Gray cloth cutting device

A cutting device and green cloth technology, which is applied in the cutting of textile materials, textile and paper making, fabric surface trimming, etc., can solve the problems of difficulty in the total thickness of green cloth, reduce processing efficiency, cutting error, etc., and achieve a simplified structure and diverse functions. , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

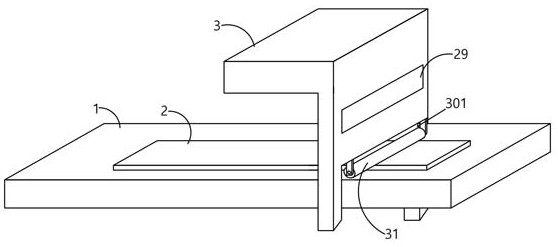

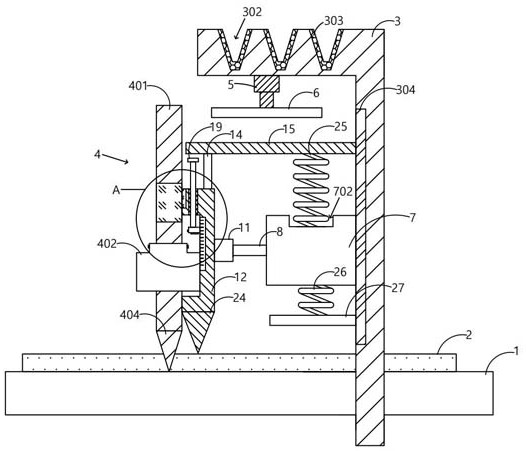

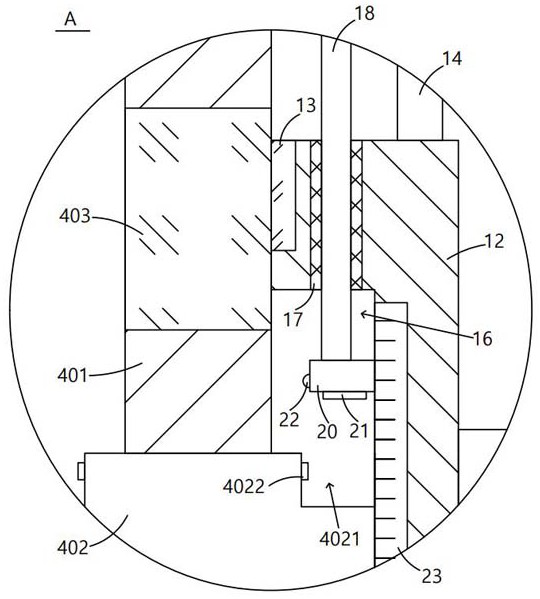

[0049] When in use, the gray cloth 2 is laid flat on the bottom plate 1. At this time, if the gray cloth 2 needs to be cut vertically, two positioning pins 4 can be taken, and the positioning pin tip 404 at the bottom of the positioning pins 4 can be inserted into the gray cloth. 2, the connecting line between the two positioning pins 4 forms a straight line, which is the line of the cutting position. Of course, for more accurate positioning, several positioning pins can also be added between the two positioning pins 4 at both ends. 4.

[0050] The L-shaped plate 3 as a whole can be driven and moved by an external power device, so that the cutting knife plate 12 is close to the positioning pin 4. At this time, the power supply of the miniature electromagnetic chuck 13 can be automatically or remotely opened, so that the miniature electromagnetic chuck 13 is energized to generate magnetism, resulting in The miniature electromagnetic chuck 13 is adsorbed and attached to the magn...

Embodiment 2

[0055] This embodiment is similar to Embodiment 1, the only difference is that in this embodiment, the gray cloth 2 can be cut obliquely. The two ends of the oblique cutting line, similarly, for more accurate positioning, several positioning pins 4 can also be added between the two positioning pins 4 at these two ends.

[0056] Then the whole L-shaped plate 3 is driven and moved by an external power device, so that the cutting blade plate 12 is close to the positioning pin 4. At this time, because the positioning pin 4 forms an oblique line, the cutting blade plate 12 is adsorbed by the miniature electromagnetic chuck 13. Also can tilt afterward, at this moment, the two adjusting rods 8 move to different degrees in the mounting groove 701, the adjusting rod 8 and the connecting block 11 are hinged by the rotating shaft 10, and the connecting block 11 and the cutting blade plate 12 are hinged. Hinged, so the position of the cutting knife plate 12 can be adjusted freely, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com