Control process for performances of steel plate during hot rolling and flat rolling process of single-stand steckel mill

A technology of a single-stand steel-steel mill, which is applied in the field of performance control of hot-rolled flat-rolled steel plates in a single-stand steel-steel rolling mill, can solve problems such as uneven temperature distribution, uneven performance distribution, and rapid temperature drop of steel plates, and achieve improved product quality. Performance qualification rate, optimization of steel burning process, and improvement of primary rolling yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

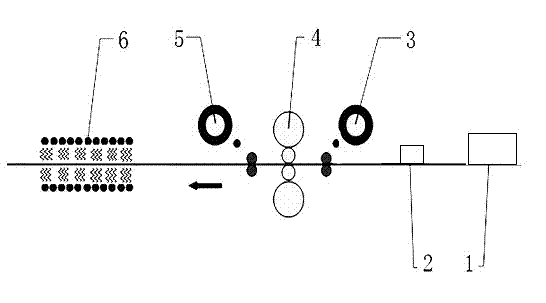

Image

Examples

Embodiment 1

[0017] A performance control process for hot-rolled flat-rolled steel sheets in a single-stand furnace coil mill. The process requires a furnace temperature of 1200°C, a rolling pass of 4+7 passes, a second-stage rolling temperature of 890°C, and a billet thickness of 3.2 hours after warming. The heating temperature of the middle tail is 1220°C, 1200°C, and 1230°C in sequence; the first to third passes start the large scale descaling of the rolling mill, and the fifth to tenth passes start high pressure and small flow: the odd pass is opened in the first half of the rolled piece, and the even pass Open at the second half of the rolled piece, and open the air purge of the coil rolling mill in the 5th to 11th passes; the original steel throwing speed is 1.50m / s 2 , acceleration 0.015 m / s 2 ;When the steel throwing is finished, the cooling water of the penultimate group will be automatically closed; the edge shielding of the cooling system will be enabled, and each side will be s...

Embodiment 2

[0026] A control process for the performance uniformity of hot-rolled flat-rolled steel sheets in a single-stand furnace coil mill. The process requires a furnace temperature of 1200°C, a rolling pass of 4+7 passes, a second-stage rolling temperature of 940°C, and a thickness of the billet to be warmed for 3.5 hours. , the heating temperature of the head, middle and tail of the billet is 1215°C, 1200°C, and 1240°C in sequence; the first to third passes start the large descaling of the rolling mill, and the sixth to tenth passes start high pressure and small flow: odd passes are opened in the first half of the rolled piece, The even pass is opened in the second half of the rolled piece, and the air purge of the coil rolling mill is started in the 5th to 11th passes; the original steel throwing speed is 1.54m / s 2 , acceleration 0.01 m / s 2 ;When steel throwing is finished, the cooling water of the penultimate group 1 and 2 will be automatically closed; the side shielding of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com