Texturing roll rolling system and method of UCMW tandem cold rolling mill

A cold tandem rolling mill and texturing roll technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of inability to adapt to the texturing roll rolling mode, and achieve surface quality and shape guarantee. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

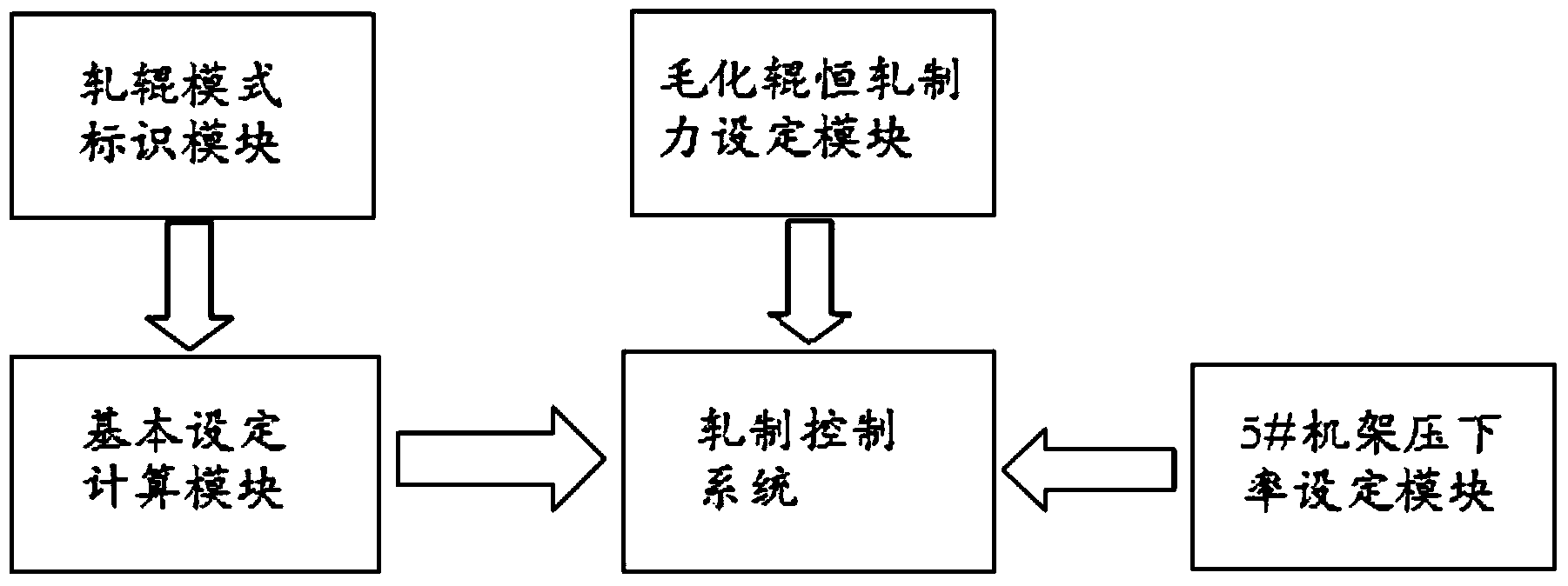

[0035] like figure 1 As shown, a UCMW cold tandem cold mill textured roll rolling system includes a roll mode identification module, a basic setting calculation module, a textured roll constant rolling force setting module, a 5# frame reduction rate setting module, and rolling control system;

[0036] The roll mode identification module judges the roll mode;

[0037] The basic setting calculation module is connected with the roll mode identification module, selects the corresponding reduction rate constant table according to the textured roll mode judged by the roll mode identification module, obtains the required rolling parameters, and performs the setting calculation of the rolling model; The basic setting calculation module is connected with the rolling control system, and outputs the setting calculation results of the rolling model to the rolling control system;

[0038] The constant rolling force setting module of the textured roll is connected with the rolling control...

Embodiment 2

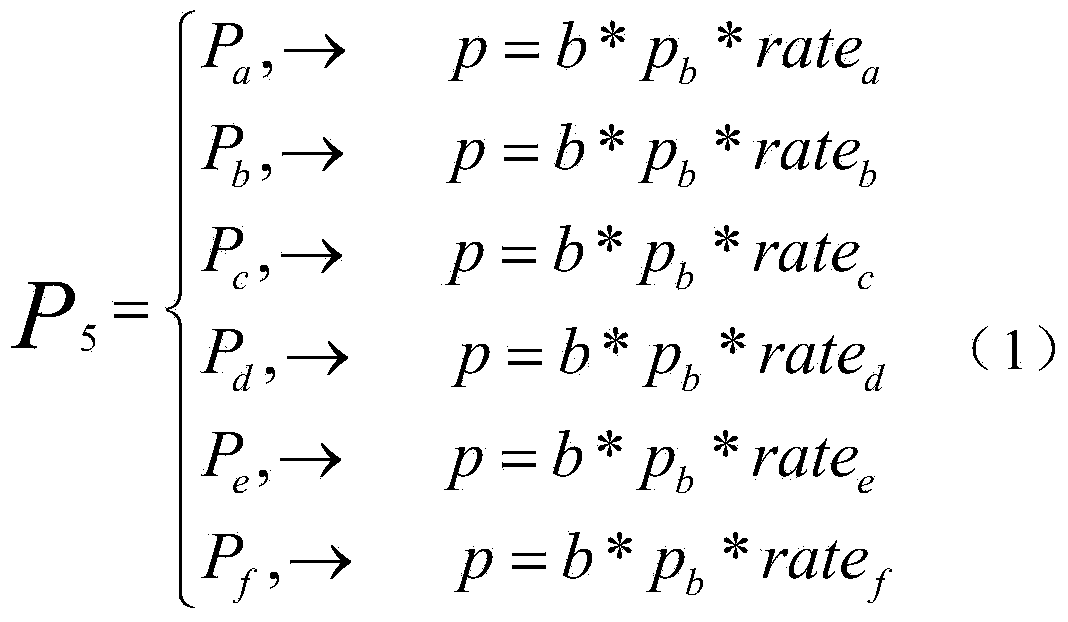

[0043] A method for rolling textured rolls of a UCMW cold tandem mill, which uses a roll mode identification module to identify the work roll mode of the 5# stand. Equip the 5# rack with textured rollers with roughness above 3.0μm (minimum roughness above 2.0μm). The basic setting calculation module obtains the required rolling parameters (used to calculate the maximum exit speed of the rolling mill, friction parameters, plate shape parameters, intermediate rolls and working roll bending and shifting amount, unit tension and initial unit tension at the taper), and then set and calculate the rolling model to determine rolling parameters such as load distribution, rolling speed, and roll gap (the specific calculation method above is It is well known in the art, and reference can be made to Chapter 5 Cold Rolling Process Control Model System of "Principles and Process Control of Strip Steel Continuous Rolling", edited by Wang Junsheng, Bai Jinlan, and Liu Xianghua, Science Press)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com