Aluminum electrolyzed waste carbon residue innocent treatment system and method thereof

A harmless treatment, aluminum electrolysis technology, applied in combustion methods, incinerators, carbon preparation/purification, etc., can solve the problems of uneven temperature distribution in the furnace, low carbon slag recycling rate, and carbon slag environmental pollution. , to achieve the effect of low production cost, novel design ideas and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

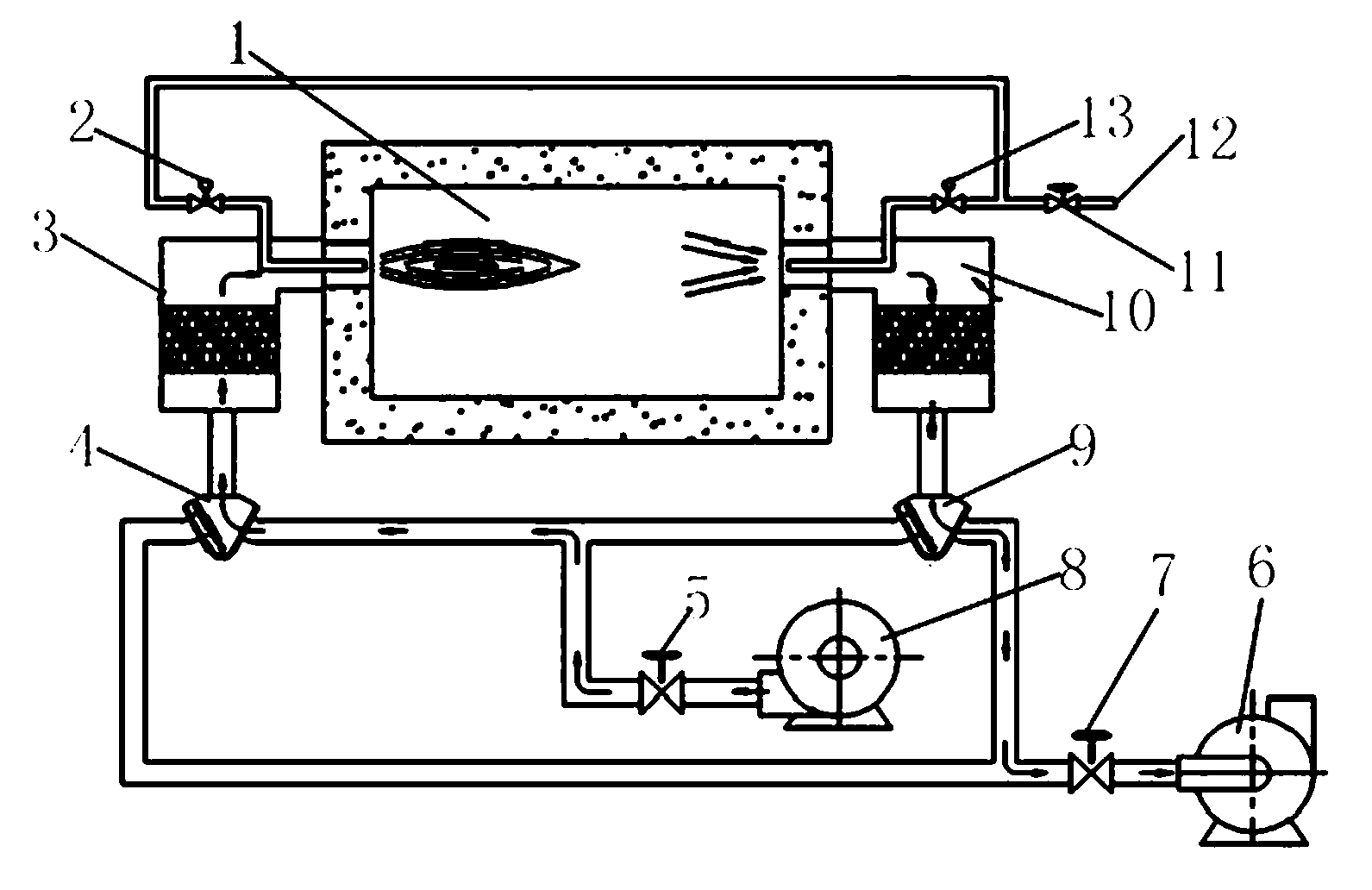

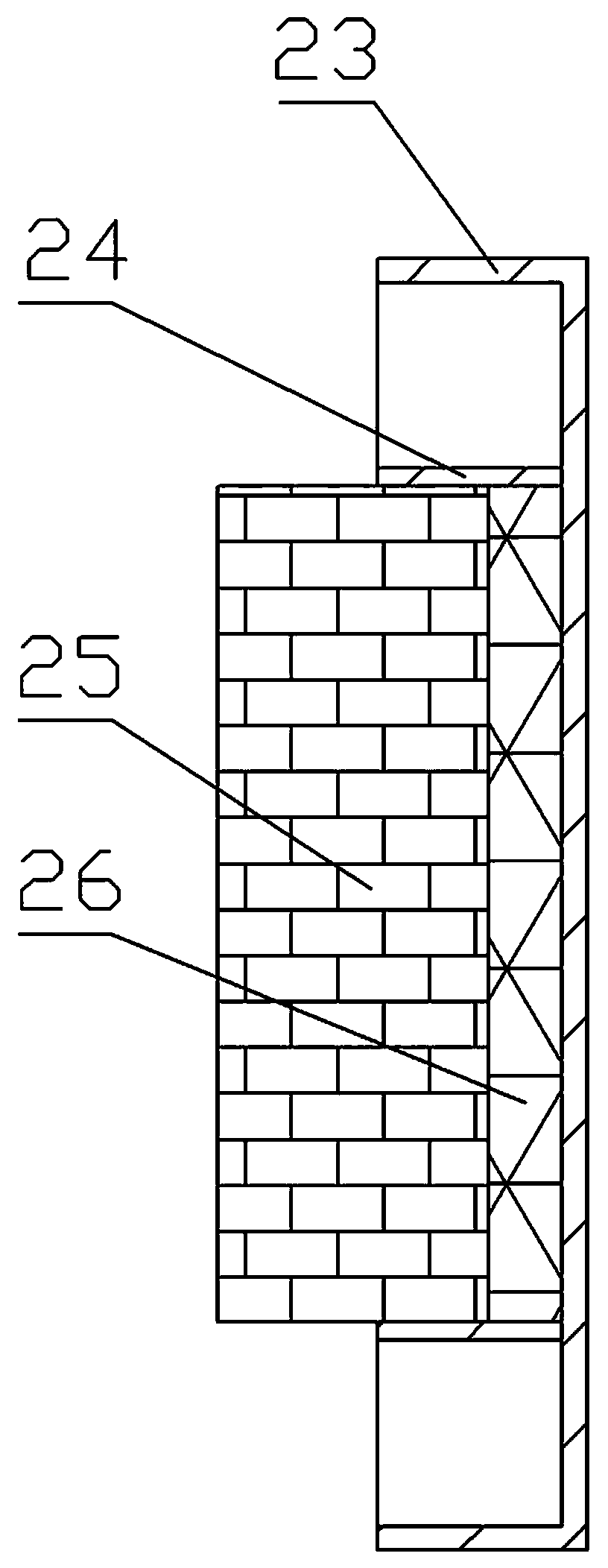

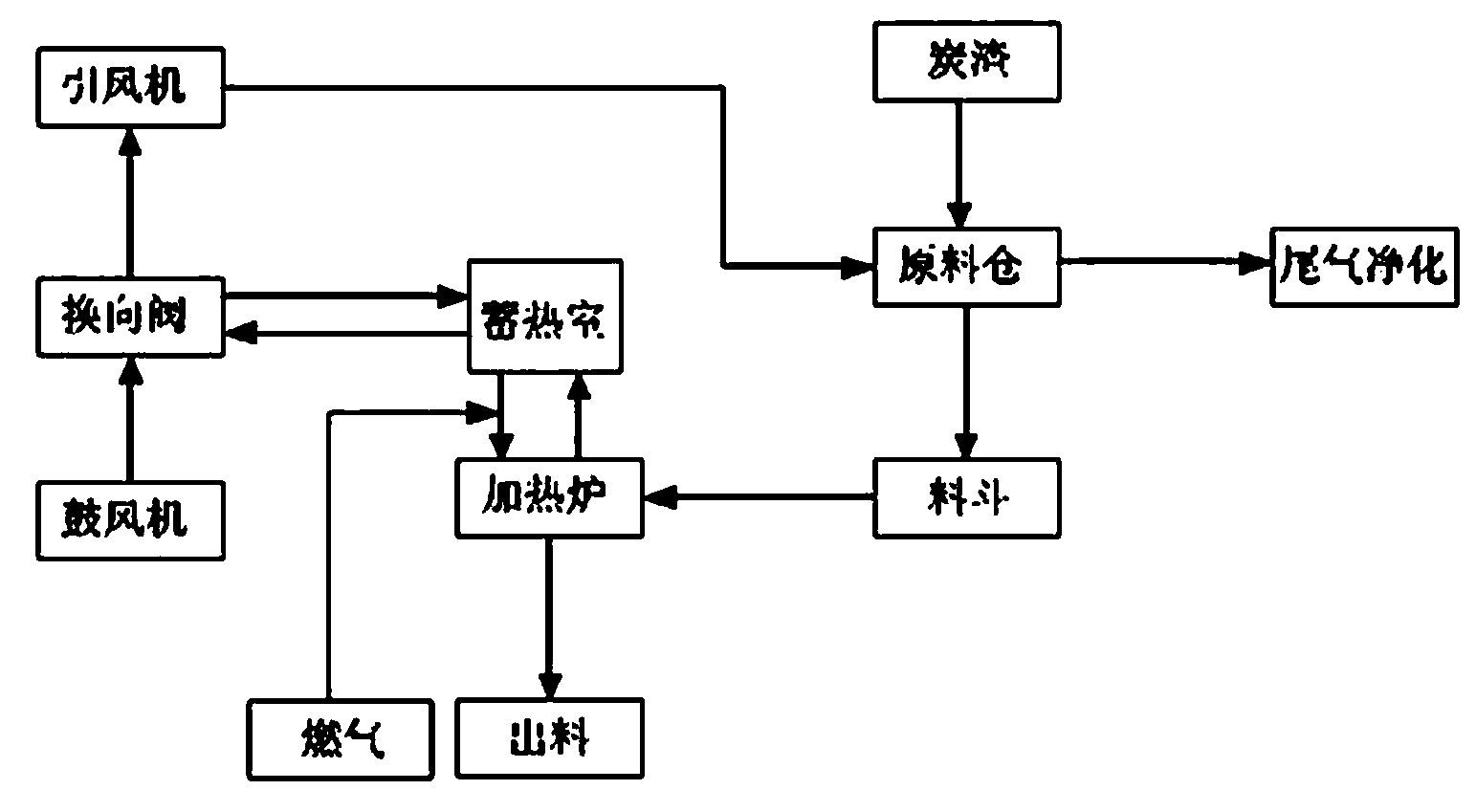

[0038] Example 1: A harmless treatment system for aluminum electrolysis waste carbon slag, see figure 1 , figure 2 , image 3 , Figure 4 , including a heating furnace, a heating cycle device, an exhaust gas purification device, a hopper correspondingly connected to the heating furnace, and a raw material bin correspondingly connected to the hopper; the heating furnace includes a hearth 1, and the heating cycle device includes a The first regenerator 3 and the second regenerator 10 in communication with the furnace, the induced draft fan 6 and the blower 8 , and the three inlets in communication with the first regenerator 3 and the second regenerator 10 respectively. Air reversing valve 4 and three air outlet reversing valves 9; the suction port of the induced draft fan is correspondingly connected with the three air inlet reversing valves and the three air outlet reversing valves, and its air outlet is correspondingly connected with the raw material warehouse The exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com