Automatic copying follow-up system of sugarcane harvester and control method thereof

A follow-up system and harvester technology, which is applied to fluid pressure actuated system components, harvesters, mechanical equipment, etc., can solve the problems of high rate of perennial root breakage, waste, and reduced germination of perennial roots in the second year, so as to solve the problems of perennial roots too high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

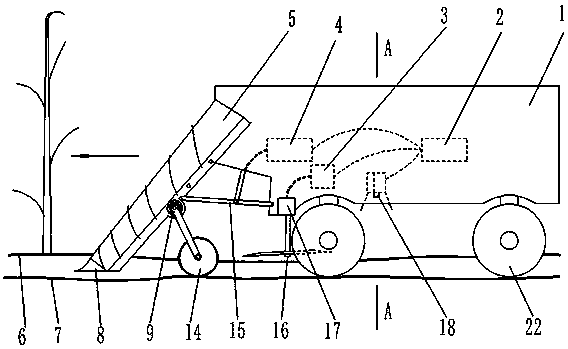

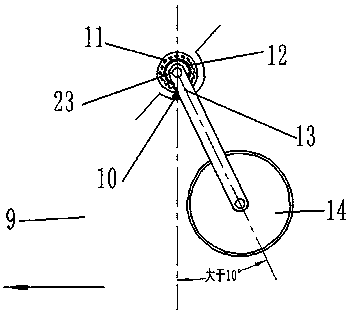

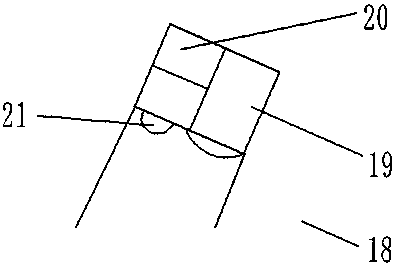

[0027]An automatic profiling follow-up system for a sugarcane harvester includes a displacement sensor device 9. The displacement sensor device 9 is a sealed structure and is installed directly behind the sugarcane supporting mechanism 5. A semiconductor angle sensor 11, a torsion spring 12, a semiconductor angle sensor 11, a torsion spring 12, The positioning bolt 10 and the rotating shaft 23, the rotating shaft 23 is fixed with a connecting rod 13, and the other end of the connecting rod 13 is equipped with a height detection wheel 14. The height detection wheel 14 can move up and down with the height change of the sugarcane canal 7, and the torsion force generated by the torsion spring 12 The cane-supporting mechanism 5 is fixed on the front end of the lifting device 15 of the cane-supporting mechanism, and the cane-supporting mechanism lifting device 15 is installed on the front end of the car body 1 and connected to the cane-supporting hydraulic control device 4. The front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com