Upper spray cooling device arranged among finishing mill racks

A cooling device and technology between stands, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problem of uneven cooling distribution, and achieve the effect of reducing temperature drop, reducing production cost and avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Attached below Figure 1-5 A preferred embodiment of the present invention is specifically introduced.

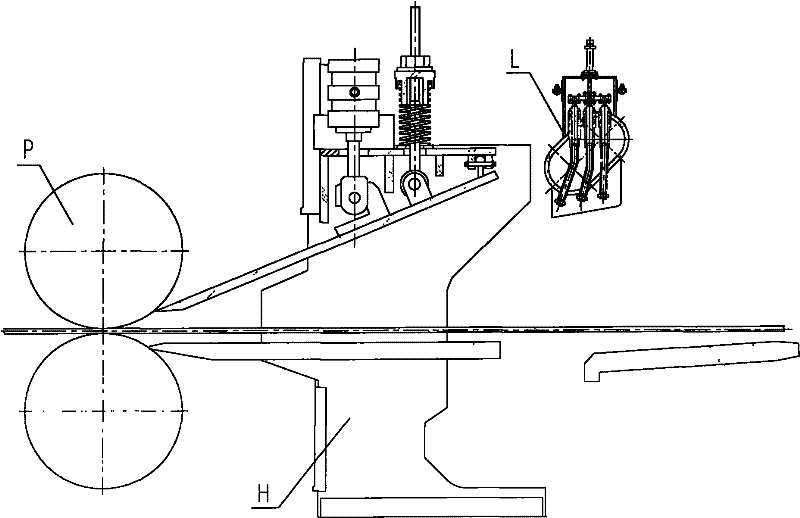

[0035] like figure 1 , the upper spray cooling device L installed between the finishing stands is set above the strip on the entrance side of the finishing stand H, and the cooled strip is formed under the rolling of the roll P.

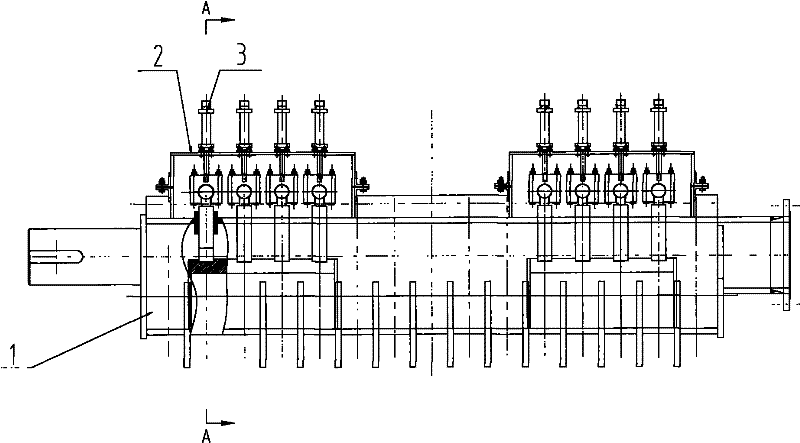

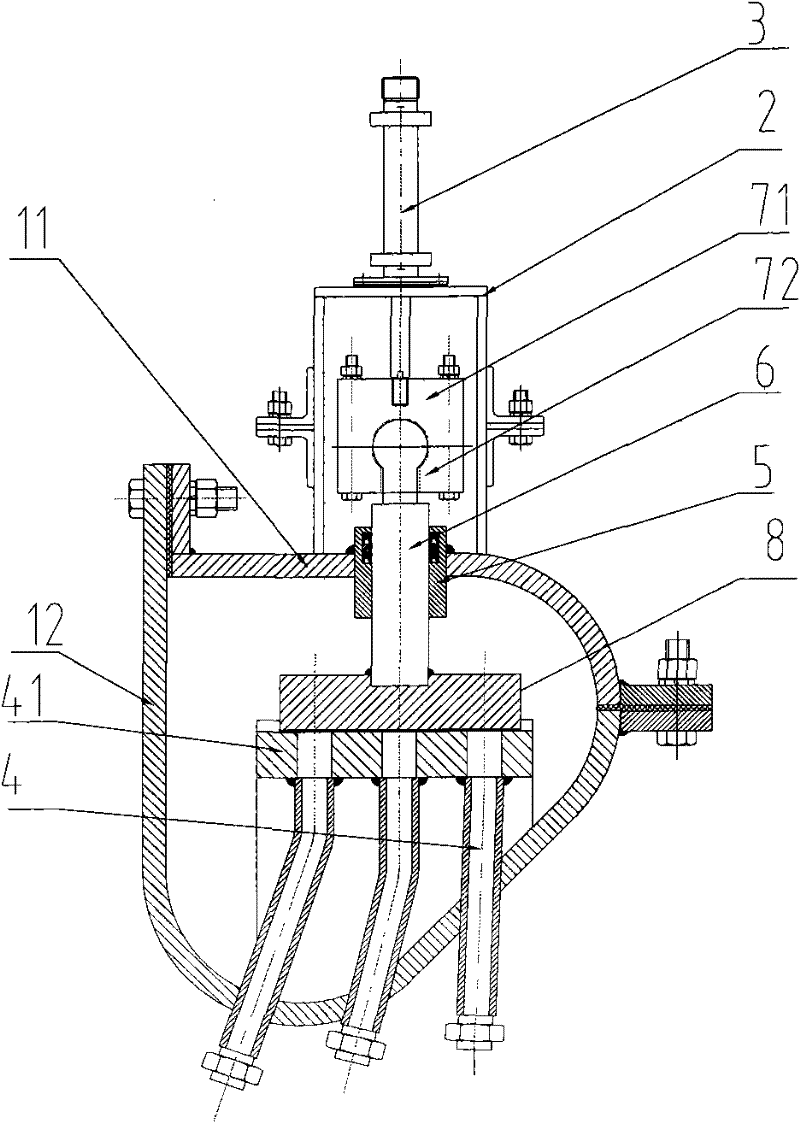

[0036] like figure 2 and image 3 As shown, the upper spray cooling device between the finishing stands includes a split header 1, including a lower tube body 12 and an upper tube cover 11 fixedly and sealingly connected with it. The header pipe 1 is set along the running direction of the vertical steel strip, and a number of discharge pipes are evenly distributed on it along the axial direction of the header pipe 1, and each row of nozzle pipes includes three nozzle pipes 4, and these three nozzle pipes 1. Arranged in the radial direction, the three nozzles 4 are connected to the header 1 through their upper ports, and the upper ports...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com