Cr<3+>-activated alumina glass-ceramic for agricultural greenhouse and its preparation method and use

A technology of glass-ceramics and alumina, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of organic film pollution and waste, and achieve the effect of solving pollution and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 7

[0022] Will Al 2 o 3 with Cr 2 o 3 Mix according to the proportions shown in Table 1, put them into a high-temperature furnace and burn them at 1600°C for 2 hours, at 1650°C for 0.5 hours, and cool naturally to obtain a pink powder mixture.

Embodiment 8- Embodiment 14

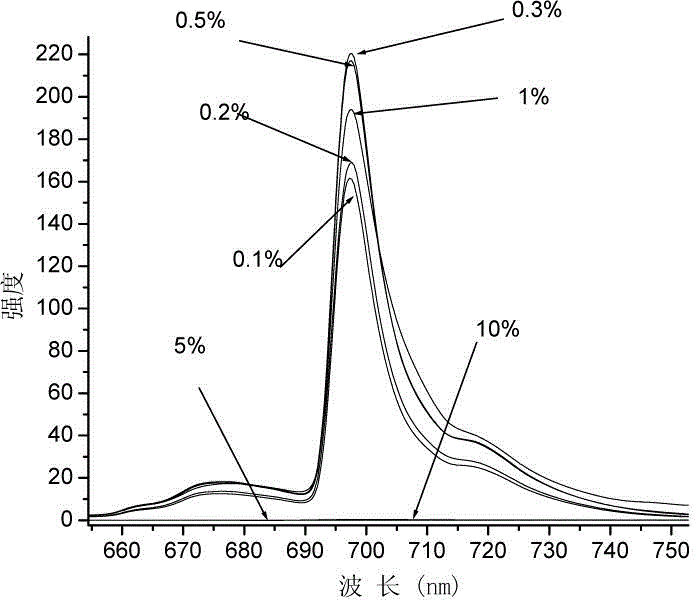

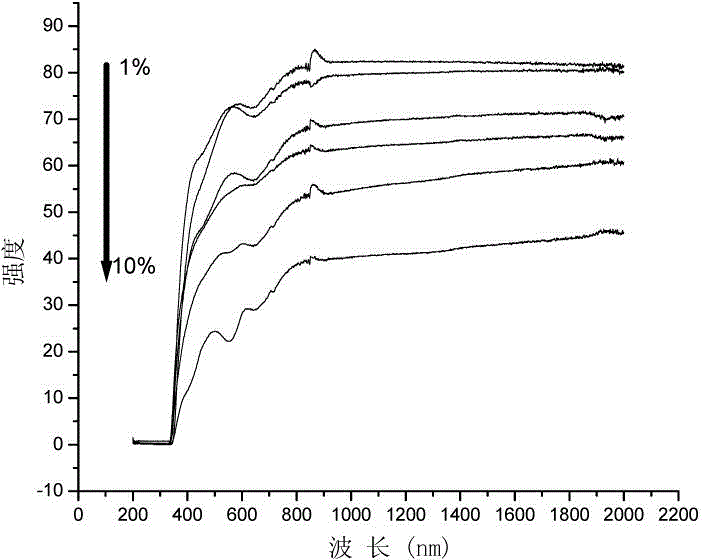

[0024] (2) Press TeO 2 : Na 2 CO 3 :ZnO:BaCO 3 =7:1:1:1 (molar ratio) Measure each component as the glass-forming matrix, and the glass-forming matrix and the pink powder mixture (embodiment 4) prepared in step (1) are uniform in proportion as described in Table 2 Mix, melt in a high-temperature furnace at 650°C for 2 hours, and anneal at 400°C for 2 hours to obtain Cr 3+ Activated alumina glass-ceramics. The resulting glass sheet is then polished on both sides.

[0025] Table 1

[0026]

[0027]

[0028] Table 2

[0029]

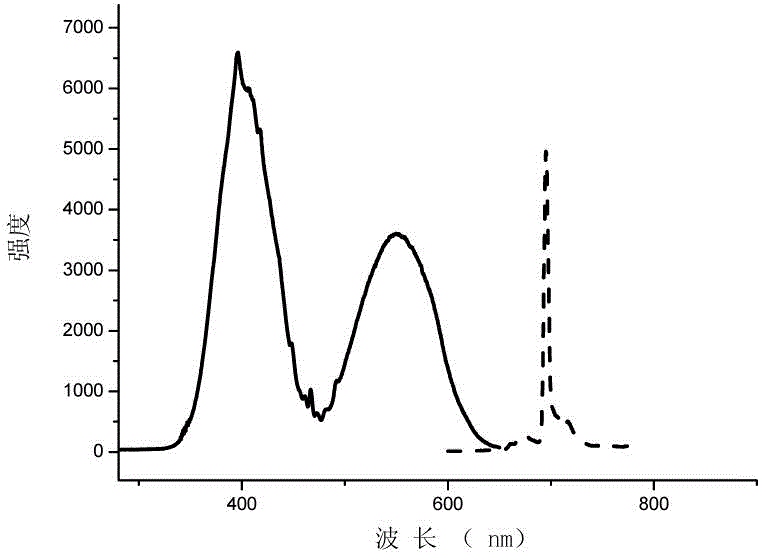

[0030] Choose the Al made in embodiment 4 2 o 3 with Cr 2 o 3 mixture, testing its excitation and emission spectra, such as figure 1 shown. Wherein, the solid line is the excitation spectrum of light with a wavelength of 696nm, and the dotted line is the emission spectrum of light with a wavelength of 400nm. From figure 1 It can be seen that the Al prepared by the present invention 2 o 3 with Cr 2 o 3 The mixture has broadband abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com