Rolling process of limit-specification steel plate of 2800mm double-stand heavy and medium plate mill

A technology with extreme specifications and double racks, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems such as no advantages, achieve the effects of optimizing steel burning process, widening the range of specifications, and improving temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

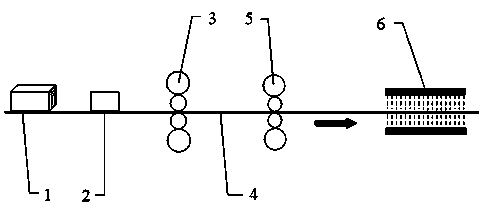

Image

Examples

Embodiment 1

[0024] A 2800mm double-stand medium and heavy plate rolling mill extreme thick plate rolling process, the rolling process requires a tapping temperature of 1200°C, a reduction of each rough rolling pass of less than 31mm, a rough rolling finish rolling temperature of above 1030°C, and a rough rolling finish temperature of 1030°C. The rolling speed is between 1.48~1.5m / s, the reduction of each pass in the finishing rolling stage is less than 12mm, the finishing rolling temperature is not lower than 880°C, and the rolling speed in the finishing rolling stage is between 2.08~2.35m / s, the temperature of turning red is 810~850℃.

[0025] In this example, one piece of P20 die steel plate is selected, the actual size of the billet is 320mm*2070mm*2305mm, the rolling thickness is 123.81mm (positive tolerance rolling), and a total of 10 passes are rolled, of which 6 passes are rough rolled, and the passes are pressed The weights are 24.24mm, 29.88mm, 29.09mm, 30.91mm, 28mm, 21.48mm, 4...

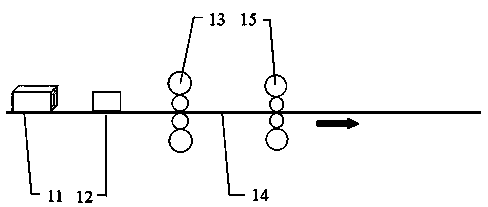

Embodiment 2

[0034] A 2800mm double-stand medium and heavy plate rolling mill limit thin plate rolling process, the rolling process requires a tapping temperature of 1200~1220°C, the reduction of each pass of rough rolling is less than 26mm, and the finishing temperature of rough rolling is above 1060°C. The rolling speed of rough rolling is between 1.4~3m / s, the reduction of each pass in the finishing rolling stage is less than 8mm, the finishing rolling temperature is not lower than 840℃, and the rolling speed in the finishing rolling stage is between 3.72~4m / s s.

[0035] In this example, one piece of Q345B steel plate is selected, the actual size of the billet is 180mm*2060mm*1232mm, the rolling thickness is 5.82mm (negative tolerance rolling), and a total of 12 passes are rolled, including 7 passes for rough rolling, and the reduction in passes Respectively 24.83mm, 23.79mm, 25.26mm, 24.07mm, 25.39mm, 20.34mm, 12.03mm, finish rolling 5 passes, pass reductions are 7.27mm, 5.18mm, 3.16...

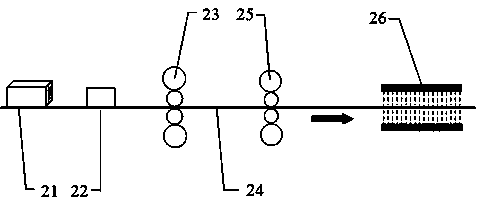

Embodiment 3

[0044] A 2800mm double-stand medium and heavy plate mill extreme wide plate rolling process, the rolling process requires a tapping temperature of 1180~1220°C, a reduction of each rough rolling pass of less than 23mm, and a finishing temperature of rough rolling above 1040°C , the rough rolling speed is between 1.5~1.55m / s, the reduction of each pass in the finishing rolling stage is less than 10mm, the finishing rolling temperature is not lower than 840℃, and the rolling speed in the finishing rolling stage is between 2.5~ 3.38m / s.

[0045] In this embodiment, one piece of Q390GJCZ25 steel plate is selected, the actual size of the billet is 260mm*2570mm*2982mm, the rolling thickness is 60.95mm, and there are 13 rolling passes in total, including 7 rough rolling passes, and the reductions of the passes are 22.81mm and 21.3mm respectively. mm, 21.76mm, 21.64mm, 21.69mm, 21.57mm, 21.73mm, 6 passes of finish rolling, the pass reductions are 9.97mm, 9.05mm, 9.01mm, 7.97mm, 7.28mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com