Four-pressure-roller mechanical intra-machine puller

A mechanical puller technology, applied in the field of metal cutting, can solve the problems of limited adjustment range, short overall life, large investment, etc., and achieve the effect of expanding the specification range, reliable pulling process, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

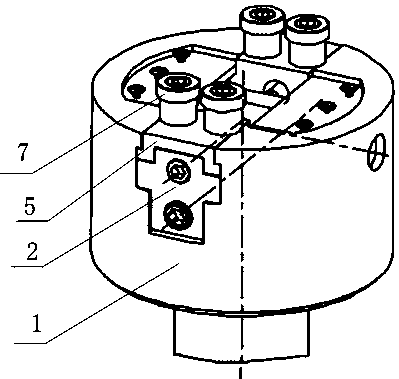

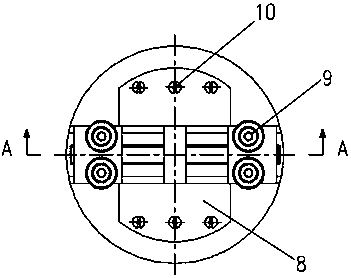

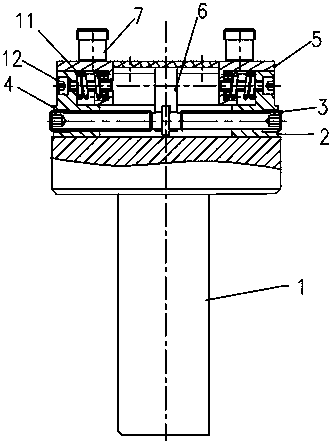

[0021] figure 1 , 2 , 3,4,5, right fixed block 2, left fixed block 4, stage clip 11, slide block 5 are connected by countersunk head hexagonal long screw 12 to form a single sliding body. The left and right sliding bodies are connected by a two-way screw 3, and the two-way screw 3 cooperates with the fixed bushing 6, and they jointly form a sliding assembly pair. There is a flat platform on the small end of the body 1, which is installed in the tool holder of the CNC lathe through a standard interface. The fixed axle sleeve 6 is fixed in the middle-shaped chute of the body 1 by the fastening screw 13, and is fixed. A pair of pressure rollers 7 are installed on the end face of the slide block 5 by means of countersunk head hexagonal short screws 9 . Rotate the two-way screw 3, the two sliding bodies slide relatively in the groove, and the pressing wheel 7 moves synchronously thereupon, thereby realizing the adjustment of the clamping range of the puller. On the end face of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com