Positioning mechanism

A technology of positioning mechanism and limit plate, applied in positioning devices, metal processing equipment, feeding devices, etc., can solve problems such as material waste, achieve the effects of improving economic benefits, saving production costs, and solving material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

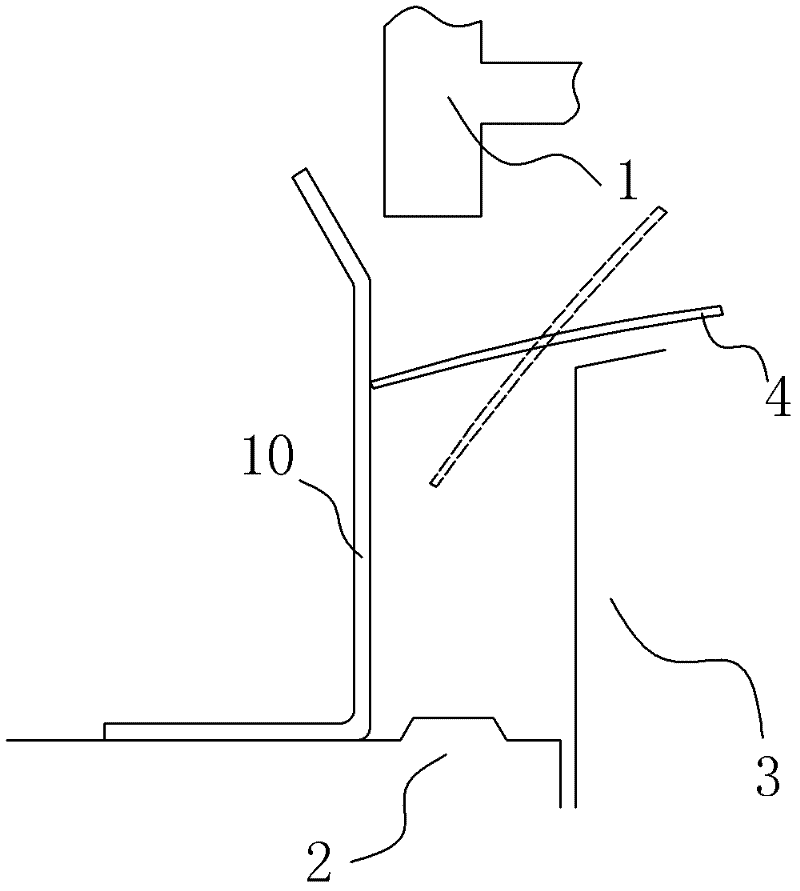

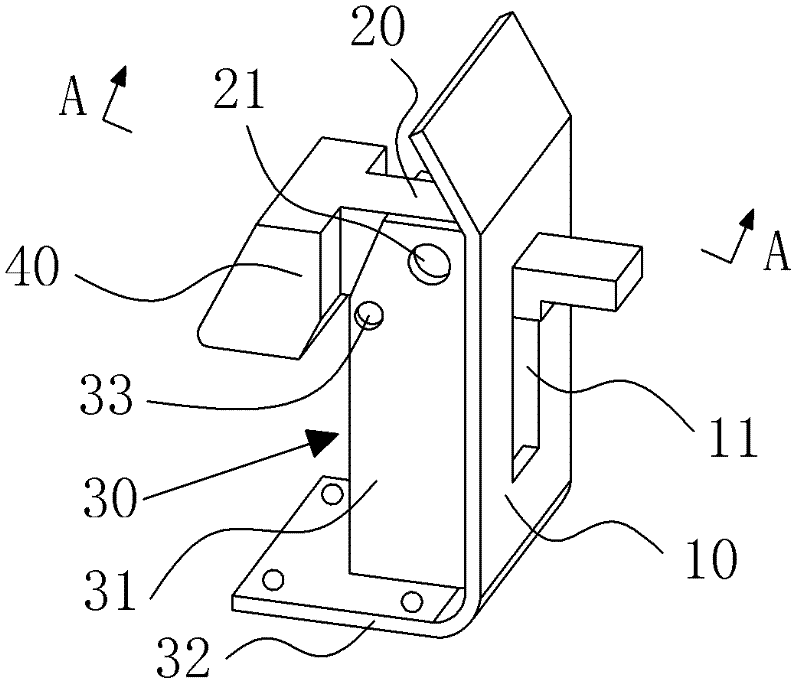

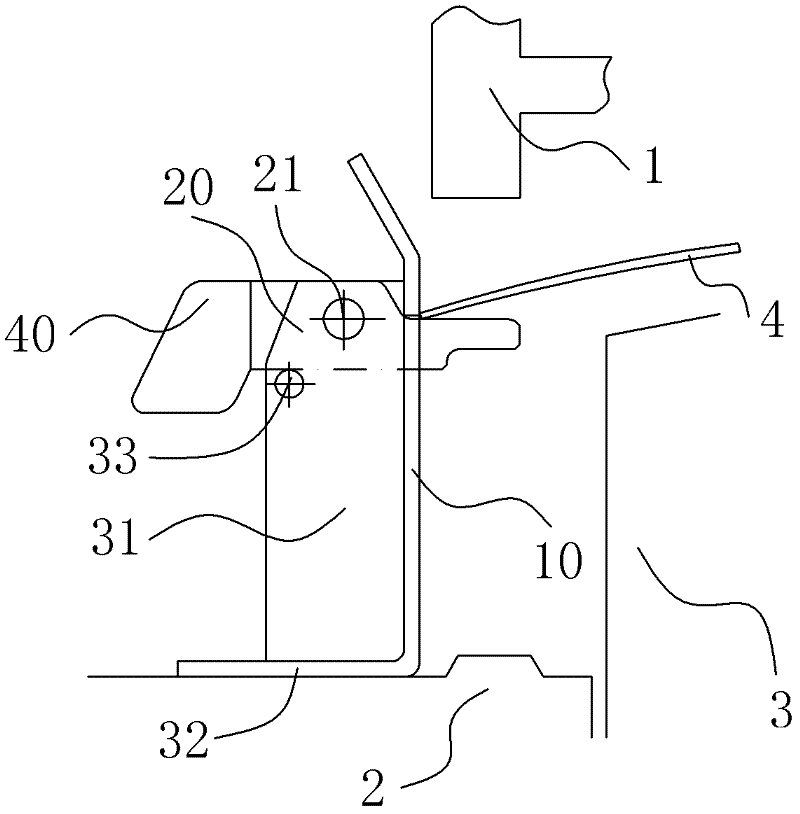

[0011] Embodiments of the present invention will now be described with reference to the drawings.

[0012] A positioning mechanism. The positioning mechanism includes a limit plate 10 arranged vertically on the blank holder 2 and a movable part. The movable parts are in two positions respectively. , and the second is to retract to at least the retracted position flush with the plate surface of the limiting plate 10 . By setting up a movable part, when the material plate 4 enters the mould, the movable part is in the protruding position protruding to the front of the limit plate 10, and the material plate is positioned to prevent the suspension end of the material plate 4 from sliding down; 4 When stamped by the mold, the movable part is retracted to at least flush with the plate surface of the limiting plate 10, so that the material plate 4 entering the mold can be well positioned without affecting the material plate 4 Stamping, so that the material plate 4 of appropriate siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com