Peeling device for hollow spiral electrifying hose of dust collector and application method thereof

A vacuum cleaner and hose technology, which is applied in the field of electrified hose processing, can solve the problems of hollow hoses without effective peeling devices, and achieve the effects of preventing force deformation, reducing difficulty, and accurately controlling cutting length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

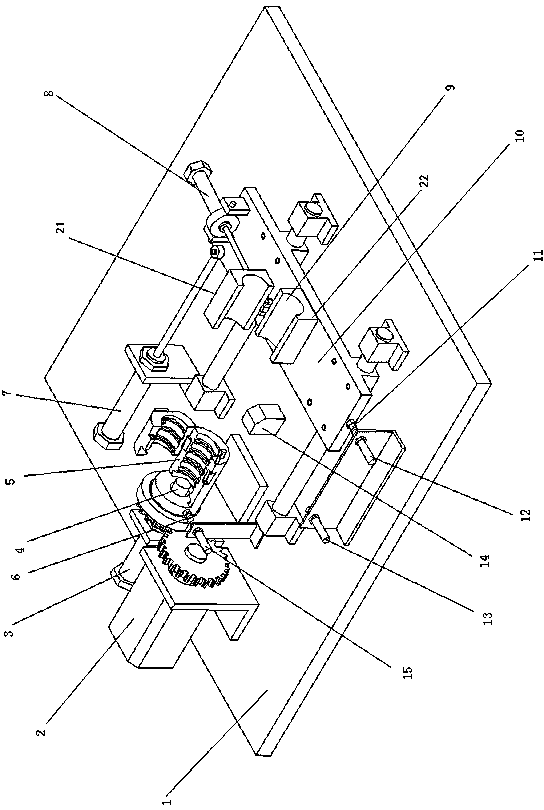

[0030] As shown in the figure, a peeling device for a hollow spiral electrified hose of a vacuum cleaner includes a base 1, a rotary cutter 5, a servo motor 2, a first cylinder 8, a second cylinder 7, a third cylinder 3, a guide rail slide 10, a soft Pipe clamping device 9 , hose inner push rod 4 , first inductive switch 12 , second inductive switch 13 , third inductive switch 15 , fourth inductive switch 14 .

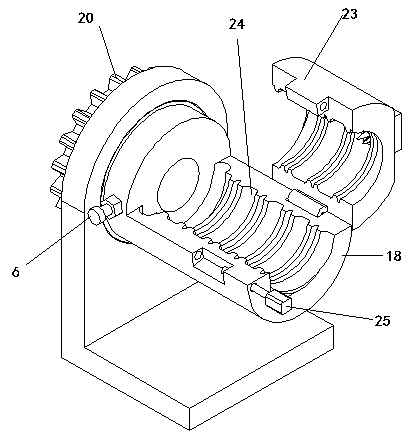

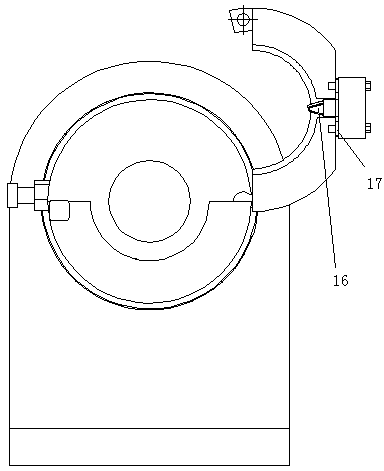

[0031] The servo motor, the second cylinder, the third cylinder, the guide rail slide, the first induction switch, the second induction switch, the third induction switch, and the fourth induction switch are installed on the base, and the rotating tool and the servo motor are connected to each other through gear 20 meshing; The hose clamping device and the first cylinder are installed on the guide rail slide; the guide rail slide is connected to the second cylinder; the upper cover 21 of the hose clamping device is connected to the first cylinder; connect.

[0032] Po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com