Material with high tensile strength and application thereof

A technology with high tensile strength and raw materials, applied in the direction of additive processing, can solve problems such as waste of banana stalk resources, and achieve the effect of increasing added value and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

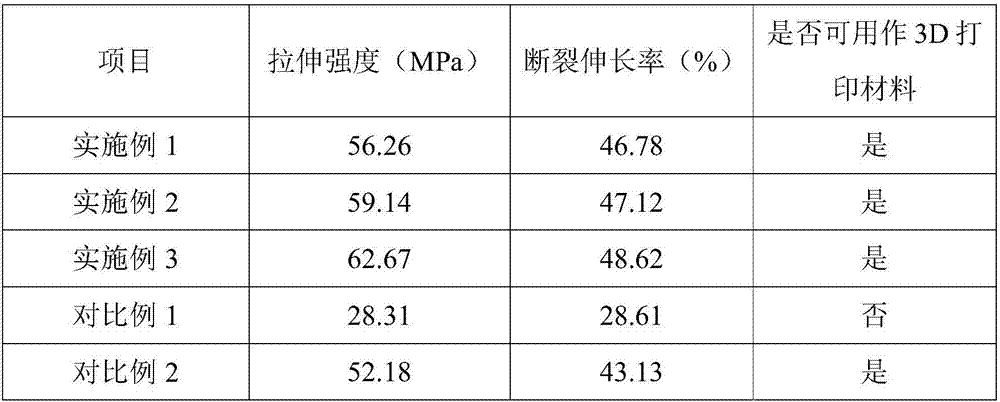

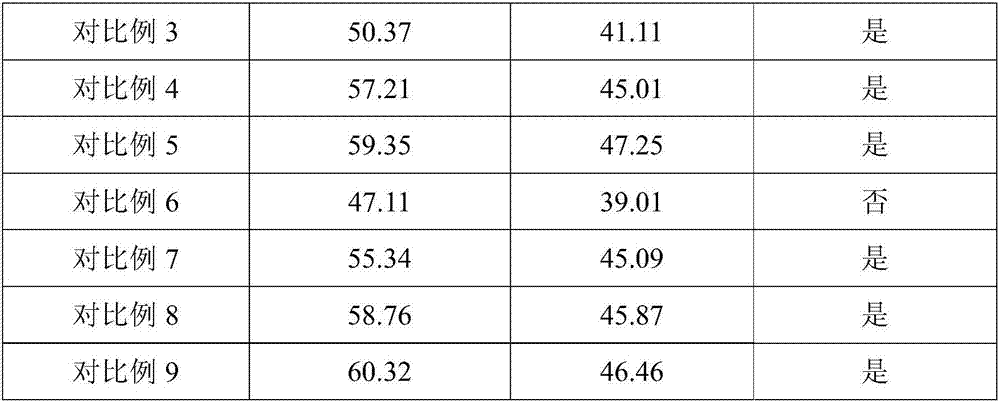

Examples

Embodiment 1

[0072] A high tensile strength material, in parts by weight, comprising the following raw materials: 98 parts of banana stalks, 28 parts of kaolin, 63 parts of polylactic acid, 24 parts of potassium tripolyphosphate, 1.2 parts of graphene, fatty alcohol polyoxyethylene ether 6 parts of ammonium sulfate, 0.5 parts of triethanolamine soap, 4.5 parts of compound agent I, 3.6 parts of compound agent II;

[0073] The composite agent I includes the following raw materials in parts by weight: 1.7 parts of glycidyl methacrylate, 4.6 parts of modified polyacrylate, 2.2 parts of bis(2-ethylhexyl) phthalate, antioxidant 2 parts of agent 1076, 4.3 parts of polyaluminum chloride, 3 parts of ACR foam regulator, 2 parts of aerosol generating agent, 3.2 parts of coupling agent kh-550;

[0074] The composite agent II is in parts by weight and includes the following raw materials: 152 parts of tapioca starch, 18 parts of dimethyl phosphite, N-ethyl-5-methyl-2-(1-methylethyl)cyclohexyl 6 parts ...

Embodiment 2

[0092] A high tensile strength material, in parts by weight, comprising the following raw materials: 130 parts of banana stalks, 32 parts of kaolin, 70 parts of polylactic acid, 30 parts of potassium tripolyphosphate, 1.6 parts of graphene, fatty alcohol polyoxyethylene ether 8 parts of ammonium sulfate, 0.7 parts of triethanolamine soap, 6.5 parts of complex agent I, and 5 parts of compound agent II;

[0093] The compounding agent I includes the following raw materials in parts by weight: 2.5 parts of glycidyl methacrylate, 5.4 parts of modified polyacrylate, 3.2 parts of bis(2-ethylhexyl) phthalate, antioxidant 3 parts of agent 1076, 5.3 parts of polyaluminum chloride, 4 parts of ACR foam regulator, 3 parts of aerosol generating agent, 4.5 parts of coupling agent kh-550;

[0094] The composite agent II is in parts by weight and includes the following raw materials: 165 parts of tapioca starch, 20 parts of dimethyl phosphite, N-ethyl-5-methyl-2-(1-methylethyl)cyclohexyl 8 pa...

Embodiment 3

[0112] A high tensile strength material, in parts by weight, comprising the following raw materials: 156 parts of banana stalks, 36 parts of kaolin, 78 parts of polylactic acid, 35 parts of potassium tripolyphosphate, 2 parts of graphene, fatty alcohol polyoxyethylene ether 10 parts of ammonium sulfate, 0.8 parts of triethanolamine soap, 8.7 parts of compound agent I, 6.2 parts of compound agent II;

[0113] The compounding agent I includes the following raw materials in parts by weight: 3.5 parts of glycidyl methacrylate, 6.2 parts of modified polyacrylate, 4 parts of bis(2-ethylhexyl) phthalate, antioxidant 4 parts of agent 1076, 6.3 parts of polyaluminum chloride, 5 parts of ACR foam regulator, 4 parts of aerosol generating agent, 5.6 parts of coupling agent kh-550;

[0114] The composite agent II is in parts by weight and includes the following raw materials: 182 parts of tapioca starch, 22 parts of dimethyl phosphite, N-ethyl-5-methyl-2-(1-methylethyl)cyclohexyl 10 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com