Miniature airborne up-converter and manufacturing process thereof

A frequency converter and minicomputer technology, applied in the field of small airborne up-converter and its manufacturing process, can solve problems such as low complexity, achieve the effect of increasing phase detection frequency, reducing error rate, improving pass rate and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

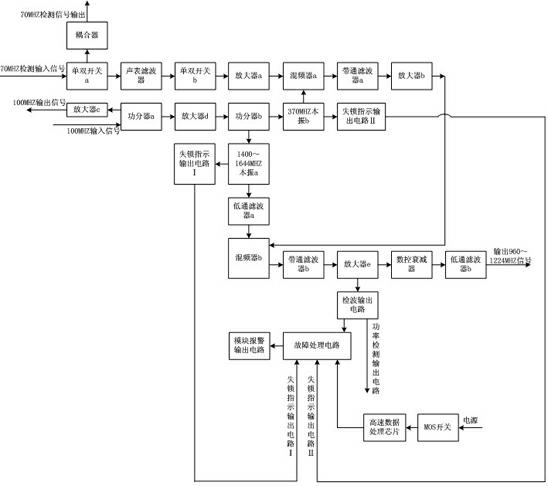

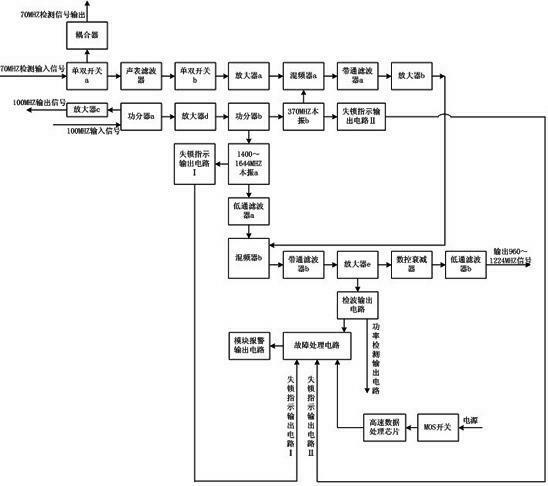

[0027] like figure 1 As shown, a small airborne up-converter is composed of three parts: a local oscillator circuit, a frequency conversion channel circuit and a power control circuit. The output terminal of the local oscillator circuit and the power control circuit are respectively connected to the frequency conversion channel circuit.

[0028] The local oscillator circuit includes a coupler, an SAW filter, a mixer a, a band-pass filter a, a low-pass filter a, one or more local oscillators, one or more power dividers, one or more amplifiers, The external 70MHz detection input signal is connected to the SAW filter through the single and double switch a, the other end of the single and double switch a is connected to the 70MHz detection signal output line through the coupler, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com