A high-precision aluminum profile cutting machine

An aluminum profile and cutting machine technology, which is applied in metal processing equipment, metal sawing equipment, manufacturing tools, etc., can solve the problems of potential safety hazards, aluminum profile workpiece offset, low cutting accuracy, etc., to improve cutting Efficiency, improved cutting precision, and stable cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

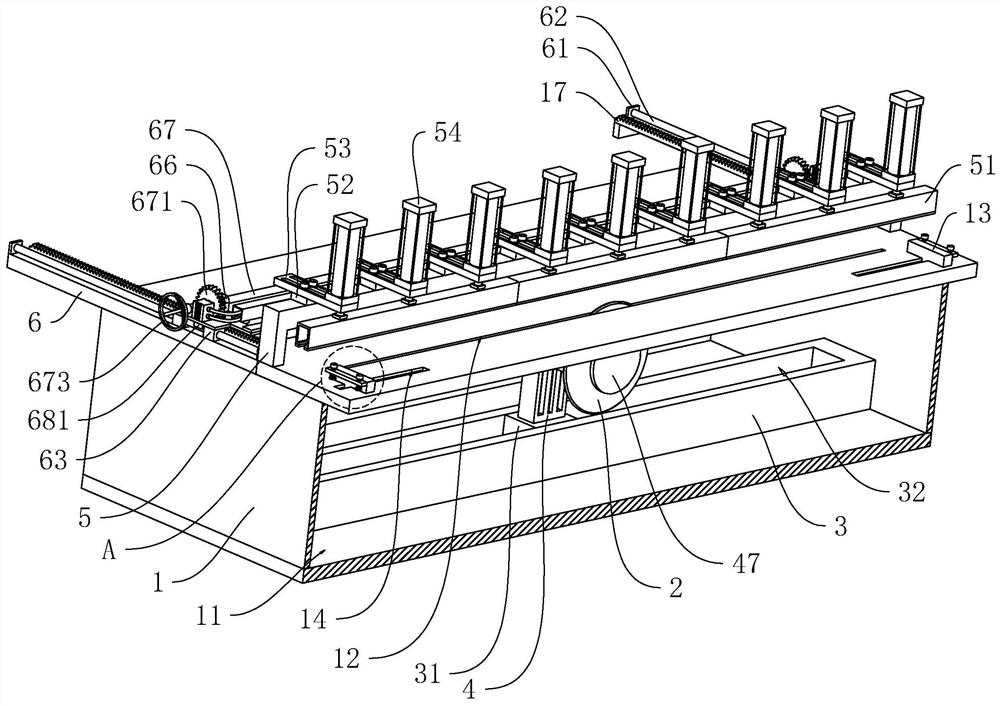

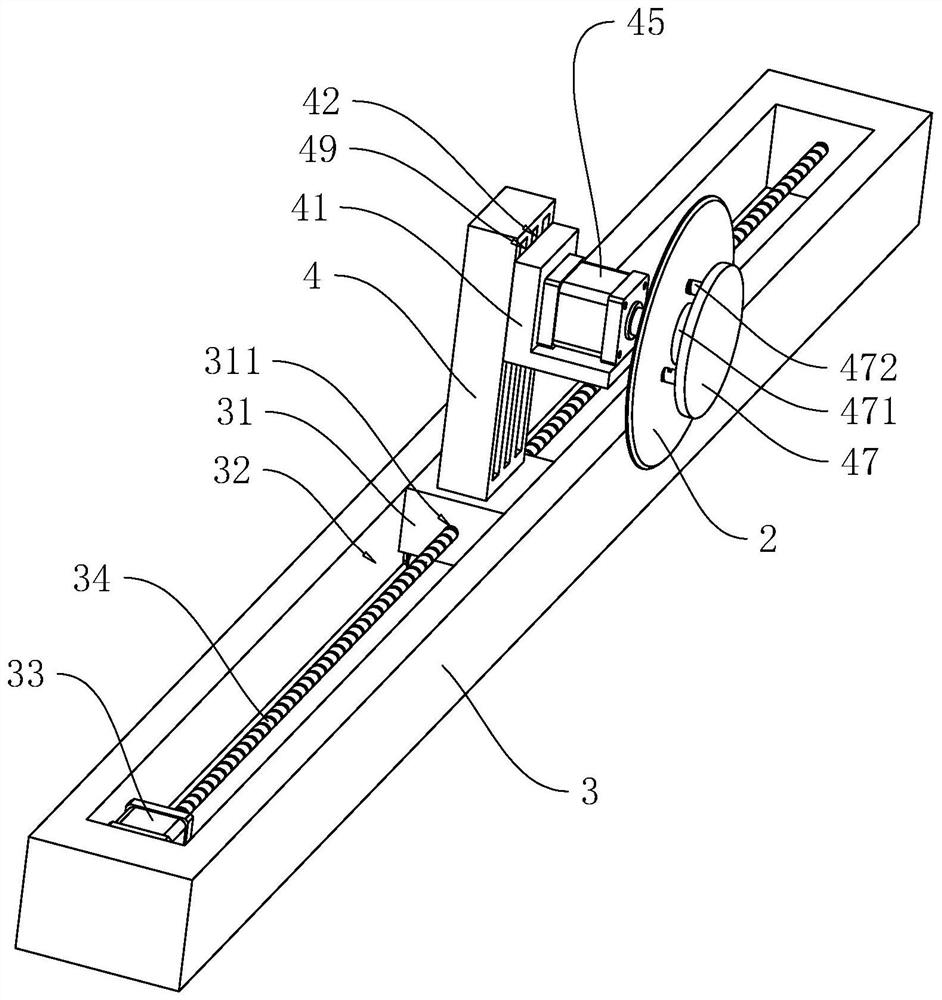

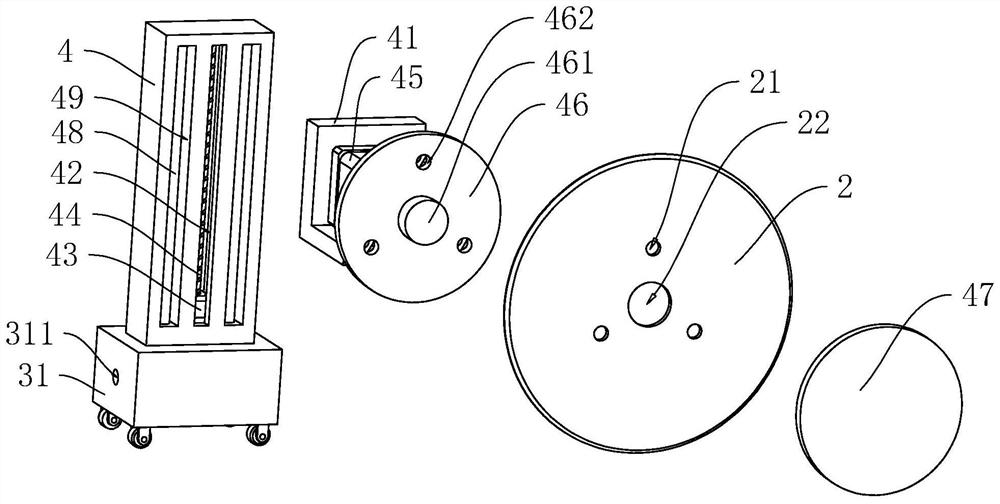

[0041] Attached to the following Figure 1-8 This application will be described in further detail.

[0042] The embodiment of the present application discloses a high-precision aluminum profile cutting machine. refer to figure 1 , the cutting machine includes a workbench 1, on which a cutting device is arranged, which not only facilitates the fastening and installation of the aluminum profile workpiece on the cutting end face on the workbench 1, but also can The profile workpiece has the effect of automatic cutting, which can reduce the deviation of the aluminum profile workpiece during cutting, thereby improving the cutting accuracy of the aluminum profile workpiece and reducing the potential safety hazards during cutting.

[0043] Specifically, refer to figure 1 , in this embodiment, the cutting device includes a driving mechanism and a cutting saw blade 2 . Wherein, a placing cavity 11 is opened inside the worktable 1, and the driving mechanism is stably installed insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com