Quantitative location self-propelled hopper device

A hopper device and self-propelled technology are applied in the field of quantitative positioning self-propelled hopper devices, which can solve the problems of inaccurate feeding position, large number of feeders, and high labor intensity of breeders, and achieve the effect of saving cost and not wasting feed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

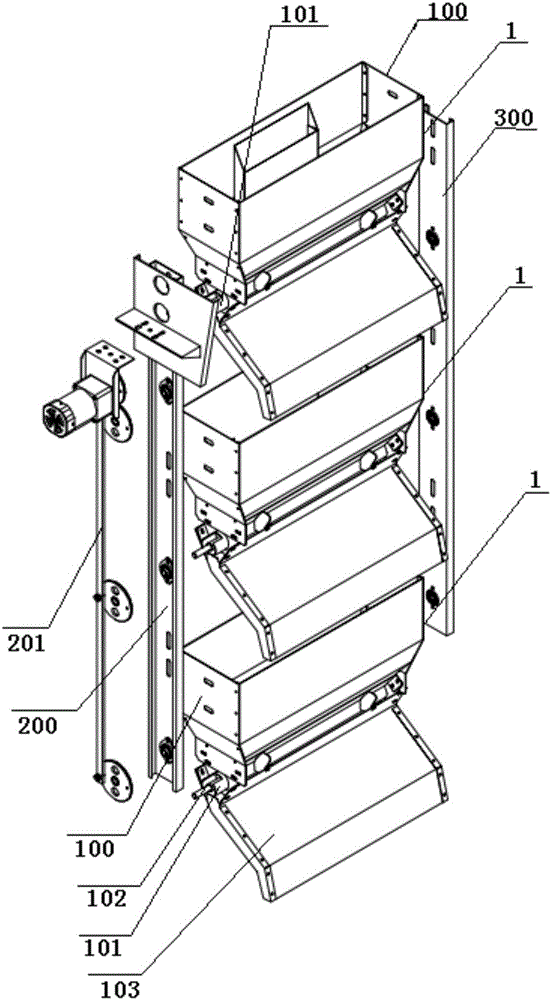

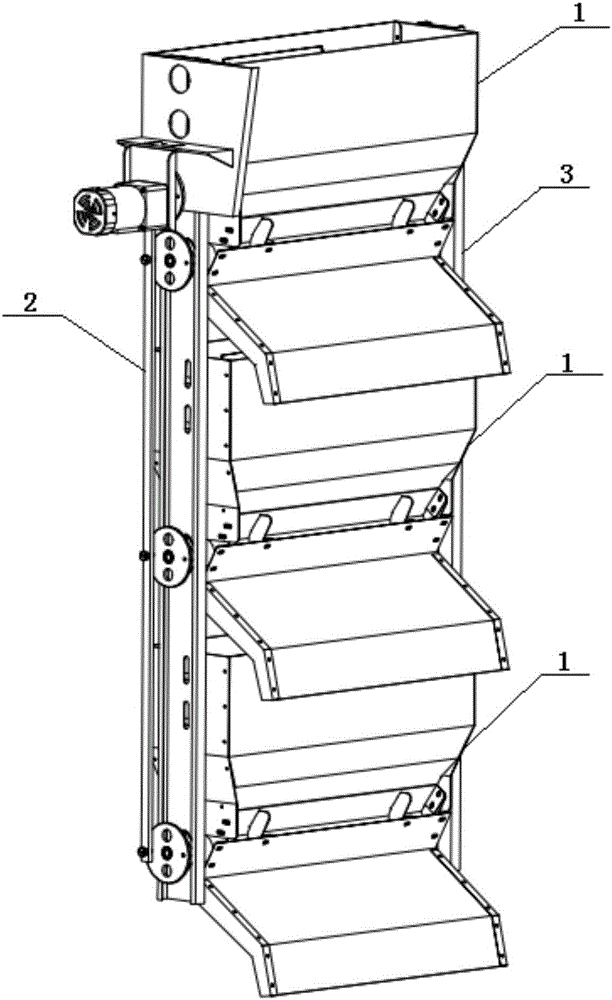

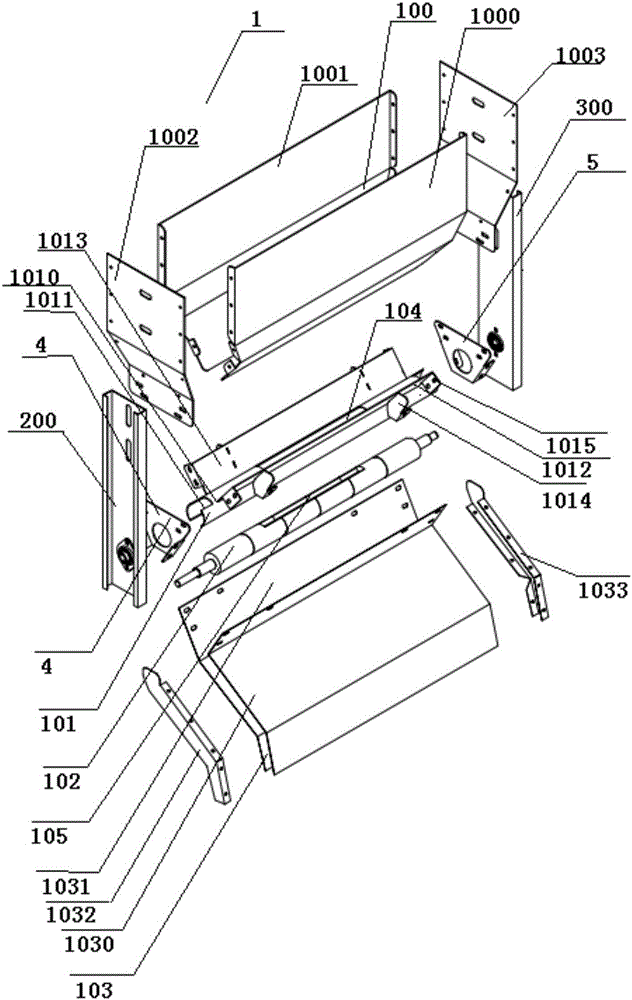

[0015] refer to figure 1 , figure 2 and image 3 A quantitatively positioned self-propelled hopper device provided by the present invention includes multiple groups of feeding devices 1 corresponding to a plurality of feeding pans on the breeding site and traction devices placed on both sides of the feeding device, and the traction devices include Traction device one 2 and traction device two 3, the feeding device 1 is arranged and installed between the traction device one 2 and traction device two 3 from top to bottom, and the feeding device includes a silo with an open bottom 100. A transverse shaft sleeve 101 connected to the bottom end of the silo 100, a transverse connecting shaft 102 placed inside the shaft sleeve 101 and connected to the shaft sleeve, and a blanking body 103 connected to the shaft sleeve 101 , the shaft sleeve 101 is provided with a blanking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com