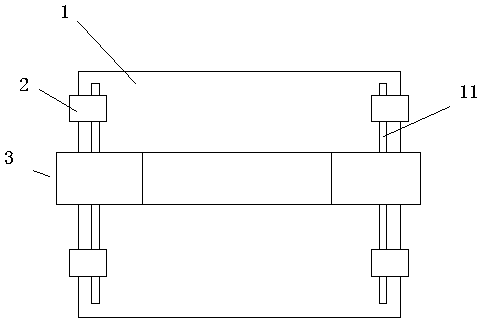

Apparel fabric tailoring machine platform

A cutting machine and clothing technology, applied in the cutting of textile materials, marking textile materials, textile and paper making, etc., can solve the problems of inability to fix, slow cutting, uneven tailoring, smoothness, etc., and achieve the effect of convenient positioning and cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

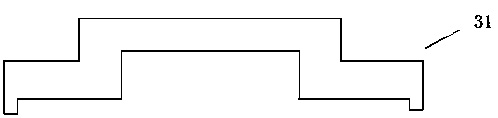

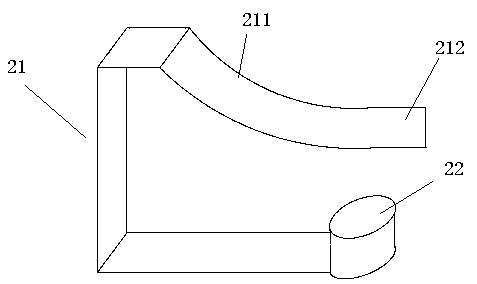

[0025] Cutting and marking chalk and a cutting device are installed in the middle part of the upper bracket. The cutting and marking chalk is fixed in the upper bracket by the base. The cutting device is installed in the upper bracket. In one embodiment, the cutting device includes a scribe mark detector, a cutter, and a controller. The cutter, the scratch detector, and the cutting and marking chalk are arranged in sequence, that is, when the cutting device moves from the top to the bottom of the pedestal 1, the cutting knife and the scoring are arranged sequentially from top to bottom. Detectors, clipping and scribing chalk. The scratch mark detector is used to detect the scratch mark, and the tailor-made mark chalk can be chalk doped with fluorescent material which is easily detected by the scratch mark detector. When the laser scribing mark detector detects the scribing marks of the cutting chalk, it triggers the cutting knife from the lower part of the stowed state to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com