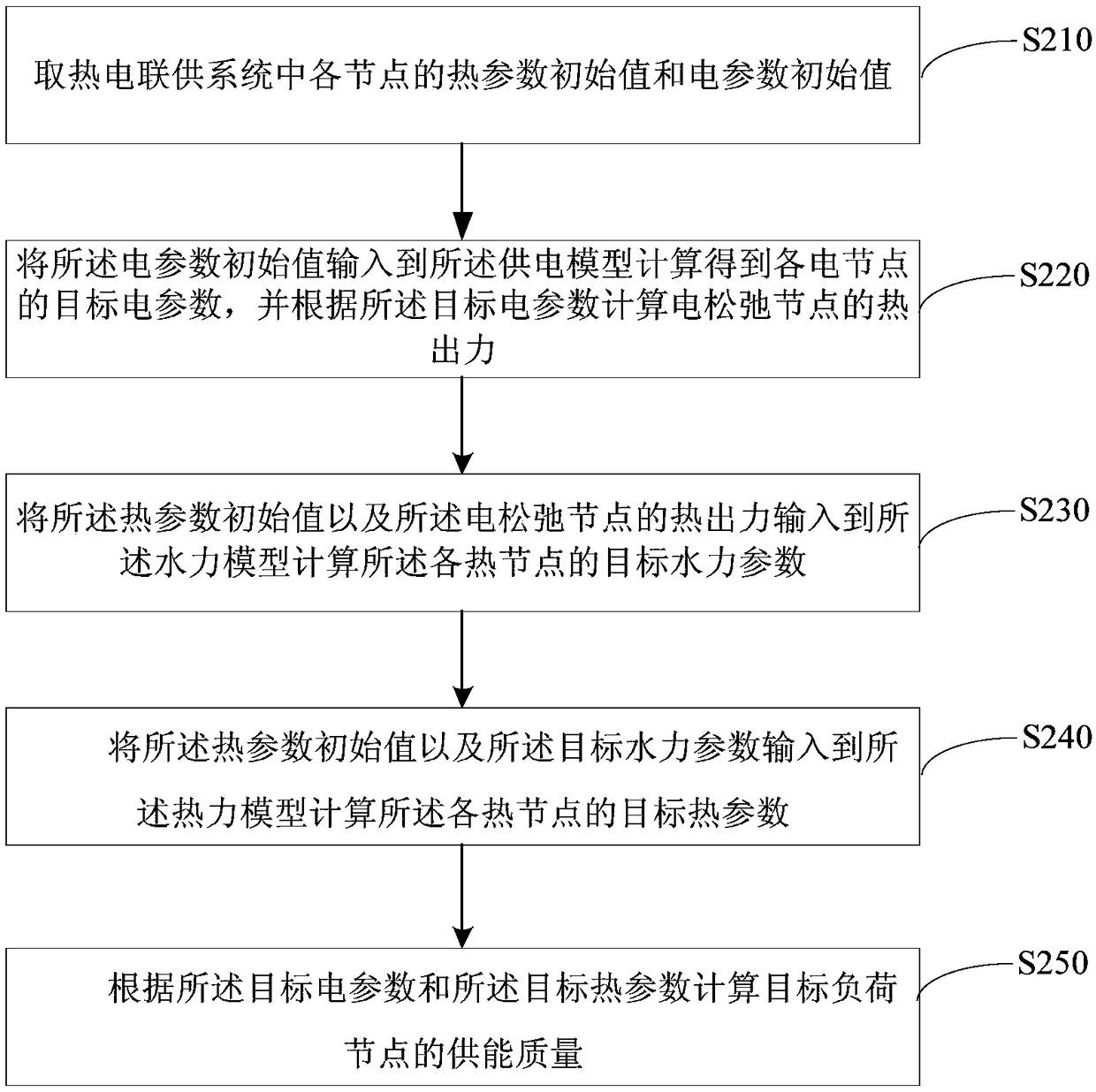

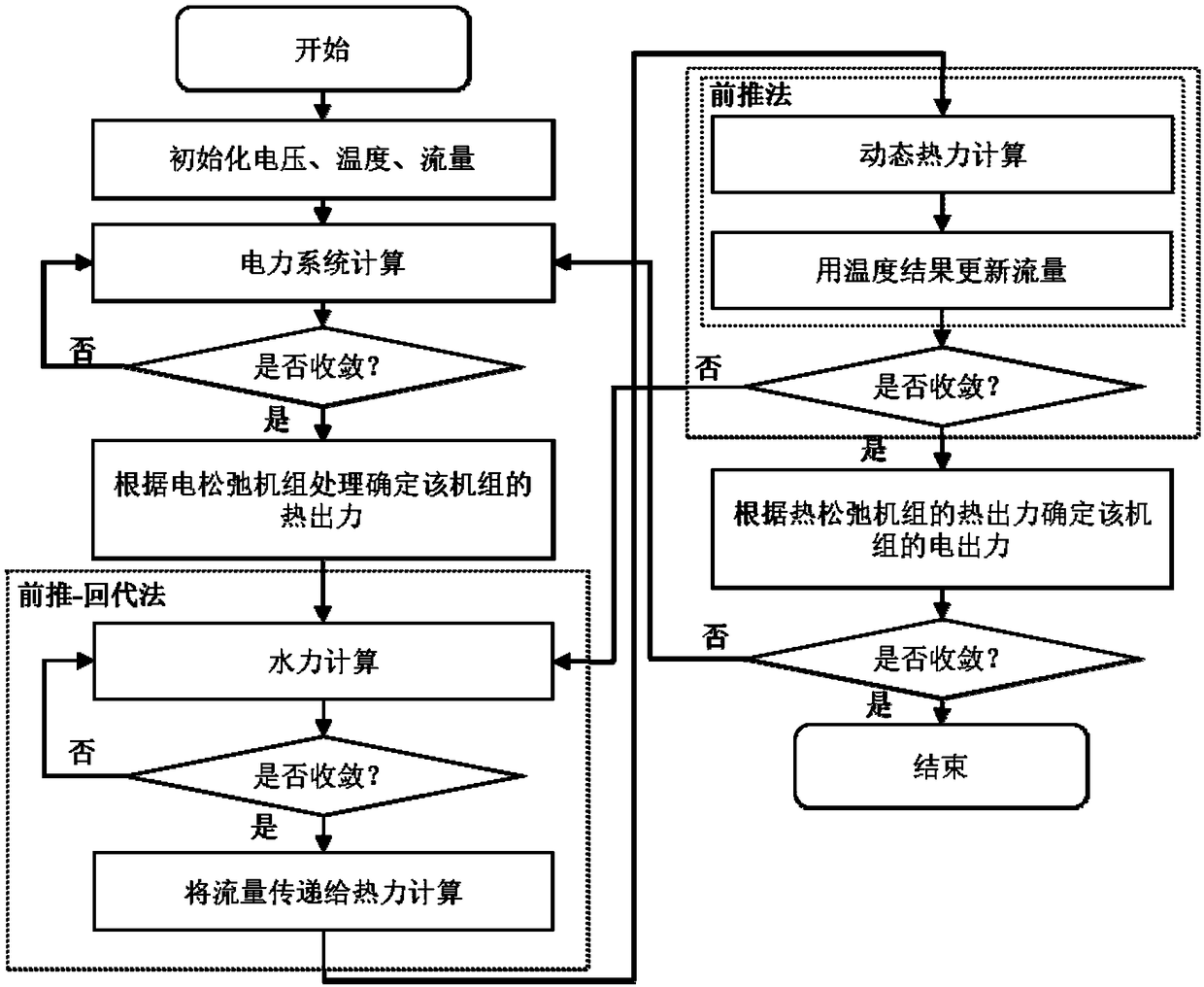

Thermoelectric energy supply calculation method, device, electronic device and storage medium

ActiveCN109145441AImprove reliabilityIncrease flexibilityDesign optimisation/simulationSpecial data processing applicationsElectricityCoupling

The embodiment of the invention discloses a calculation method, a device, an electronic device and a storage medium for supplying heat and power. The method comprises the following steps: obtaining the initial values of heat parameters and electric parameters of each node in a combined heat and power supply system; inputting the initial value of the electric parameter into the power supply model to calculate the target electric parameter of each electric node, and calculating the heat output force of the electric relaxation node according to the target electric parameter; inputting the initialvalue of the heat parameter and the heat output force of the electric relaxation node to the heating model to calculate the target heat parameter of each heat node; the energy supply quality of the target load node being calculated according to the target electric parameter and the target thermal parameter, and the problems of inaccurate calculation of the energy supply quality and waste of resources in the prior art being solved. Considering the influence of thermoelectric coupling in the process of energy supply, the dynamic process of heating system and the specific parameters of energy supply demand on the user side, the quality of energy supply is calculated quantitatively to achieve a more reasonable, flexible and economic energy supply.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

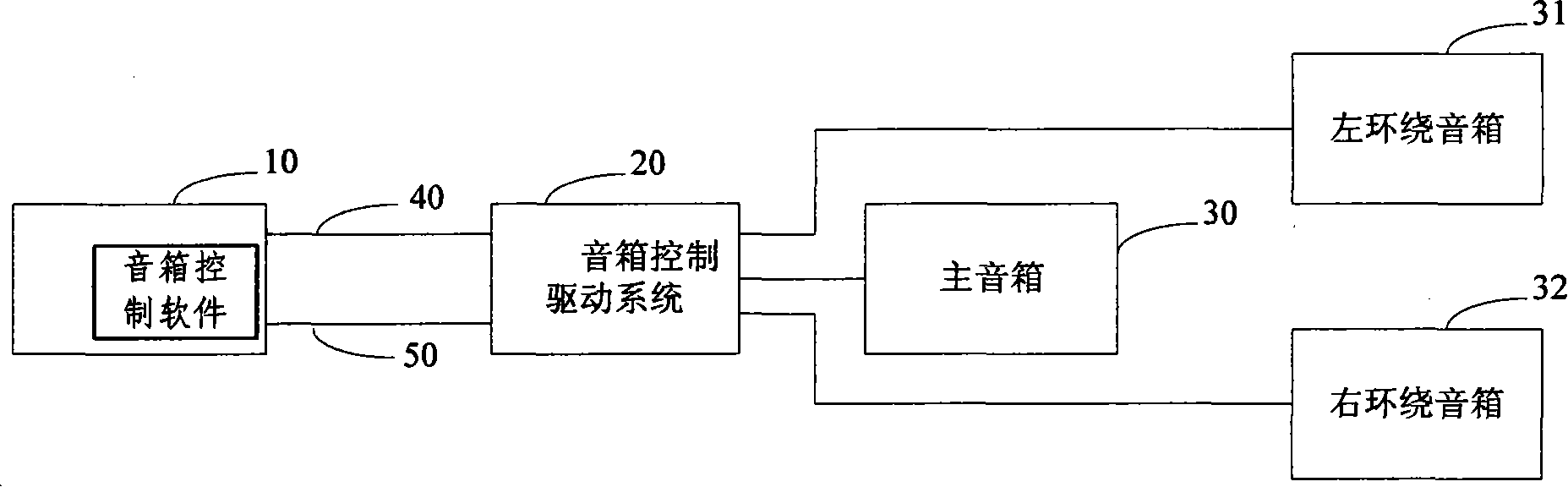

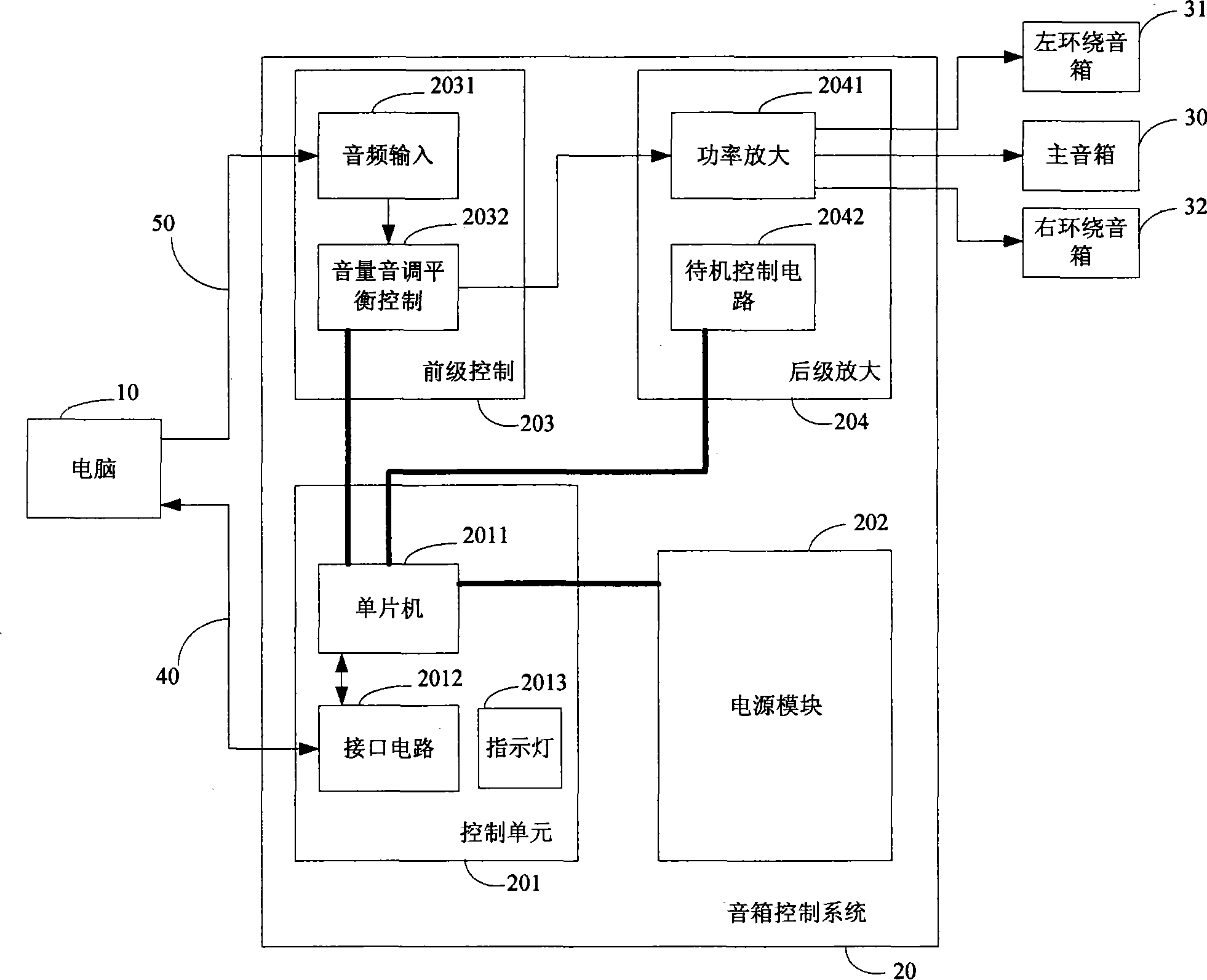

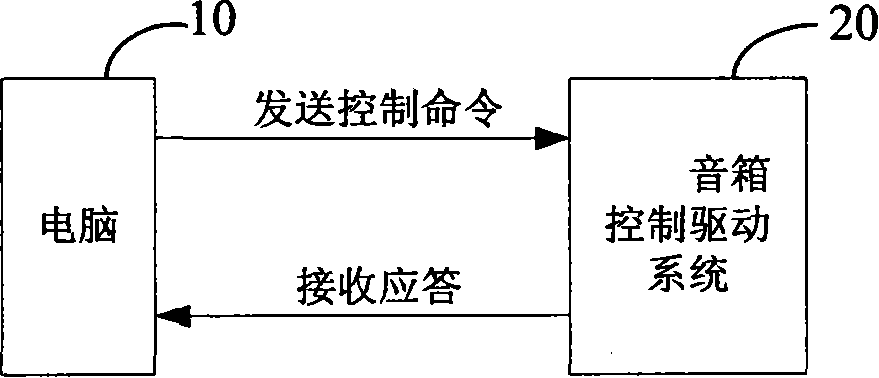

Loadspeaker box control driving method and system thereof

ActiveCN101158890AOvercome the disadvantages of inconvenient operation and short service life of mechanical partsSolve problems such as wasteSound input/outputTransducer circuitsMicrocontrollerCommand and control

The invention provides a speaker control driving method and a system thereof, which is used for controlling the speaker working through a computer. The invention comprises: a voice band line, and a communication line; a front-end control connected with the computer through the voice band line; a back-end amplifier connected with the signal output end of the front-end control through the communication line; a control unit containing a chip microprocessor used for processing a relevant control signal, the control unit is connected with the computer through the communication line and establishes the communication link with a speaker control software arranged on the computer, using for commanding and controlling the coordination of front-end control and back-end amplification; and a power source module. The invention has the advantages in that: the system is convenient for a user to operate the speaker and improves the speaker service life, and controls the speaker to complete automatic power-up and automatic shutdown, thereby thoroughly solving the problems of strong noise on the speaker caused by computer power-up and shutdown.

Owner:TYMPHANY ACOUSTIC TECH (HUIZHOU) CO LTD

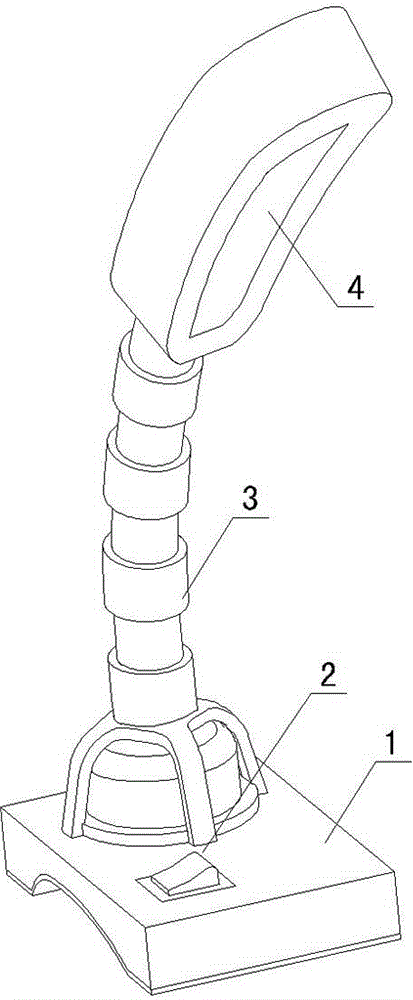

Table lamp with convenient-to-exchange switch

ActiveCN103953872ASolve problems such as wasteEasy to replacePoint-like light sourceElectric circuit arrangementsPower switchingMechanical engineering

The invention provides a table lamp with a convenient-to-exchange switch. The table lamp comprises a lamp base, a power supply switch, a lamp rod and a luminous body, wherein the power supply switch is a switch controlling piece which is detachably arranged on the lamp base, a containing cavity is correspondingly formed in the lamp base, an electric conductor is correspondingly arranged inside the containing cavity and on the power supply switch and are capable of realizing the electrical connection of the power supply switch and power supply, the power supply switch comprises an outer shell, a switch button arranged on the outer shell, a switch movable contact piece and a reset spring located outside the outer shell, the electric conductor is formed by two conducting pins arranged at the bottom of the power supply switch and two conducting spring pieces correspondingly arranged inside the containing cavity, the conducting spring pieces are electrically connected with the power supply, and the conducting pins are electrically connected with the switch movable contact piece. When the table lamp is used, a user can directly take the power supply switch out and exchange for another good power supply switch when the power supply switch is damaged, and the exchanging is convenient and safe.

Owner:朱柏立

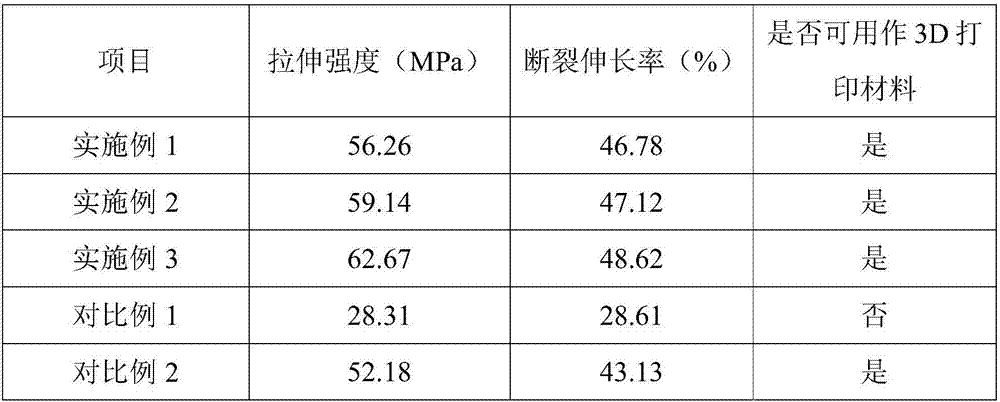

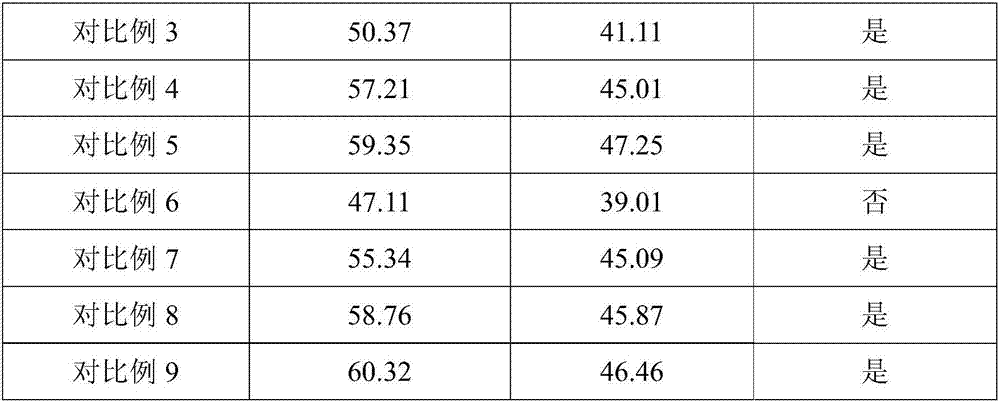

Material with high tensile strength and application thereof

InactiveCN107345078ASolve problems such as wasteFully recycleAdditive manufacturing apparatusAdditional valuesGraphene

The invention discloses a high tensile strength material and its application. The high tensile strength material comprises the following raw materials in parts by weight: 96-158 parts of banana stalks, 28-36 parts of kaolin, 62 parts of polylactic acid ‑78 parts, potassium tripolyphosphate 24‑35 parts, graphene 1.2‑2 parts, fatty alcohol polyoxyethylene ether ammonium sulfate 6‑10 parts, triethanolamine soap 0.5‑0.8 parts, complex agent I 4.5‑8.7 parts, Composite agent II 3.6-6.2 parts. The material of the invention can be widely used in the technical field of 3D printing. The invention can fully recycle banana stalks and kaolin, expand the application range of banana stalks and kaolin, and increase the added value of banana stalks and kaolin.

Owner:广西丰达三维科技有限公司

Automatic filling device for wine bottle

InactiveCN108190815ARealize automatic correspondenceLess prone to outflowLiquid bottlingGear wheelTransmission belt

The invention discloses an automatic filling device for a wine bottle. The automatic filling device comprises a pedestal; a supporting device is arranged at the lower end of the pedestal; the pedestalis provided with a mounting groove; one side of the bottom inside the mounting groove is fixedly provided with a second driving device; the opposite sidewalls inside the mounting groove are rotationally connected with a third rotating rod; the tail end of an output shaft of the second driving device is connected with the third rotating rod through a second transmission belt; and a first bevel gear is arranged on the third rotating rod in a penetrating manner. The automatic filling device disclosed by the invention realizes automatic correspondence between the wine bottle and a filling machine, provides conveniences for filling, makes the wine be hard to overflow, solves the problems that a traditional filling device is not high in automation degree and the wine bottle and the filling machine easily generate non-correspondence which causes filling errors, prevents the problem such as waste caused by overflowing of the wine, reduces the expenses of an enterprise, and is simple in structure, convenient to operate and suitable for popularization.

Owner:郑州星联新创信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com