Laminar cooling edge shielding device and control method

A laminar cooling and edge technology, applied in workpiece cooling device, temperature control, metal rolling, etc., can solve problems such as differences in strip performance, reduce temperature drop, prevent batch quality accidents, and improve flatness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

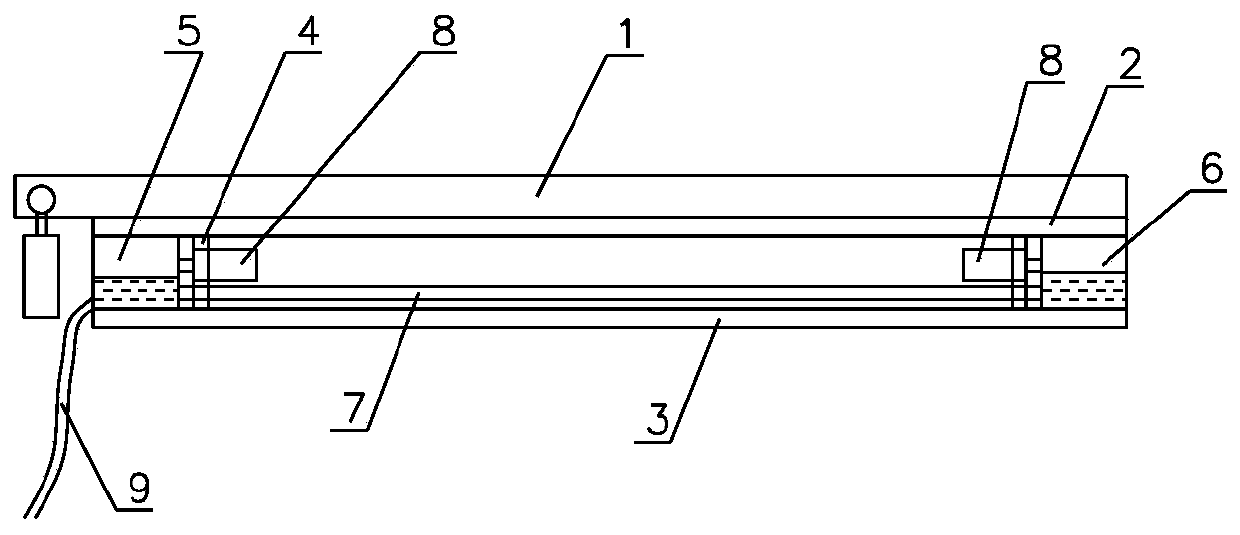

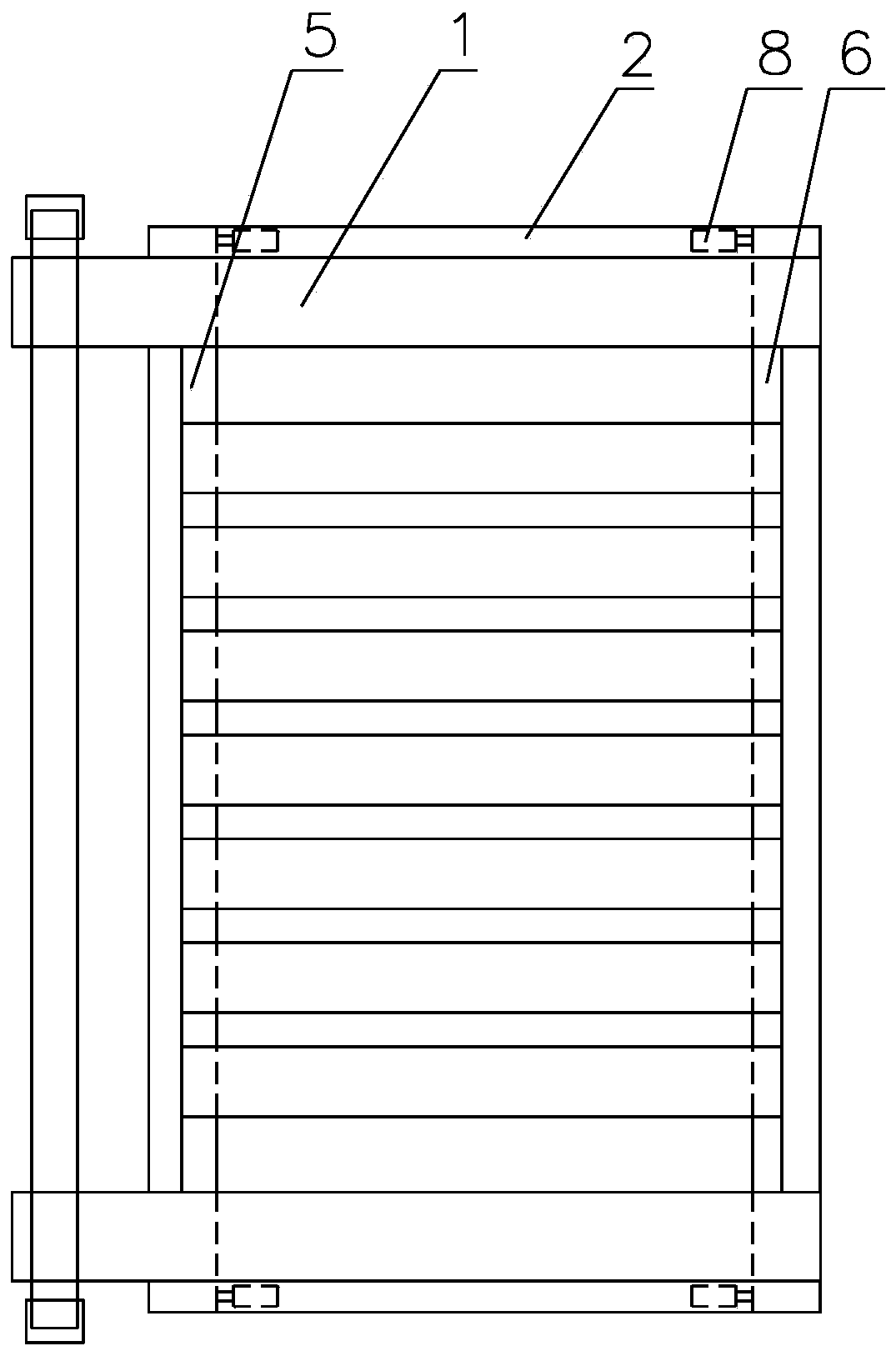

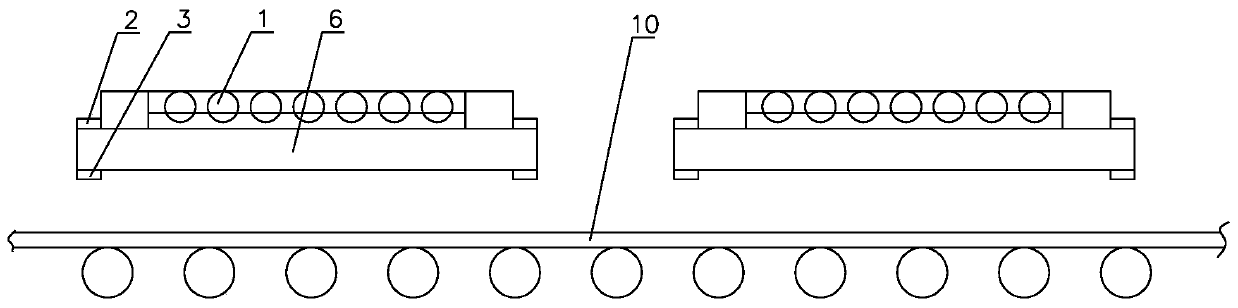

[0020] Such as Figure 1-Figure 3 , a laminar flow cooling edge shielding device, comprising an upper layer flow header device 1, the two ends of the upper layer flow header device are fixedly connected to a water tank support beam, and the two sides of the water tank support beam are respectively provided with a transmission side water collection tank 5, working The side water collection tank 6, the water tank support beam includes an upper fixed beam 2 and a lower fixed beam 3, the upper fixed beam 2 and the lower fixed beam 3 are connected by a connecting bracket 4, and a water tank hydraulic cylinder 8 is arranged on the connecting bracket 4, and the transmission side set The water tank 5 and the working side sump 6 are respectively pushed by their respective water tank hydraulic cylinders 8 to slide on the support beam of the water tank. The trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com