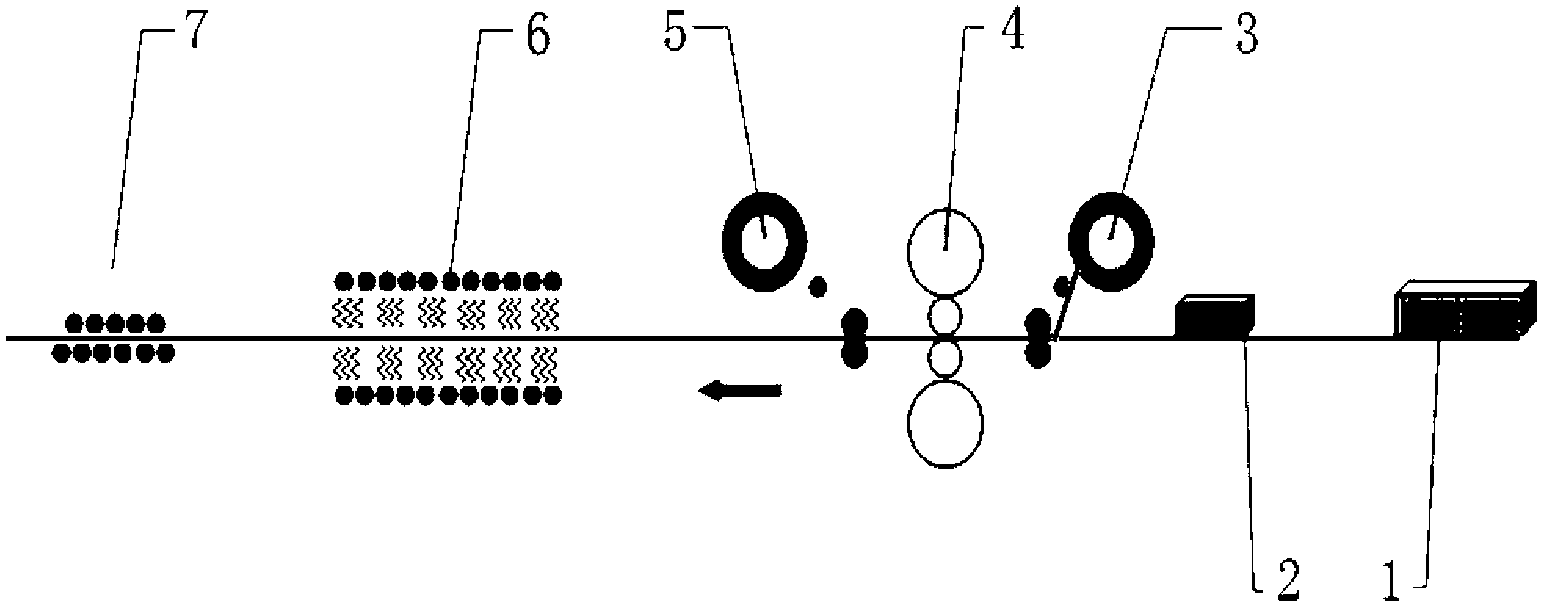

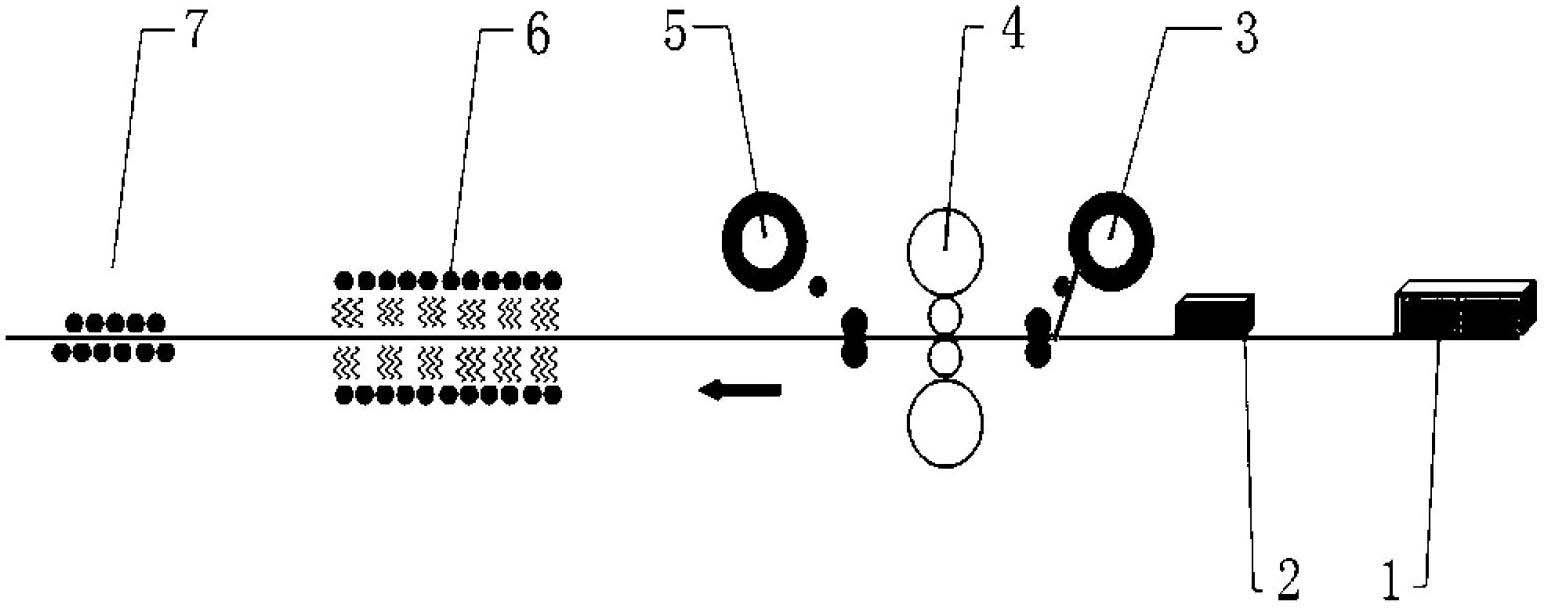

Plate shape control method of hot-rolling and coiled-rolling steel plate of single-rack steekle mill

A furnace coil rolling mill and steel plate shape technology, which is applied in the field of steel rolling, can solve the problems of excessive temperature drop, uneven temperature distribution, and excessive temperature difference of the rolled piece, so as to improve the primary rolling rate, increase production capacity and efficiency, and speed up The effect of production rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment is a strip shape control process for hot-rolling and rolling X65 pipeline steel in a single-stand furnace coil mill. The heating temperature was 1235°C. The rolling pass is 4+7 passes, the stage rolling temperature is 960°C, and the thickness of the billet is 5.6h after warming. The 7th to 10th passes are coiling, the rolling tension is 24 tons, and the temperature of the coiling furnace is raised to 900°C. The reduction rate of the 10th pass is 17%, the reduction rate of the 11th pass is 11%; the bending force of the 6th pass to the 10th pass is 990 tons, 950 tons, 840 tons, 770 tons, 590 tons . The final rolling speed is 1.60m / s; after the production of work rolls exceeds 900 tons, the cooling water around the work rolls is turned on; if the width of the rolled piece is > 3m, the edge shielding of the cooling system is used, and the cooling water ratio is 0.5; The roll gap at the entrance and exit of the straight machine is set according to the plas...

Embodiment 2

[0034] This embodiment is a flat shape control process for hot-rolling and rolling X70 pipeline steel in a single-stand furnace coil mill. The heating temperature is 1240°C. The rolling pass is 4+7 passes, the stage rolling temperature is 960°C, and the thickness of the billet is warmed for 4 hours. The 7th to 10th passes are coiling, the rolling tension is 28 tons, and the temperature of the coiling furnace is raised to 950°C. The reduction rate of the 10th pass is 17%, the reduction rate of the 11th pass is 11%; the bending force of the 6th pass to the 10th pass is 980 tons, 940 tons, 860 tons, 790 tons, 580 tons . The final rolling speed is 1.55m / s; after the production of work rolls exceeds 800 tons, the cooling water around the work rolls is turned on; if the width of the rolled piece is > 3m, the side shielding of the cooling system is used, and the cooling water ratio is 0.5; The roll gap at the entrance and exit of the straight machine is set according to the plasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com