Flue gas desulfurization byproduct-based inorganic gelled material and preparation method thereof

A technology of inorganic cementitious materials and desulfurization by-products, which is applied in the field of building materials, can solve the problems of chemical stability affecting durability, desulfurization ash is difficult to burn cement, and economic benefits are difficult, and achieves significant economic and social benefits, production Low cost and avoid high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

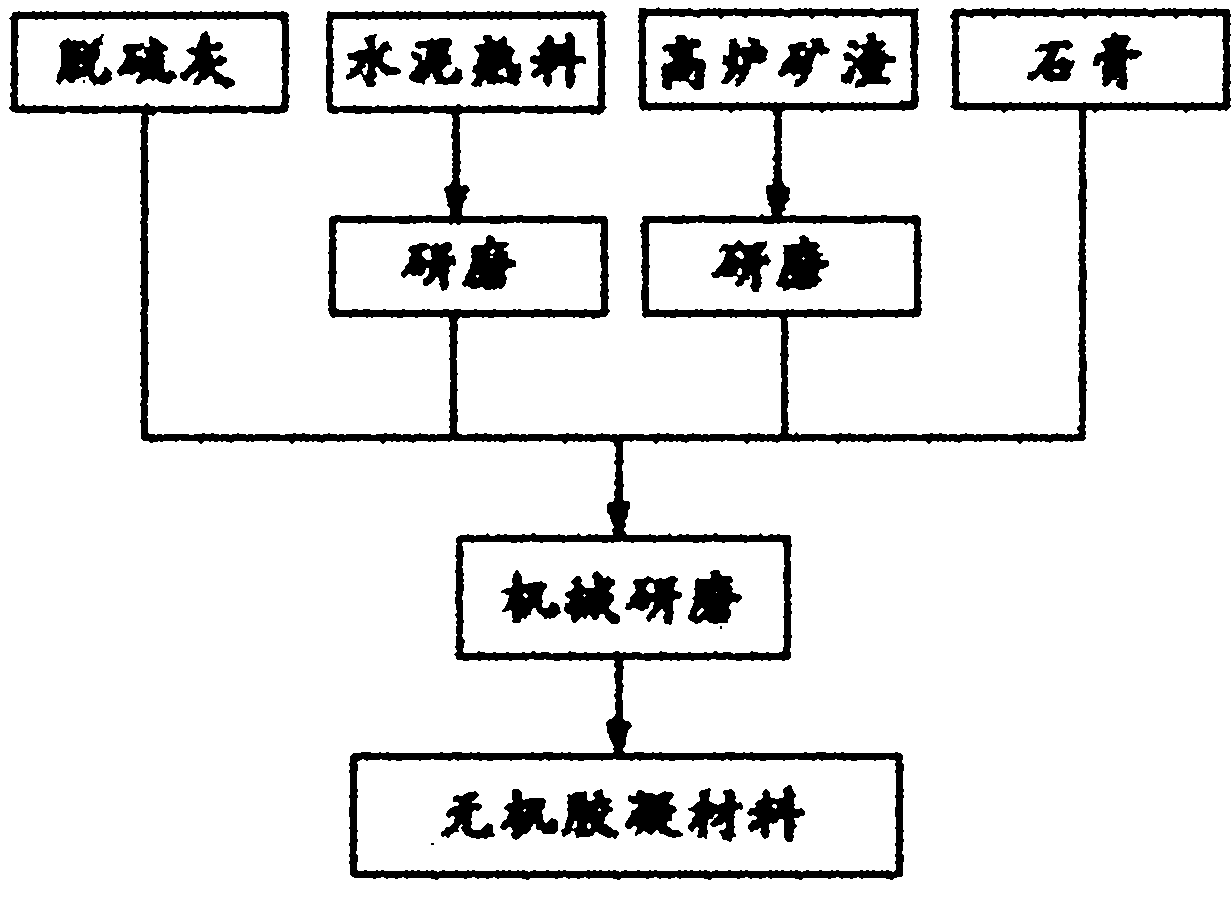

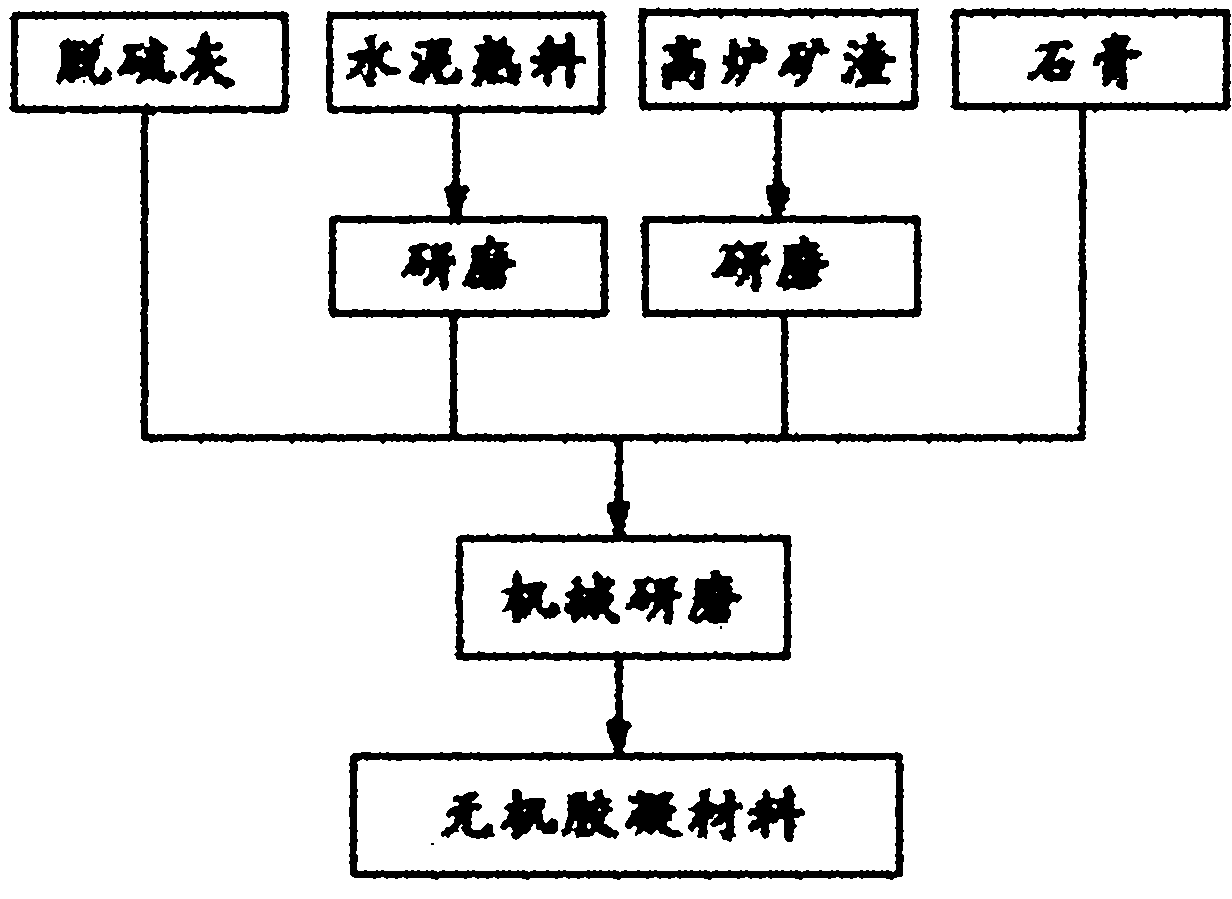

Method used

Image

Examples

Embodiment 1

[0023] An inorganic cementitious material, which is made by mixing and grinding the desulfurized ash produced by the flue gas desulfurization treatment of coal-fired power stations, supplemented by slag, gypsum and cement clinker. Among them: the desulfurization ash is the powder obtained by drying and sieving the desulfurization by-products produced by the semi-dry flue gas desulfurization process of the circulating fluidized bed. The remaining rate is about 3.48%. The calcium oxide content in the desulfurization ash is 55%, the sulfur oxide content is 28%, and the silicon and aluminum oxide content is 6%. The slag is selected from the granulated blast furnace slag in the national standard GB / T-203, and its water content is about 0.85%, and the particle size is all controlled below 2.0mm. The gypsum is selected from the first-grade dihydrate gypsum in the national standard GB5483-85. The cement clinker is selected from the P.O Portland cement clinker in the national standard...

Embodiment 2

[0031]Another inorganic cementitious material, which is made by mixing and grinding the desulfurized ash produced by the flue gas desulfurization treatment of coal-fired power stations, supplemented by slag, gypsum and cement clinker. Among them: the desulfurization ash is the powder obtained by drying and sieving the desulfurization by-products produced by the reflux circulating fluidized bed semi-dry flue gas desulfurization process. The moisture content is about 0.64%, and the 0.074mm square hole The excess sieve rate is about 4.76%, the calcium oxide content in the desulfurization ash in the desulfurization ash is 60%, the sulfur oxide content is 26%, and the silicon and aluminum oxide content is 5.8%. The slag is selected from the granulated blast furnace slag specified in the national standard GB / T-203, and its water content is about 0.90%, and the particle size is all controlled below 2.0mm. The gypsum is selected from the first-grade dihydrate gypsum in the national st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com