Water cutting vacuum positioning mechanism of automobile roof

A technology of water jet cutting and positioning mechanism, applied in metal processing and other directions, can solve problems such as safety and quality hidden dangers, long production cycle time, substrate indentation or indentation, etc., achieve a high degree of automation, reduce labor intensity, The effect of saving input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

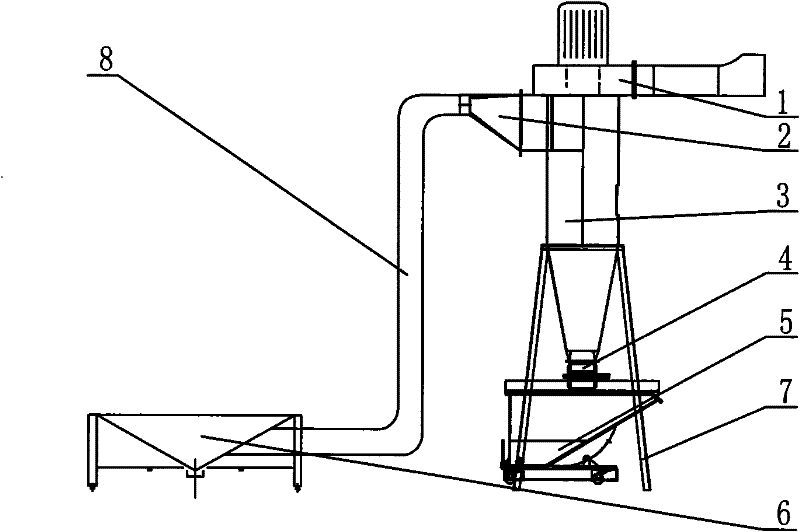

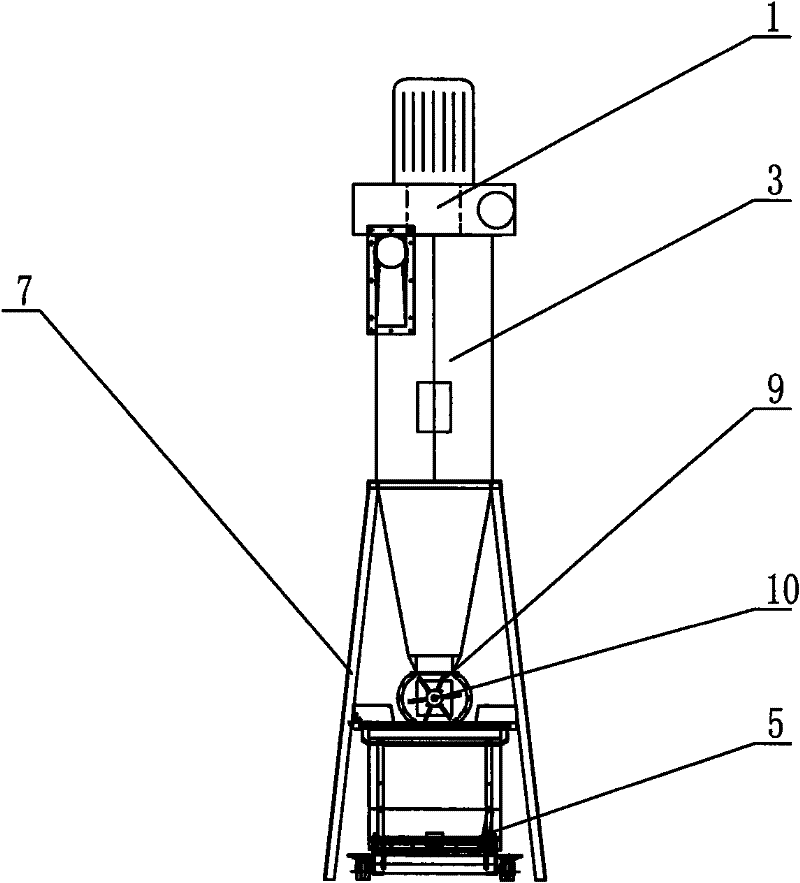

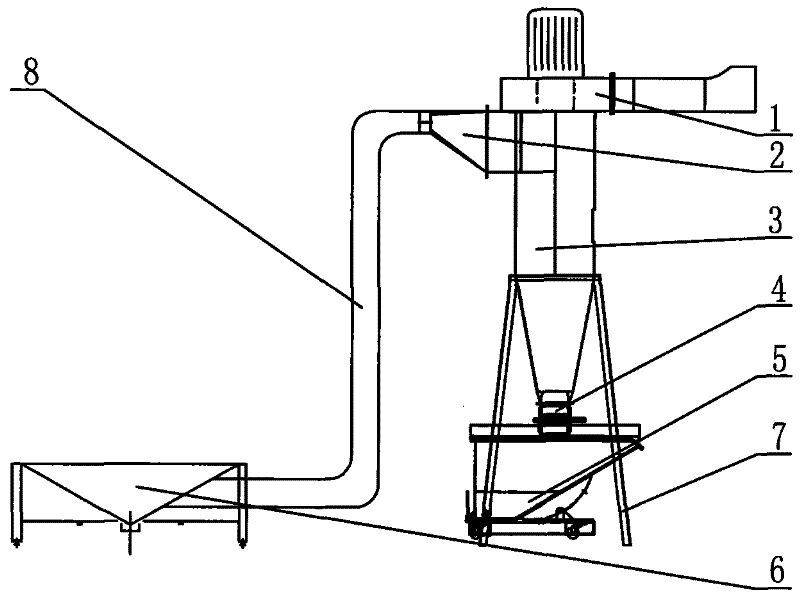

[0011] Such as Figure 1~2 As shown: the vacuum positioning mechanism includes fan 1, suction port 2, vacuum barrel 3, material removal device 4, waste trolley 5, cutting fixture 6, frame 7, air duct 8, blade 9, impeller 10, etc.

[0012] The present invention adopts to install vacuum tank 3 on frame 7, blower fan 1 is installed on the top of vacuum tank 3, utilizes flange to install material removal device 4 at the bottom of vacuum tank 3, is provided with suction port 2 on the top of vacuum tank 3, The air suction port 2 is connected with the cutting jig 6 through the air pipe 8; the waste trolley 5 is arranged at the bottom of the material removal device 4; the fan is generally a centrifugal fan.

[0013] The material removing device 4 is provided with several blades 9 on the impeller 10 , and the blades 9 can rotate around the impeller 10 .

[0014] The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com